Patents

Literature

51results about How to "To achieve dredging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pipeline oil stain cleaning agent and preparation method thereof

ActiveCN105542986AEffective emulsificationEfficient degradationOrganic detergent compounding agentsNon-ionic surface-active compoundsAdditive ingredientCleansing Agents

The invention provides a pipeline oil stain cleaning agent and a preparation method thereof, and relates to an oil stain cleaning treatment technology. The pipeline oil stain cleaning agent is characterized in that the effective ingredients of the pipeline oil stain cleaning agent comprise a compound microorganism preparation, and microorganisms in the compound microorganism preparation comprise Bacillus stearothermophilus and Brevibacillus sp.. In further improvement, the effective ingredients of the pipeline oil stain cleaning agent further comprise an enzyme preparation, a low-molecular-weight peptide and a glycolipid biological surfactant. The microorganism preparation takes grease ingredients existing in pipelines as the main carbon source and can emulsify and degrade the grease ingredients in the pipelines through metabolism and reproduction activities of the microorganisms themselves; meanwhile, the microorganism preparation can restrain reproduction of harmful bacteria in the environment, facilitate growth and reproduction of endogenous good bacteria in the environment and prevent the odor problem and other problems from occurring, and therefore the effects for achieving long-time and effective oil removing and pipeline dredging can be achieved; the fermentation technology is simple, easy to control and low in production cost.

Owner:中林山水(北京)生态科技有限公司 +1

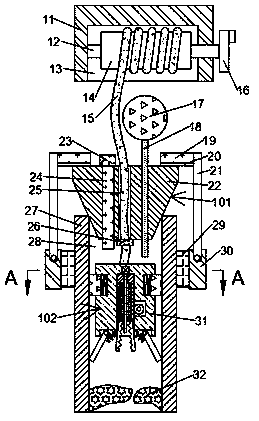

Dredging device for domestic sewer pipeline

InactiveCN107254901AReduce breakageRealize instant dredging effectDomestic plumbingSludgeEngineering

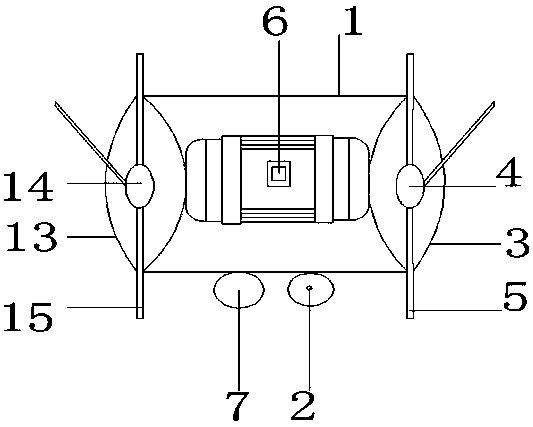

The invention discloses a dredger for household sewer pipes, which comprises a main hollow shell, the bottom of which is provided with a universal rolling device, and the center of the inside of the main hollow shell is provided with a main hollow structure, the main hollow shell is provided with a limit ring structure in the middle of the main hollow structure, and a NdFeB permanent magnet is placed above the limit ring structure in the main hollow structure, and the The interior of the NdFeB permanent magnet is provided with a plurality of through-hole structures communicating with its upper and lower surfaces, and a first air check valve is installed inside each of the through-hole structures. The present invention can achieve instant dredging effect through large-scale air pressure, so that the clogged sludge is instantly disintegrated under strong air pressure, thereby realizing the dredging effect. In addition, the device uses suction-type air pressure for disintegration, which can reduce the sewer pipeline due to air pressure. And the phenomenon of breakage caused by it, at the same time, the device has an independent air suction structure, which is convenient and quick to use.

