Method for producing ore slag micro powder by blast furnace water slag

A technology of blast furnace slag and slag fine powder, which is applied in the direction of cement production, etc., can solve the problems of dust noise pollution, cost reduction, etc., and achieve the effect of improving economic benefits, reducing costs, and realizing low-cost production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

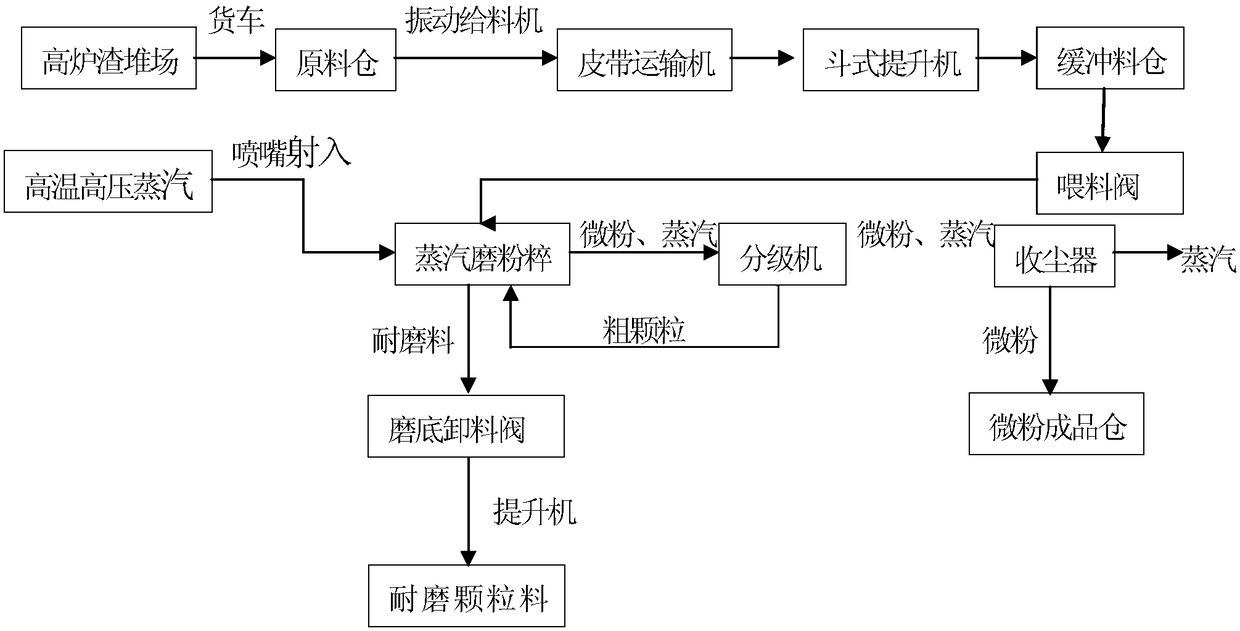

Image

Examples

Embodiment 1

[0033] A method for producing fine slag powder by using blast furnace slag, a method for producing slag fine powder by using blast furnace slag, the particle size of the blast furnace slag is 2-4 mm, the water content is 10%, and the mass of each component of the furnace charge slag is Percent content is TFe: 0.3%, SiO 2 : 25%, Al 2 o 3 : 16%, CaO: 35%, MgO: 10%, TiO 2 : 8%, MnO: 0.6, S: 1.1, and the balance is impurities.

[0034] It includes the following steps:

[0035] (1) Blast furnace slag is loaded into the raw material bin by truck, and a vibrating feeder is installed under the raw material bin to feed the material to the belt conveyor at an appropriate speed. The blast furnace slag on the belt conveyor is lifted to the buffer bin by the elevator, and then passed The feeding valve feeds the material into the steam mill, the frequency of the feeding valve is controlled at 15Hz, and the hourly feeding volume is controlled at 4.5 tons;

[0036] (2) The blast furnace ...

Embodiment 2

[0039] A method for producing slag fine powder by using blast furnace slag, the particle size of the blast furnace slag is 2-5 mm, the water content is 12%, and the mass percentage of each component of the furnace charge slag is TFe: 0.6%, SiO 2 : 30%, Al 2 o 3 : 14%, CaO: 31%, MgO: 10%, TiO 2 : 7%, MnO: 0.4, S: 1.0, and the balance is impurities.

[0040] It includes the following steps:

[0041] (1) Blast furnace slag is loaded into the raw material bin by truck, and a vibrating feeder is installed under the raw material bin to feed the material to the belt conveyor at an appropriate speed. The blast furnace slag on the belt conveyor is lifted to the buffer bin by the elevator, and then passed The feeding valve feeds into the steam mill, where the frequency of the feeding valve is controlled at 10Hz, and the hourly feeding volume is controlled at 4 tons;

[0042] (2) The blast furnace slag fed into the steam mill is pulverized under the impact of the high-temperature and...

Embodiment 3

[0045] A method for producing fine slag powder by using blast furnace slag, a method for producing slag fine powder by using blast furnace slag, the particle size of the blast furnace slag is 2-4 mm, the water content is 15%, and the mass of each component of the furnace charge slag is Percent content is TFe: 0.6%, SiO 2 : 30%, Al 2 o 3 : 14%, CaO: 31%, MgO: 10%, TiO 2 : 7%, MnO: 0.4, S: 1.0, and the balance is impurities.

[0046] It includes the following steps:

[0047] (1) Blast furnace slag is loaded into the raw material bin by truck, and a vibrating feeder is installed under the raw material bin to feed the material to the belt conveyor at an appropriate speed. The blast furnace slag on the belt conveyor is lifted to the buffer bin by the elevator, and then passed The feeding valve feeds into the steam mill, the frequency of the feeding valve is controlled at 20Hz, and the hourly feeding volume is controlled at 5 tons;

[0048] (2) The blast furnace slag fed into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com