Small-quality powder electric grinding machine

A technology of powder electric and grinder, which is applied in cocoa, grain processing, food science, etc. It can solve the problems of low work efficiency, high labor intensity, small grinding contact area, etc., and achieves convenient operation, strong practicability, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

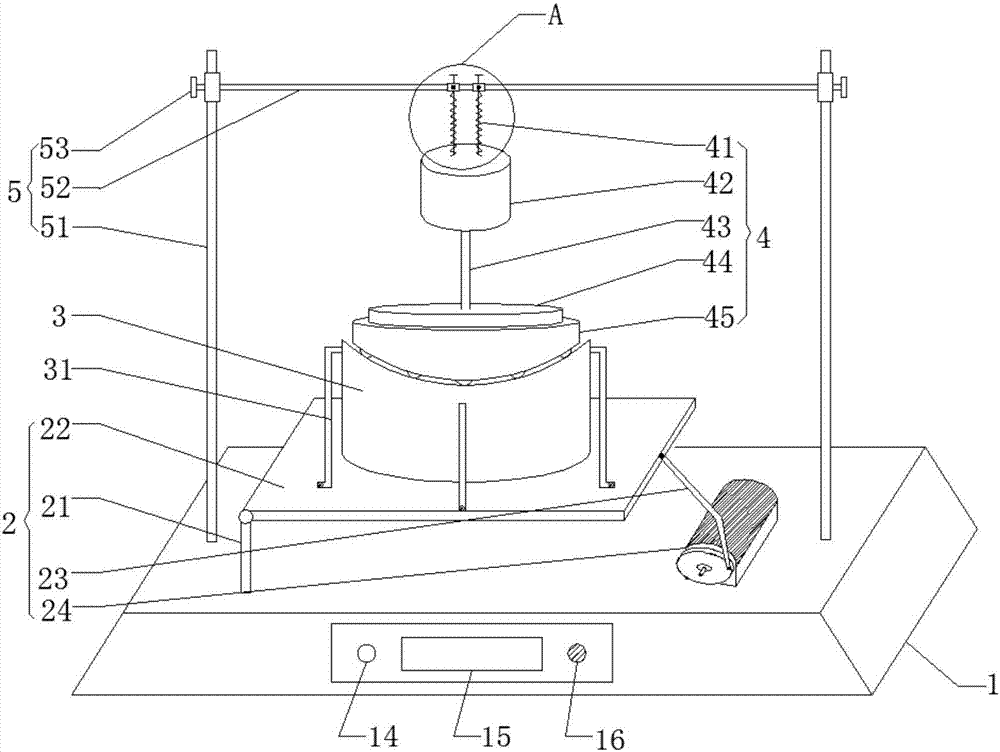

[0027] according to figure 1 Shown: a small amount of powder electric grinder, including: a base 1, a stage 2, a mortar body 3, a lifting grinding mechanism 4, and a lifting grinding mechanism 4 for supporting the lifting grinding mechanism 4 The support frame 5;

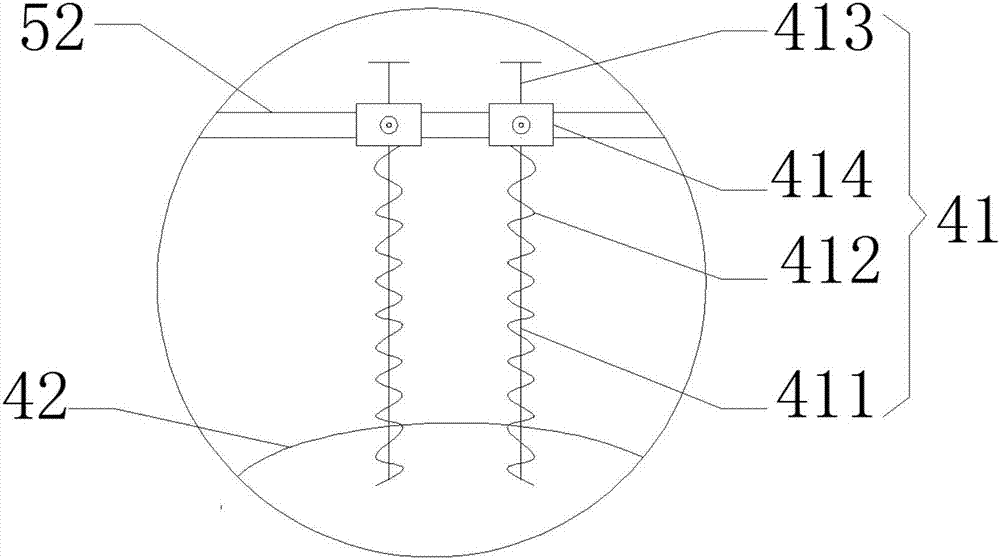

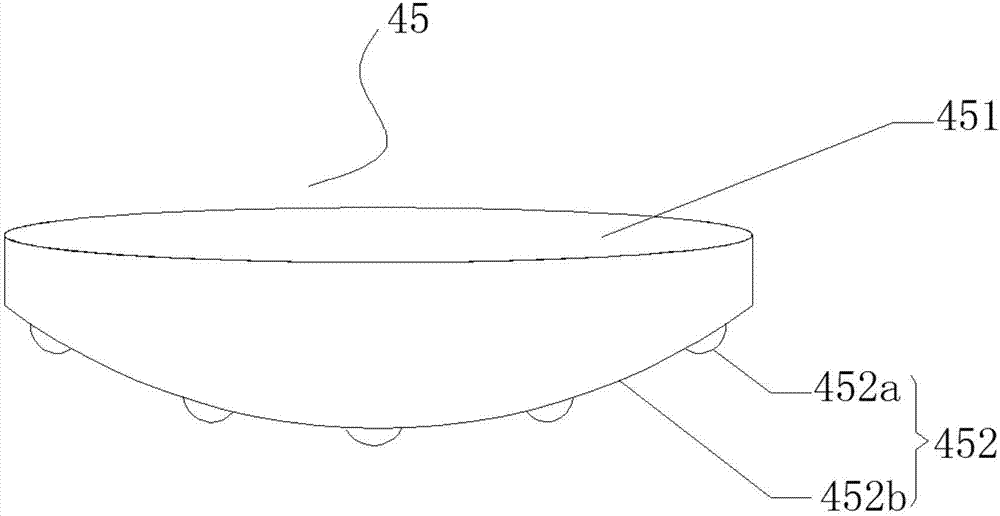

[0028] Wherein, the lifting grinding mechanism 4 includes: a telescopic unit 41, a grinding motor 42, a shaft coupling 43, a counterweight disc 44, and a grinding sheet 45 connected sequentially from top to bottom, and the telescopic unit 41 is vertically fixed on the The support frame 5, the lower end surface of the grinding sheet 45 is arranged opposite to the upper end surface of the mortar body 3, and the lower end surface of the grinding sheet 45 and the upper end surface of the mortar body 3 are both arc-shaped ;

[0029] During the working process, the grinding motor 42 drives the hard rod 411 in the telescopic unit 41 to stretch toward the side of the mortar body 3 , and the coupling 43 under the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com