Owner:曾翰进

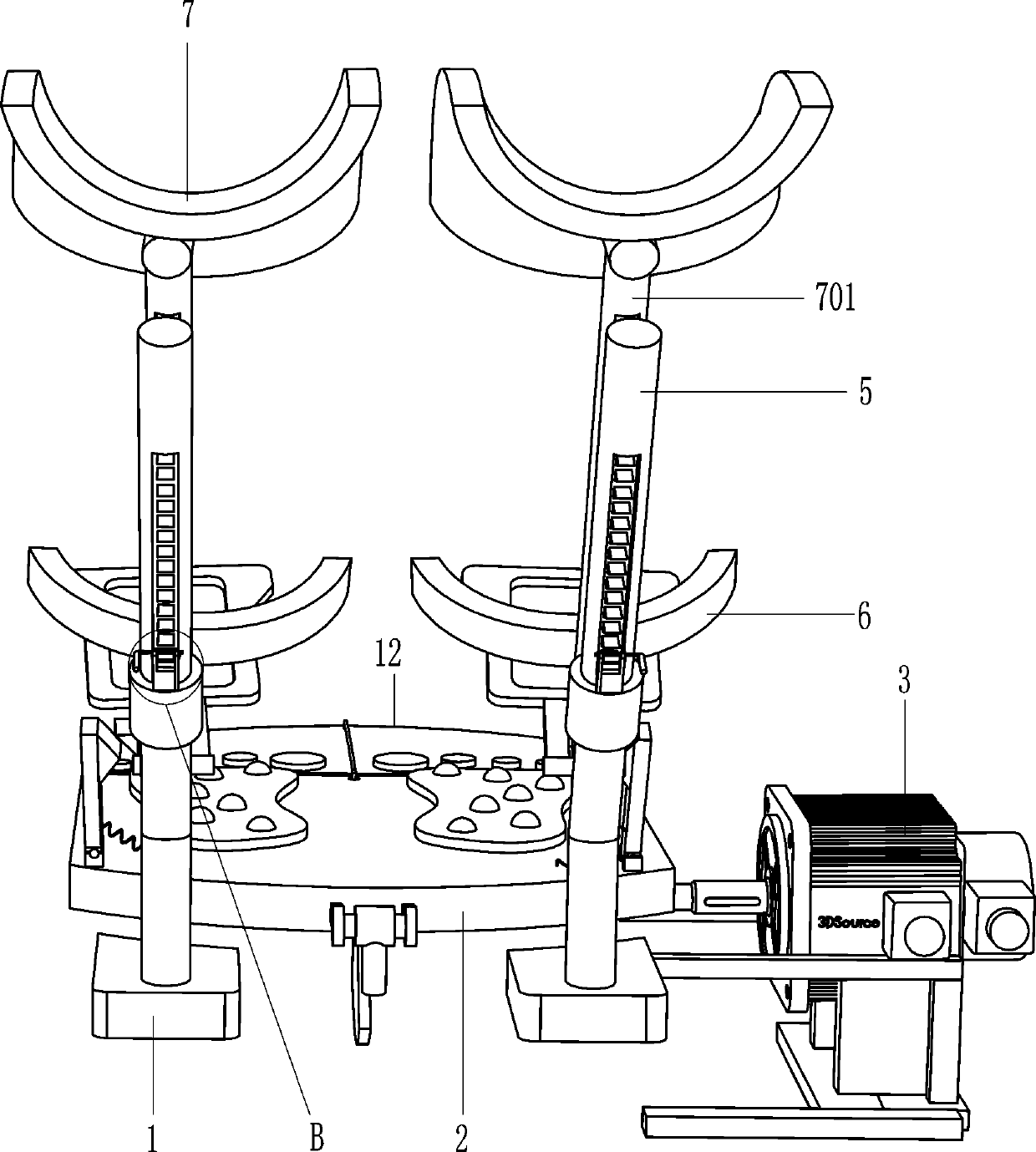

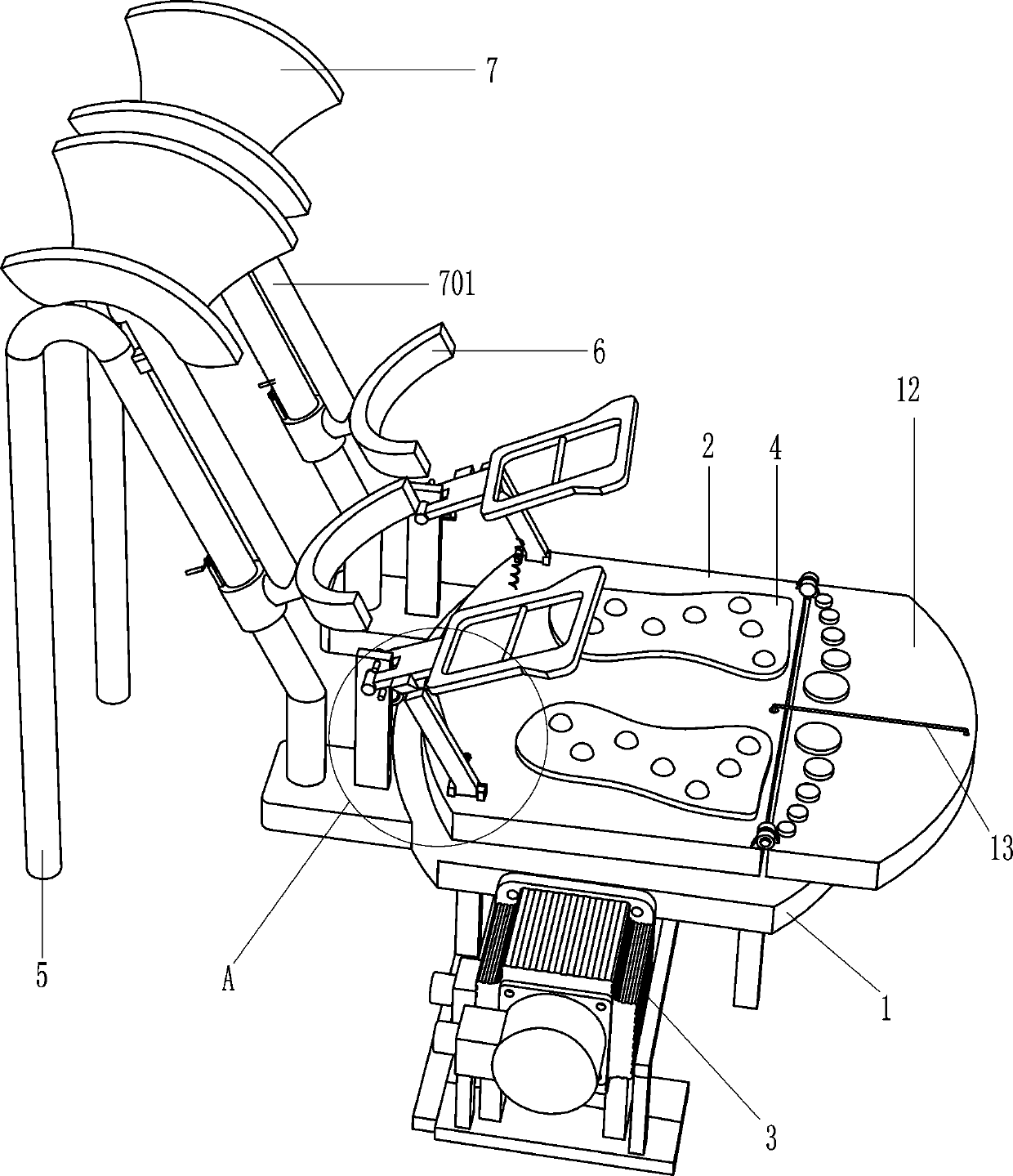

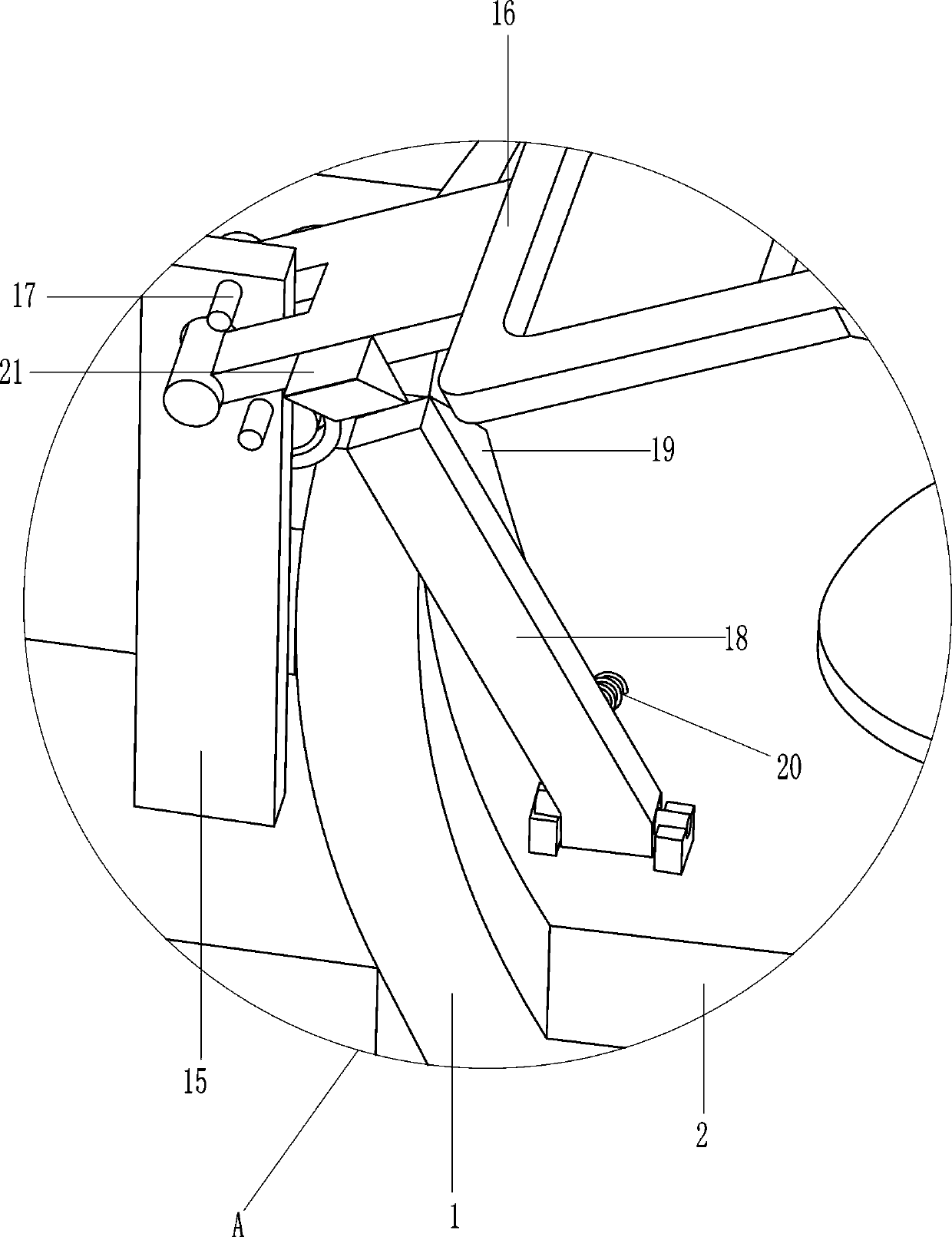

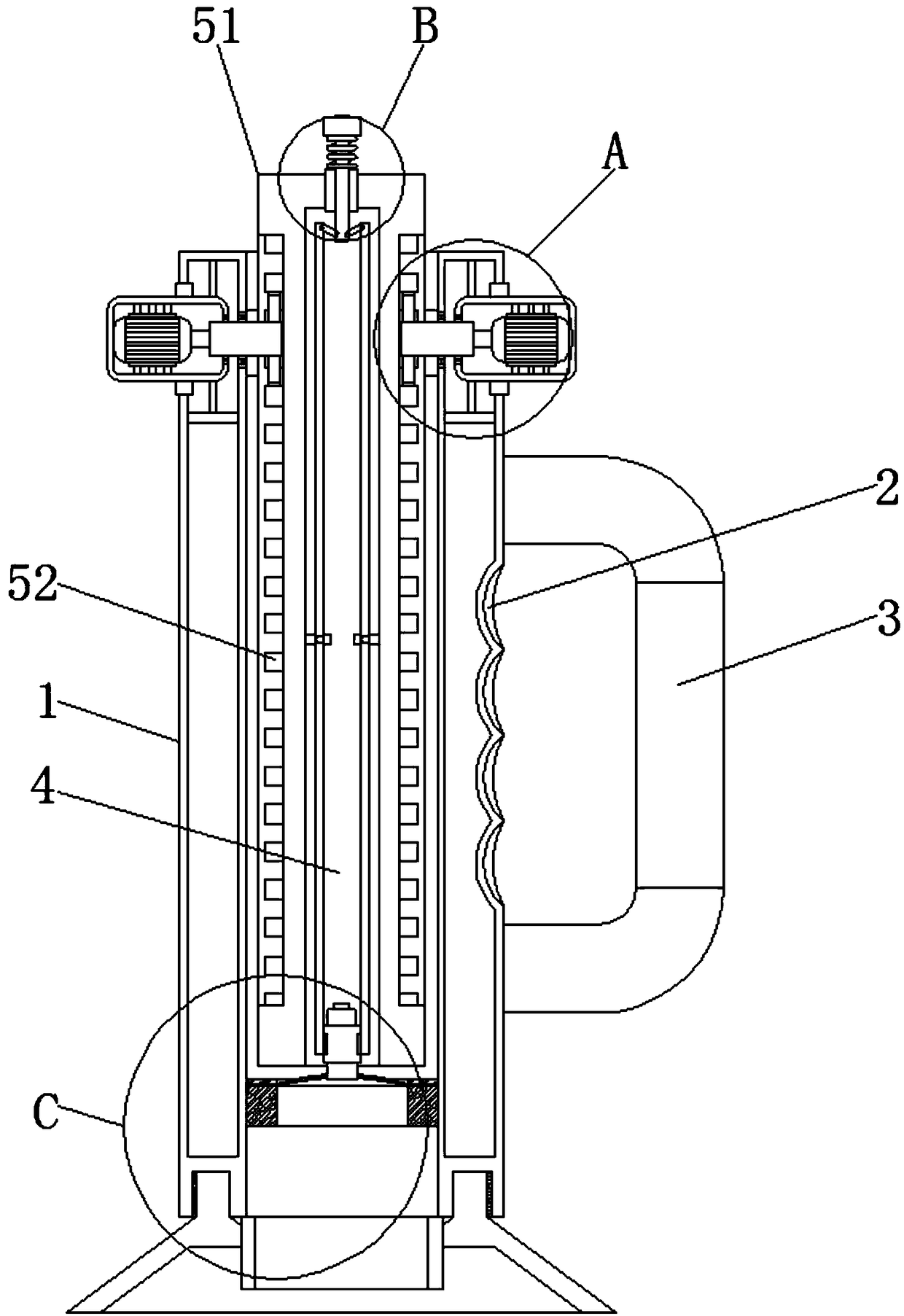

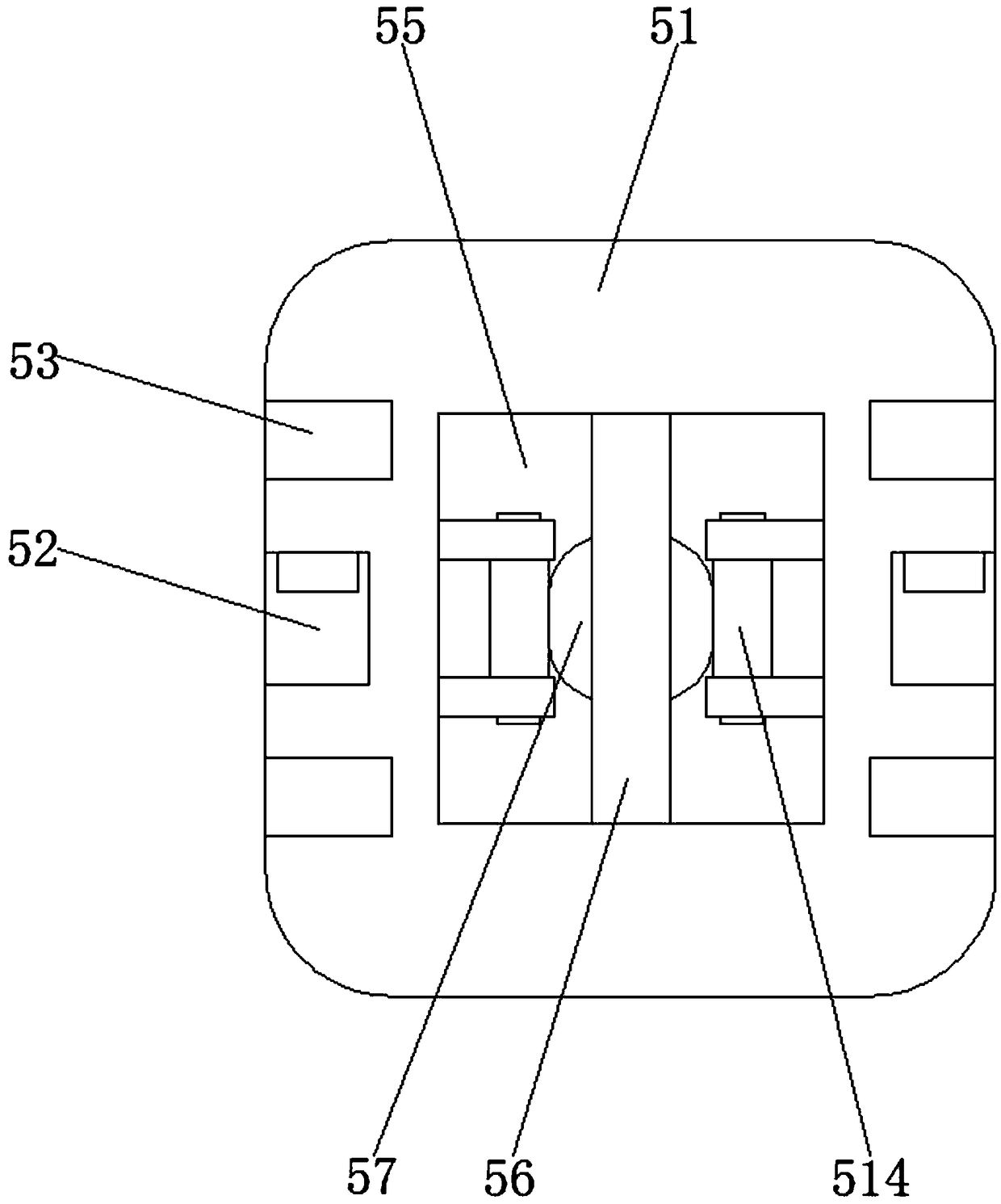

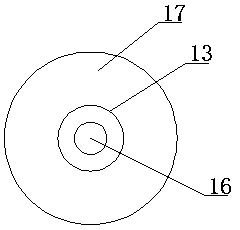

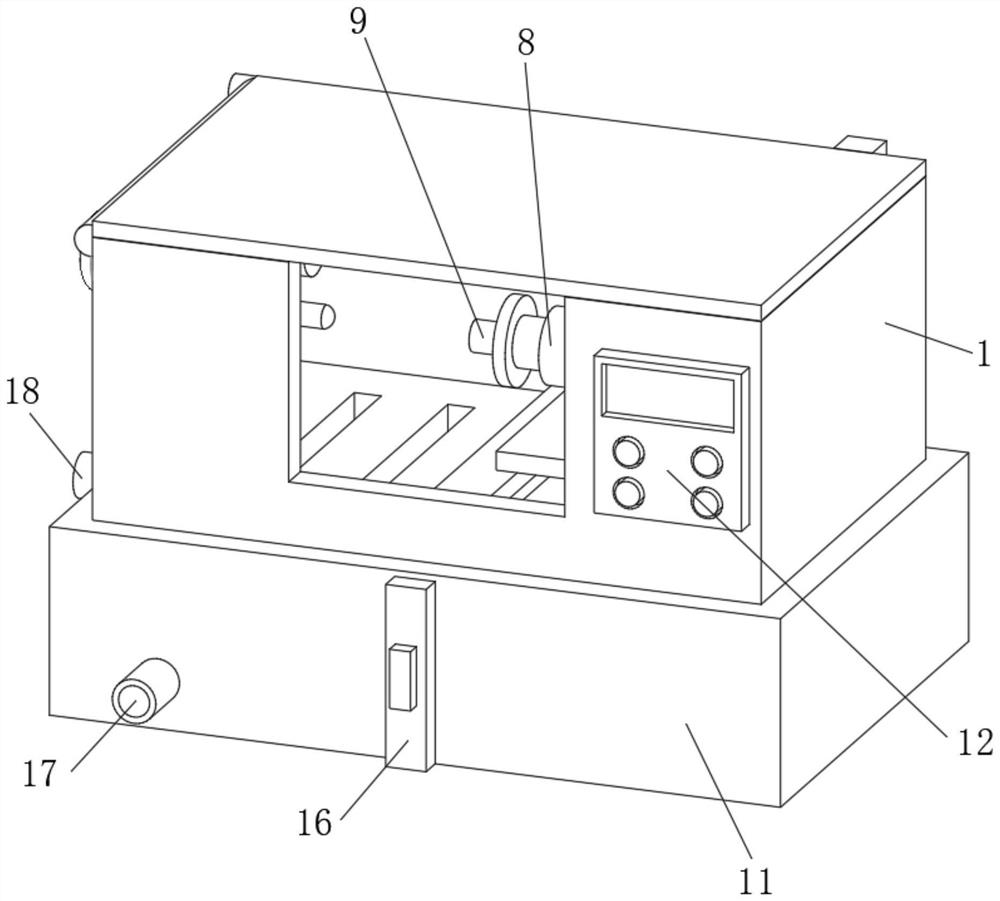

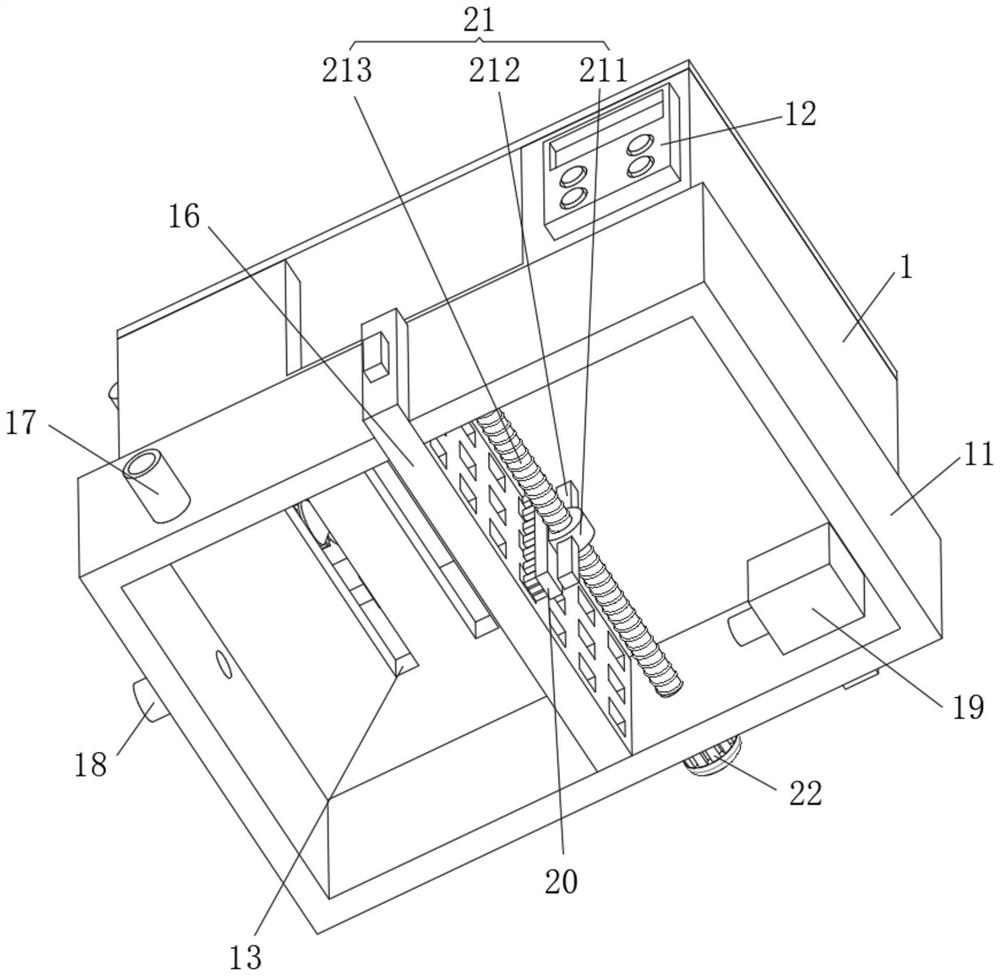

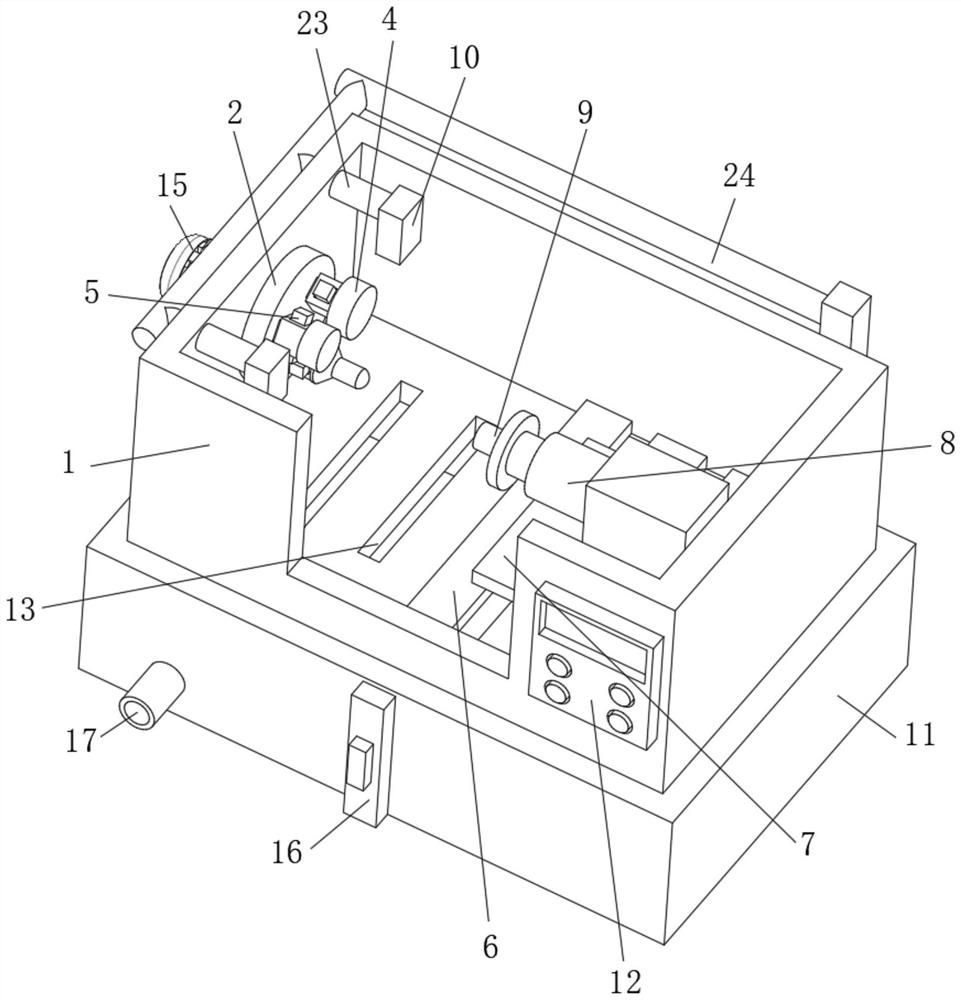

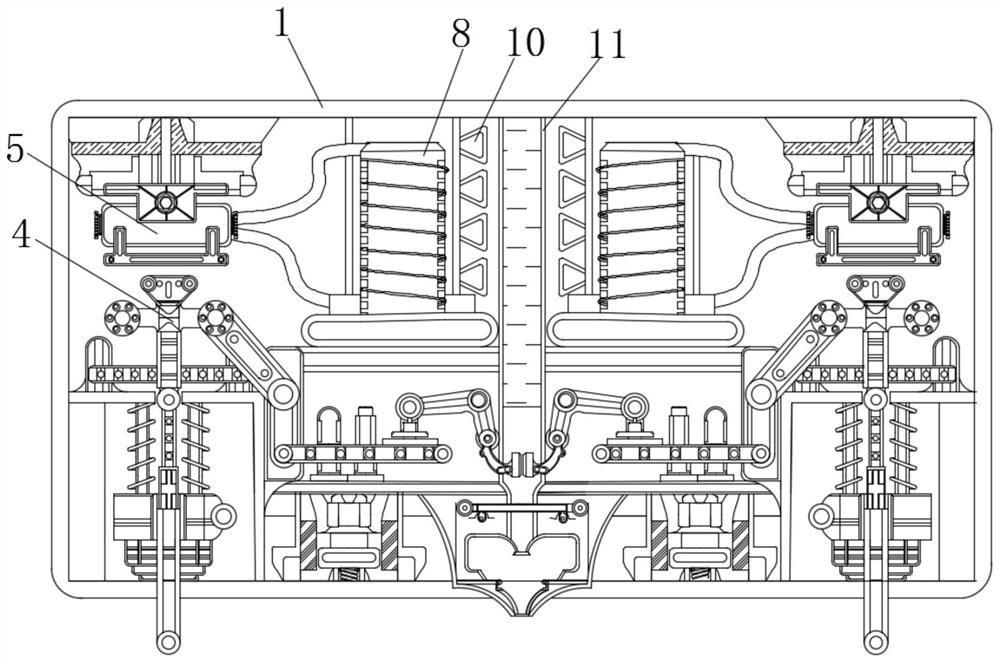

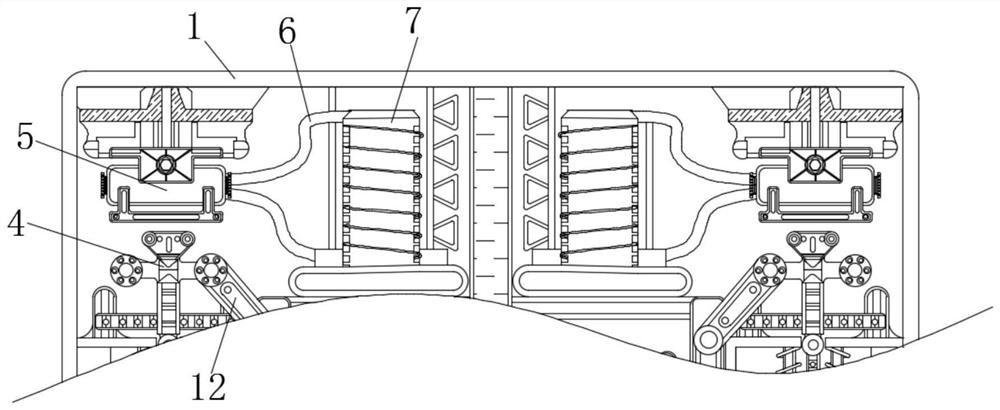

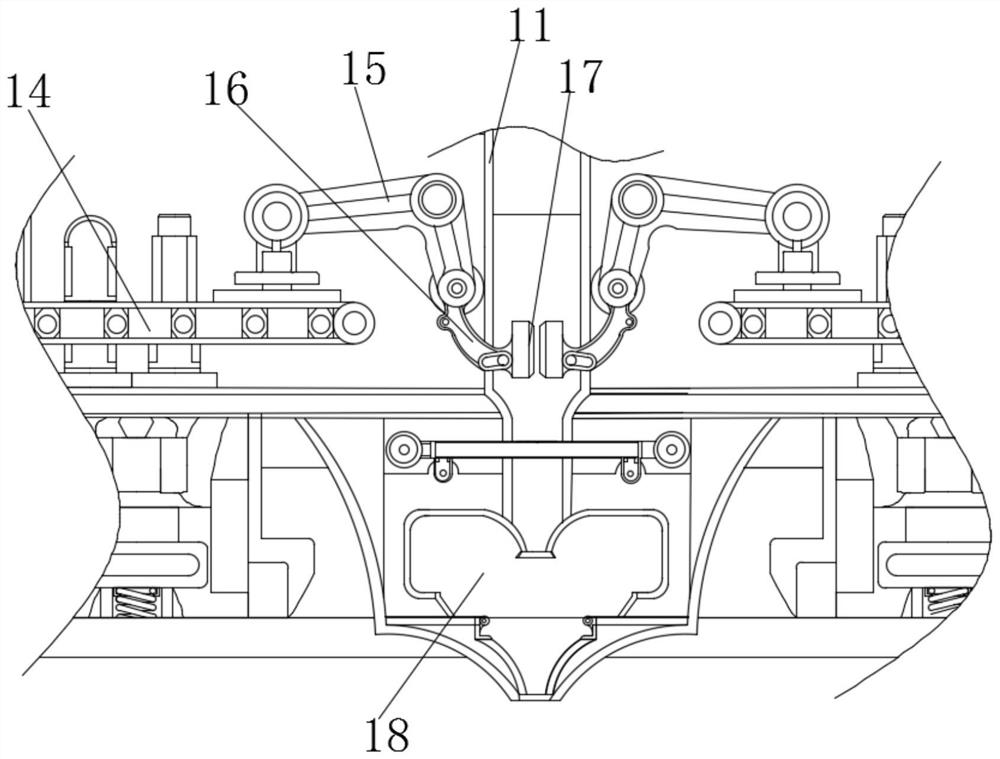

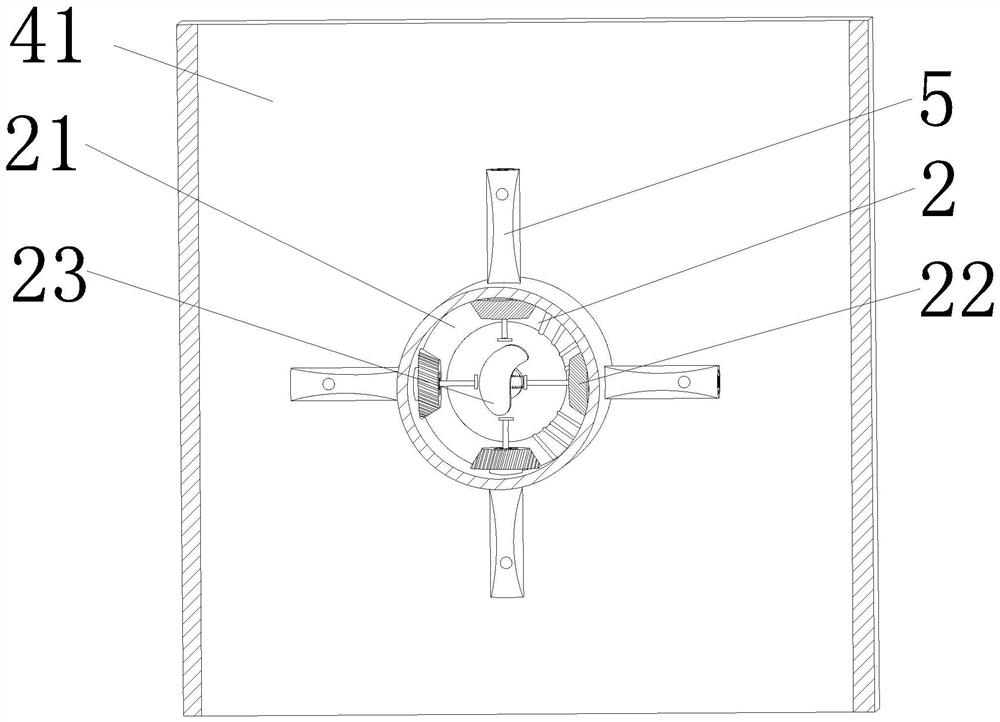

Foot massage device for dredging blood

ActiveCN110934731AAchieve massage effectTo achieve dredging effectDevices for pressing relfex pointsChiropractic devicesPhysical therapyMechanical engineering

The invention relates to a foot massage device, in particular to a foot massage device for dredging blood. The technical problem to be solved is to provide the foot massage device for blood dredging,which can automatically massage feet and achieve the effect of dredging blood at the same time. The foot massage device for dredging blood comprises a support, a beating plate, a gear motor, a massagecomponent, a transmission component, a toe massage component and the like. The beating plate is rotationally arranged at the top of the support, the gear motor is arranged on the front side of the support, and the massage component for flapping massage through rotation is arranged at the top of the support. The gear motor rotates to drive a cam to push a massage plate to massage the feet, the effect of automatically massaging the feet is achieved, through cooperation of a first contact block and a second contact block, the soles of the feet can be massaged, meanwhile, ankle joints can be swung, and the effect of dredging blood is achieved.

Owner:HEBI CITY PEOPLES HOSPITAL

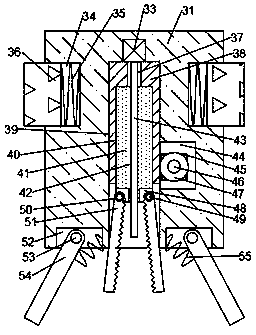

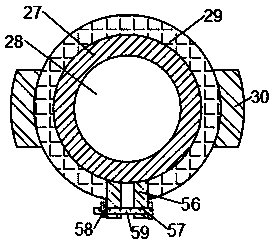

Floor drain sewer dredging device capable of instantly changing air pressure

ActiveCN109083256ATo achieve dredging effectNot upwellingSewerage structuresDomestic plumbingEngineeringAtmospheric pressure

The invention discloses a floor drain sewer dredging device capable of instantly changing air pressure and relates to the technical field of floor drain sewer cleaning. The floor drain sewer dredgingdevice capable of instantly changing air pressure comprises a supporting column, wherein a finger mark groove is formed in the middle of one side of the supporting column, the middle of one side of the supporting column is fixedly connected with a handle, the middle of the supporting column is provided with a through hole communicated with the top and bottom of the supporting column, an air pressure changing mechanism is arranged in the inner cavity of the through hole, the four sides of the bottom of the supporting column are provided with annular threaded grooves, and the bottom of the supporting column is provided with a sealing connection mechanism. The floor drain sewer dredging device capable of instantly changing air pressure can achieve the effect of accumulating air mass and completing pipe dredging through an air pressure impact force, is convenient and efficient to use, does not make dirt to upwell and saves effort in use, and the problems are solved that a floor drain and asewer connected with the floor drain are possibly blocked, the cost for floor drain refitting is high, and a common suction-type dredging device is inconvenient to use.

Owner:嘉兴昱天工业设计有限公司

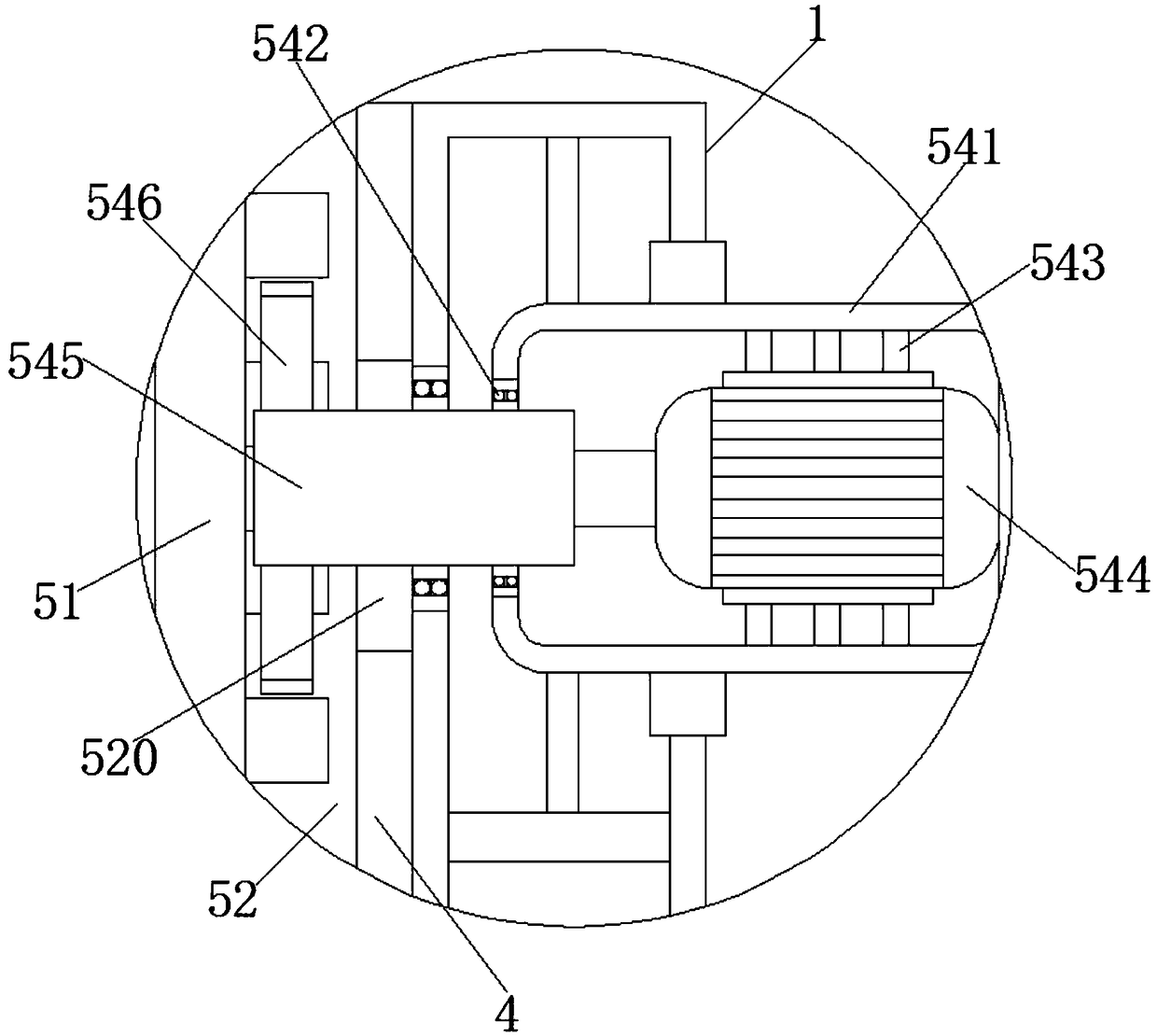

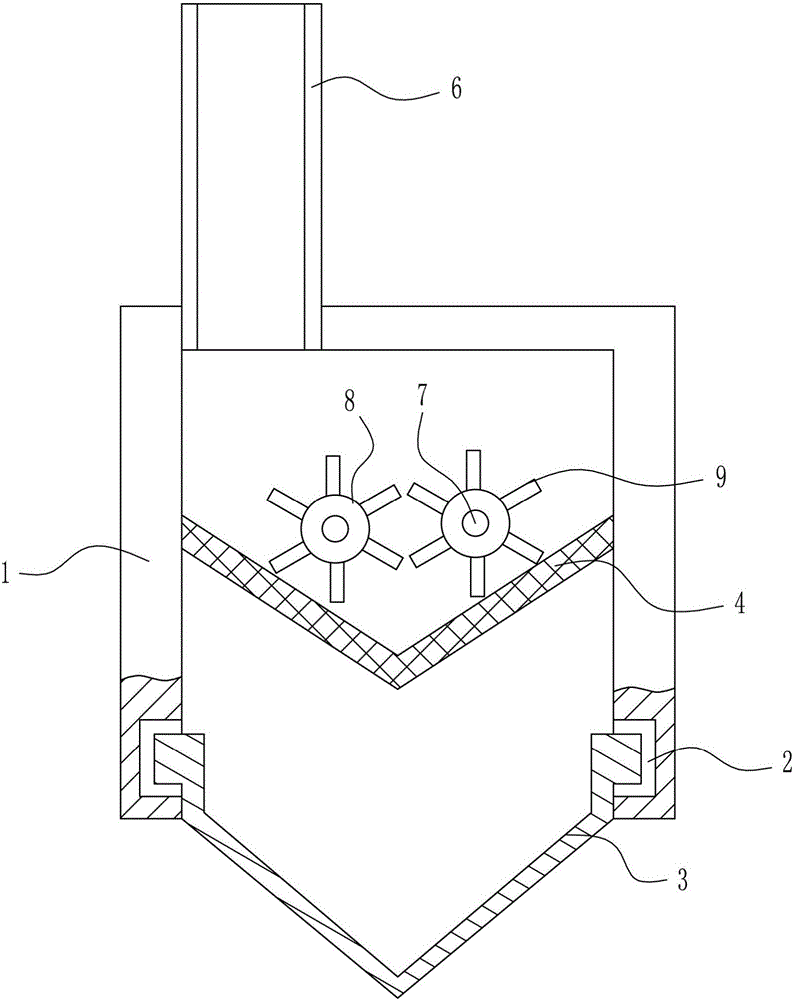

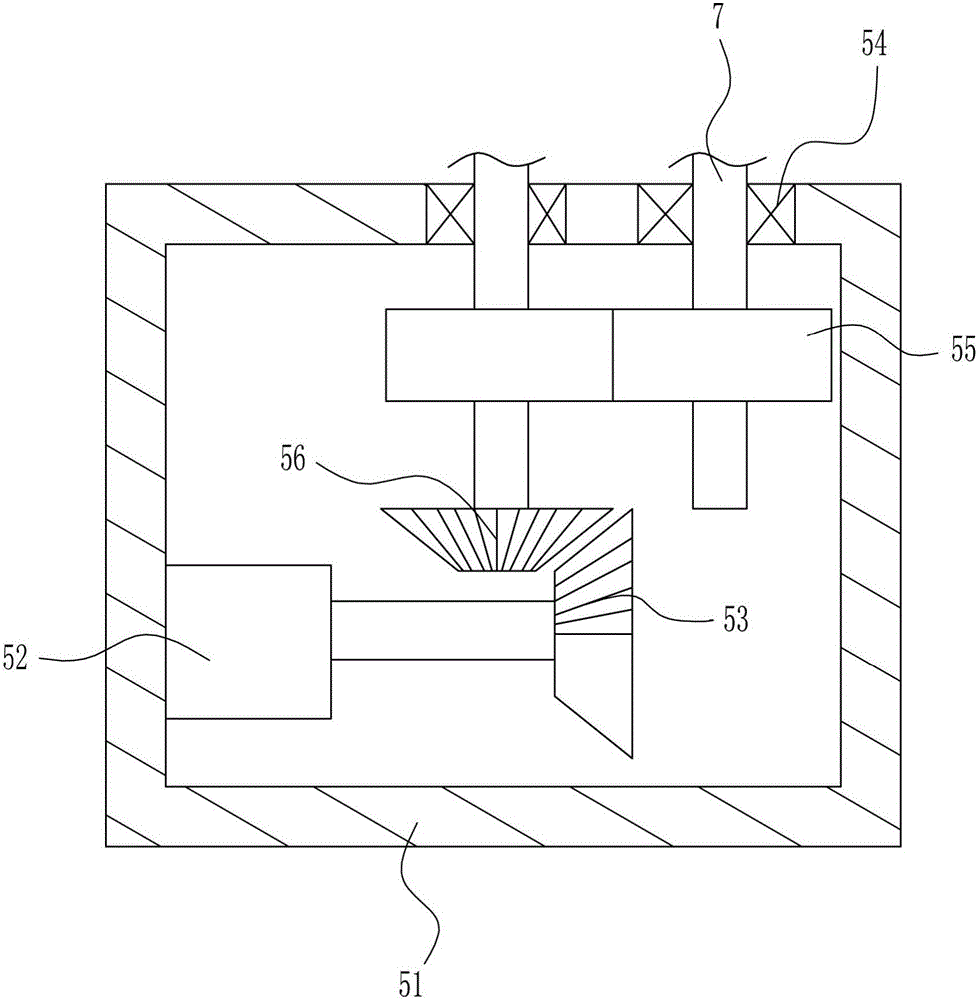

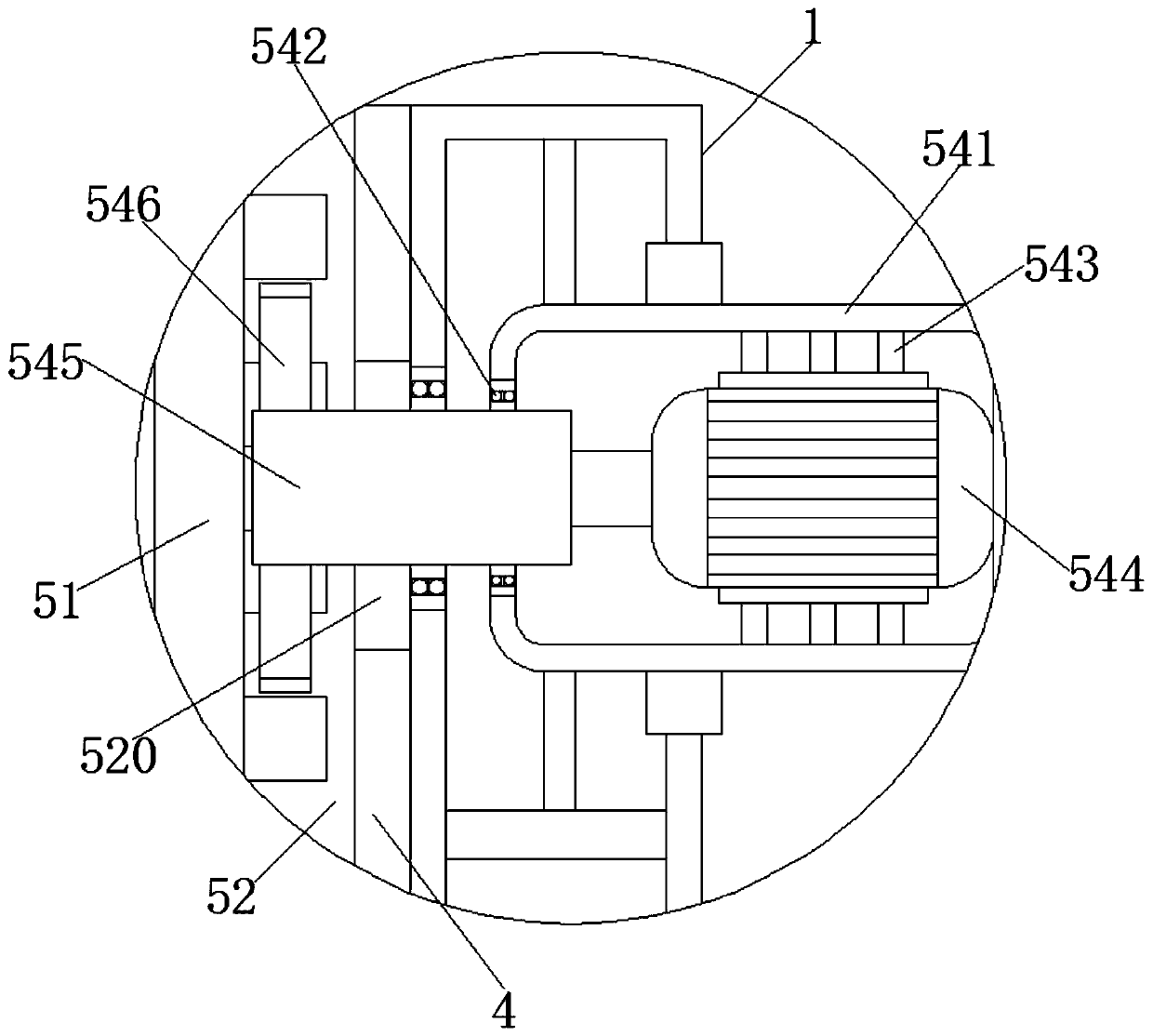

Completely smashing device for character design drawing for cartoon game development

ActiveCN106669922ATo achieve the purpose of crushingTo achieve dredging effectSievingScreeningCharacter designElectric machinery

