Device for recycling waste tools of power grid structure

A technology of recycling device and power grid structure, which is applied in grain processing and other directions, can solve the problems of inability to complete crushing treatment under closed conditions and multi-stage crushing treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

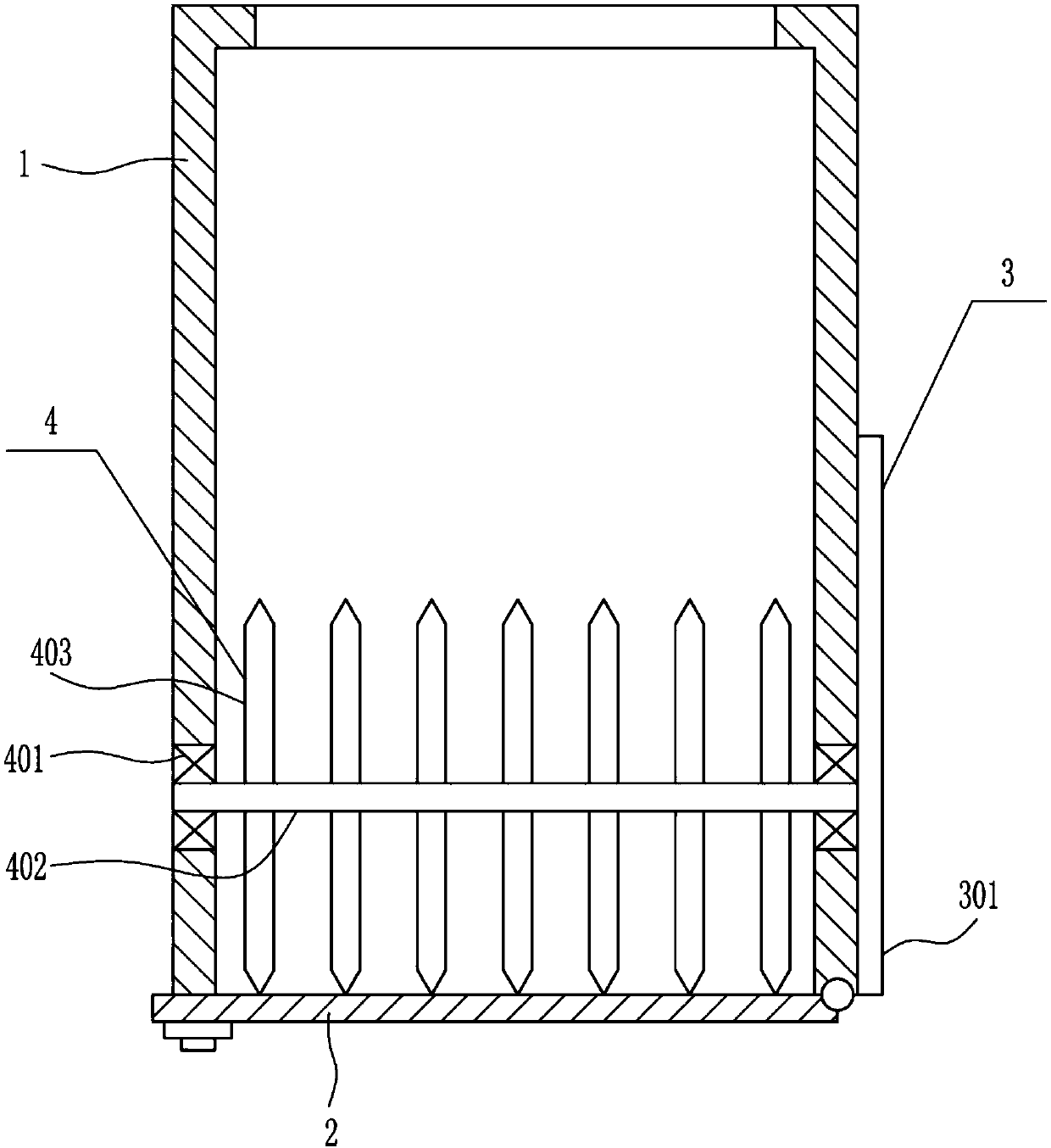

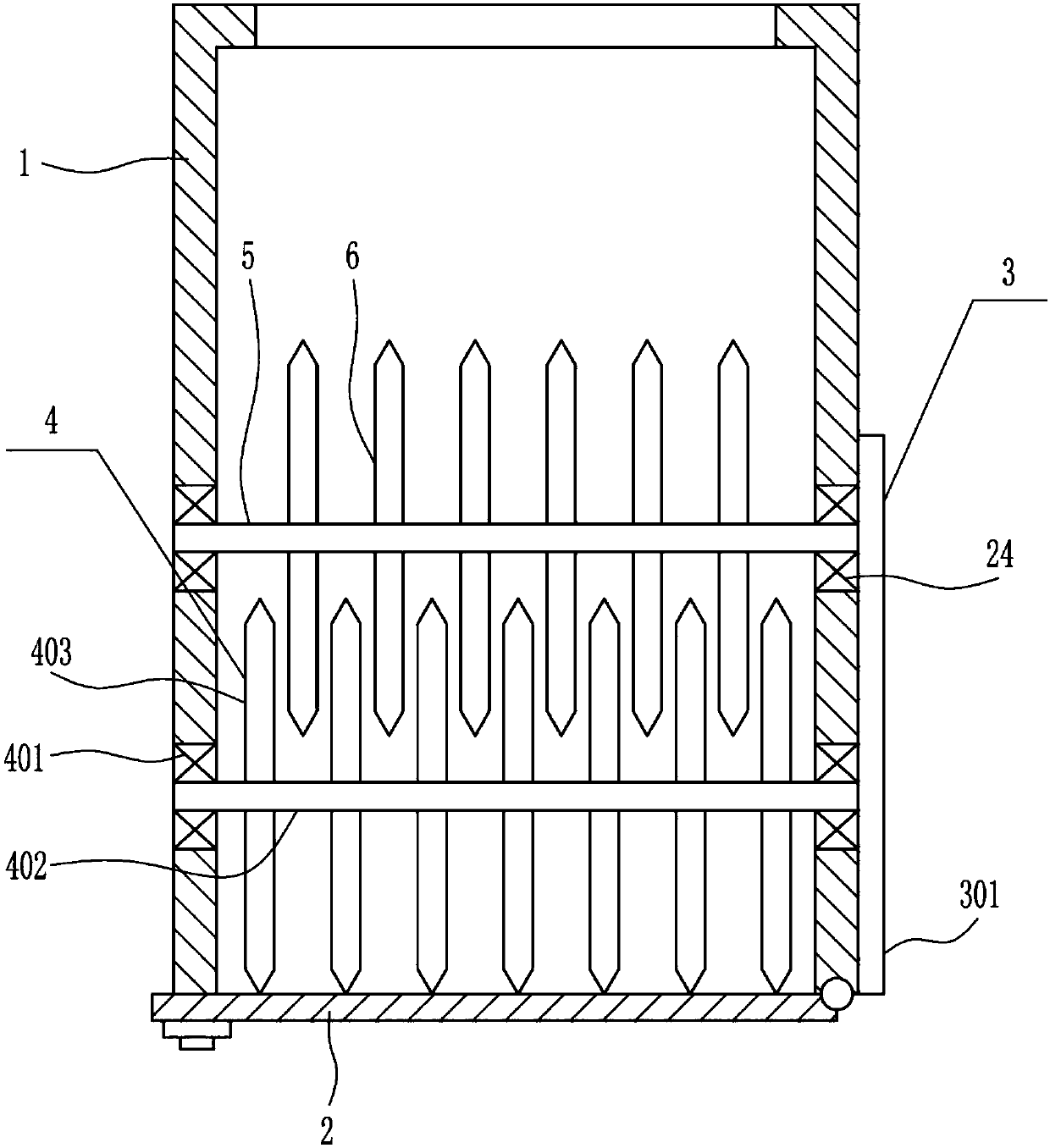

[0034] A recycling device for waste tools for power grid structure, such as Figure 1-7 As shown, it includes a box body 1, a first baffle plate 2, a driving mechanism 3 and a crushing mechanism 4, the lower part of the right side of the installation box 301 is connected with the driving mechanism 3, and the lower part of the installation box 301 is connected with the crushing mechanism 4, and the crushing mechanism 4 is connected with the crushing mechanism 4. The driving mechanism 3 is connected, and the bottom end of the right wall of the installation box 301 is rotatably connected with the first baffle plate 2, and the left part of the first baffle plate 2 is connected and fixed on the bottom end of the left wall of the installation box 301 by bolts.

Embodiment 2

[0036] A recycling device for waste tools for power grid structure, such as Figure 1-7 As shown, it includes a box body 1, a first baffle plate 2, a driving mechanism 3 and a crushing mechanism 4, the lower part of the right side of the installation box 301 is connected with the driving mechanism 3, and the lower part of the installation box 301 is connected with the crushing mechanism 4, and the crushing mechanism 4 is connected with the crushing mechanism 4. The driving mechanism 3 is connected, and the bottom end of the right wall of the installation box 301 is rotatably connected with the first baffle plate 2, and the left part of the first baffle plate 2 is connected and fixed on the bottom end of the left wall of the installation box 301 by bolts.

