Grinding device

A grinder and sliding device technology, which is applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problem of not being able to effectively ensure good contact between the angle grinder and the brake disc, which is not conducive to the operation of the wind turbine, and cannot To meet the technical requirements of the brake disc and other issues, to achieve convenient and reliable grinding effect, simple structure and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the present invention, the present invention will be described in detail below with reference to the accompanying drawings and embodiments, wherein the same reference numerals always refer to the same components.

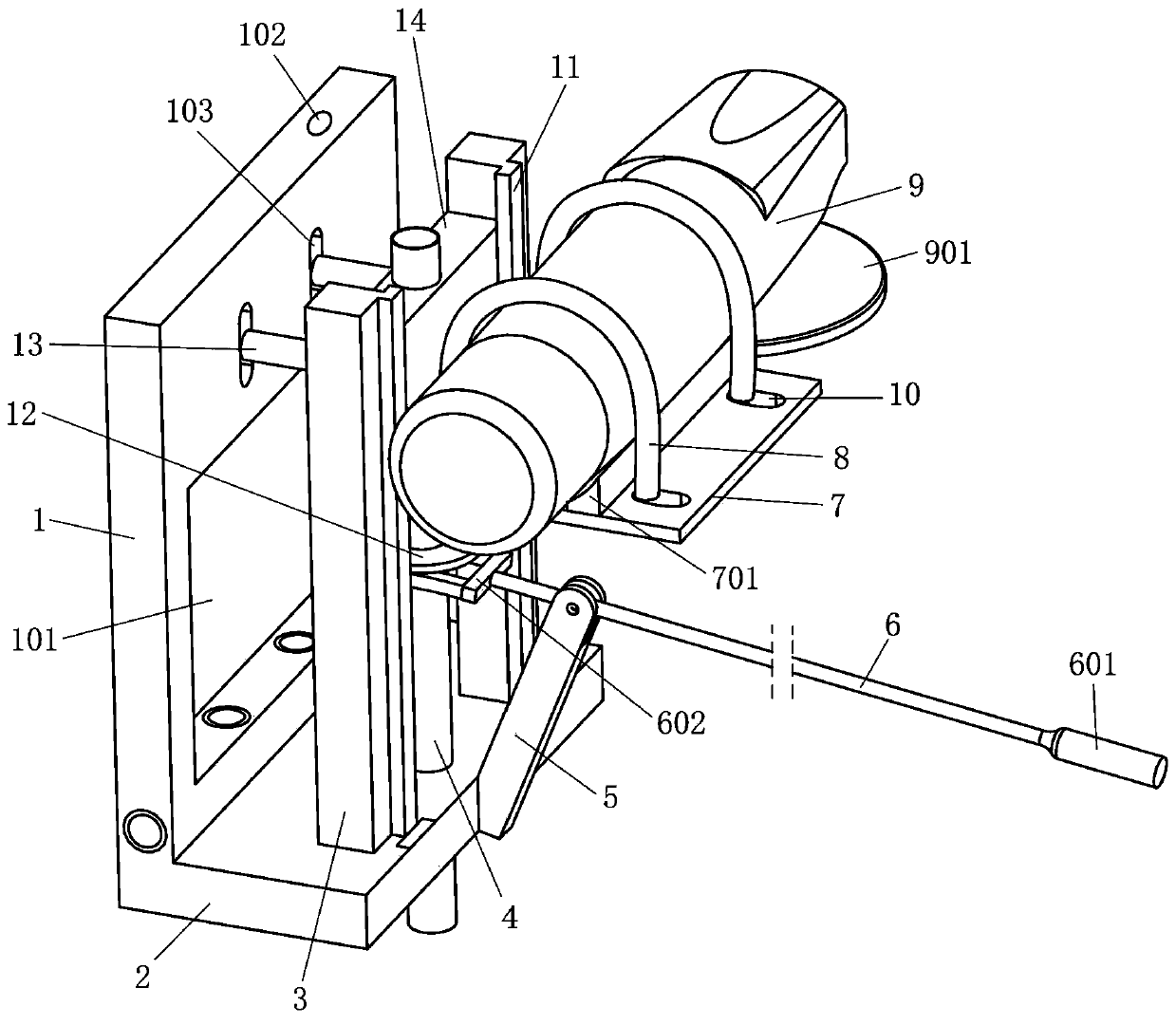