Owner:NINGBO KAKU CARTOON MAKING

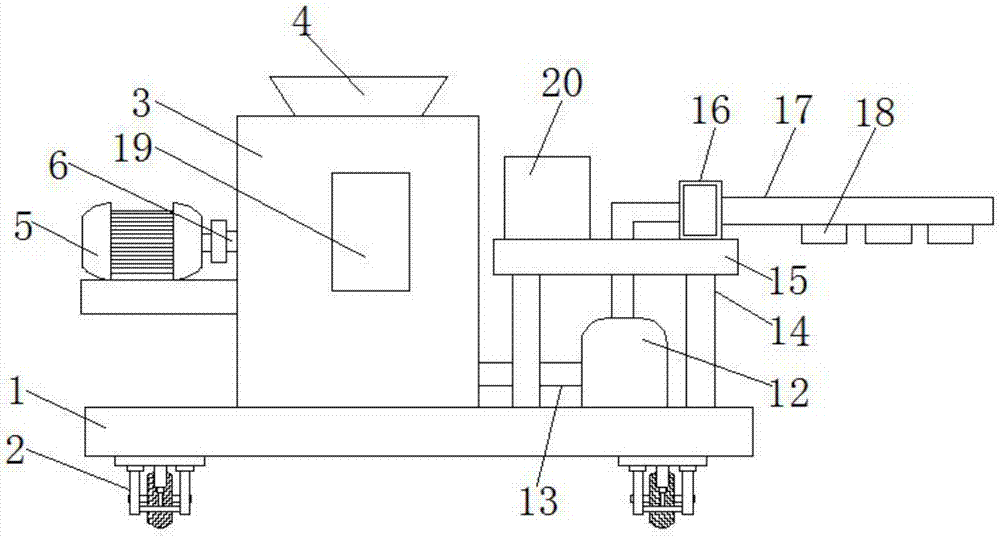

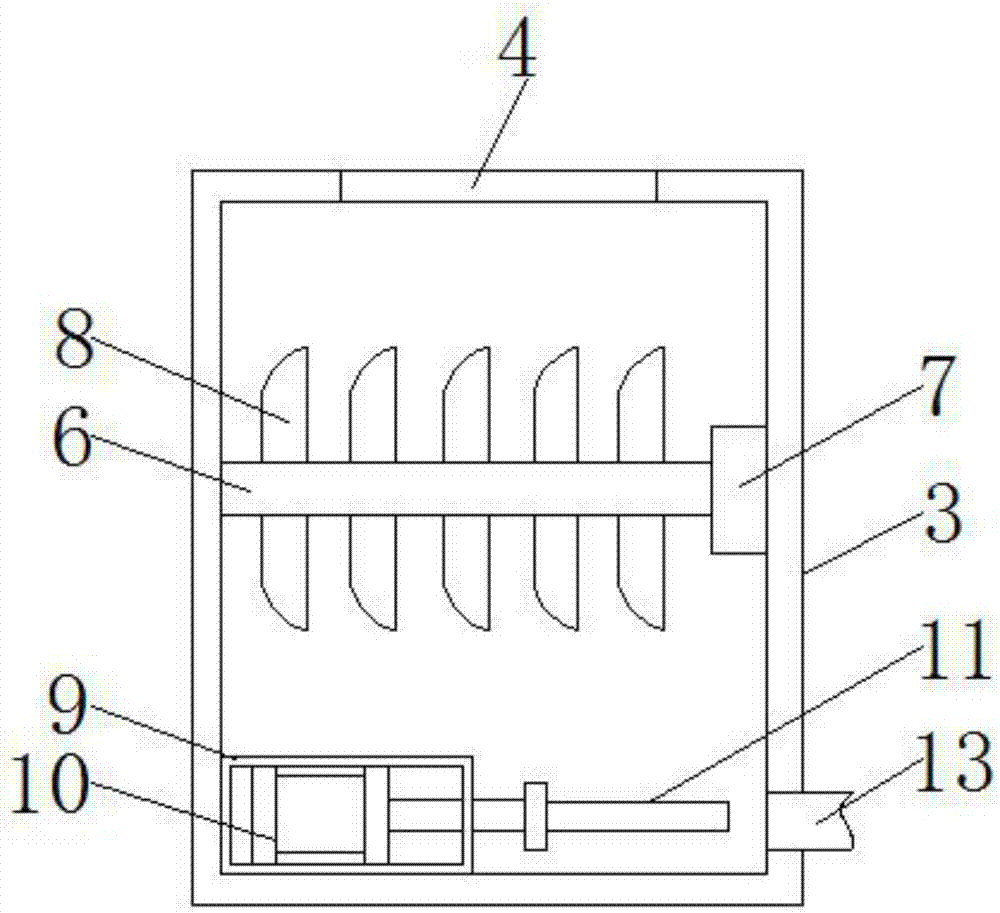

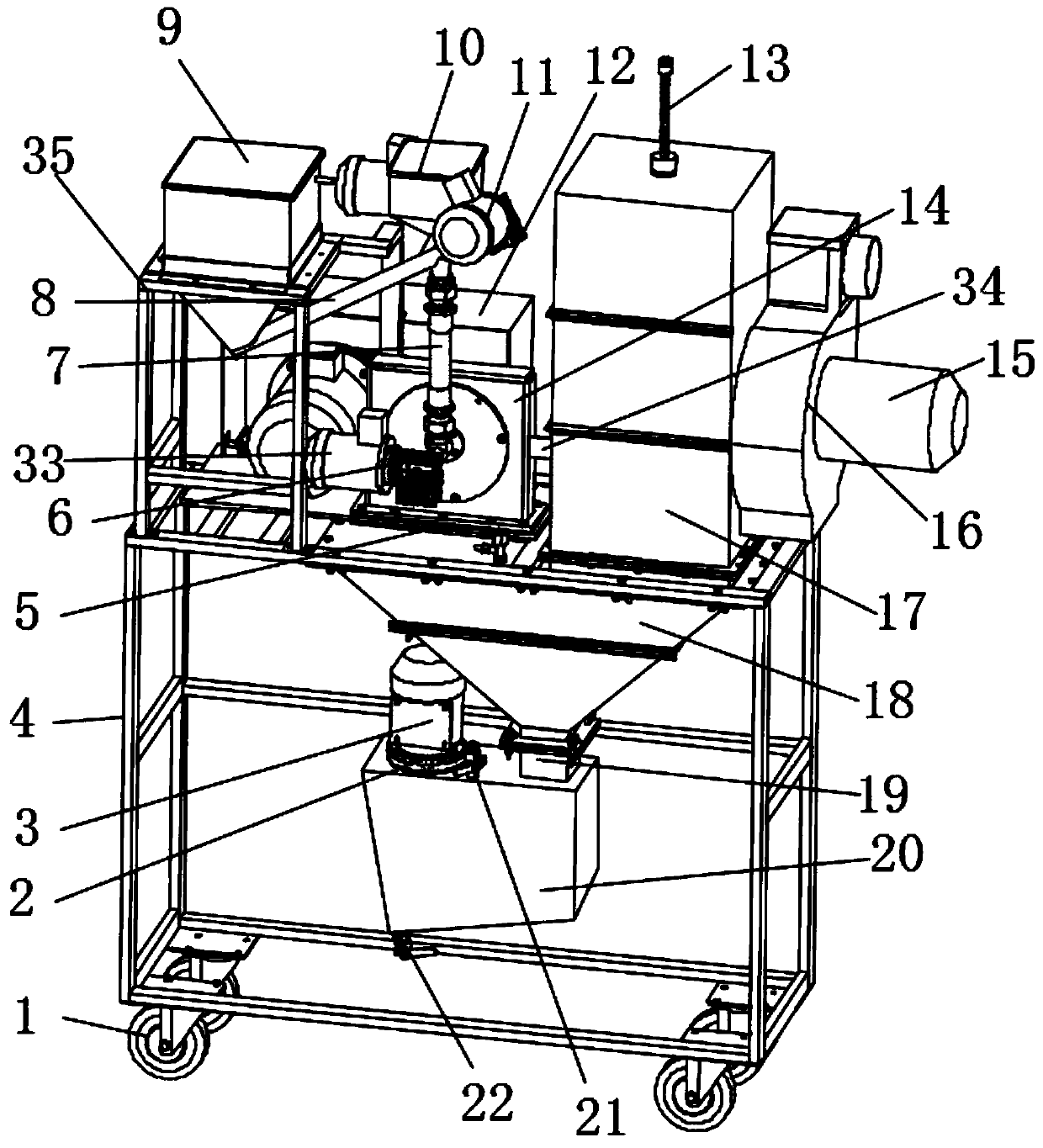

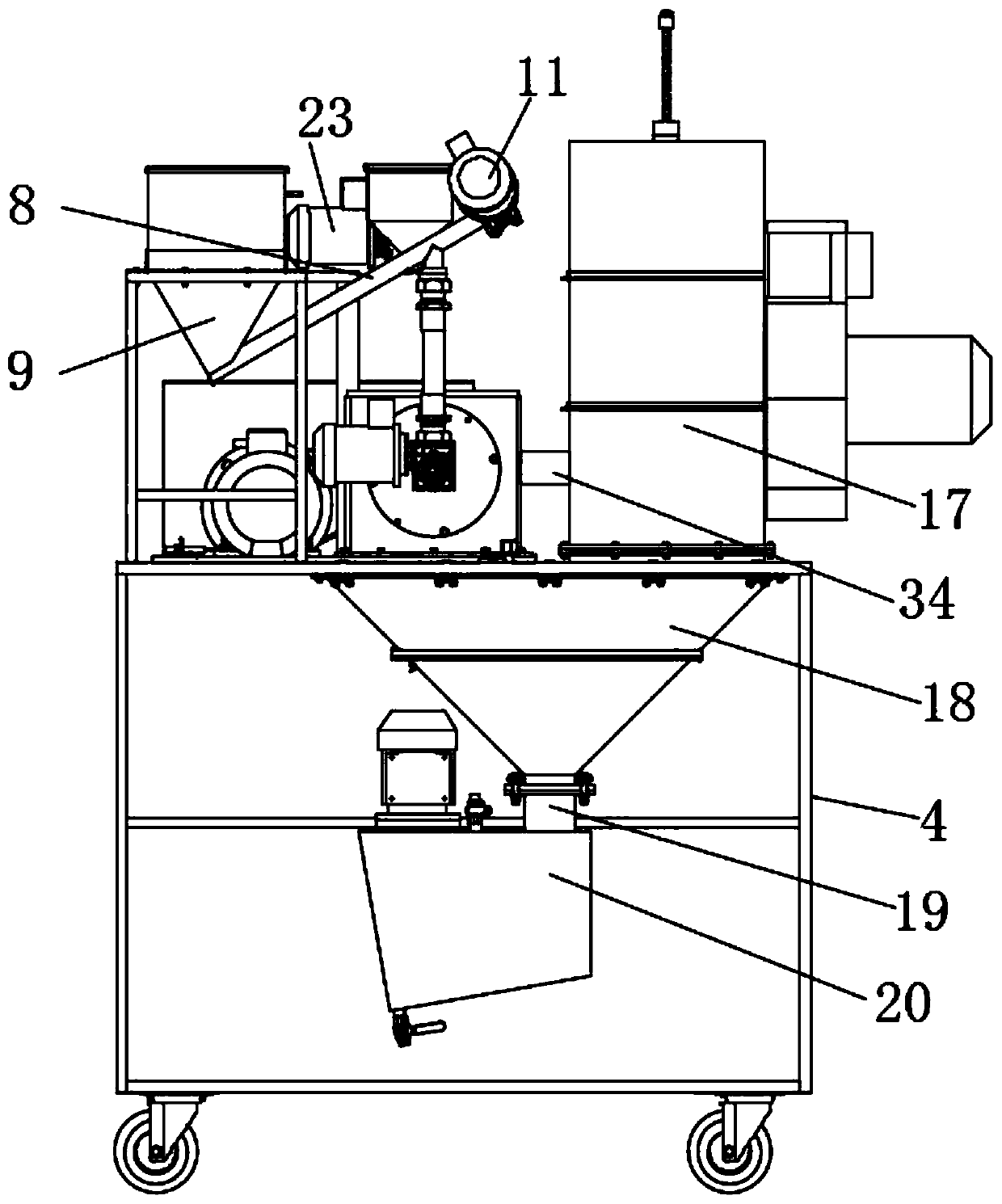

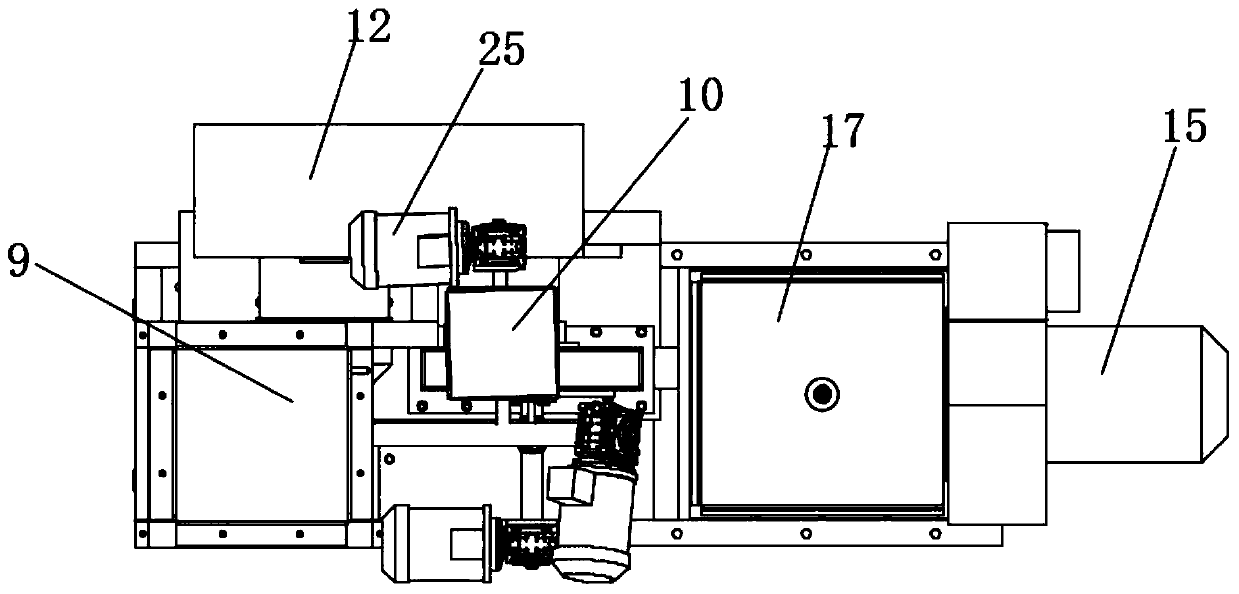

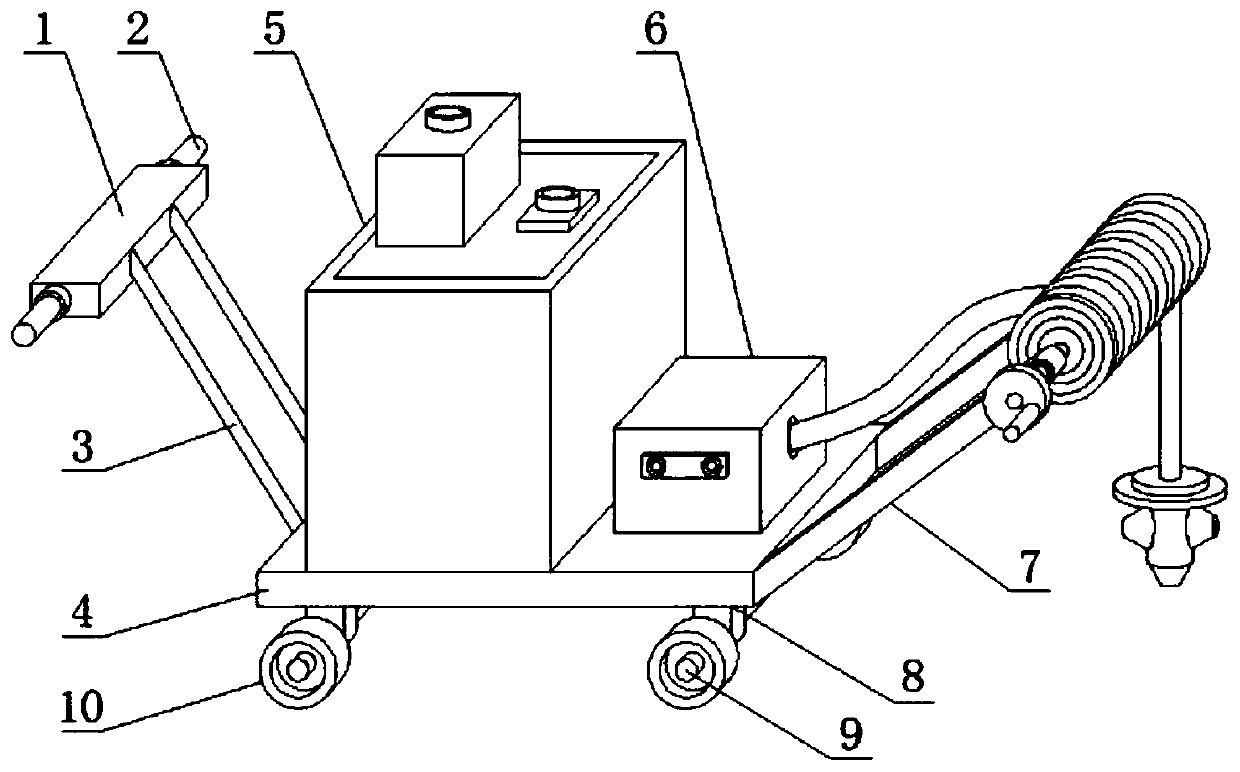

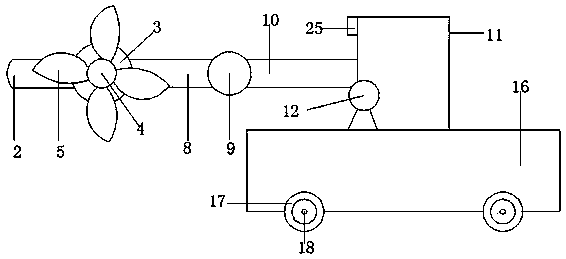

Vegetation recovering hydroseeder

The invention discloses a vegetation recovering hydroseeder which comprises a base. Movable wheels are fixedly connected to the two sides of the bottom of the base, a box body is fixedly connected to one side of the top of the base, a feeding opening is formed in the top of the box body, a supporting plate is fixedly connected to one side of the box body, a motor is fixedly connected to the top of the supporting plate, a rotating shaft is fixedly connected to an output shaft of the motor through a coupler, one end of the rotating shaft penetrates through the box body and extends into the box body to be in rotary connection with a bearing on one side of an inner wall of the box body, and a stirring blade is arranged on the lateral side of the rotating shaft and further in the box body. By means of arranging the motor, the rotating shaft, the bearing, the stirring blade, a shell, an electric push rod, an ejector rod, an air compressor, a feeding pipe, a supporting rod, a horizontal plate, a buffer tank, an injection pipe and a sprayer head, the vegetation recovering hydroseeder has simple structure and convenience in operation, improves work efficiency and reduces burden of workers at the same time.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

Floor drain sewer dredging equipment and method capable of instantly changing air pressure

InactiveCN111501973ATo achieve dredging effectNot upwellingSewerage structuresDomestic plumbingMechanical engineeringSewerage

The invention discloses floor drain sewer dredging equipment and method capable of instantly changing air pressure, and relates to the technical field of floor drain sewer cleaning. The floor drain sewer dredging equipment capable of instantly changing air pressure comprises a supporting column, a finger mark groove is formed in the middle of one side face of the supporting column, a handle is fixedly connected to the middle of one side face of the supporting column, a through hole communicating with the top and the bottom of the supporting column is formed in the middle of the supporting column, an air pressure changing mechanism is arranged in an inner cavity of the through hole, annular threaded grooves are formed in the four sides of the bottom of the supporting column, and a sealing connecting mechanism is arranged at the bottom of the supporting column. The floor drain sewer dredging equipment capable of instantly changing air pressure can achieve the effects of gathering air masses and completing pipeline dredging through air pressure impact force, is convenient and fast, avoids upwelling of dirt, saves labor during use, and solves the problems that a floor drain and a sewerline connected with the floor drain are easy to block, the cost for refitting the floor drain is high, and common suction type dredging equipment is inconvenient to use.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

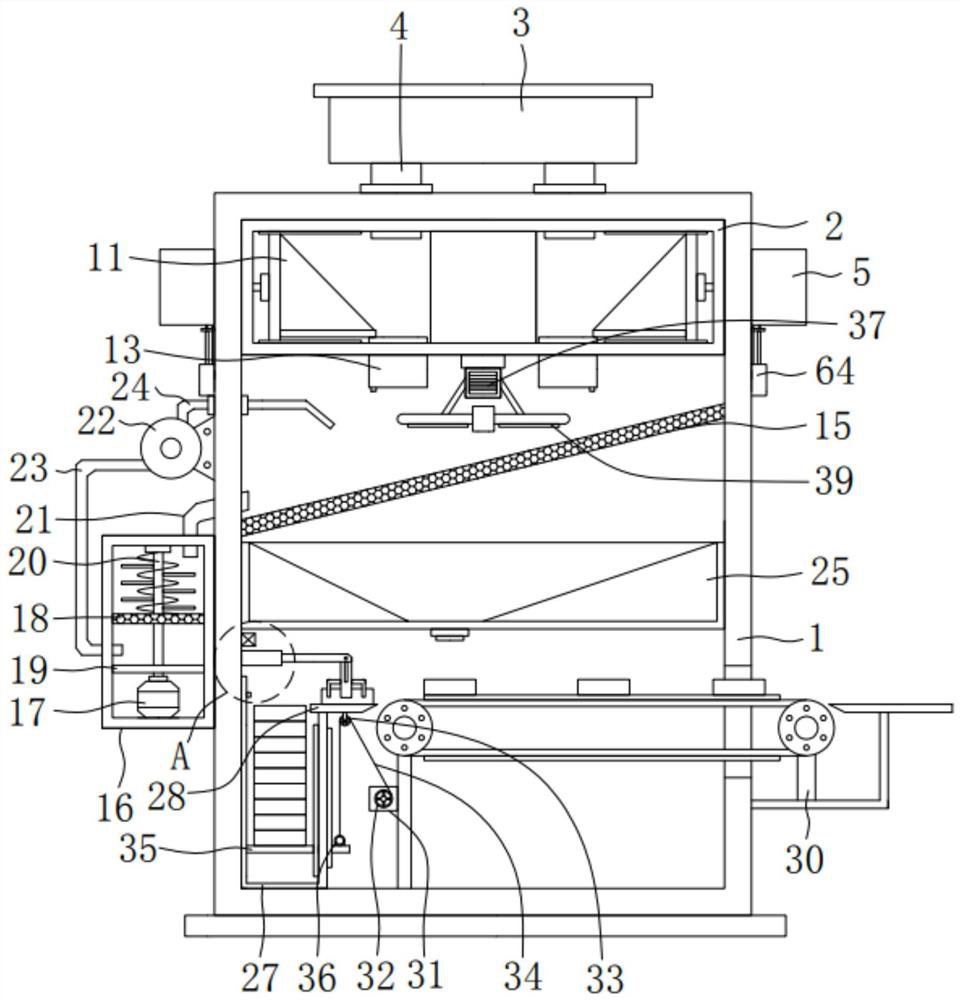

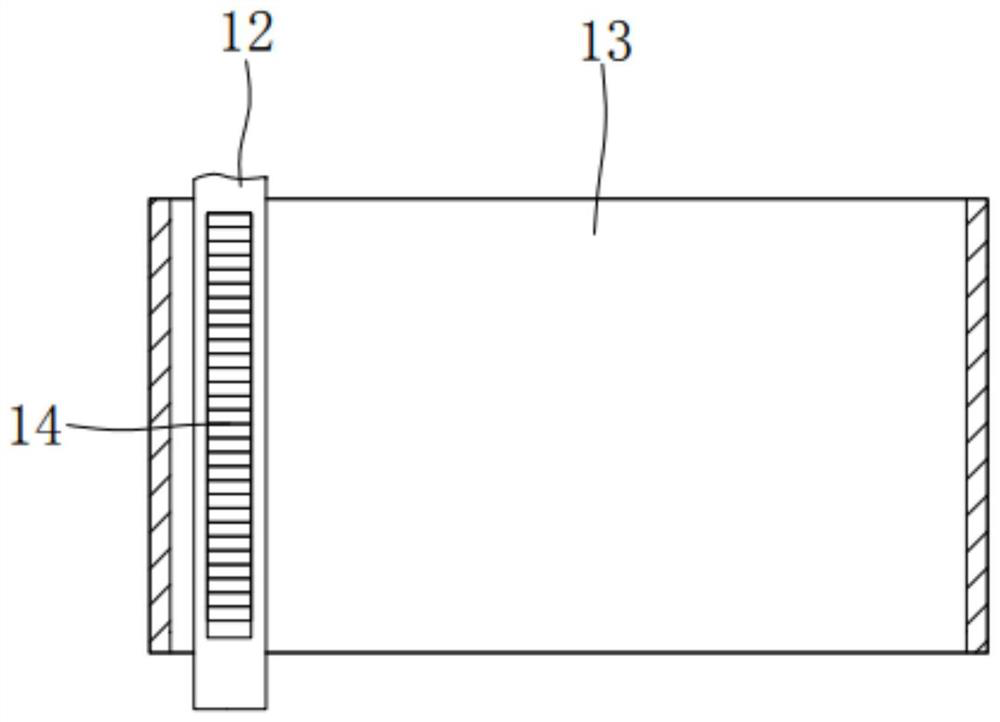

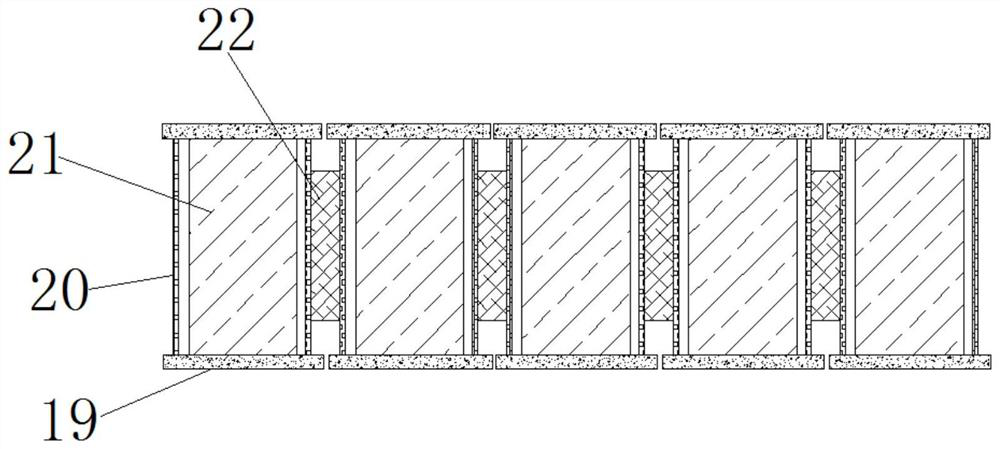

Full-automatic packaging equipment for organic fertilizer production

InactiveCN112722347AEasy to packImprove drying effectSievingScreeningAgricultural scienceAgricultural engineering

The invention provides full-automatic packaging equipment for organic fertilizer production. The full-automatic packaging equipment for organic fertilizer production comprises a processing box, a box body and a material box; the two sides of the box body are fixed to the two sides of the interior of the processing box; the material box is arranged at the top of the processing box, the bottom of the material box communicates with two discharging pipes, and the bottom ends of the two discharging pipes sequentially penetrate through the processing box and the material box and extend into the material box. According to the full-automatic packaging equipment for organic fertilizer production, through an arranged control panel, an opening of a discharging opening can be controlled, so that organic fertilizer can fall quantitatively, the situation that the discharging opening is prone to blockage, the organic fertilizer is prone to accumulation and the drying effect is affected due to the fact that the falling quantity is relatively large is avoided, the drying effect and the quality of the organic fertilizer are improved, and subsequent packaging of the organic fertilizer is facilitated.

Owner:颍上县健辉农牧有机肥有限公司

Automatic garbage recovery device and recovery method thereof

InactiveCN110813978ATo removeEasy to crush in cold zoneSolid waste disposalGrain treatmentsElectric machineryGarbage collection

The invention discloses an automatic garbage recovery device. The automatic garbage recovery device comprises a base, a feed box and a crushing box. A mounting rack is fixedly arranged at one end of the top of the base. The feed box is arranged on the top of the mounting rack. The bottom of the feed box is provided with a feed pipe. A cover plate is arranged in the position, on one side of the mounting rack, of the top of the base. The top of the cover plate is fixedly provided with supporting columns. Crushed garbage is fed into a collection box from the bottom of the crushing box and goes into a storage box through a transition pipe. The bottom surface of the storage box is an inclined plane, and a discharge port is arranged at the bottom of the inclined plane, so that the crushed garbage slides to the discharge port under the action of gravity and is discharged from the discharge port. Meanwhile, the output end of an unchoking motor drives an unchoking shaft to rotate, and unchokingblades on the unchoking shaft rotate to stir the crushed garbage to move, so that the crushed garbage can be discharged from the discharge port. The automatic garbage recovery device achieves the crushed garbage unchoking effect to protect materials against accumulation and blockage.

