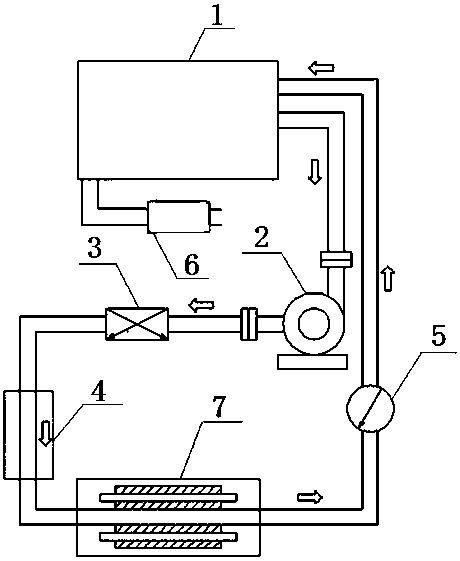

Descaling device and method of circulation cooling water system

A technology of circulating cooling water and descaling agent, applied in descaling and water softening, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as secondary pollution and zinc ion secondary pollution, and achieve descaling rate Improve, reduce secondary pollution, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] When M is 300T m, the length of the adjustable permanent magnet 7 is L=10m, then the magnetic field strength is selected to be B=30T, the flow rate of the circulating cooling water is v=2m / s, and the cross-sectional area of the pipeline is S=4m 2 , tank volume V=40m 3 , the magnetic field needs to run t=5h in advance before adding the prepared antiscalant scale agent m=2kg, and then run for 24h and then take a sample to measure the hardness of the circulating water to obtain a scale inhibition rate of 91.5%, and the cooling part 4 There is no scale deposition in the pipes and pipes, and the scale at the bottom of the tank is collected and scanned with an electron microscope to find that the scale structure is relatively loose, such as figure 2 As shown, it shows that the scale proportion of calcite structure is greatly reduced, and the expected scale inhibition effect is achieved.

Embodiment 2

[0022] When M is 350T m, the length of the adjustable permanent magnet 7 is L=7m, then the magnetic field strength is selected to be B=50T, the flow rate of the circulating cooling water is v=5m / s, and the cross-sectional area of the pipeline is S=2m 2 , tank volume V=50m 3 , the magnetic field needs to run t=5h in advance before adding the prepared antiscalant and scale agent m=2.5kg. Then after running for 24 hours, samples were taken to measure the hardness of the circulating water, and the scale inhibition rate was 93%, and there was no scale deposition in the cooling part 4 and the pipeline. The scale at the bottom of the tank was collected and scanned with an electron microscope to find that the scale structure was relatively loose. image 3 As shown, it shows that the scale proportion of calcite structure is greatly reduced, and the expected scale inhibition effect is achieved.

Embodiment 3

[0024] When M is 400T m, the length of the adjustable permanent magnet 7 is L=8m, then the magnetic field strength is selected to be B=50T, the flow rate of the circulating cooling water is v=3m / s, and the cross-sectional area of the pipeline is S=5m 2 , tank volume V=60m 3 , the magnetic field needs to run t=4h in advance before adding the prepared antiscalant scale agent m=3kg; then run for 24h and then take a sample to measure the hardness of the circulating water to obtain a scale inhibition rate of 95%, and the cooling part 4 There is no scale deposition in the pipes and pipes, and the scale at the bottom of the tank is collected and scanned with an electron microscope to find that the scale structure is relatively loose, such as Figure 4 As shown, it shows that the scale proportion of calcite structure is greatly reduced, and the expected scale inhibition effect is achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com