Box culvert crane working under low clearance conditions

A low headroom and box culvert technology, applied in the direction of traveling bridge cranes, cranes, load hanging components, etc., can solve the problems of small headroom height, affecting synchronous box culvert transportation and assembly, and cannot be assembled synchronously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

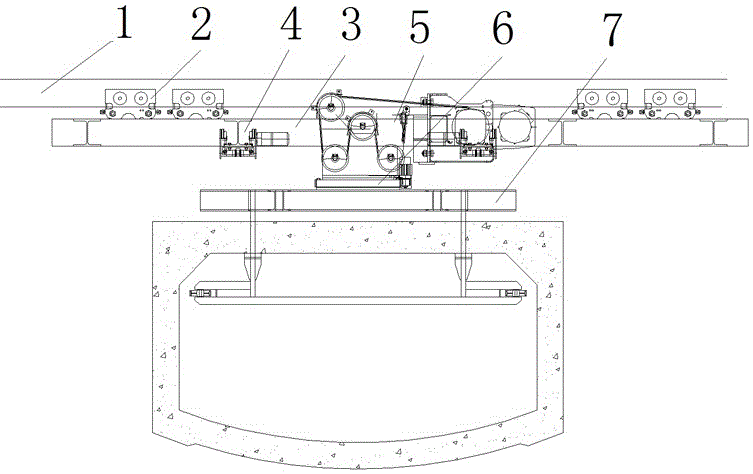

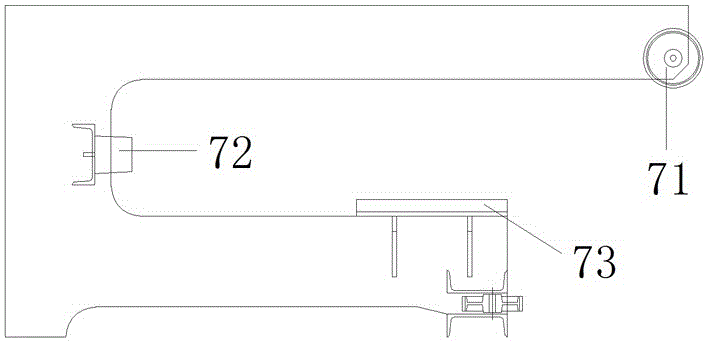

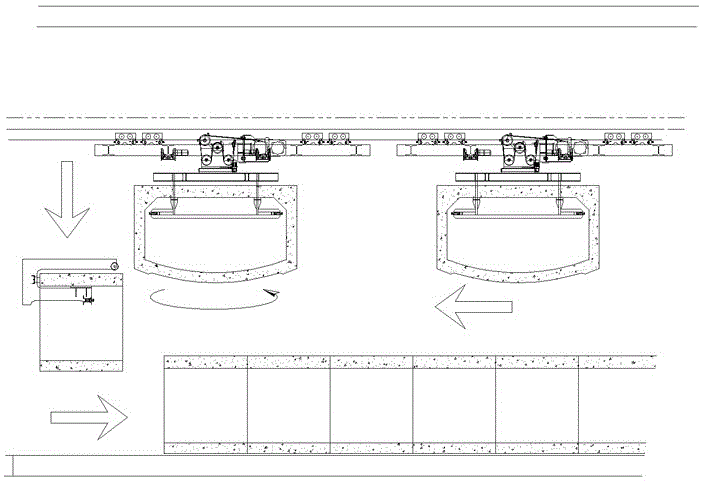

[0017] combine Figure 1-Figure 4 , an embodiment of the present invention is as follows: a box culvert crane working under low clearance conditions, including a longitudinal travel support 1, a longitudinal travel trolley 2, a transverse travel support 3, a transverse travel trolley 4, a lifting device 5, and a rotating device 6 And the box culvert bracket 7, the longitudinal traveling trolley 2 is arranged on the longitudinal traveling support 1, the longitudinal traveling trolley 2 is connected through the transverse traveling support 3, the transverse traveling trolley 4 is arranged on the transverse traveling support 3, and the rotating device 6 is arranged on the box culvert support On the frame 7, the lifting device 5 is connected with the transverse traveling trolley 4 and the rotating device 6 respectively, and the box culvert bracket 7 is a U-shaped structure.

[0018] When the box culvert crane of the present invention is installed, a beam structure is added at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com