Owner:苏州德君环卫服务有限公司

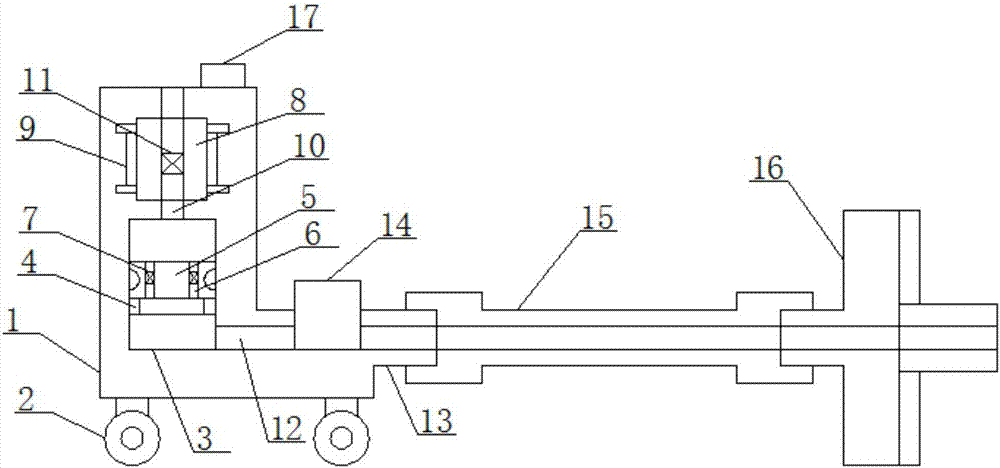

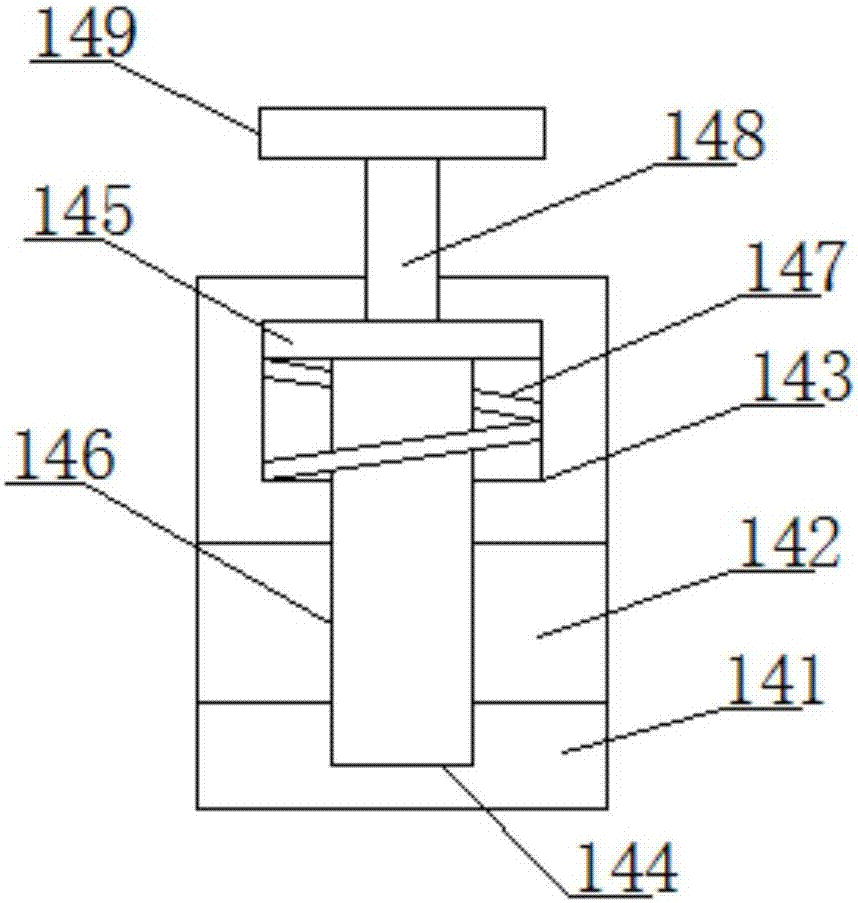

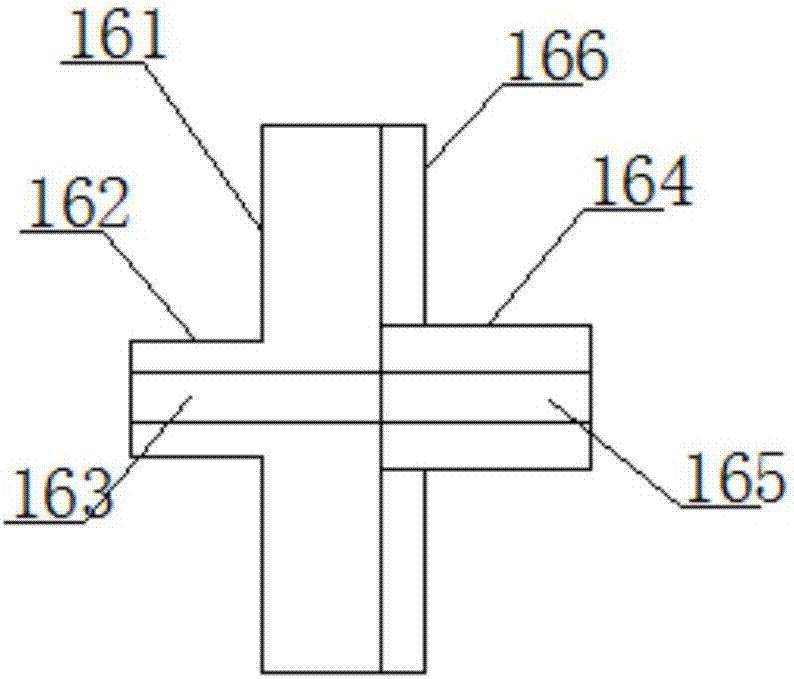

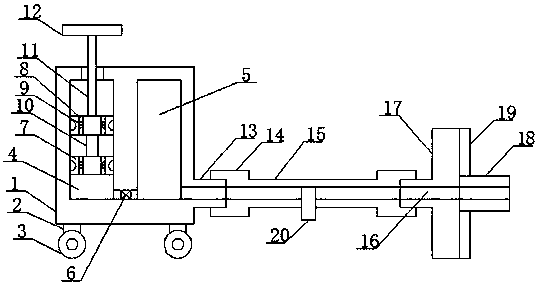

Household dredging device for sewer pipe

InactiveCN107130668AEasy to useRealize instant dredging effectDomestic plumbingPneumatic pressureEngineering

The invention discloses a household dredging device for a sewer pipe. The household dredging device comprises a blocky shell, supporting legs arranged at the bottom of the blocky shell and rollers arranged at the bottoms of the supporting legs, wherein the interior of the blocky shell is provided with a hollow compression chamber and a hollow air storage chamber; the side surface of the blocky shell is provided with a connection pipeline port communicated with the air storage chamber; the surface of the connection pipeline port is sleeved with an exhausting flexible pipe; the other end of the exhausting flexible pipe is in clamp connection with the surface of another connection pipeline port arranged on the center of one end surface of a pedal; and the center of the other end surface of the pedal is provided with an insertion pipeline integrated with the pedal. According to the invention, instant dredging effect is realized via immense air pressure, so blockage sludge is allowed to disintegrate instantly under great air pressure, and thus, dredging is realized; and the household dredging device provided by the invention has an independent air compression structure and is convenient and fast to use.

Owner:杨桢

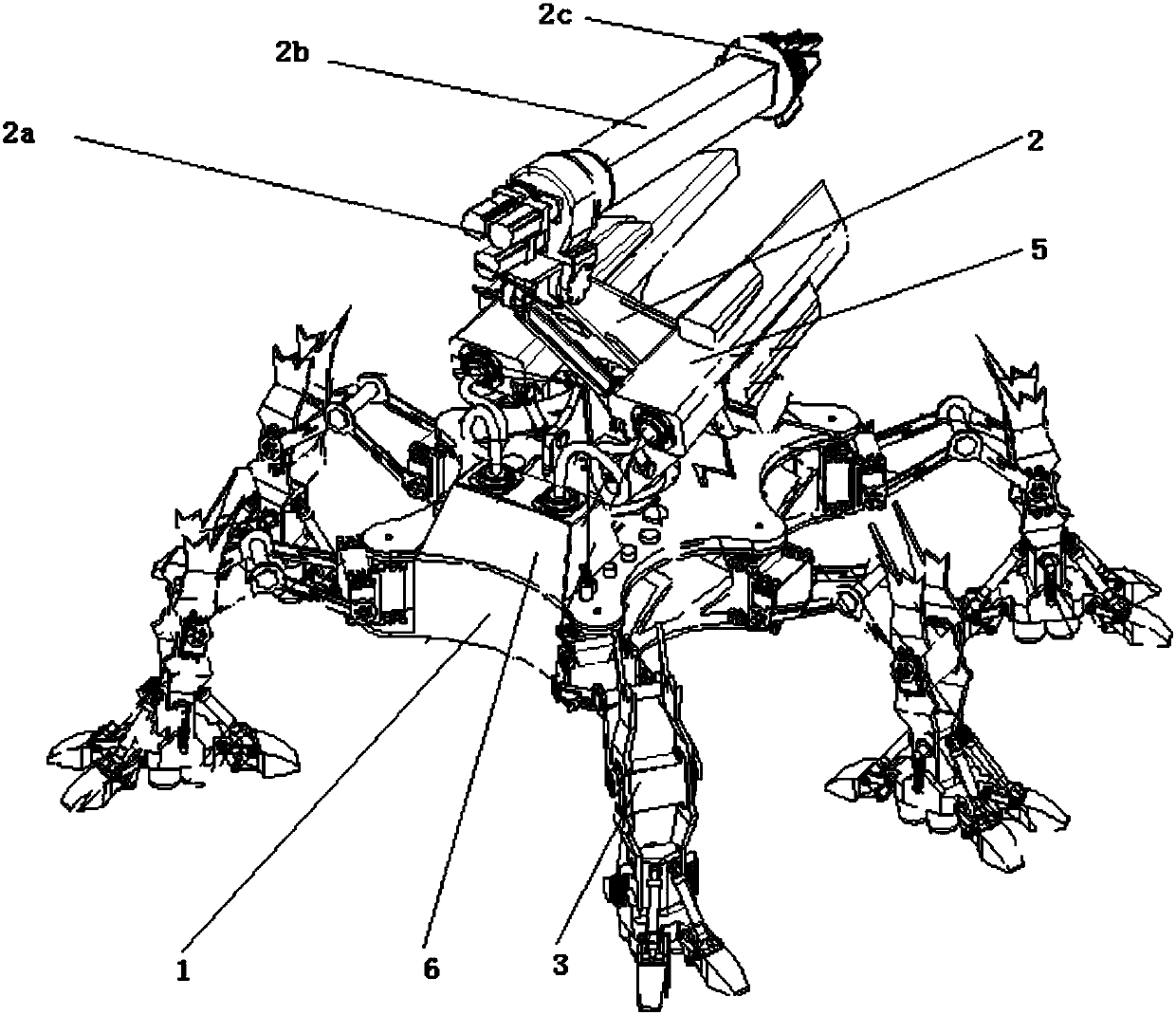

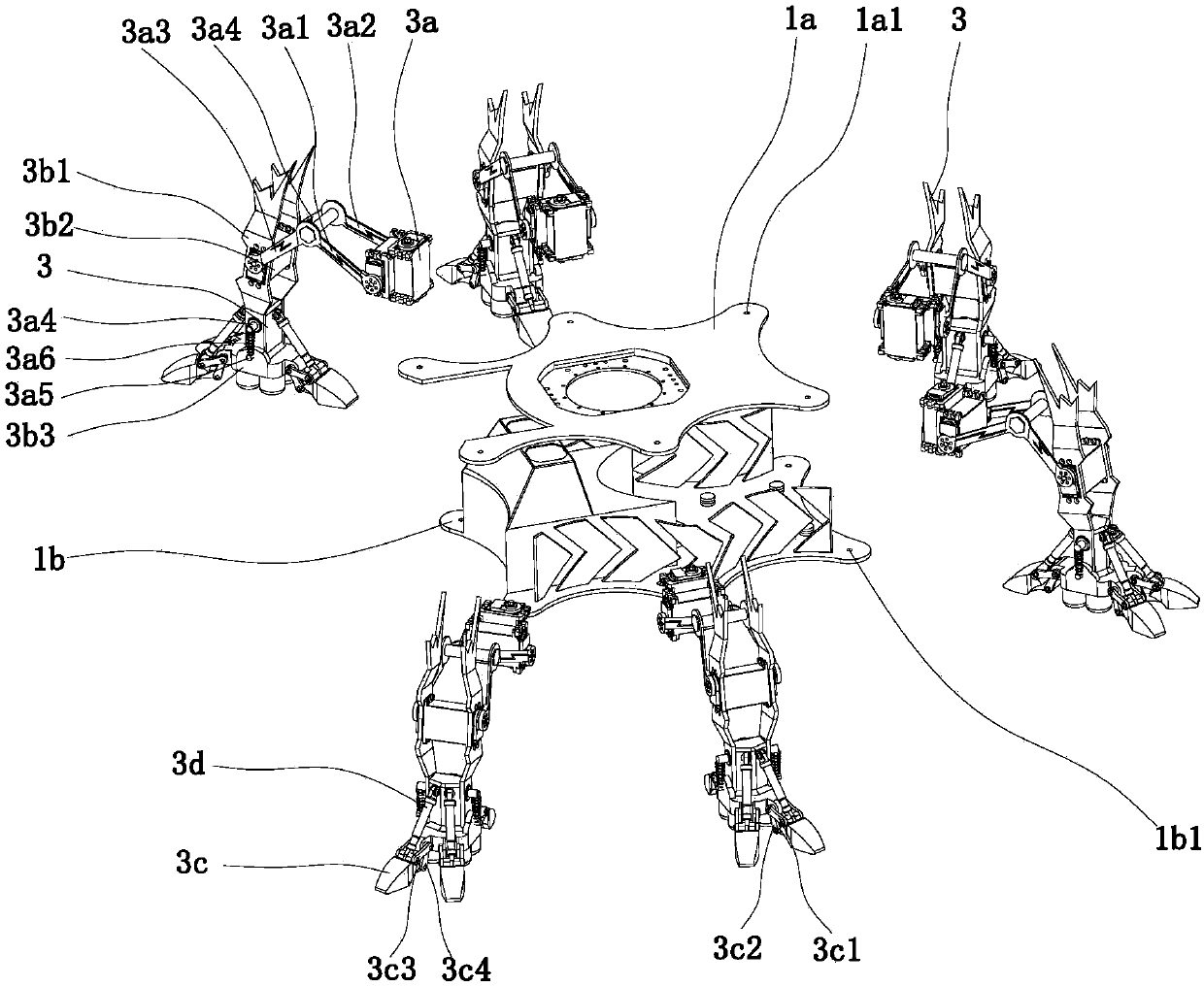

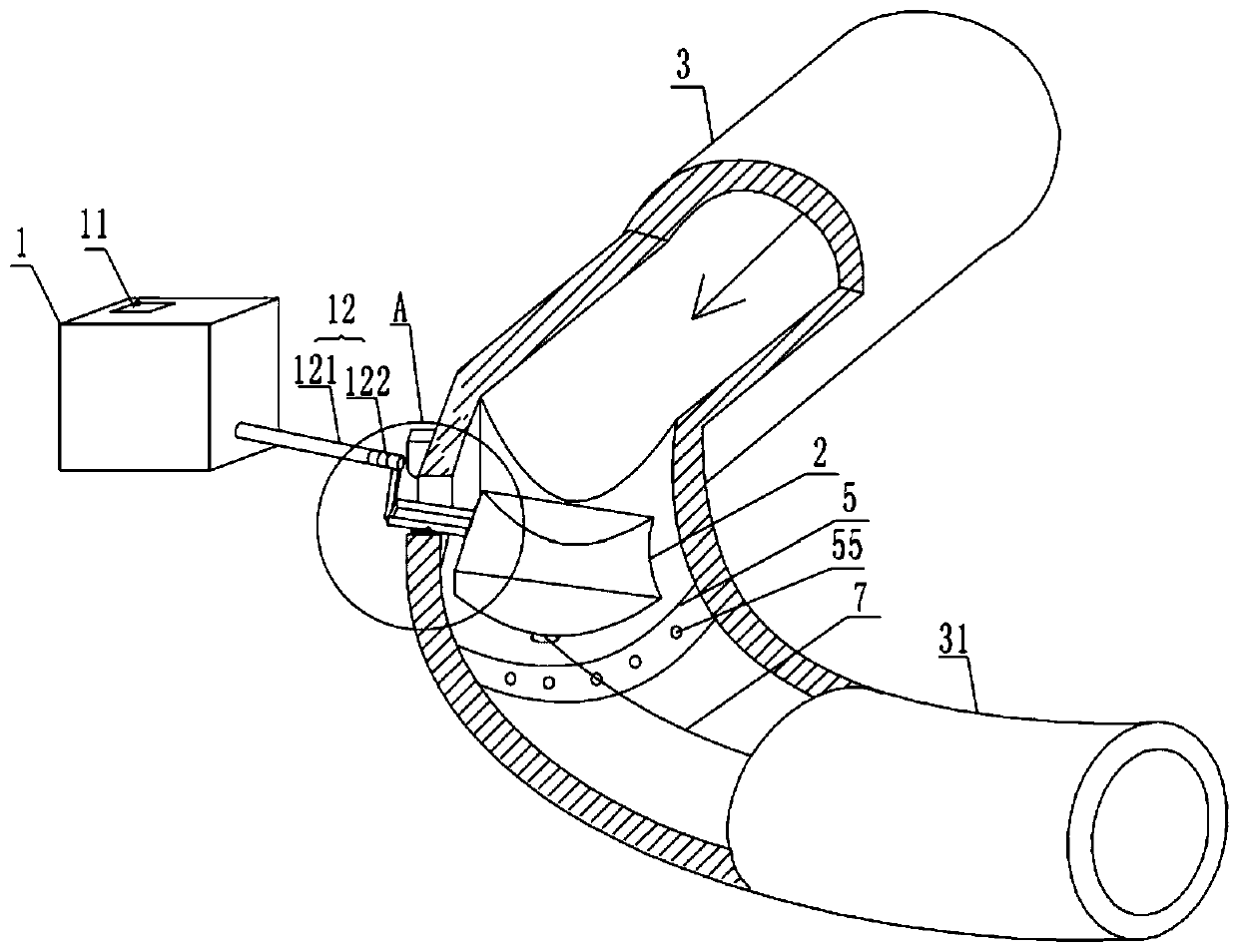

Dredging robot of sewer

InactiveCN107761939AGuaranteed uptimeTo achieve dredging effectSewer cleaningManipulatorWater flowHardness

The invention relates to the field of cleaning robots, in particular to a dredging robot of a sewer. The dredging robot of the sewer includes a drive device, a mechanical arm, a bionic six-foot mechanism and a liquid nitrogen injection device; the bionic six-foot mechanism includes six bionic feet, the liquid nitrogen injection device includes a liquid nitrogen storage box and two spray guns, andthe mechanical arm includes a blade cutting device, a telescopic air cylinder and a blade rotation motor, wherein the telescopic air cylinder drives blades to stretch forward. According to the dredging robot of the sewer, when in work, the robot adopts carried liquid nitrogen to reduce the strength and hardness of blocking materials and assists the blade cutting device to beat the blocking materials into very small pieces, and the small pieces can be washed away through water flow of the sewer; the robot adopts a CY8C3866AXI-040 chip as a control core for coordinated control of the bionic feet, the mechanical arm and the liquid nitrogen injection device. Through the cooperation of an innovative mechanical structure, the stable operation of the robot is achieved, the dredging effect is achieved, the labor cost is reduced and time is saved.

Owner:广东凯宝机器人科技有限公司

Municipal flood-proof well lid

PendingCN112942434AAchieve immobilizationExtended service lifeArtificial islandsUnderwater structuresStructural engineeringCap device

The invention discloses a municipal flood-proof well lid. The municipal flood-proof well lid comprises a lid pressing device, wherein side wall devices are arranged on the two sides of the lid pressing device in a sleeving mode, and supporting devices are fixedly connected to the bottoms of the side wall devices; and each side wall device comprises a well lid side shell, sliding grooves are formed in the middles of the inner walls of the two sides of each well lid side shell, sliding rods are connected to the interiors of the sliding grooves in a sliding mode, springs are fixedly connected to the bottoms of the sliding rods, the ends, away from the sliding rods, of the springs are fixedly connected to the bottoms of inner cavities of the sliding grooves, and pressing blocks are fixedly connected to the right sides of the sliding rods. The invention relates to the technical field of municipal administration. According to the municipal flood-proof well lid, the upper side of the well lid is subjected to downward pressure given by a vehicle in the walking process, so that the lid pressing device transmits the downward pressure to the supporting devices through the pressing blocks in the descending process, the supporting devices give supporting force to the well lid, and the well lid fixing effect is achieved; and meanwhile, the springs can give cushioning and lifting effects to the pressing blocks, so that the internal structure of the well lid is stable.

Owner:周晓亮

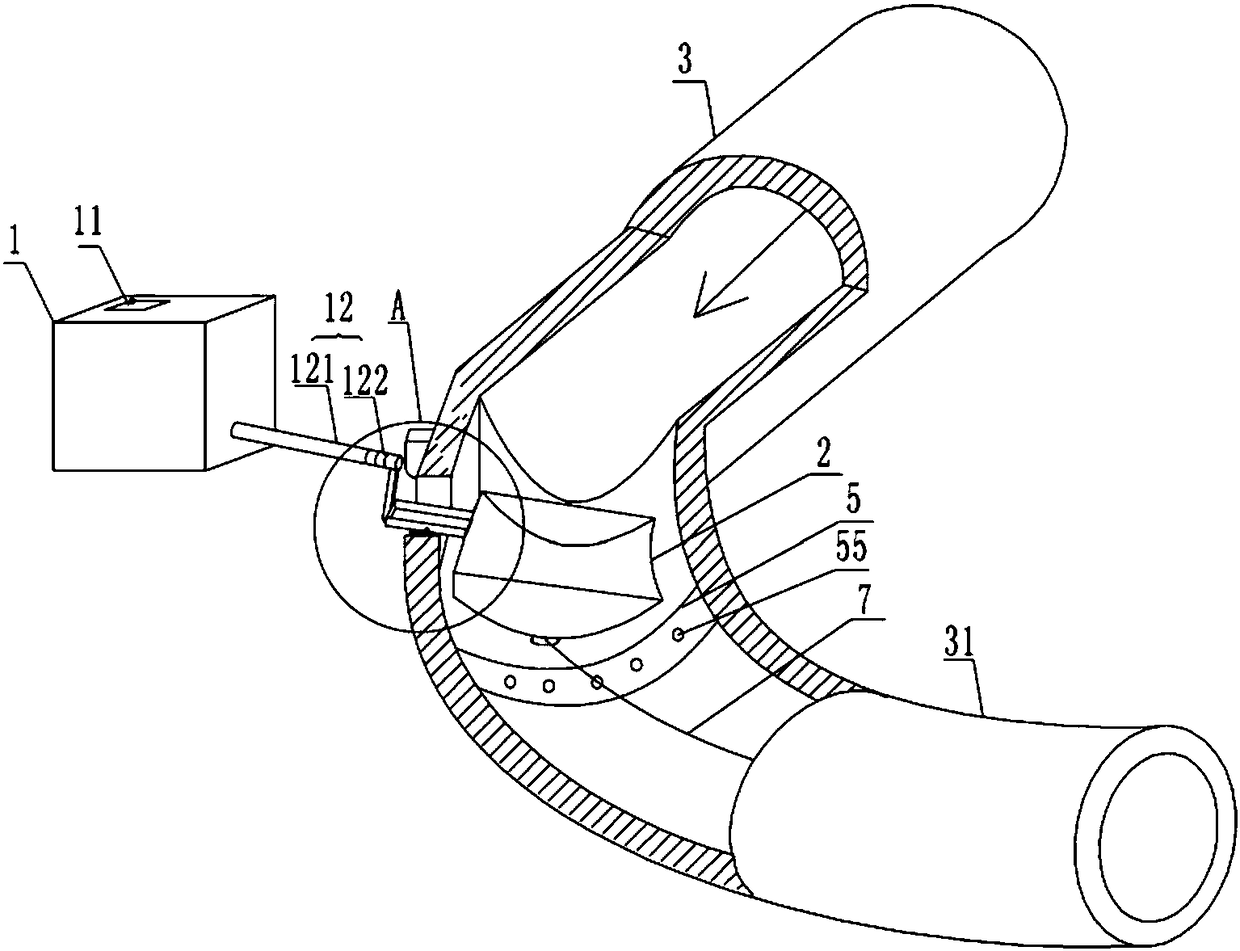

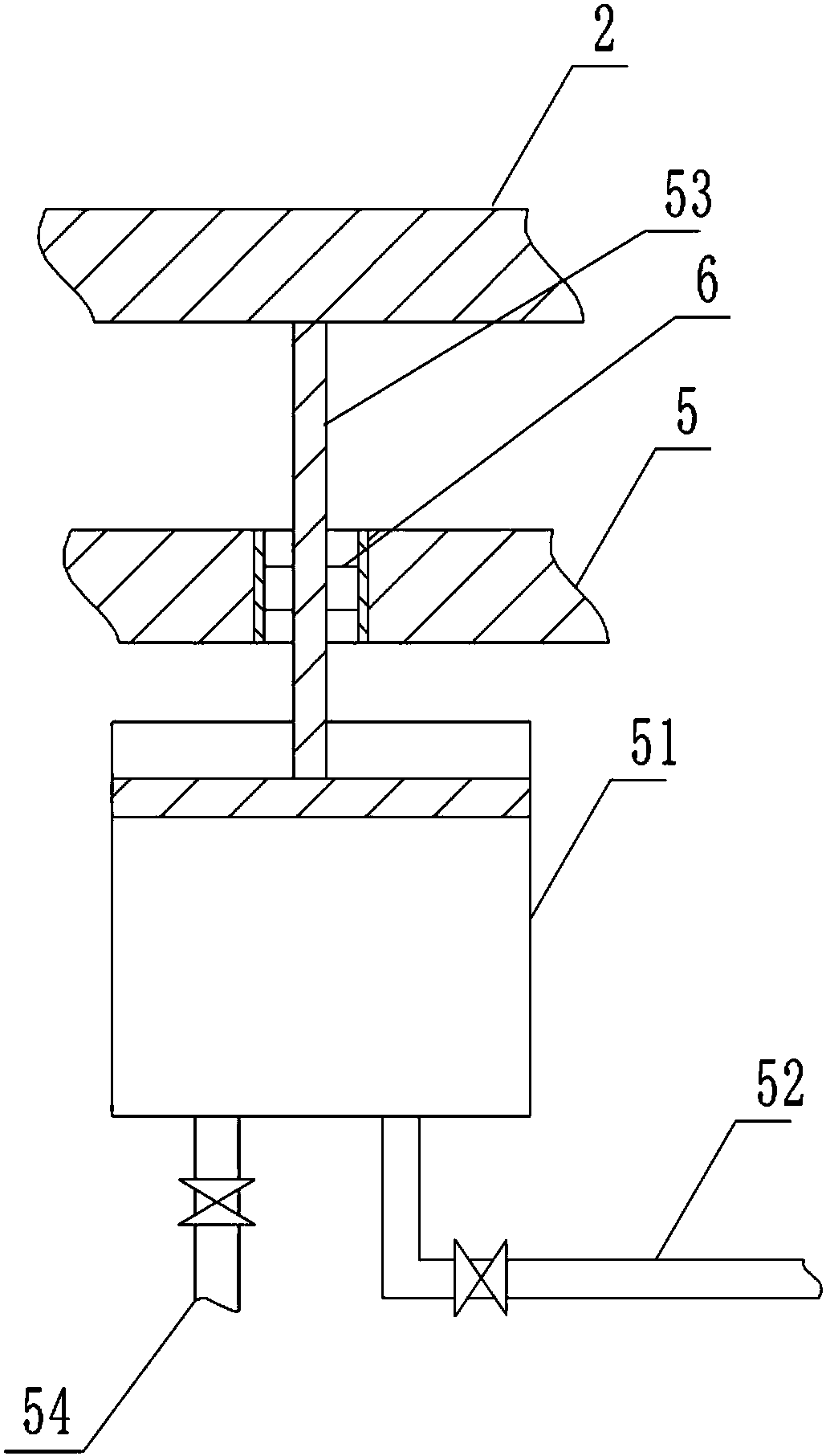

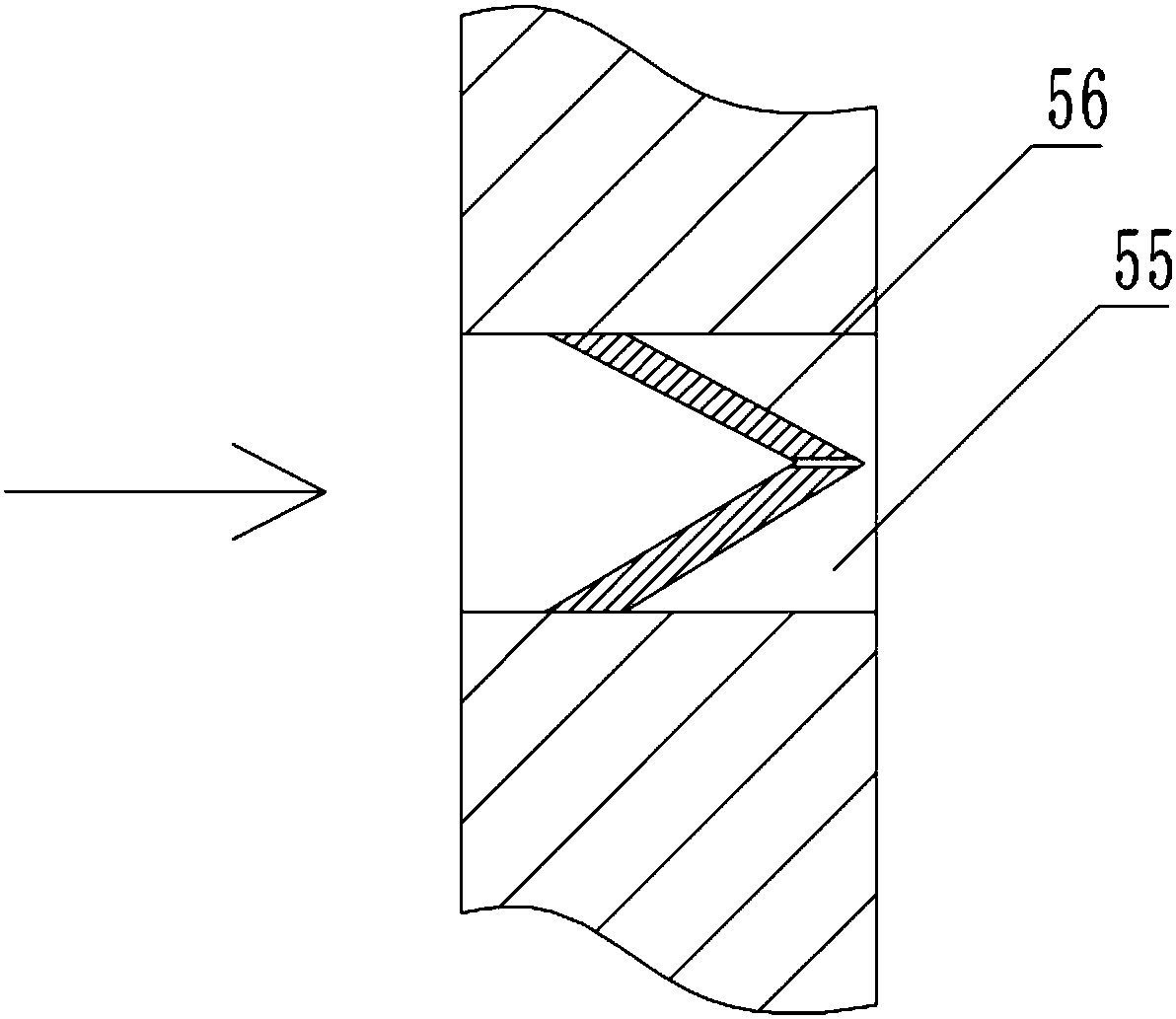

Dirty block removing, dredging and cleaning device for interior of guide pipe

InactiveCN111215403ATo achieve dredging effectExtended service lifeHollow article cleaningPipeMechanical engineering

The invention discloses a dirty block removing, dredging and cleaning device for an interior of a guide pipe. The device comprises a dredging body, a closing plug and a storage box. A storage cavity with a downward opening is formed in the storage box, a transverse shaft is rotatably mounted between the left inner wall and the right inner wall of the storage cavity, a roller is fixedly mounted onthe periphery of the transverse shaft, a connecting rope is wound on the periphery of the roller, the dredging body can be placed in a guide pipe cavity, the connecting rope is fixedly connected withthe top face of the dredging body, the closing plug can be plugged in the guide pipe cavity, and the closing plug capable of being pressed and buckled is mounted on the periphery of the guide pipe. Through the water injection manner, certain water pressure is brought to the dredging body, the dredging body can move in the guide pipe cavity to detect a dirty block, the dirty block can be effectively removed, the guide pipe cavity is dredged, meanwhile, the inner wall of the guide pipe cavity is wiped, and the service life of the guide pipe can be effectively prolonged.

