Highly-heatproof temporary plugging agent for oil wells

A temporary plugging agent, high heat resistance technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of heat resistance, temporary plugging and poor recovery performance, and achieve the effect of prolonging the temporary plugging effect, Improve thermal resistance and good structural symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

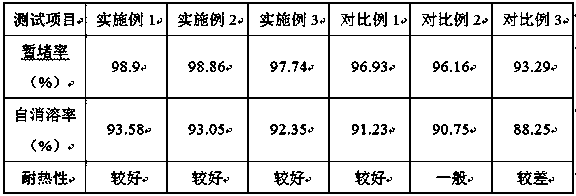

Examples

preparation example Construction

[0030] The preparation method of composite temporary plugging base material comprises the following steps:

[0031](1) Take palygorskite and pulverize it in a pulverizer, pass through a 80-mesh sieve, collect the sieved particles according to the mass ratio of 1:8~14, add hydrochloric acid with a mass fraction of 12% and mix in the reactor, at 65~80°C, at 400~ Stir at 700r / min for 40~60min, filter, collect the filter residue and add reagent A to mix according to the mass ratio of 1:8~14, heat up to 85~95°C, keep warm for 40~60min, cool naturally to room temperature, filter, take the filter cake and wash it with water After 2~4 times, dry in an oven at 90~100°C for 3~5h to obtain the dried product. Take the dried product, polyvinyl alcohol, surfactant, and ball milling medium in the ball mill according to the mass ratio of 6~10:3:1:1. Tank mixing, ball milling at 350~550r / min for 1~3h, to obtain ball mill, in parts by weight, take 25~40 parts of ball mill, 12~20 parts of dimeth...

Embodiment 1

[0036] Surfactant: Mix cetyltrimethylammonium bromide and dodecyldimethylbetaine at a mass ratio of 7:1 to obtain a surfactant.

[0037] Ball milling medium: Mix acetone and ethanol solution with a volume fraction of 70% at a mass ratio of 1:3 to obtain a ball milling medium.

[0038] Additive: Mix sodium polyacrylate, polyacrylamide, and hydroxymethyl cellulose in a mass ratio of 3:2:1 to obtain the additive.

[0039] Reagent A: Take 10% hydrogen peroxide and 15% NH at a mass ratio of 15:7 4 Cl solutions were mixed to obtain reagent A.

[0040] Reagent B: Mix PBS buffer with a pH value of 7.8~8.2 and ammonium bicarbonate at a mass ratio of 13:4 to obtain Reagent B.

[0041] Auxiliary agent: Mix decene, magnesium stearate, and microcrystalline paraffin wax at a mass ratio of 6:5:1 to obtain an auxiliary agent.

[0042] Nitrocellulose treatment material: mix nitrocellulose, OP-10, triethyl citrate, and water with a nitrogen content of 12.1% according to a mass ratio of 5:1:1...

Embodiment 2

[0049] Surfactant: Mix cetyltrimethylammonium bromide and dodecyldimethylbetaine at a mass ratio of 7:2 to obtain a surfactant.

[0050] Ball milling medium: Mix acetone and ethanol solution with a volume fraction of 70% at a mass ratio of 1:5 to obtain a ball milling medium.

[0051] Additives: Mix sodium polyacrylate, polyacrylamide, and hydroxymethyl cellulose at a mass ratio of 5:2:1 to obtain additives.

[0052] Reagent A: Take 10% hydrogen peroxide and 15% NH at a mass ratio of 20:7 4 Cl solutions were mixed to obtain reagent A.

[0053] Reagent B: Mix PBS buffer with a pH value of 8.0 and ammonium bicarbonate at a mass ratio of 19:4 to obtain Reagent B.

[0054] Auxiliary agent: Mix decene, magnesium stearate, and microcrystalline paraffin wax at a mass ratio of 8:5:1 to obtain an auxiliary agent.

[0055] Nitrocellulose treatment material: mix nitrocellulose with a nitrogen content of 13.1%, OP-10, triethyl citrate, and water at a mass ratio of 7:1:1:25, mix them wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com