Branch slicing shredder

A pulverizer and slicing technology, applied in the field of pulverizing machinery, can solve problems such as easy stuffy cars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

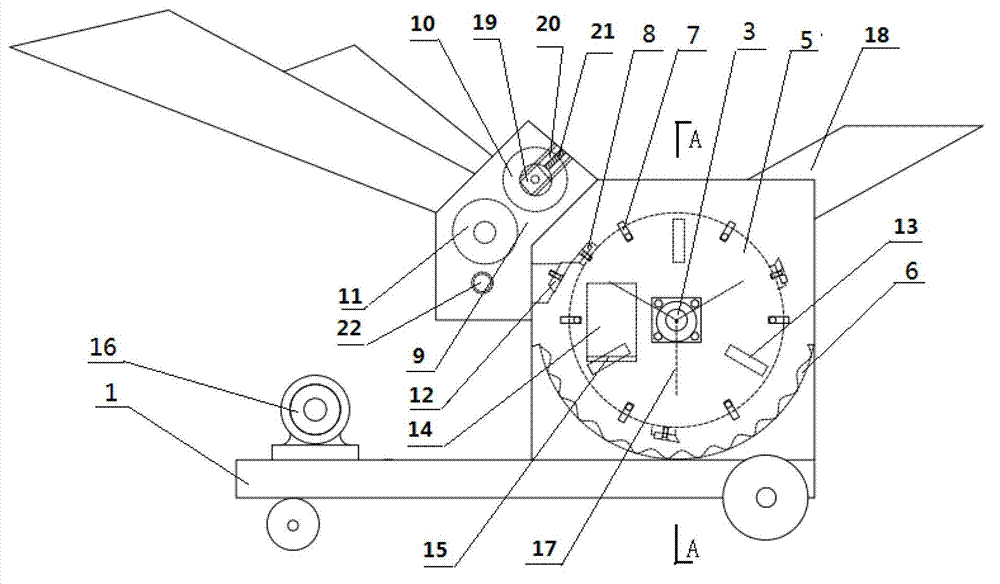

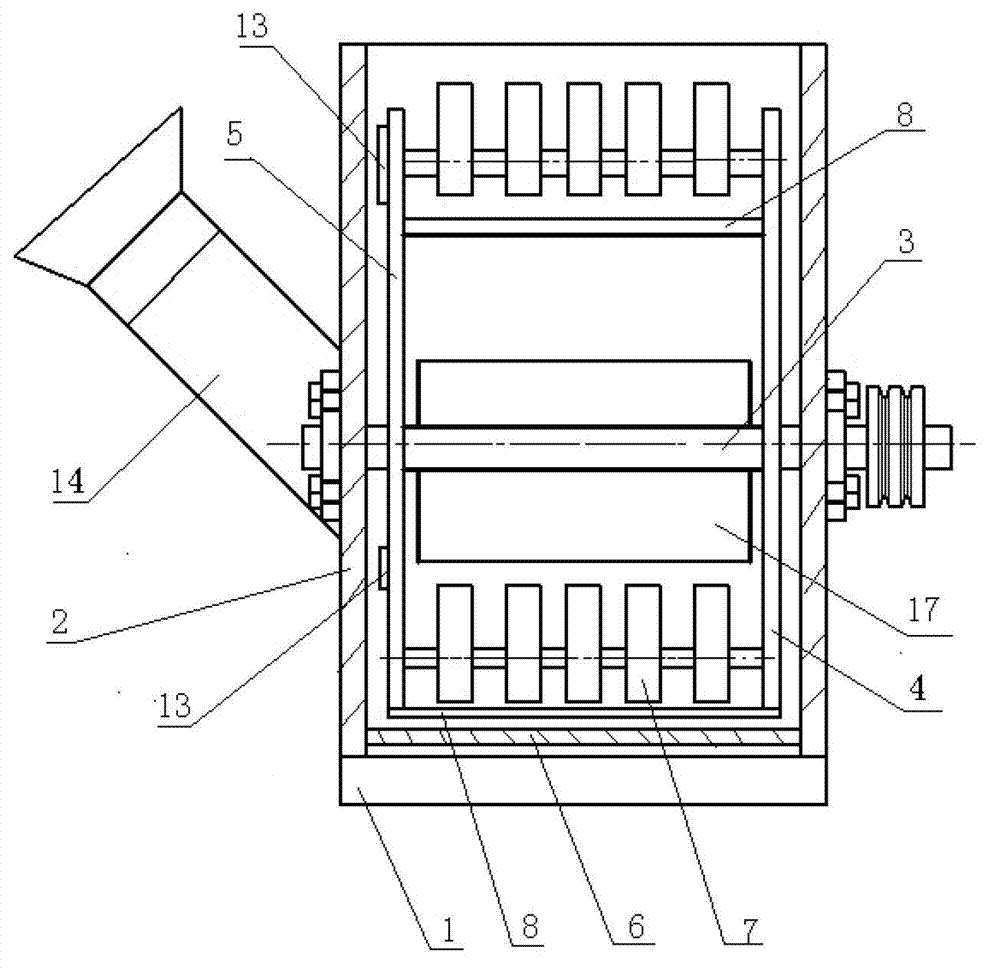

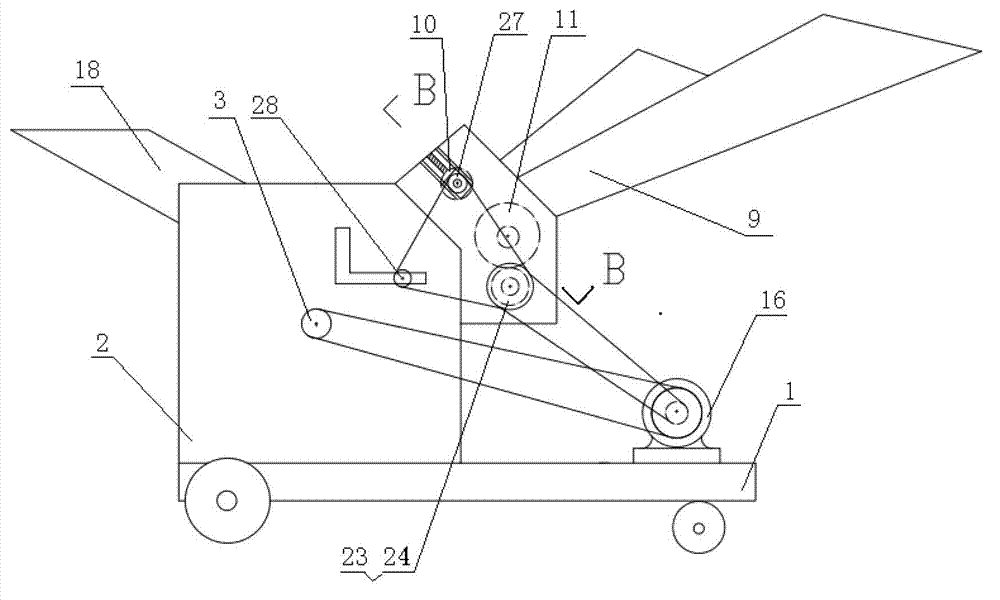

[0015] Attached below figure 1 , 2 , 3, 4 describe an embodiment of the present invention.

[0016] A kind of twig slicing grinder, which has a base 1, on which a casing 2 and a motor 16 are fixed, and a circular cutterhead I4 and a circular cutterhead II5 are installed in the casing 2 through a main shaft 3, and the casing 2 A jaw plate 6 is fixed below the 2, and 6 groups of hammer assemblies 7 and 3 active knives 8 are evenly distributed along the circumferential direction between the circular cutter head I4 and the circular cutter head II5, and the hammer assembly 7 and the active knives 8 are arranged in a staggered manner; The upper feeding roller 10 that can move elastically up and down and the lower feeding roller 11 with a fixed position are installed on the main feeding port 9 of the housing 2, and the main fixed knife 12 is fixed below the main feeding port 9; Three evenly distributed auxiliary movable knives 13 are inlaid on the outer surface of II5, and the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com