Owner:东阳鸿松机械科技有限公司

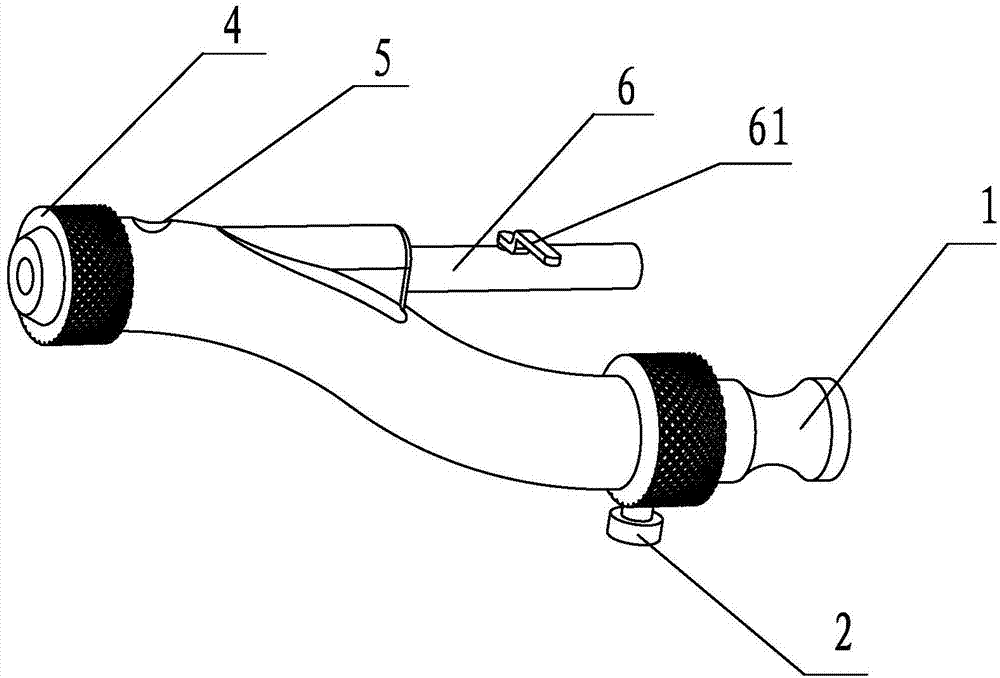

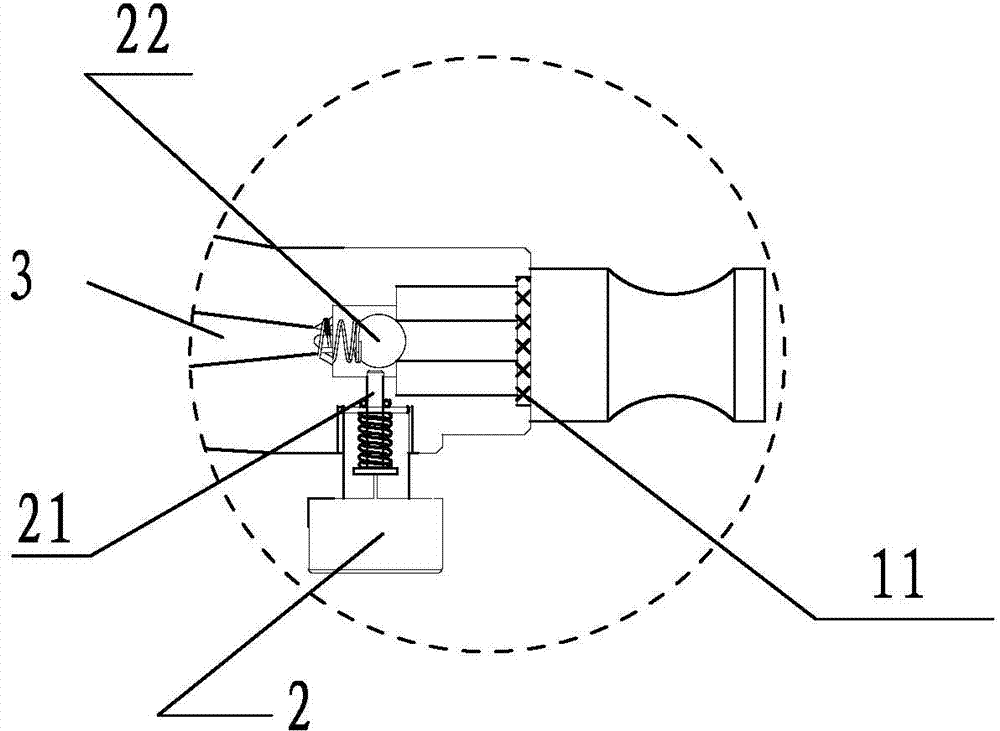

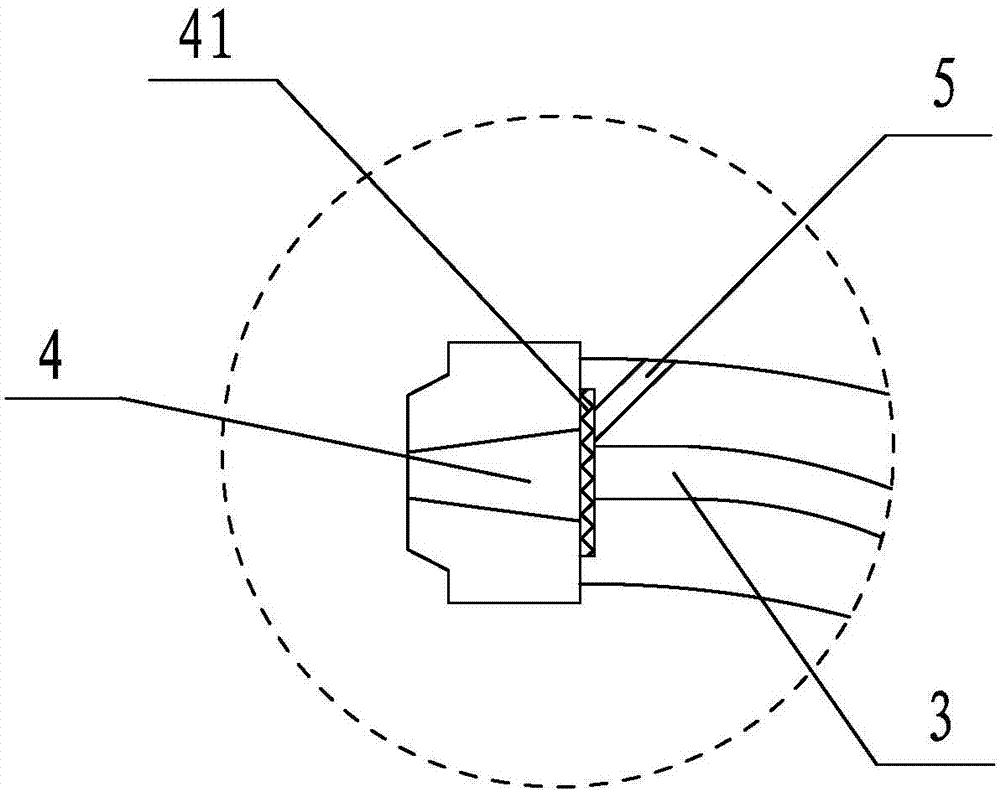

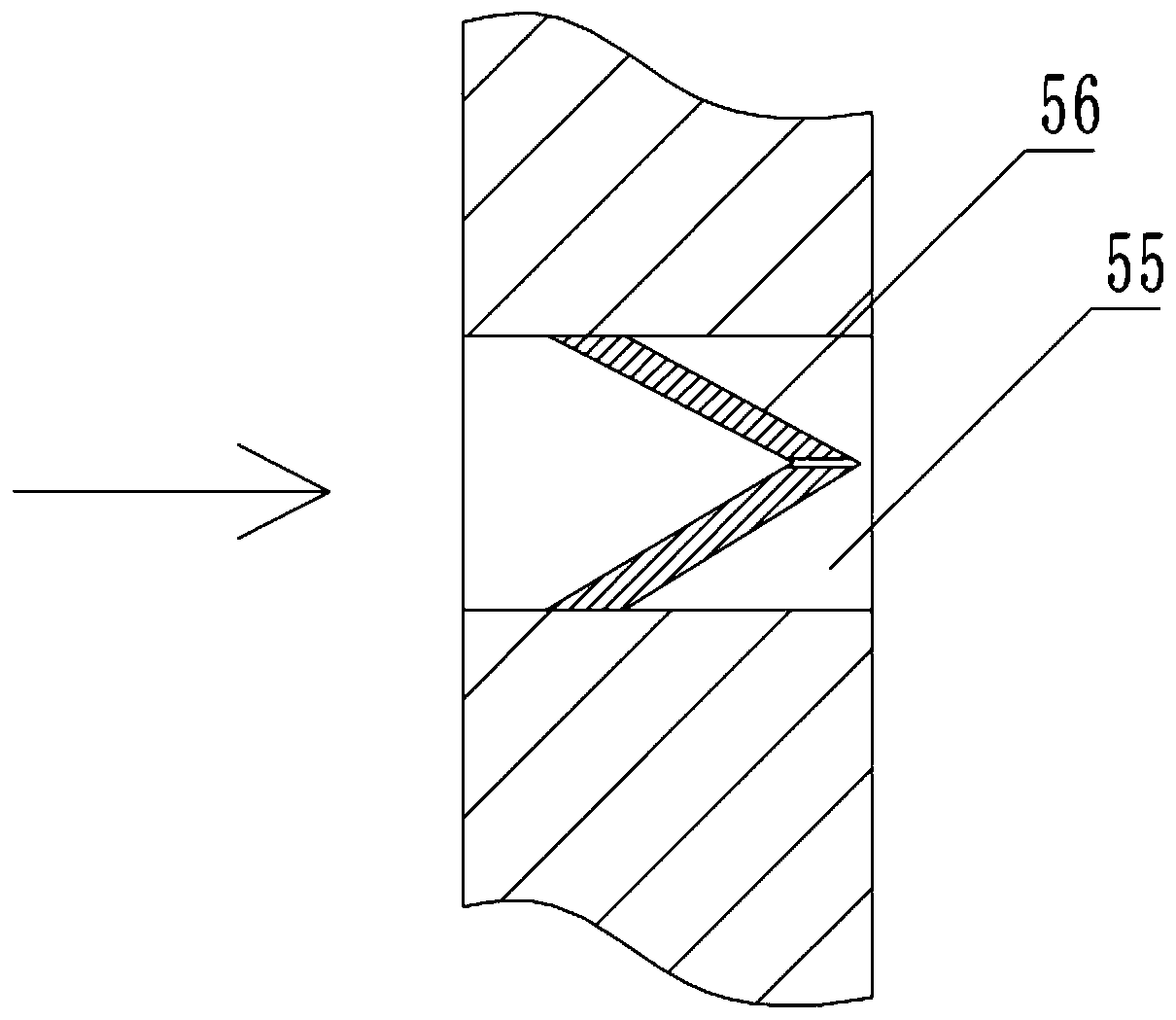

Spray gun for mortar mechanical spraying

ActiveCN103938839AAchieve cloggingRealize flush cleaningBuilding constructionsWater channelSteel ball

The invention discloses a spray gun for mortar mechanical spraying. The spray gun comprises a spray gun body and is characterized in that the tail end of the spray gun body is connected with a quick connector, a first layer filter net is arranged between the quick connector and the spray gun body, an anti-blocking trigger is arranged on the side face of the tail end of the spray gun body and connected with an ejector rod, the ejector rod abuts against a steel ball, the steel ball is arranged in a feed channel, a movable nozzle is arranged at the head end of the spray gun body, a second layer filter net is arranged between the movable nozzle and the spray gun body, a clear water channel is arranged between the second layer filter net and the outer surface of the head end of the spray gun body, and an air pressure channel is arranged on the outlet of the feed channel. The probability that the spray gun is usually blocked can be reduced, and construction efficiency is improved.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

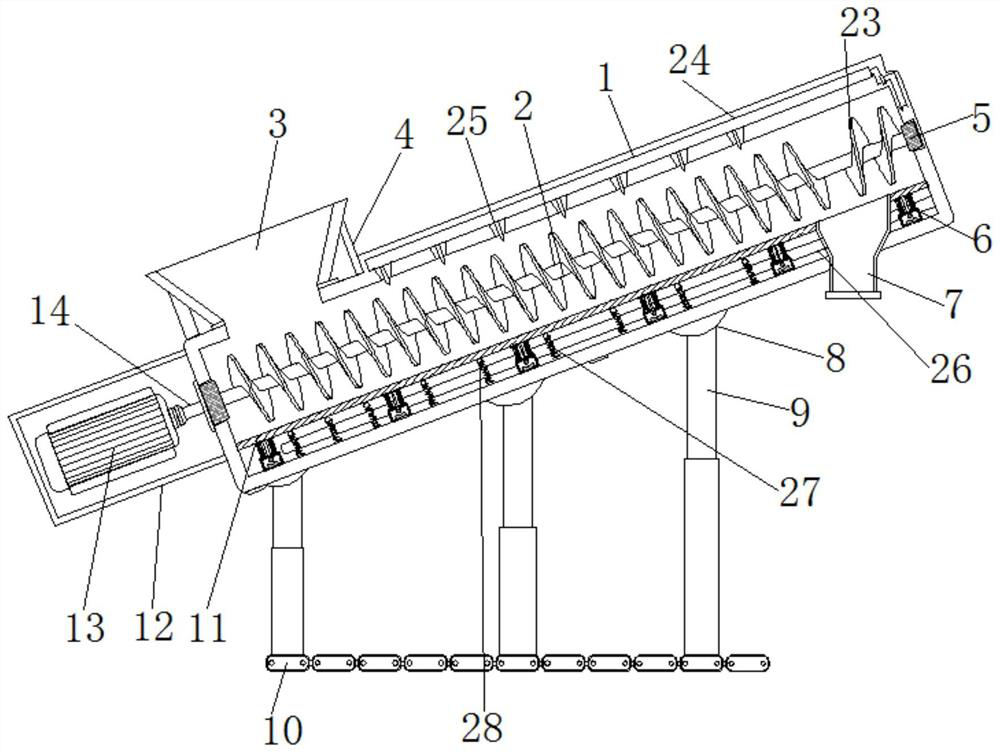

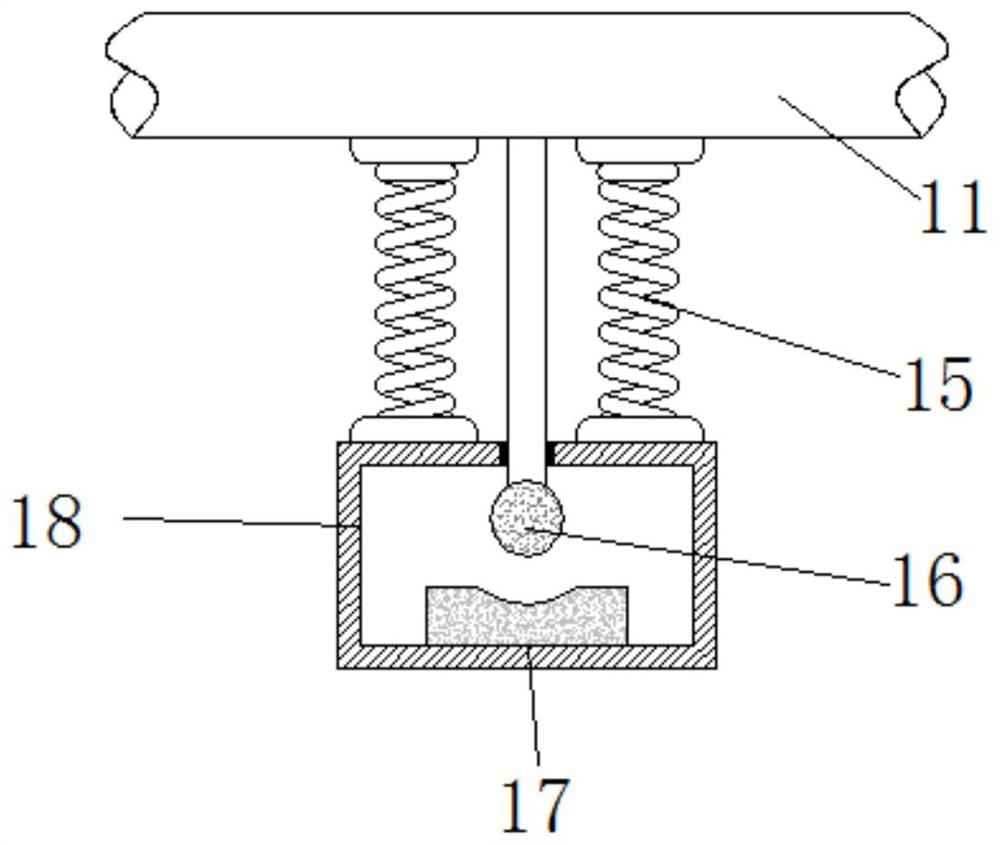

Earthwork screw conveying device with blockage early-warning function

InactiveCN111977315AWith blockage warning functionIncrease the bearing areaConveyorsControl devices for conveyorsElectrical connectionPropeller

The invention relates to the technical field of earthwork excavation, and discloses an earthwork screw conveying device with a blockage early-warning function. The device comprises a conveying unit, wherein a screw propeller is movably installed in the conveying unit, the left and right ends of the screw propeller are movably installed at the left and right ends in the conveying unit through bearings, a bearing plate is movably installed in the lower side of the conveying unit, and an early-warning device is fixedly installed on the lower side of the bearing plate. When the inner part of the screw conveying device is blocked, internal earthwork cannot be conveyed to the right end, so that the pressure of the internal bearing plate is increased; after the bearing plate is pressed, a springmechanism is compressed, and when the pressure reaches a certain level, a sensing part at the lower end of the spring mechanism can make contact with a triggering part; and after the sensing part is in contact with the triggering part, an electrical connection is generated, and an early-warning module gives an alarm, so that the effect of timely early warning when the conveying unit is blocked isachieved.

Owner:广州比木云建筑科技有限公司

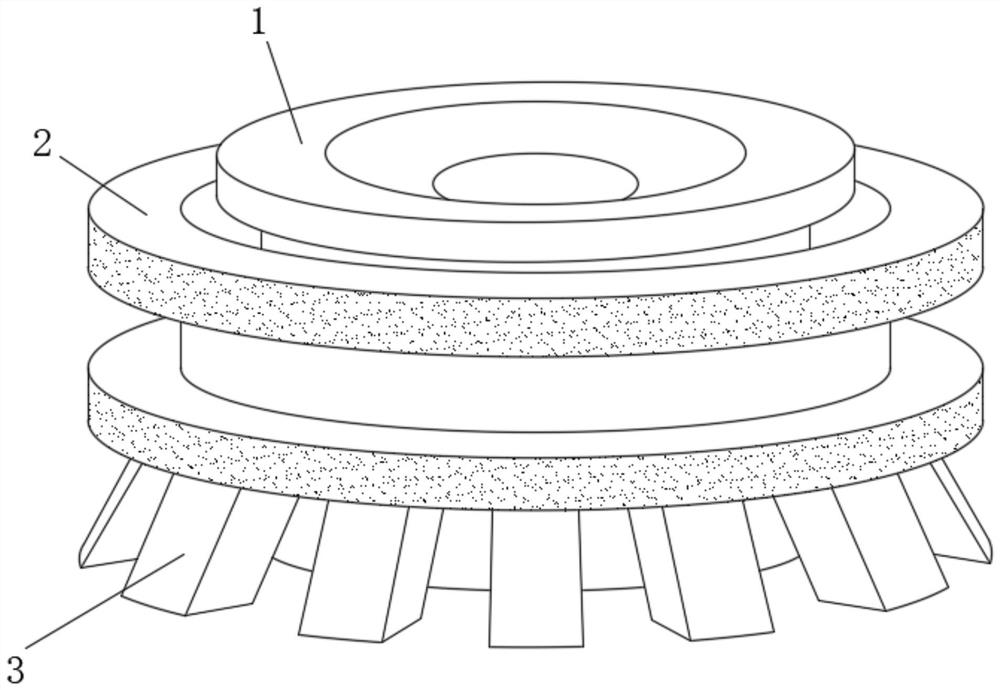

Grinding device for removing burrs of hardware parts

PendingCN114227431AAchieve separationSolve the blockageEdge grinding machinesGrinding wheel securing apparatusWater storage tankProcess engineering

The invention discloses a grinding device for removing burrs of hardware parts, and relates to the technical field of hardware part machining, in particular to the grinding device for removing the burrs of the hardware parts, the grinding device comprises a grinding device body, and a rotating disc is arranged on the left side of the interior of the grinding device body. According to the grinding device for removing the burrs of the hardware parts, through cooperation of the grinding device body, the water storage tank, the filter plate and the water spraying pipe, the filter plate is used for filtering water, the separation effect of water and impurities is achieved, the water purification effect is achieved, the problem that all connecting water pipes are blocked is effectively solved, the mode that the filter plate is used for removing the impurities of the water is adopted, and the practicability is high. And the situation that impurities fall into all the connecting water pipes along with flowing of water, and consequently all the connecting water pipes are blocked is avoided, the dredging effect of workers on all the connecting water pipes is saved, the workload of the workers is reduced, and it is guaranteed that the continuous water outlet dust falling procedure of deburring machining of hardware parts is conducted stably.

Owner:安徽尧工数控科技有限公司

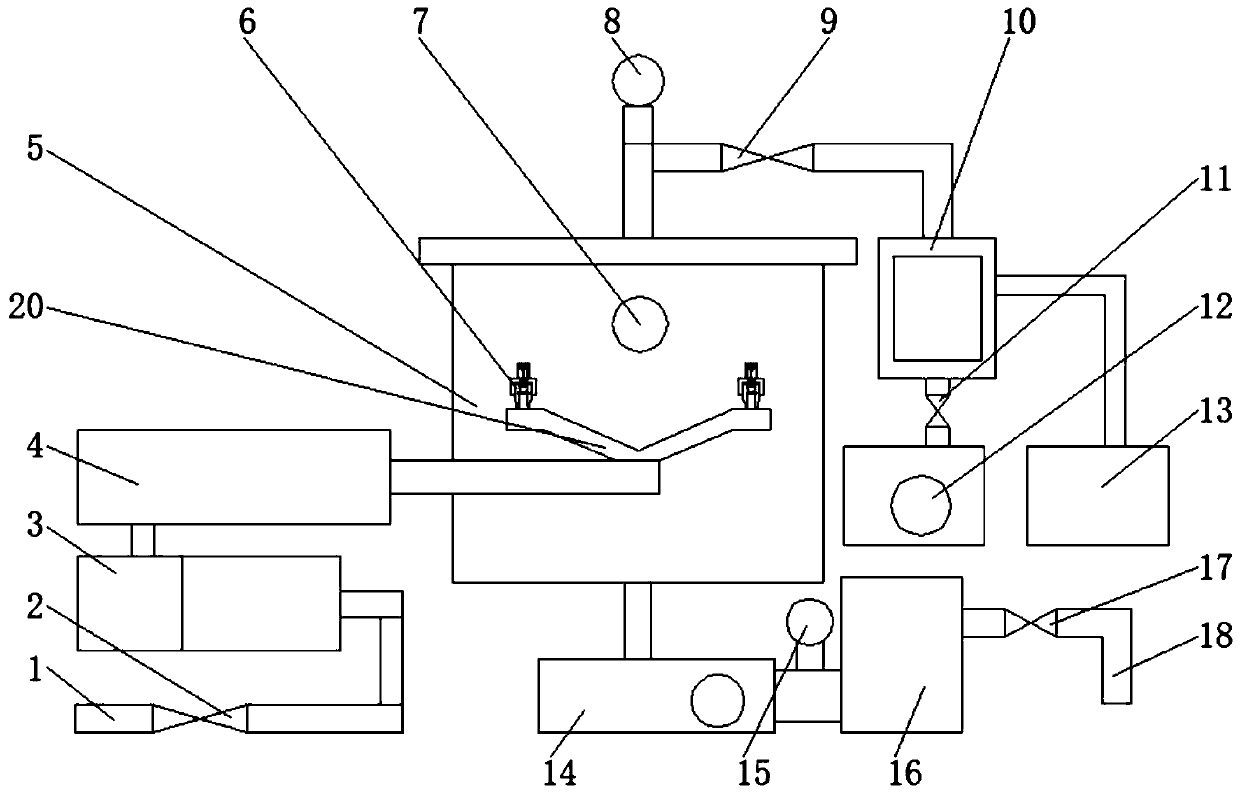

Municipal pipeline dredging device

The invention discloses a municipal pipeline dredging device which comprises a top plate, a handle, connecting rods, a rack, a water storage assembly, a dredging assembly, a lifting assembly, fixed lug plates, connecting rotation shafts and moving wheels. The fixed lug plates are installed on the periphery of the bottom of the rack through welding, the moving wheels are arranged on the outer sidesof the fixed lug plates, and each connecting rotation shaft is inserted and installed between the corresponding two fixed lug plates. Two ends of each connecting rotation shaft penetrate through thecorresponding fixed lug plates to be fixedly connected with the corresponding moving wheels by screws, the two ends of one side of the rack are fixedly provided with the connecting rods through welding, the other end of each connecting rod is fixedly provided with the top plate through welding, and one side of the top of the rack is provided with the water storage assembly. The municipal pipelinedredging device is convenient to move and small in occupied area, and the position of a high-pressure spray head can be adjusted according to different use environments when the municipal pipeline dredging device is used; and in addition, the municipal pipeline dredging device has a disinfection function and is favorable for improvement of the sanitation effect in a pipeline.