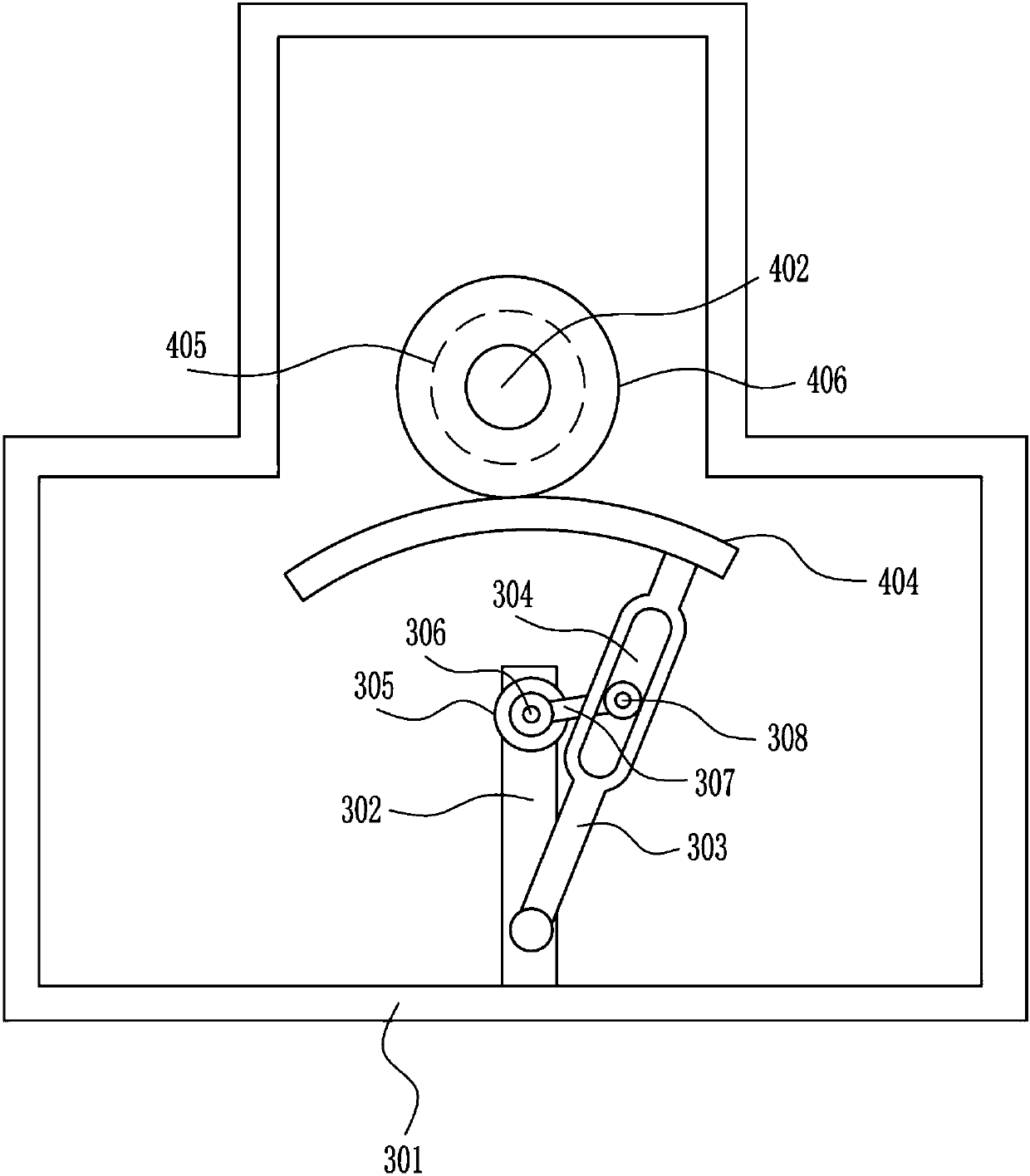

[0037] Drive mechanism 3 includes installation box 301, pole 302, swing bar 303, first motor 305, runner 306, first rotating rod 307 and slide shaft 308, and installation box 301 right side bottom is connected with installati...

Embodiment 3

[0039] A recycling device for waste tools for power grid structure, such as Figure 1-7 As shown, it includes a box body 1, a first baffle plate 2, a driving mechanism 3 and a crushing mechanism 4, the lower part of the right side of the installation box 301 is connected with the driving mechanism 3, and the lower part of the installation box 301 is connected with the crushing mechanism 4, and the crushing mechanism 4 is connected with the crushing mechanism 4. The driving mechanism 3 is connected, and the bottom end of the right wall of the installation box 301 is rotatably connected with the first baffle plate 2, and the left part of the first baffle plate 2 is connected and fixed on the bottom end of the left wall of the installation box 301 by bolts.

[0040] Drive mechanism 3 includes installation box 301, pole 302, swing bar 303, first motor 305, runner 306, first rotating rod 307 and slide shaft 308, and installation box 301 right side bottom is connected with installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com