Spray gun for mortar mechanical spraying

A technology of spray gun and mortar, which is applied in the direction of construction and building structure, and can solve problems such as easy to cause blockage and affect low construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

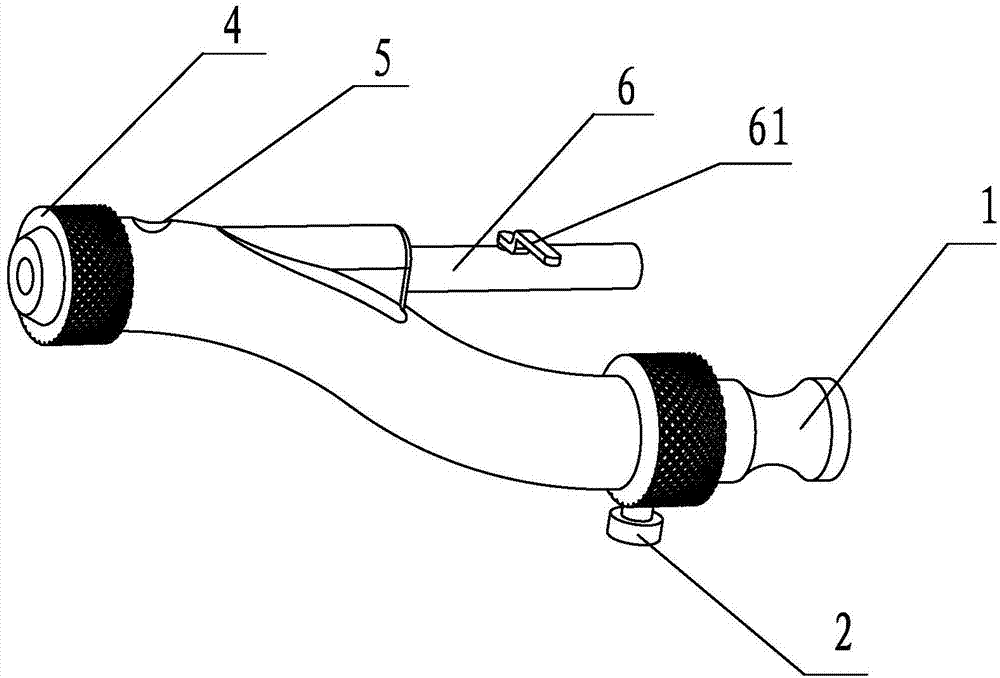

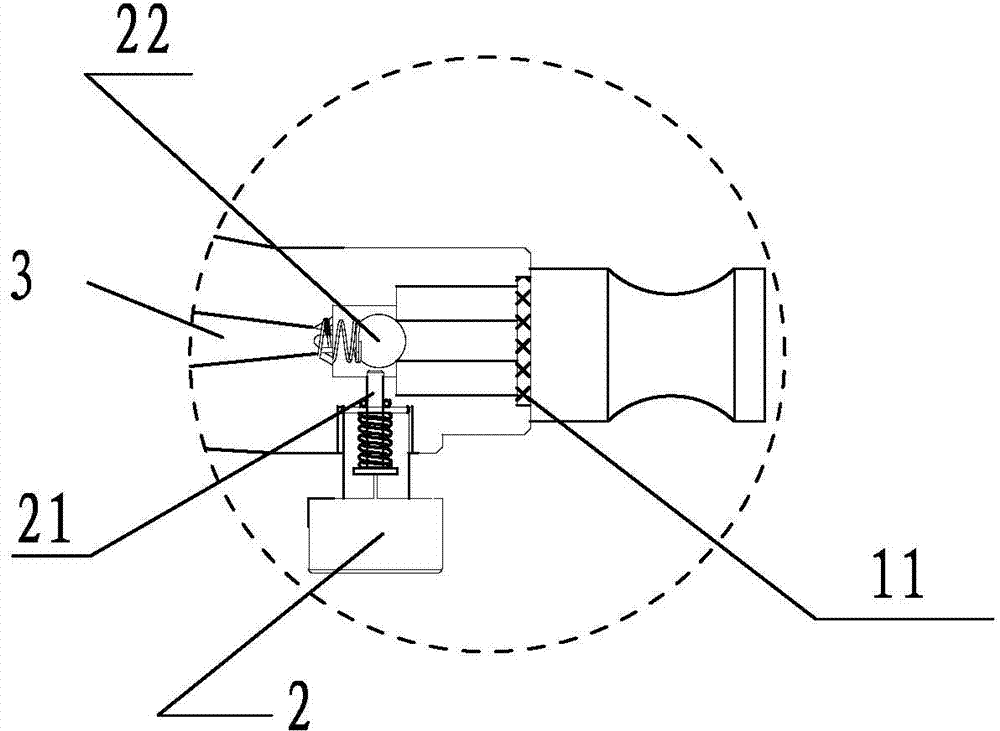

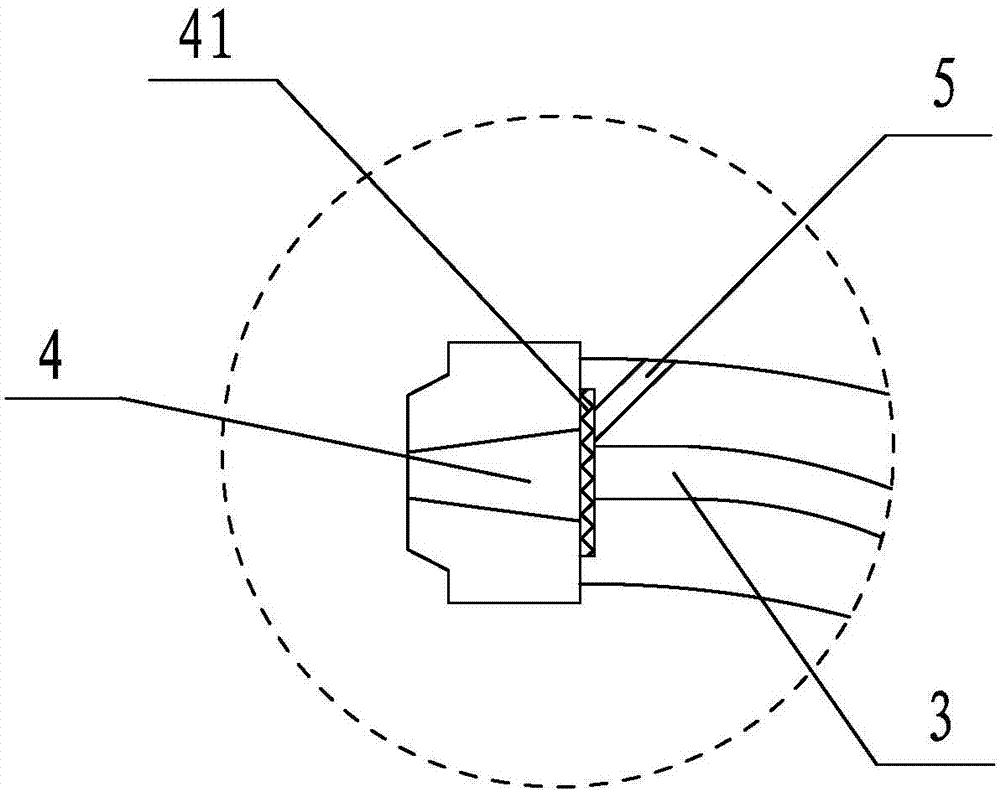

[0014] Such as figure 1 and figure 2 As shown, a spray gun for mortar mechanized spraying of the present invention includes a spray gun body, and a quick connector 1 is connected to the end of the spray gun body. The quick connector is widely used in the industrial field, and its main advantage is that it is very fast and convenient to connect some equipment , using the movable bayonet on it can accurately and quickly realize the connection with the equipment, the first layer of filter screen 11 is set between the quick connector 1 and the spray gun body, and the anti-clogging trigger 2 is set on the side of the end of the spray gun body, The anti-clogging actuator is connected with a push rod 21, and the push rod pushes against a steel ball 22, and the steel ball is arranged in the feed passage 3. Preferably, a steel ball is arranged between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com