Owner:睢宁景舜农业发展有限公司

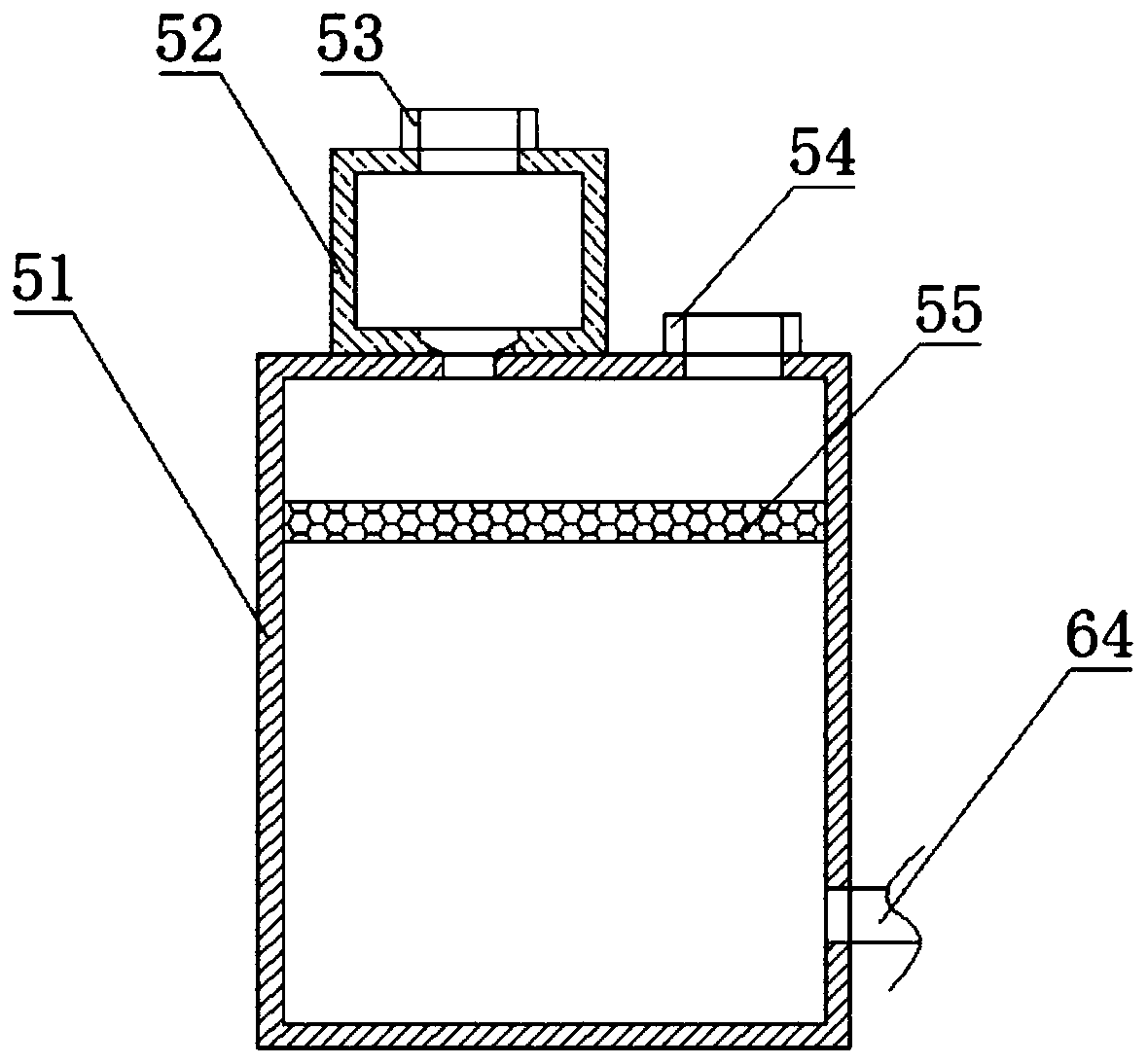

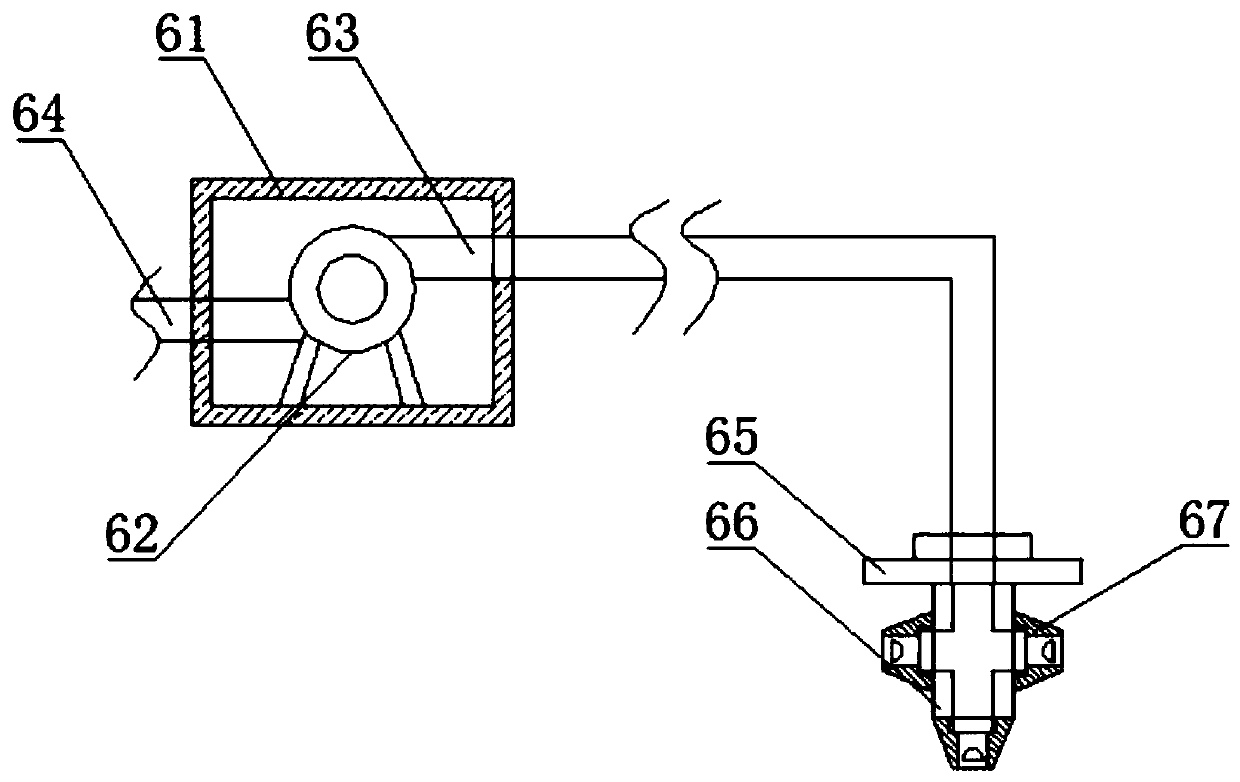

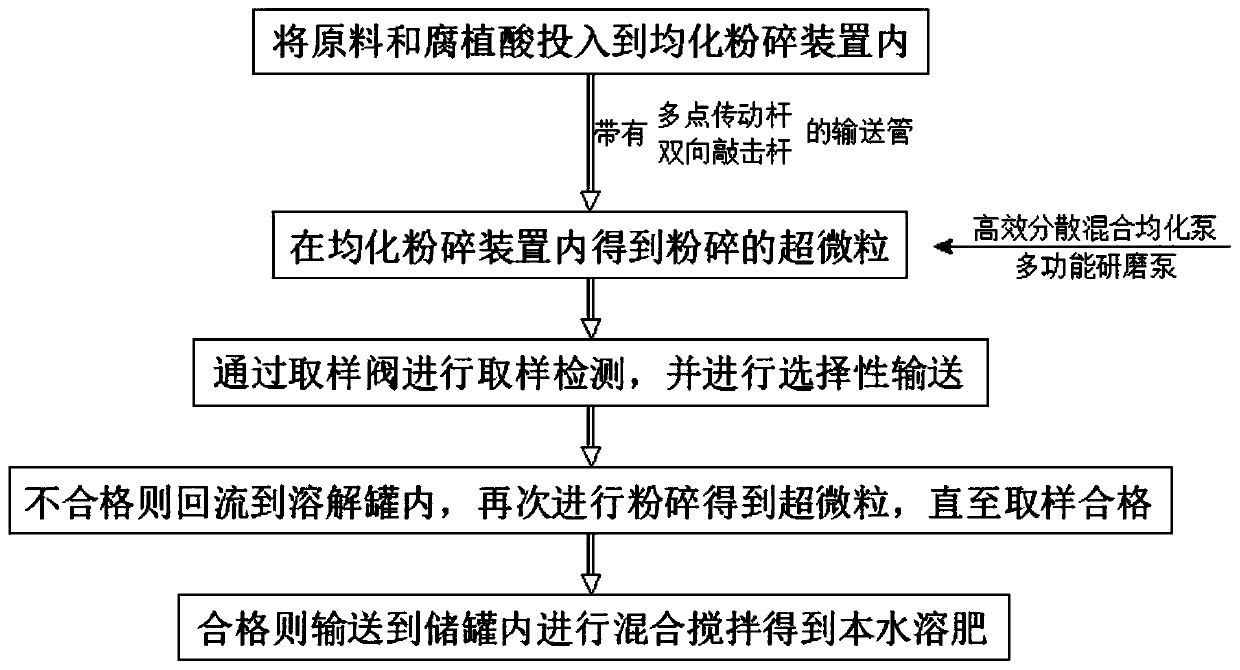

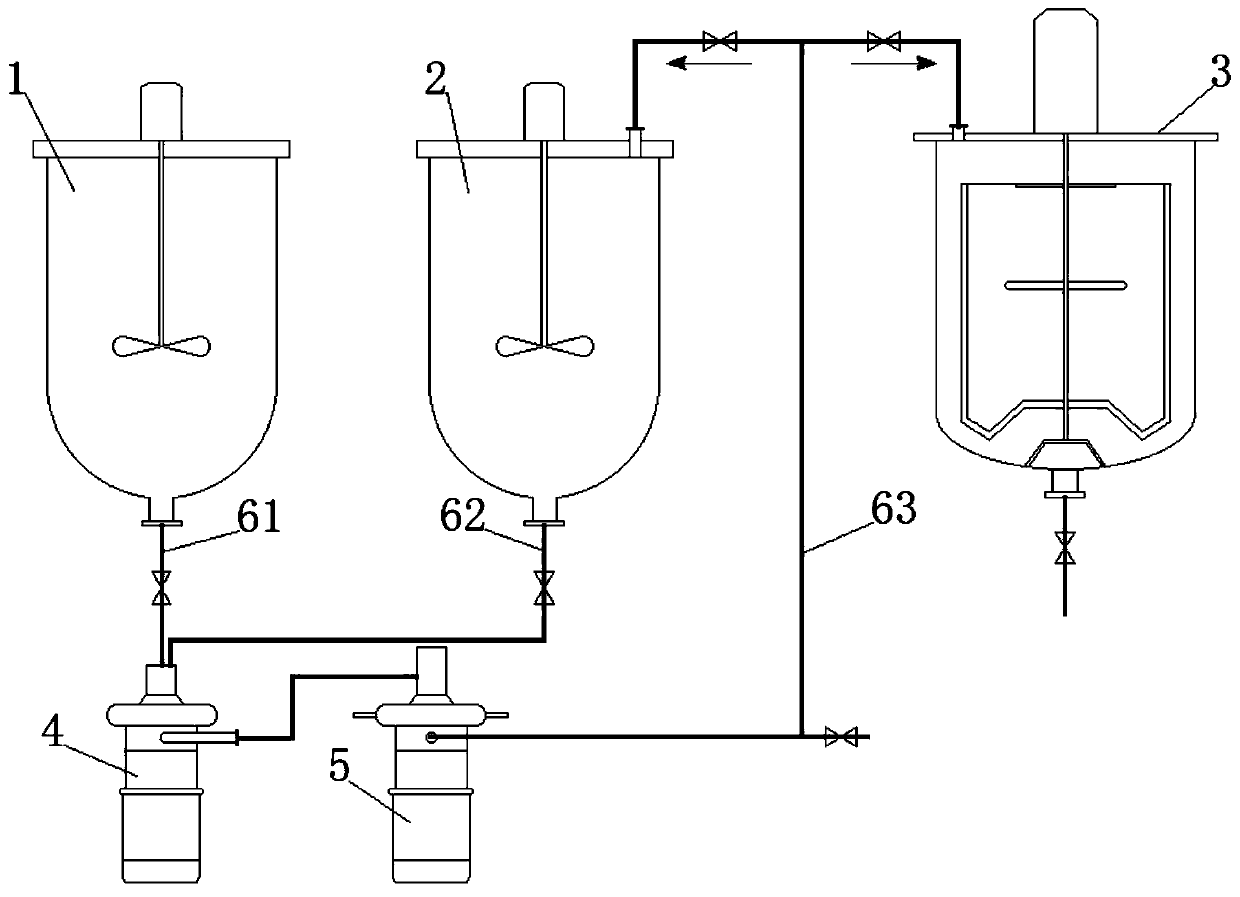

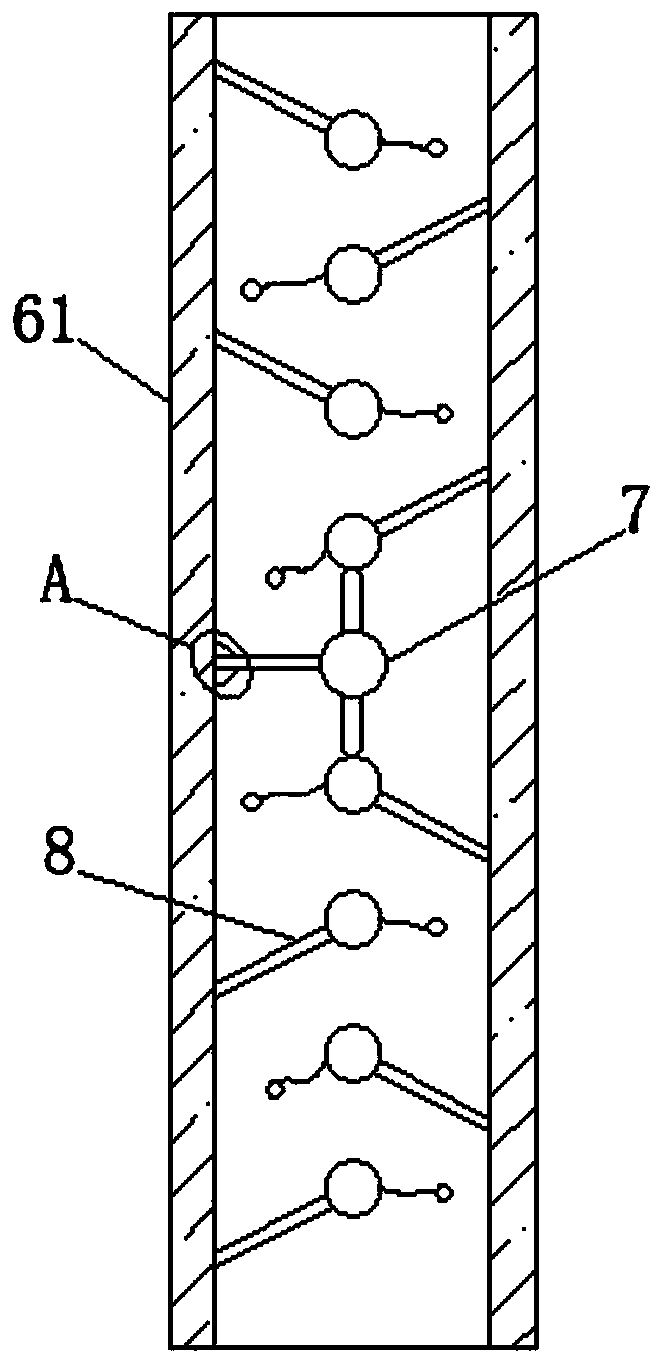

Process for producing humic acid liquid suspension water-soluble fertilizer

ActiveCN110627585AImprove anti-blocking performanceGuaranteed linkageFertilizer mixturesWater solubleLiquid suspension

The invention discloses a process for producing a humic acid liquid suspension water-soluble fertilizer and belongs to the technical field of fertilizer production. According to the process for producing the humic acid liquid suspension water-soluble fertilizer, due to arrangement of a homogenizing crushing device, a conventional grinding treatment process procedure can be reduced, and the production efficiency can be improved; in addition, as crushed ultramicron granules are small, irrigation can be implemented through trickle irrigation directly, and the transportation cost of the water-soluble fertilizer to a target fertilization place to be used can be effectively reduced; and meanwhile, due to arrangement of double-direction knock rods and multi-point transmission rods, linkage of a plurality of multi-point transmission rods can be achieved in conveying tubes in the conveying process of raw materials and humic acid, in addition, even if blocking is caused, the multi-point transmission rods can be driven to move through the double-direction knock rods, furthermore, an effect of dredging inside can be achieved, the dredging difficulties of a left conveying tube and a right conveying tube after blocking can be alleviated, and furthermore, the production efficiency of the water-soluble fertilizer can be effectively improved.

Owner:WENZHOU HAO STAR MACHINERY EQUIP MFG

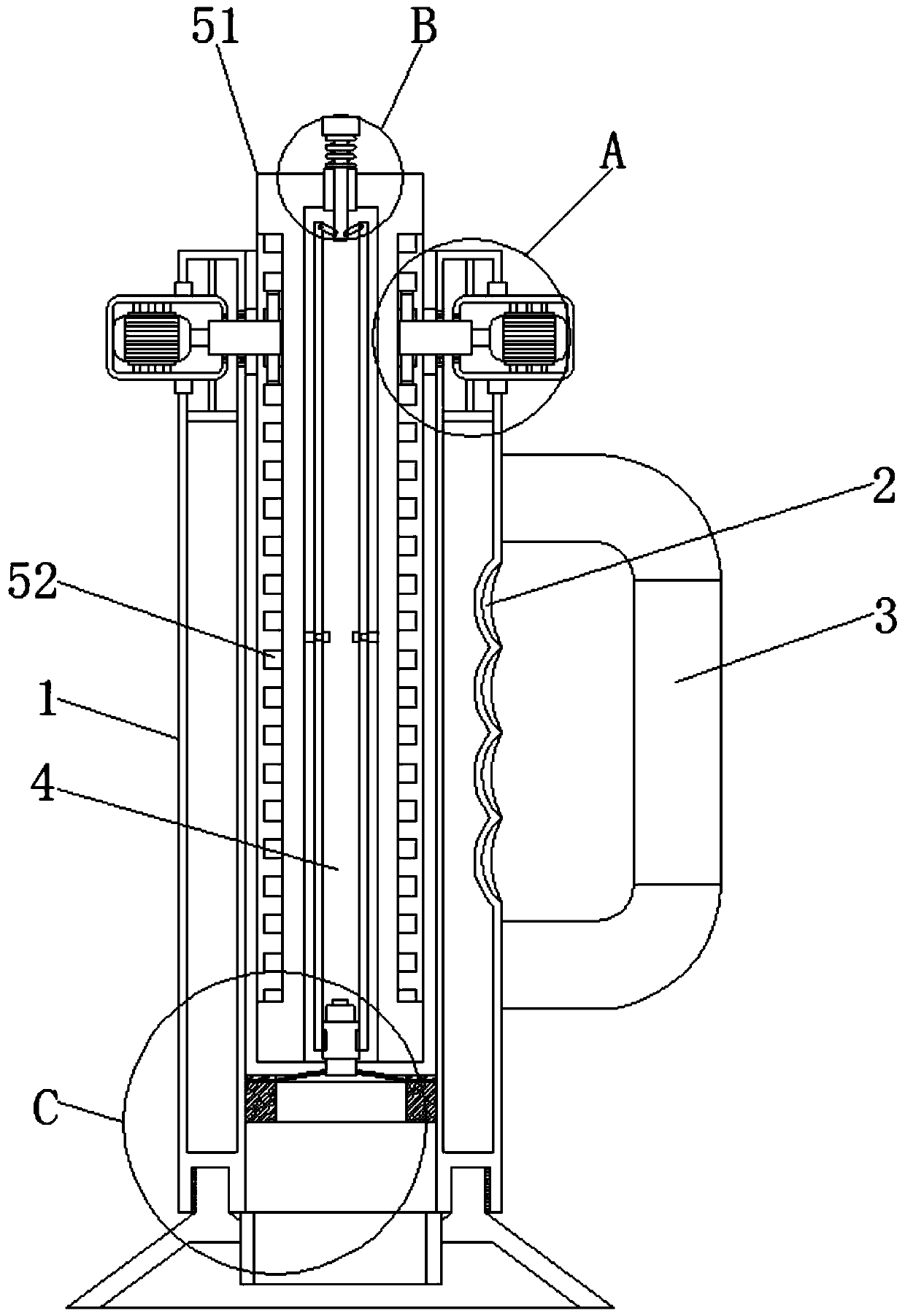

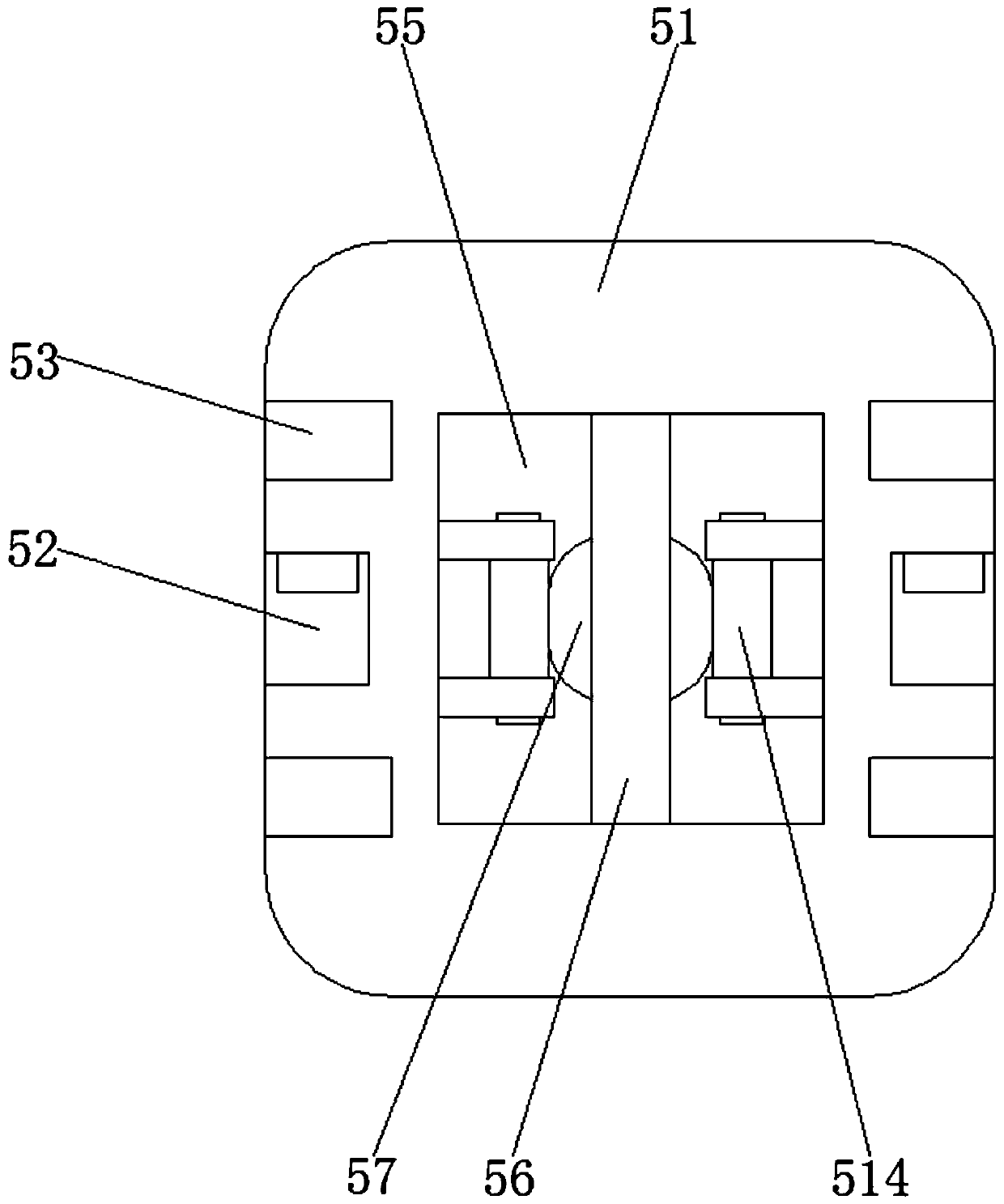

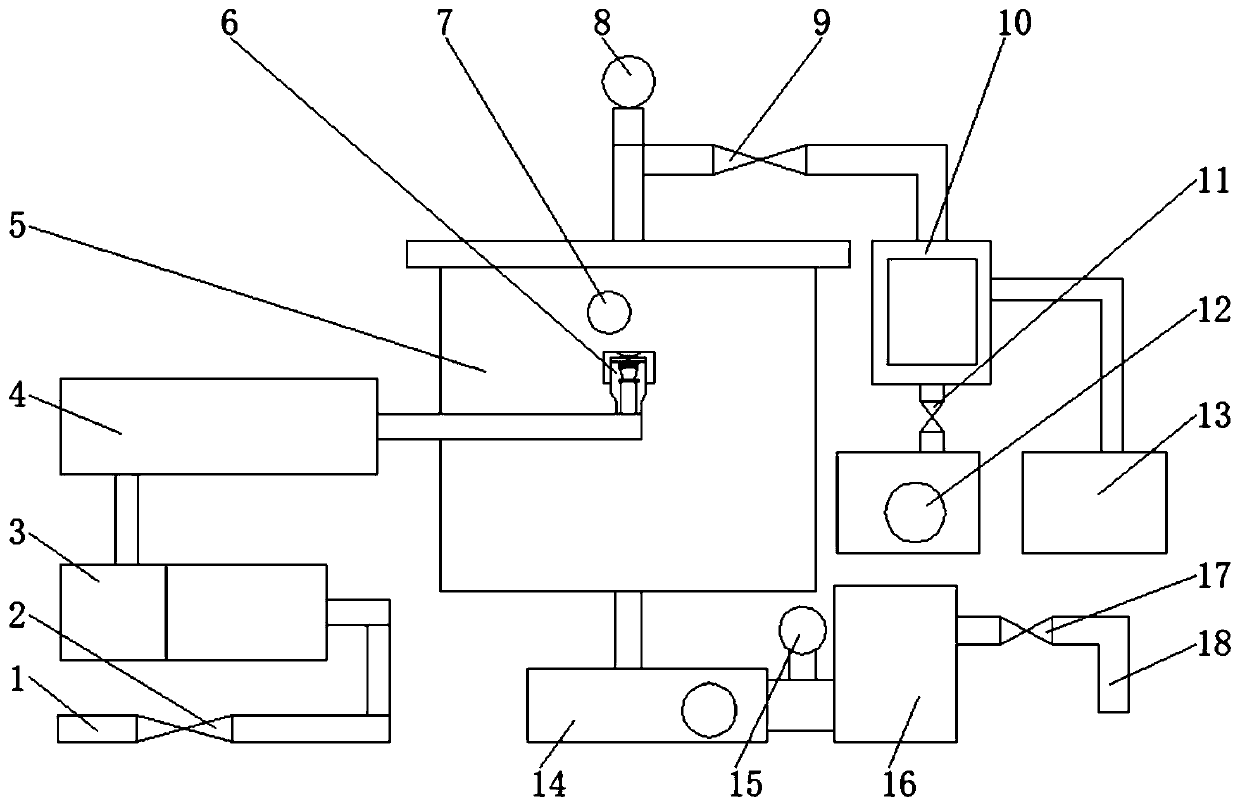

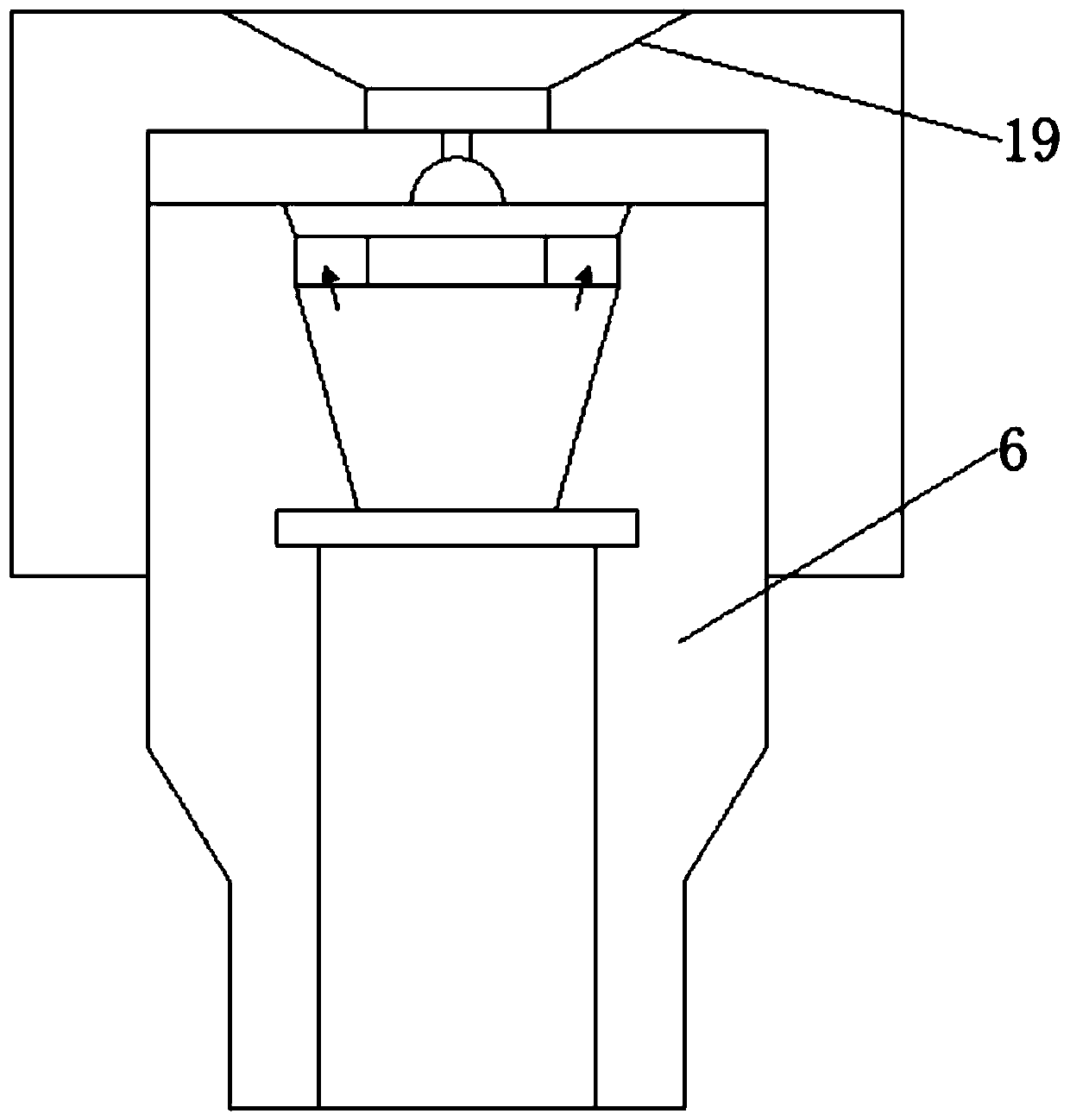

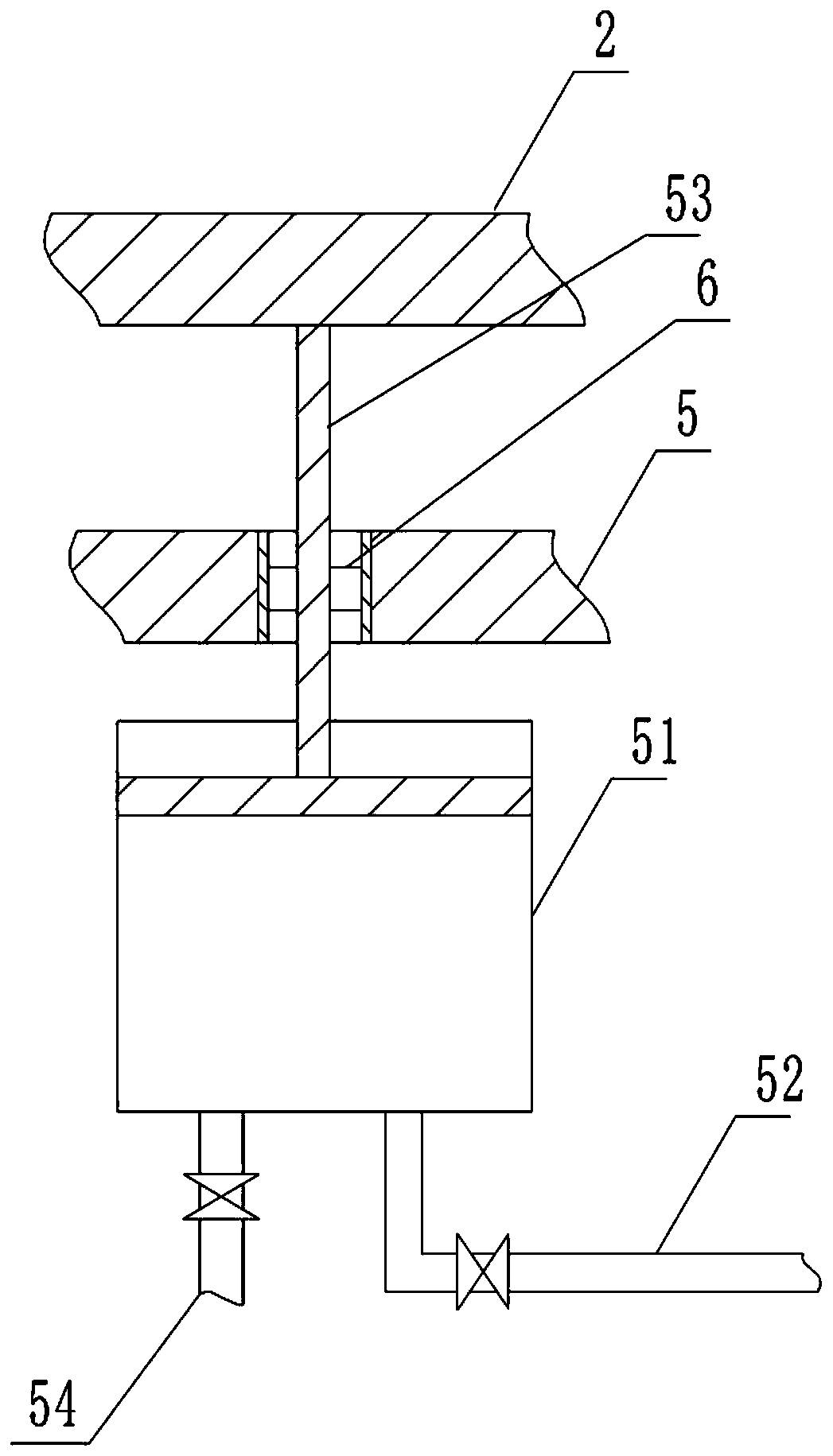

Vacuum oil filter

ActiveCN111097226AGuaranteed normal formationTo achieve dredging effectFiltration circuitsInlet valveOil mist

The invention relates to the technical field of filtering equipment and discloses a vacuum oil filter. The vacuum oil filter comprises an oil inlet pipe; an oil inlet valve is fixedly installed in themiddle of the oil inlet pipe; a primary filter is fixedly installed at one end of the oil inlet pipe; a heater is connected to the upper portion of the primary filter through a pipe; a vacuum cylinder is connected to one side of the heater through a pipe; and an oil mist spray head is fixedly installed on the pipe on one side of the heater. Compared with the prior art, the technical scheme adoptsa piston needle which is arranged in the nozzle of the oil mist spray head and moves up and down to dredge a nozzle of the oil mist spray head; oil mist sprayed from the oil mist spray head pushes the piston needle to move upwards, and when the nozzle is blocked, less oil mist is sprayed out, the pushing force on the piston needle is reduced, the spring cannot be pushed to be compressed; and thenthe piston needle moves downwards and penetrates through the nozzle under the influence of the elasticity of the spring, so that the dredging effect on the oil mist spray head is achieved, the formation of the oil mist is ensured, and the use effect of the oil mist spray head is improved.