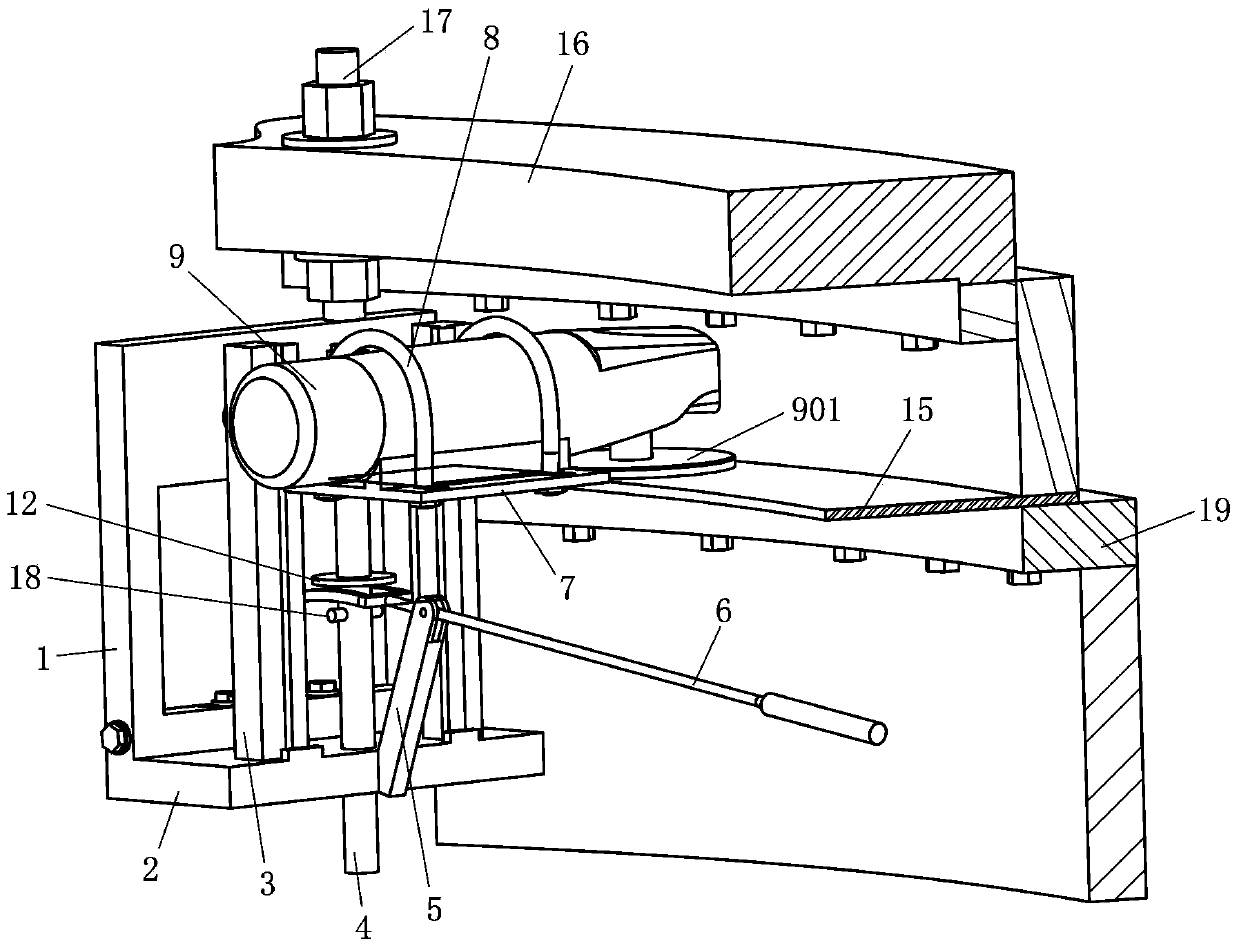

[0034] figure 1 is a schematic structural diagram of a grinding device according to an embodiment of the present invention; figure 2 Yes figure 1 Schematic diagram of the working state of the grinding device shown in the wind turbine.

[0035] refer to figure 1 and figure 2 , according to the embodiment of the present invention, the provided grinding device can be applied to various devices to grind the surface to be polished, and during the grinding operation, it can be adaptively placed horizontally according to the specific orientation of the surface to be polished , upright or inclined to place the sanding device. The grinding device provided by the present invention will be specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com