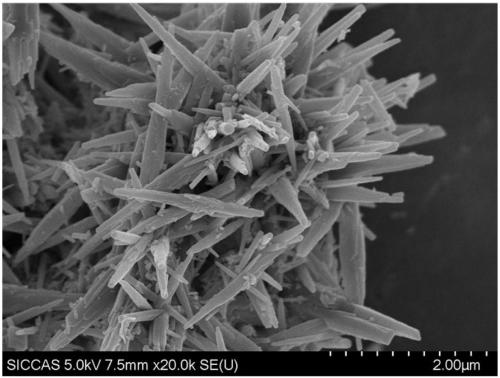

Aragonite type crystal seeds and aragonite type light calcium carbonate and preparation method thereof

A light calcium carbonate and aragonite-type technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problem of low solid content of calcium hydroxide, complex post-treatment process, Low production efficiency and other issues, to achieve the effect of stable product quality, low production cost, and industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The automatic mechanical vertical steel kiln is adopted, the limestone with a size of 30-60mm is selected, the content of magnesium oxide is 0.5%, the ratio of coal to stone is 80kg / T limestone, the calcination temperature is controlled between 1000°C and the calcination time is 25h.

[0039] Lime is digested in hot water at 80°C, and the mass ratio of lime to water is 1:6. Add water to the digested rough pulp to adjust the concentration to 12%, first pass through a 100-mesh sieve, and then pass through a hydrocyclone to remove impurities to obtain a fine pulp. The temperature of the fine pulp is controlled at 45°C.

[0040] Pour the fine slurry into a carbonization tower, add phosphoric acid with a relative dry weight of 4% of calcium hydroxide, 0.5% sodium dihydrogen phosphate, and 0.5% sodium hexametaphosphate as crystal form control agents, and stir evenly.

[0041] Ventilate for carbonization, the kiln gas concentration is 30%, and the end point of carbonization ne...

Embodiment 2

[0045] The automatic mechanical vertical steel kiln is adopted, the limestone with a size of 30-60mm is selected, the content of magnesium oxide is 1.5%, the ratio of coal to rock is 80kg / T limestone, the calcination temperature is controlled between 1000°C and the calcination time is 25h.

[0046] Lime is digested in hot water at 80°C, and the mass ratio of lime to water is 1:6. Add water to the digested coarse pulp to adjust the concentration to 12%, first pass through a 100-mesh sieve, and then pass through a hydrocyclone to remove impurities to obtain a fine pulp. The temperature of the fine pulp is controlled at 50°C.

[0047] Pour the refined slurry into a carbonization tower, add phosphoric acid with a relative calcium hydroxide equivalent dry weight of 4.5%, 0.5% sodium dihydrogen phosphate, and 1.0% sodium hexametaphosphate as crystal form control agents, and stir evenly.

[0048] Ventilate for carbonization, the kiln gas concentration is 30%, and the end point of car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com