Owner:上海韦航装备科技有限公司

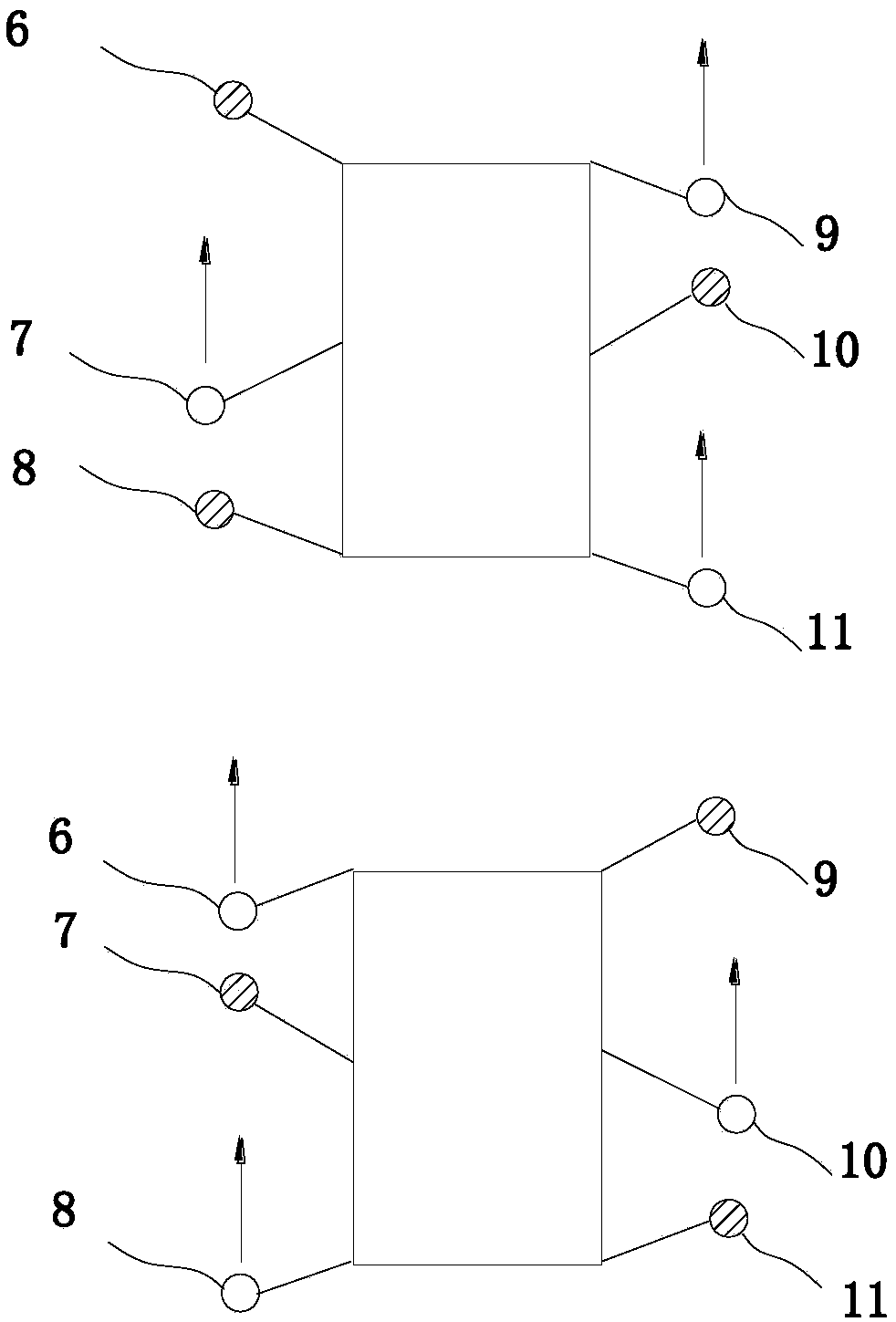

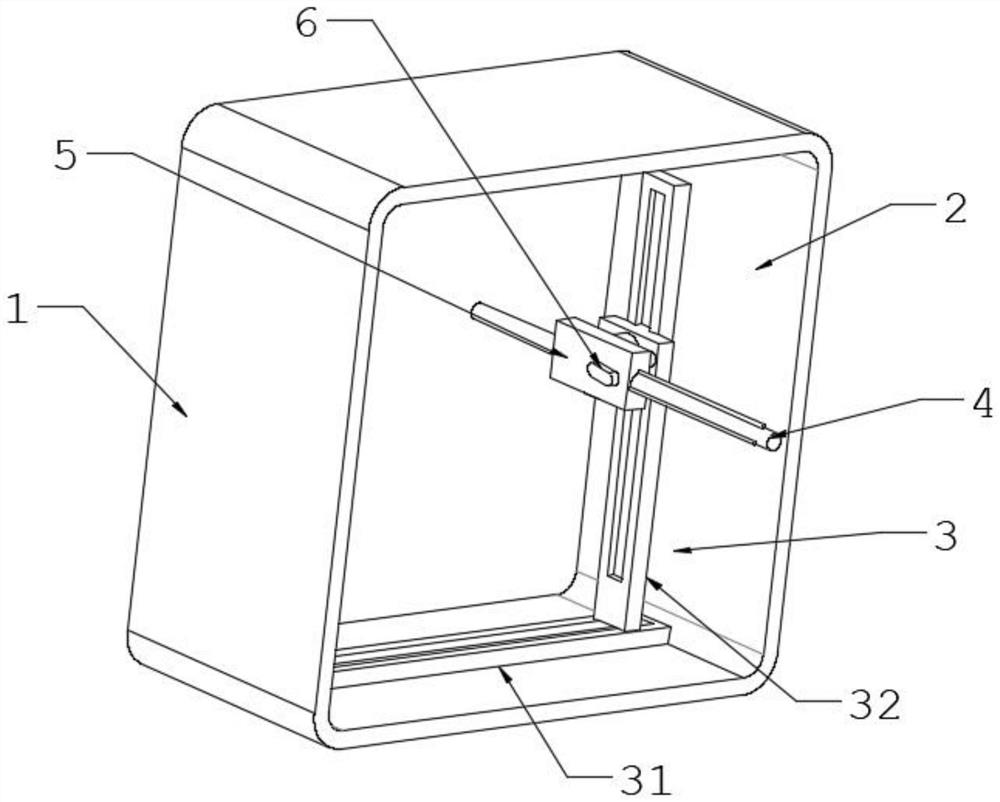

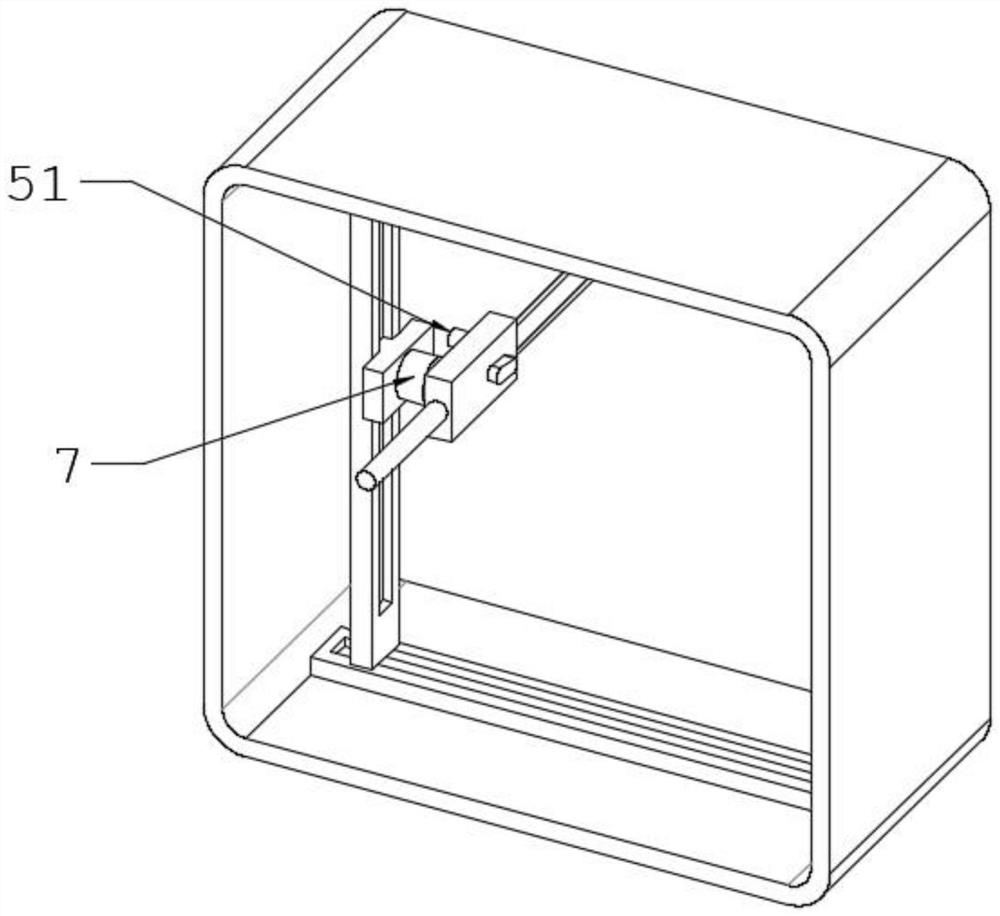

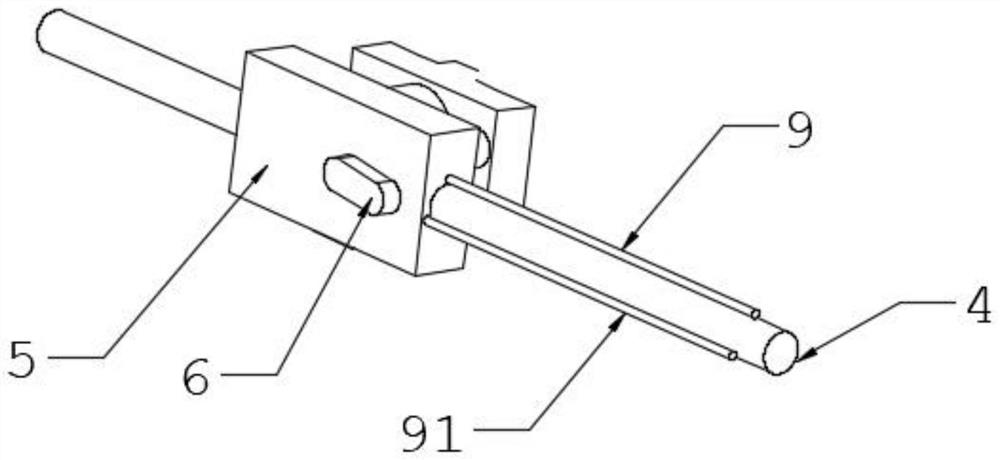

Drainage auxiliary device and drainage method applied to hepatobiliary surgery department

The invention relates to the technical field of drainage, and discloses a drainage auxiliary device applied to the hepatobiliary surgery department and a drainage method.The drainage auxiliary device comprises a drainage tube following device and an action prediction assembly, the drainage tube following device comprises a frame, an equipment mounting cavity is formed in the frame, and a two-dimensional driving assembly is arranged in the equipment mounting cavity; the two-dimensional driving assembly is provided with a rotation driving assembly, the rotation driving assembly is provided with a tube conveying box, the tube conveying box is internally provided with a channel for a drainage tube to pass through, the tube conveying box is internally provided with a roller assembly, the roller assembly is used for driving the drainage tube to move in the channel, and the tube conveying box is further provided with a temperature adjusting assembly. In the drainage process, in time when a patient acts, the wound can be prevented from being pulled to a large extent, discomfort such as pain is avoided, the height of the tube conveying box can be made to be lower than the position height of the contact point of the drainage tube and the human body, and it is guaranteed that drainage substances are smoothly and rapidly discharged.

Owner:河南省直第三人民医院

Environment-friendly device for preventing interior of glue from being blocked during mobile phone interior dispensing

InactiveCN112427245AAvoid cloggingTo achieve dredging effectLiquid surface applicatorsSpraying apparatusAdhesive glueMobile phone

The invention relates to the technical field of smart phone manufacturing, and discloses an environment-friendly device for preventing an interior of glue from being blocked during mobile phone interior dispensing. The device comprises a shell, wherein ejector rods are movably connected to the lower end of the shell, reset springs are movably connected to the upper ends of the ejector rods, movingblocks are fixedly connected to the upper ends of the ejector rods, piezoelectric plates are movably connected to the upper ends of the moving blocks, electric wires are fixedly connected to the right ends of the piezoelectric plates, metal wires are fixedly connected to the right ends of the electric wires, fixed blocks are movably connected into the metal wires, protective covers are connectedto the outer surfaces of the fixed blocks in a sleeving mode, and heat blowing openings are fixedly connected to the right ends of the protective covers. Through transmission of the electric wires, heat of the interiors of the metal wires is increased, so that the temperature of the interiors of the protective covers is increased, the glue in a channel is slightly heated through heat dissipation of the heat blowing openings, the glue blocked in the channel is heated and melted, and an effect of unblocking the blocked glue is achieved.

Owner:景德镇近忠南商贸有限公司

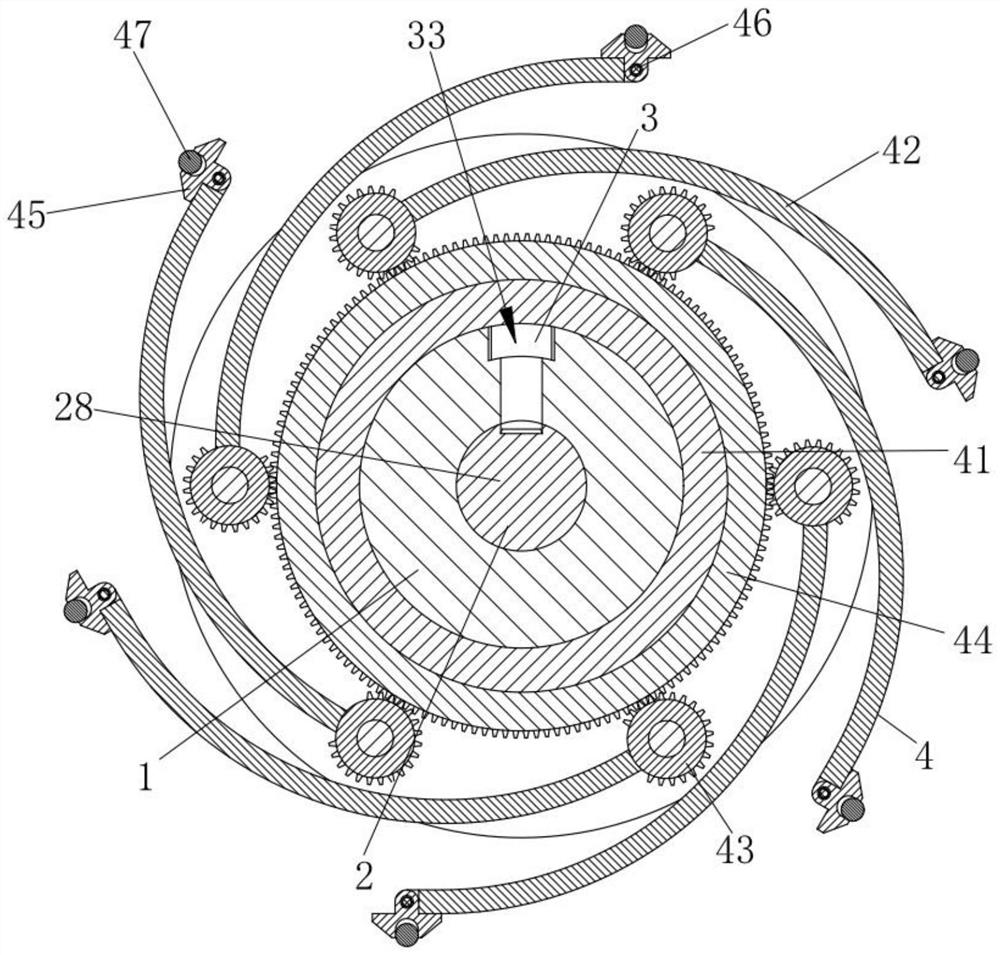

Underwater dredging robot gripper

PendingCN110439051ATo achieve dredging effectImprove dredging effectMechanical machines/dredgersPropellerSilt

The invention discloses an underwater dredging robot gripper. The gripper comprises a base and a main body, wherein a motor is arranged inside the main body, a spiral base A is arranged on the left side of the main body, a spiral shaft A is arranged on the left side of the spiral base A, a plurality of propeller blades A are arranged around the spiral shaft A, a spiral base B is arranged on the right side of the main body, a spiral shaft B is arranged on the right side of the spiral base B, a plurality of propeller blades B are arranged around the spiral shaft B, a vibrating rod is arranged onthe right side of a silt inlet, a mechanical arm A is arranged on the right side of the main body, a mechanical arm B is arranged on the right side of a movable shaft, a control end is arranged at the right end of the mechanical arm B, a camera is arranged at the top of the left side of the control end, thebase is arranged below the control end, transmission rods are arranged at the upper end andthe lower end in the base correspondingly, and rolling wheels are arranged at the two ends of the transmission rods. The bottom of the main body of the gripperis provided with the vibrating rod so that silt can be loosened, stirring blades on the two sides of the main body are used for stirring to enable the silt to be mixed with river water and flow along with the river water, and turbid silt flow can be pumped out through a dredge pump, so that the dredging effect is enhanced.

Owner:广西万鑫源环境科技工程有限公司

Pipeline dredging device for hydraulic engineering construction

InactiveCN114575444AEasy to operateQuick unblockSewer cleaningHydro energy generationEnvironmental geologyMarine engineering

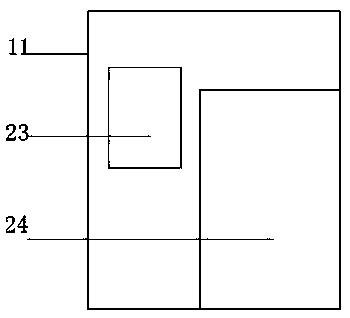

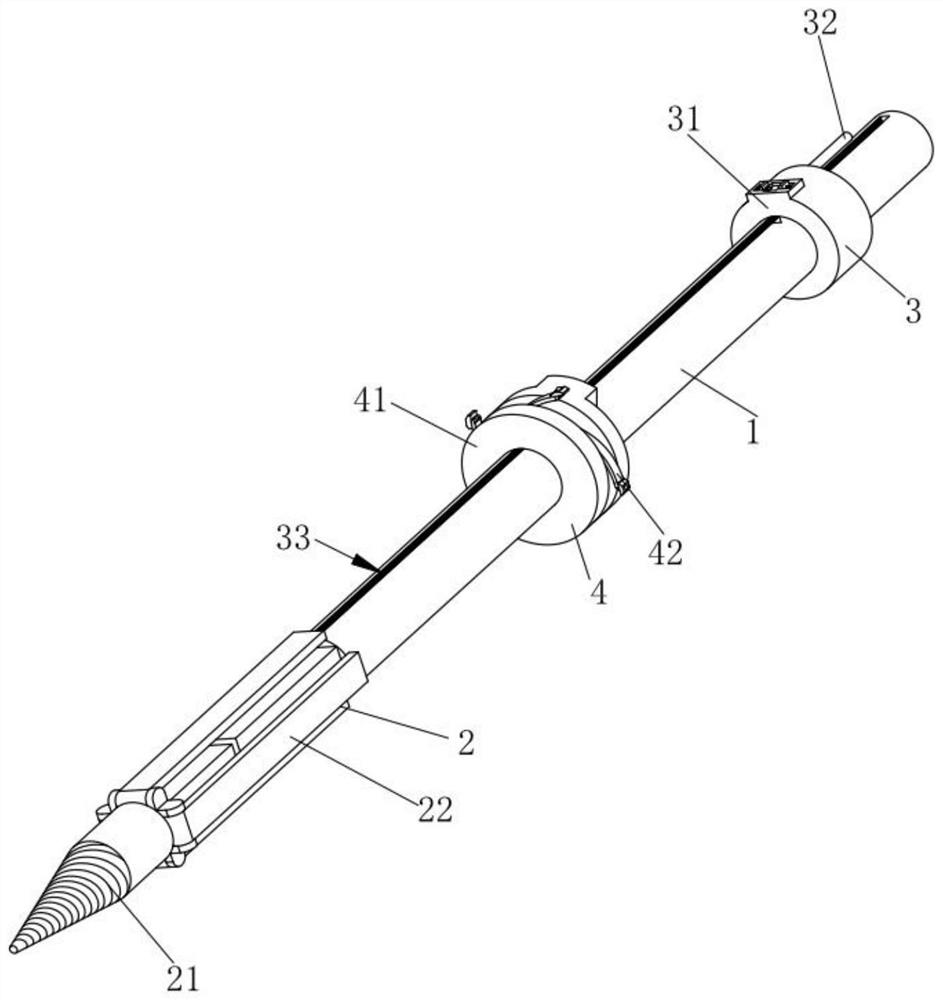

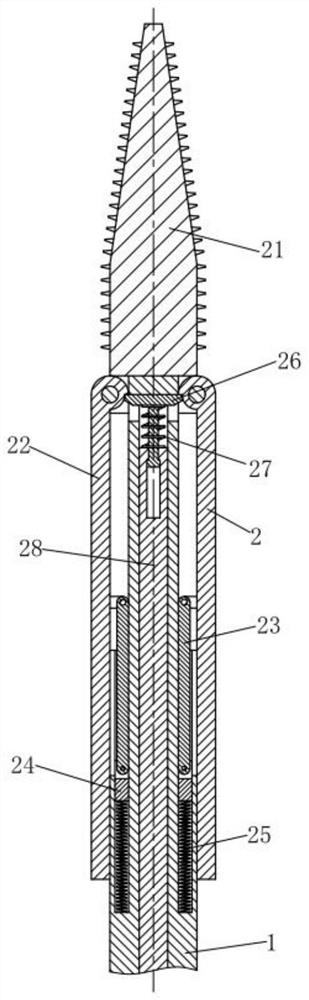

The invention relates to the technical field of sewer pipe dredging, in particular to a pipeline dredging device for hydraulic engineering construction, which comprises a mounting rod, a dredging structure, an adjusting structure, a supporting structure, a positioning structure and a fixing structure, the dredging structure can be used for taking out blockages located in the deeper position of the pipeline, rapid dredging of the sewer pipeline is achieved, an operator can control the working state of the dredging structure outside the pipeline through the adjusting structure, operation is convenient, and practicability is high. The dredging structure can be timely fixed after the working state of the dredging structure is adjusted through the fixing structure, blockages can be conveniently dragged out of a pipeline, it can be guaranteed that the mounting rod can be kept in the middle of the pipeline after the mounting rod stretches into the pipeline through the supporting structure, and therefore normal work of the dredging structure is guaranteed; and the supporting radius of the supporting structure can be adjusted and fixed through the positioning structure, so that the pipeline dredging device is suitable for dredging pipelines with different pipe diameters.

Owner:永梅

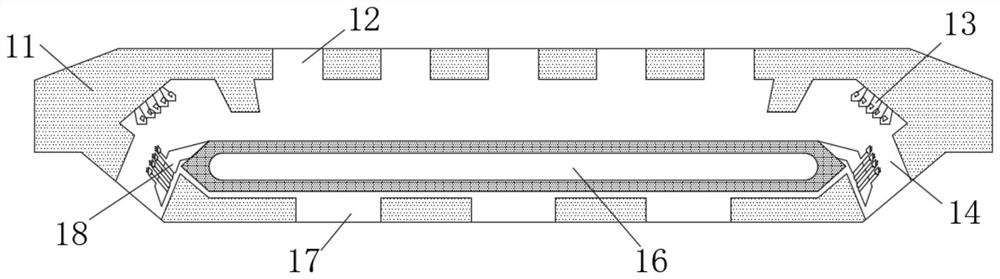

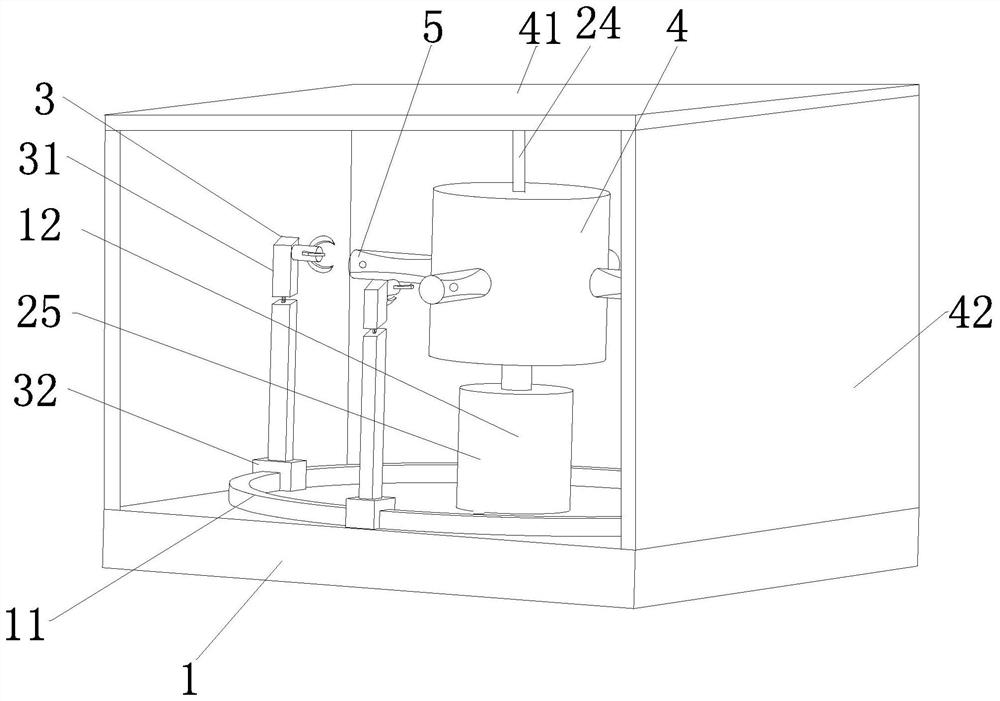

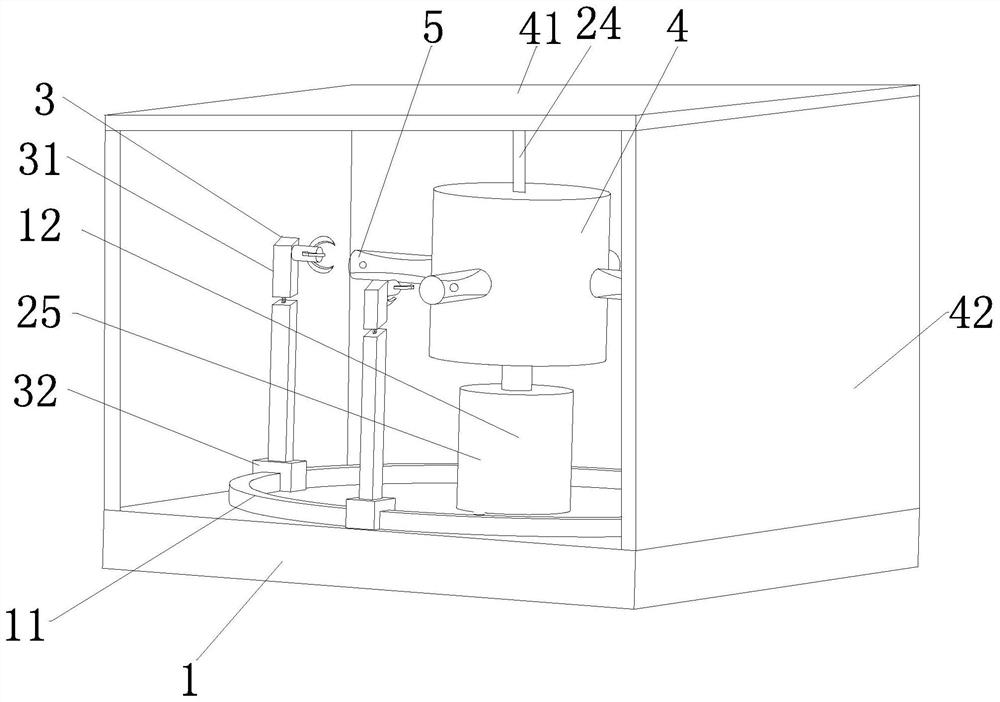

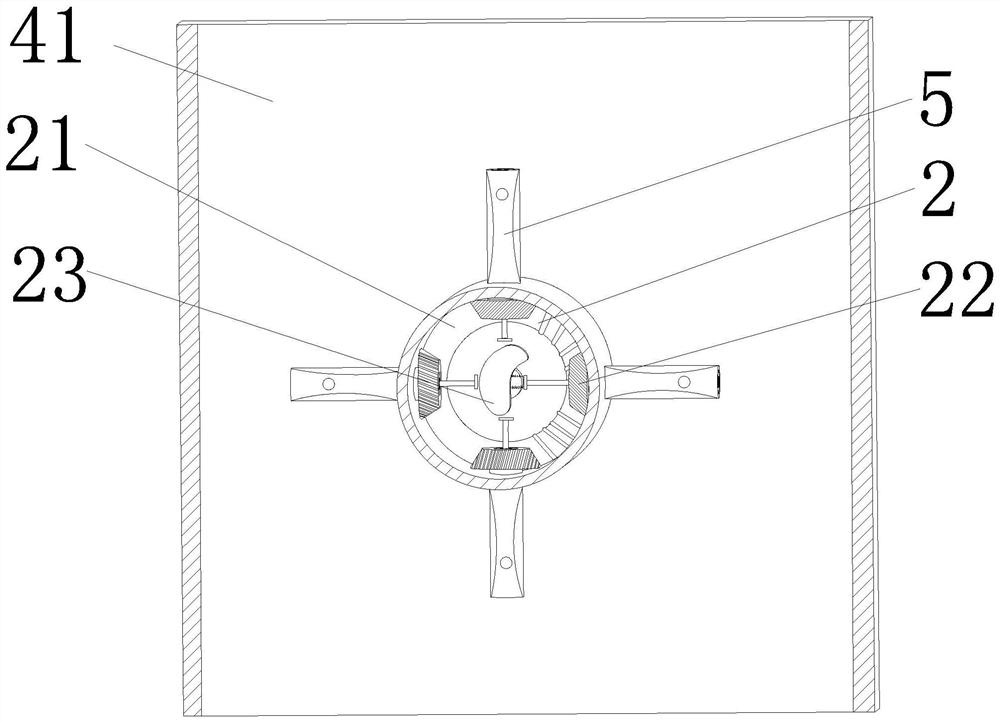

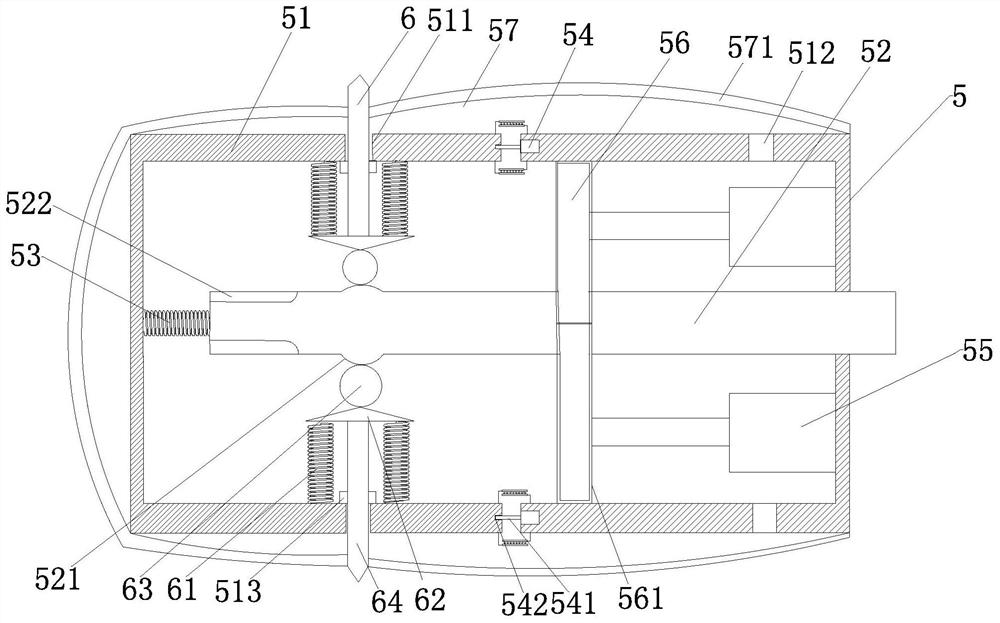

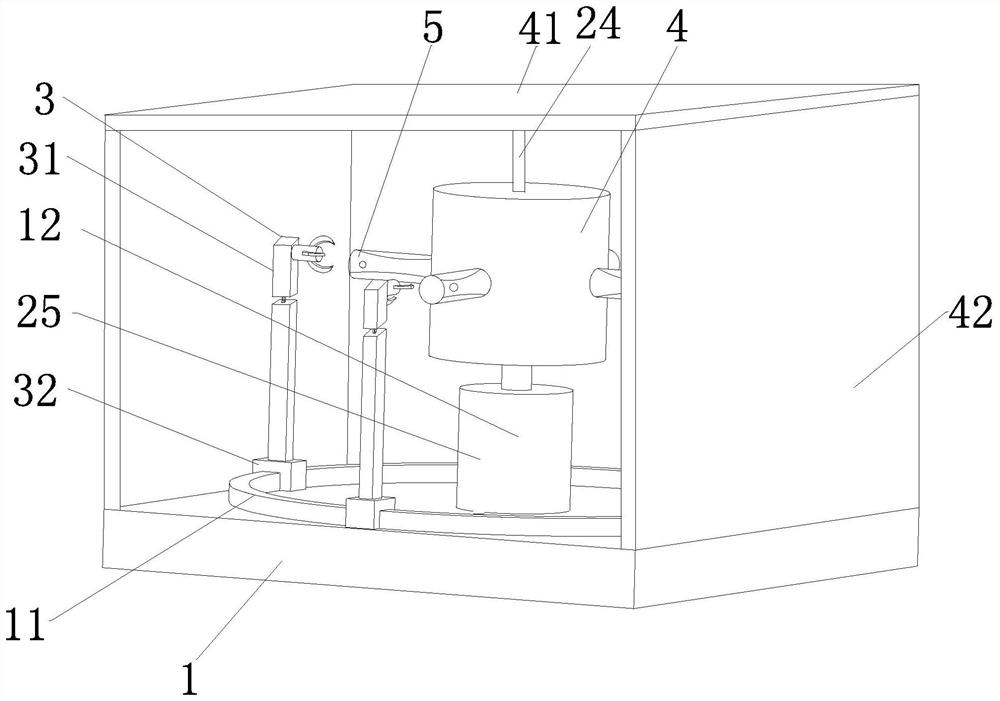

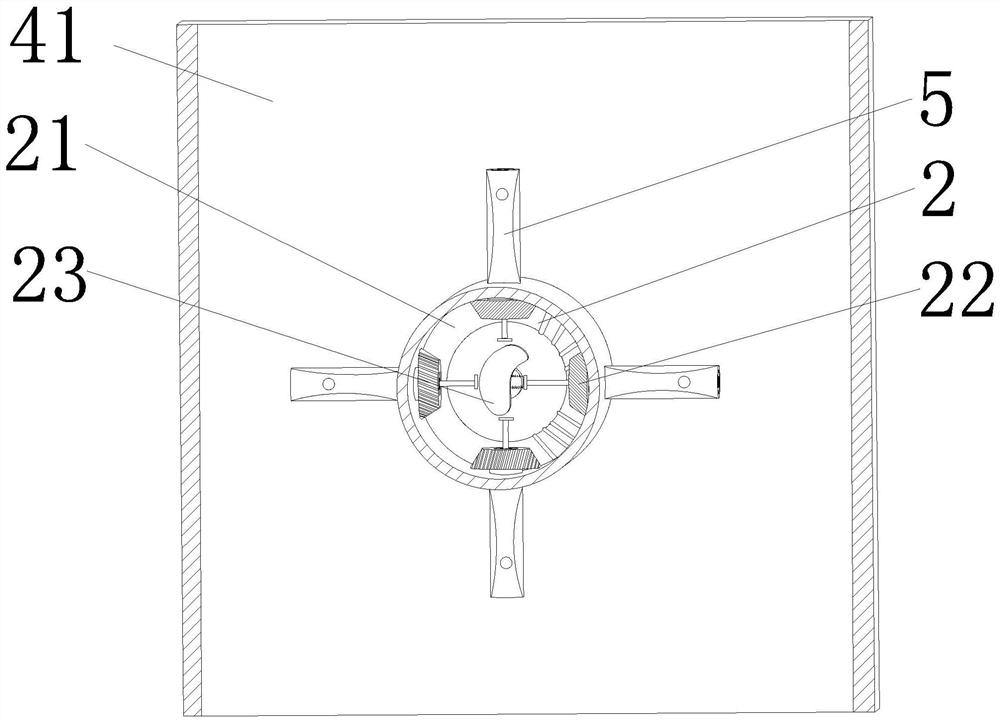

Processing technology for iron and steel smelting boiler accessory

ActiveCN112344357AQuick Pick and CleanShorten the timeAir/fuel supply for combustionSolid removalElectric machineWorkbench

The invention relates to a processing technology for an iron and steel smelting boiler accessory. The processing technology uses hood processing equipment, the equipment is provided with a workbench,wherein an annular electric sliding block is installed on the upper end face of the workbench, a plurality of sets of matched clamping devices are installed on the annular electric sliding block, a main motor is installed on the upper end face of the workbench, the main motor is located on the inner side of the clamping devices, a containing barrel is installed on an output shaft of the main motorand is of a cylindrical structure with the hollow interior and the two closed ends, a top plate is installed above the containing barrel, side plates are symmetrically installed at the left end and the right end of the lower end face of the top plate, one ends, away from the top plate, of the side plates are mounted on the upper end face of the workbench, a start device is installed in the middleof the inner side of the containing barrel, and cleaning devices are evenly arranged in the circumferential direction of the outer side wall of the containing barrel and penetrate through the containing barrel. According to the processing technology, the problems that in the prior art, for boiler hood cleaning, the manual cleaning cost is high, the cleaning steps are complex, and cleaning is notcomprehensive or poor can be solved.

Owner:江苏台正数控设备有限公司

Car washing device

ActiveCN108217879AFull flocculationFor quick outflowVehicle cleaning apparatusWater/sewage treatment by flocculation/precipitationSewageSewage treatment

The invention relates to the technical field of car washing, and particularly relates to a car washing device. The car washing device comprises a sewage collecting pipe, and also comprises a flocculating agent box and a container for mixing, wherein the flocculating agent box is provided with a feeding opening and a discharging pipe; the discharging pipe comprises a fixed pipe and a telescopic pipe; the sewage collecting pipe comprises an unloading pipe and a draining pipe; the unloading pipe is communicated with the draining pipe which is used for pouring sewage into the container for mixingintermittently; a hinging hole is formed in the pipe wall of the unloading pipe; the container for mixing is positioned in the unloading pipe, and is fixedly provided with a swinging rod; a rotary shaft is fixed on the hole wall of the hinging hole; the swinging rod is rotatably connected with the rotary shaft; a pushing rod is fixed between the swinging rod and the telescopic pipe; a tension spring is arranged between the swinging rod and the hole wall of the hinging hole; a plugging block is also fixed on the pipe wall of the unloading pipe; a flocculating-agent channel is arranged on the swinging rod. The car washing device has the beneficial effects that the problem of failure to treat the sewage in car washing in the prior art can be solved; meanwhile, full flocculation of the sewagealso can be guaranteed in sewage treatment.

Owner:重庆安布伦斯科技有限公司

Highly-heatproof temporary plugging agent for oil wells

InactiveCN109777382AImprove stabilityImprove surface activityDrilling compositionPolymer scienceRecovery performance

The invention discloses a highly-heatproof temporary plugging agent for oil wells, and belongs to the technical field of oil exploitation. Anions in the system are captured by a cationic polymer on the surface of the system to improve the stability of the temporary plugging in the oil wells. NH3 and CO2 gases produced by the cationic polymer can remove the polar groups on the surface and generatepores in the surface in order to gradually achieve the dredging effect, so the heatproof performance is improved, and the temporary plugging cycle is prolonged. A self-made polyester resin is used, gallic acid can be pyrolyzed at a high temperature to produce free aromatic rings, and the free aromatic rings are dispersed in the self-made polyester resin, so the heatproof property of the polyesterresin is further improved, the mechanical properties of the plugging structure are enhanced, and the temporary plugging effect is improved; and the reduction of the viscosity and internal mechanical properties with the increase of temperature and the long-time action cooperates with the gases generated in the system to achieve the plugging releasing effect. The problems of poor heatproof performance, poor temporary plugging performance and poor recovery performance of conventional temporary plugging agents for oil wells are solved in the invention.

Owner:于鑫娅

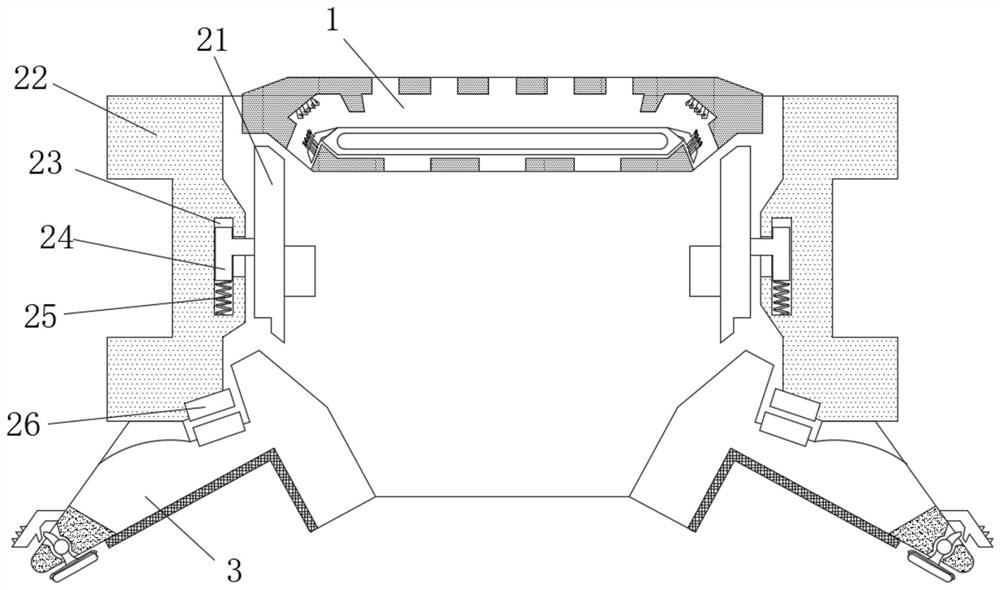

Steel smelting boiler hood treatment system

InactiveCN112355842AQuick Pick and CleanShorten the timeGrinding drivesCleaning using toolsElectric machineEngineering

The invention relates to a steel smelting boiler hood treatment system which comprises a workbench, a starting device, clamping devices, a containing cylinder, cleaning devices and a through hole device. An annular electric sliding block is installed on the upper end face of the workbench, the multiple matched clamping devices are installed on the annular electric sliding block, and a main motor is installed on the upper end face of the workbench. A main motor is located on the inner sides of the clamping devices, the containing cylinder is installed on an output shaft of the main motor and isof a cylindrical structure with the hollow interior and the two closed ends, a top plate is installed above the containing cylinder, and side plates are symmetrically installed at the left end and the right end of the lower end face of the top plate. The ends, away from the top plate, of the side plates are arranged on the upper end face of the workbench. The starting device is arranged in the middle of the inner side of the containing cylinder, the cleaning devices are evenly arranged in the circumferential direction of the outer side wall of the containing cylinder and penetrate through thecontaining cylinder. By means of the steel smelting boiler hood treatment system, the problems that in the prior art, for boiler hood cleaning, the manual cleaning cost is high, the cleaning steps are complex, and cleaning is not comprehensive or poor can be solved.

Owner:深圳市果源石油化工有限公司

A processing technology for iron and steel smelting boiler accessories

ActiveCN112344357BQuick Pick and CleanShorten the timeAir/fuel supply for combustionSolid removalElectric machineProcess engineering

The invention relates to a processing technology for iron and steel smelting boiler accessories, which uses an air cap processing equipment, the equipment has a worktable, an annular electric slider is installed on the upper end surface of the worktable, and an annular electric slider is installed on the annular electric slider. There are multiple sets of matching clamping devices. The main motor is installed on the upper end surface of the worktable. The main motor is located inside the clamping device. The output shaft of the main motor is installed with a placing cylinder. A top plate is installed above the placing cylinder, side plates are installed symmetrically at the left and right ends of the lower end face of the top plate, the end of the side plate far from the top plate is installed on the upper end surface of the worktable, a starting device is installed in the middle of the inner side of the placing cylinder, and the cleaning device is arranged along the circumference of the outer side wall of the placing cylinder. Evenly arranged in the direction, the cleaning device passes through the placing cylinder, and the present invention can solve the existing problems of boiler air cap cleaning: high manual cleaning cost, complicated cleaning steps, incomplete cleaning and the like.

Owner:江苏台正数控设备有限公司

Car wash sewage treatment device

ActiveCN108217879BFull flocculationFor quick outflowVehicle cleaning apparatusWater/sewage treatment by flocculation/precipitationSewageSewage treatment

The invention relates to the technical field of car washing, and particularly relates to a car washing device. The car washing device comprises a sewage collecting pipe, and also comprises a flocculating agent box and a container for mixing, wherein the flocculating agent box is provided with a feeding opening and a discharging pipe; the discharging pipe comprises a fixed pipe and a telescopic pipe; the sewage collecting pipe comprises an unloading pipe and a draining pipe; the unloading pipe is communicated with the draining pipe which is used for pouring sewage into the container for mixingintermittently; a hinging hole is formed in the pipe wall of the unloading pipe; the container for mixing is positioned in the unloading pipe, and is fixedly provided with a swinging rod; a rotary shaft is fixed on the hole wall of the hinging hole; the swinging rod is rotatably connected with the rotary shaft; a pushing rod is fixed between the swinging rod and the telescopic pipe; a tension spring is arranged between the swinging rod and the hole wall of the hinging hole; a plugging block is also fixed on the pipe wall of the unloading pipe; a flocculating-agent channel is arranged on the swinging rod. The car washing device has the beneficial effects that the problem of failure to treat the sewage in car washing in the prior art can be solved; meanwhile, full flocculation of the sewagealso can be guaranteed in sewage treatment.

Owner:重庆安布伦斯科技有限公司

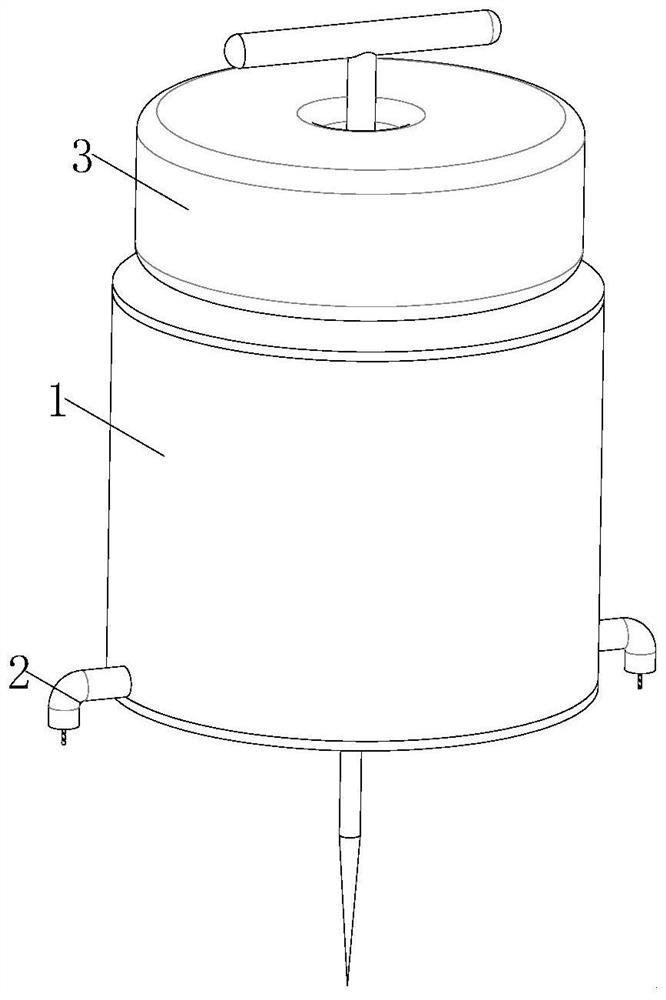

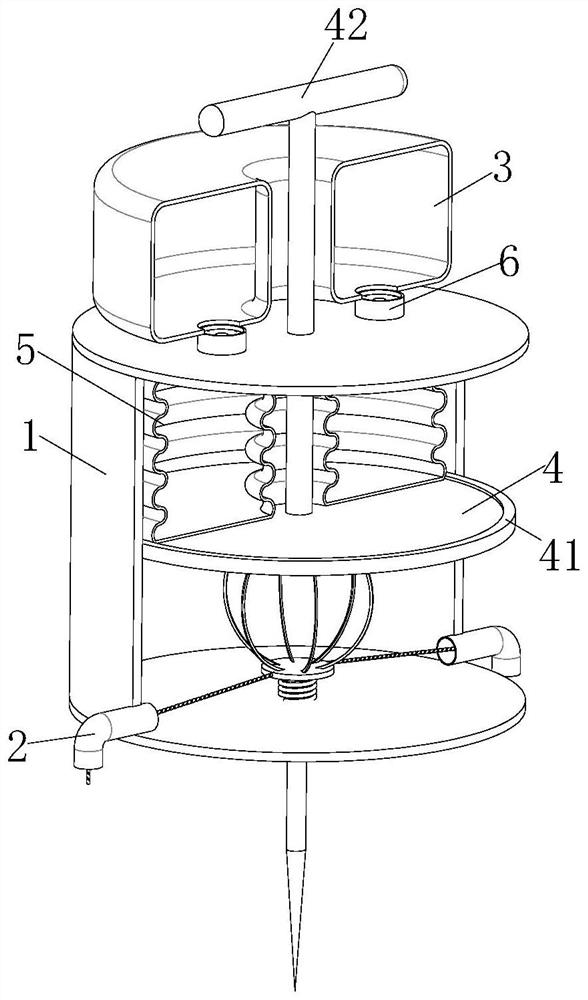

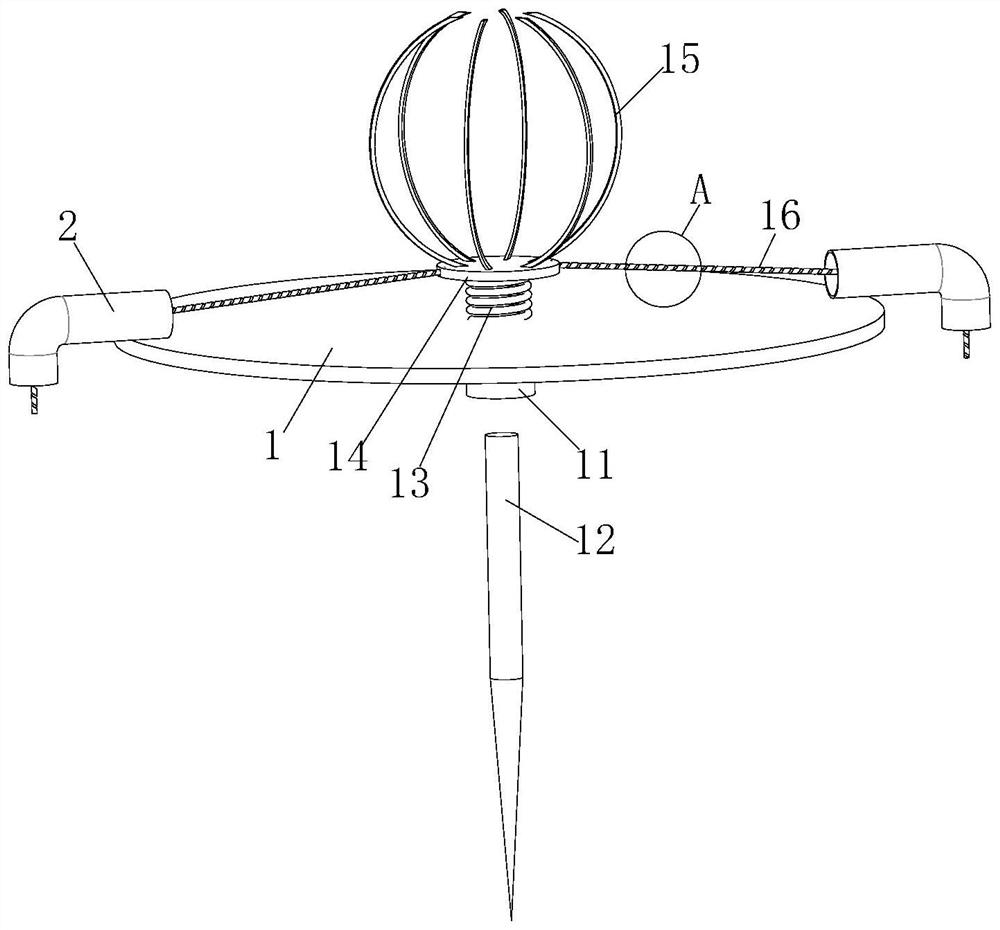

Drip irrigation equipment suitable for arid regions

ActiveCN114568257AProduces the effect of drip irrigationEasy accessClimate change adaptationWatering devicesAgricultural irrigationDrip irrigation

The invention relates to the technical field of agricultural irrigation, and discloses drip irrigation equipment suitable for arid regions, which comprises an irrigation box, and a side pipe is fixedly connected to the side edge, close to the lower end, of the irrigation box; an upper expansion bag is arranged at the upper end of the irrigation box, a built-in plate is arranged in the irrigation box, a pull rod is welded to the upper end of the built-in plate, the upper end of the pull rod upwards extends out of the irrigation box, a built-in expansion bag is fixedly installed at the upper end of the built-in plate, and the built-in expansion bag is located at the upper end of the built-in plate; the upper end of the built-in expansion bag is fixedly connected with a connecting pipe communicated with the interior of the built-in expansion bag. According to the device, through the upward movement process of a built-in plate, a built-in expansion bag and gas in the built-in expansion bag enter an upper expansion bag, gas in the upper expansion bag can slowly enter the built-in expansion bag, the built-in expansion bag pushes the built-in plate downwards, water in an irrigation box can be squeezed out from a side pipe, and the drip irrigation effect is achieved.

Owner:青阳县青宁农业科技发展有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com