Double-station belt sanding system for sanding hammer heads

A double-station, abrasive belt technology, applied in abrasive belt grinders, grinding workpiece supports, grinding machine parts, etc., can solve the problems of poor grinding effect, low efficiency, large space occupied, etc., to achieve grinding consistency Good, high controllability, the effect of improving the grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

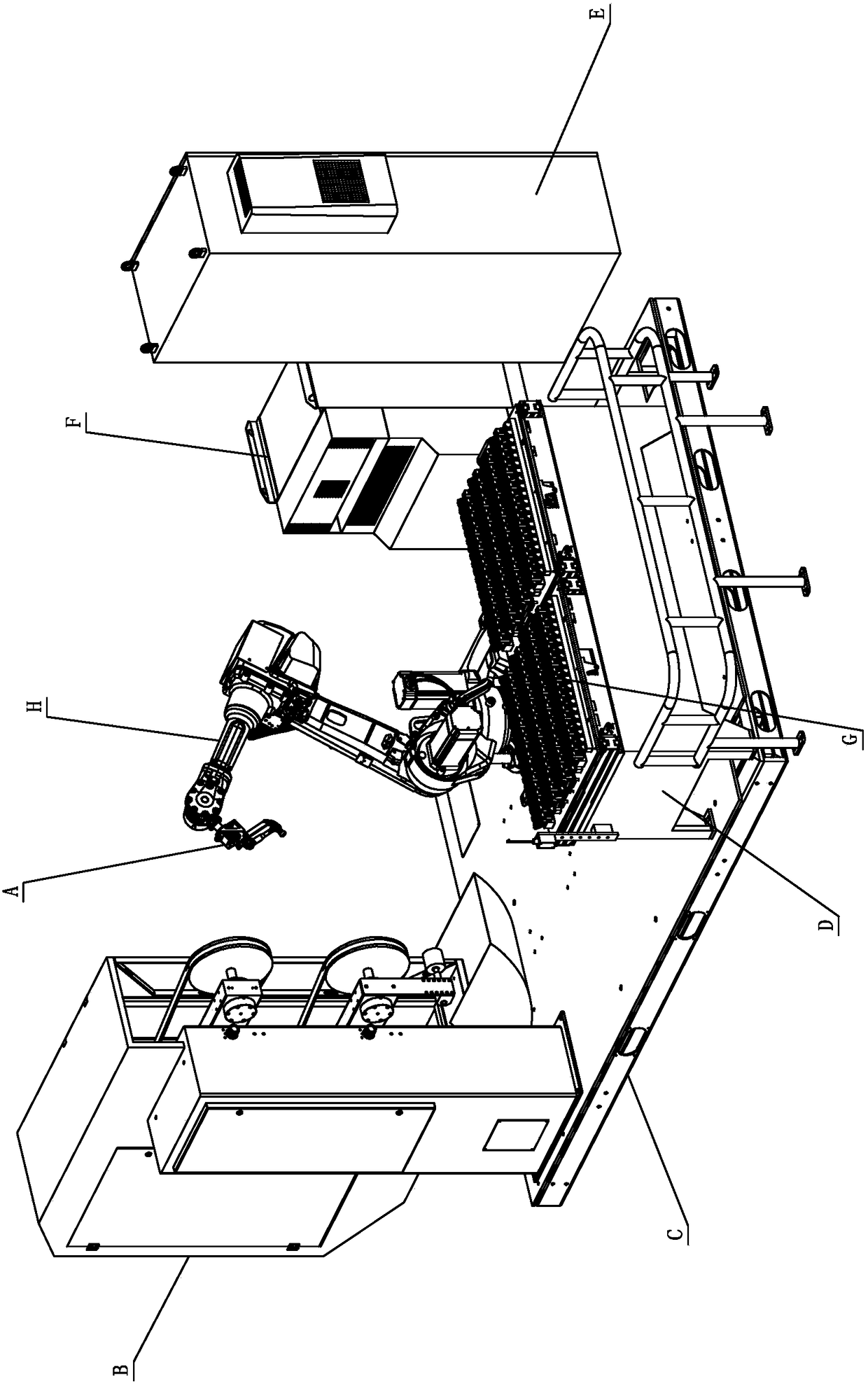

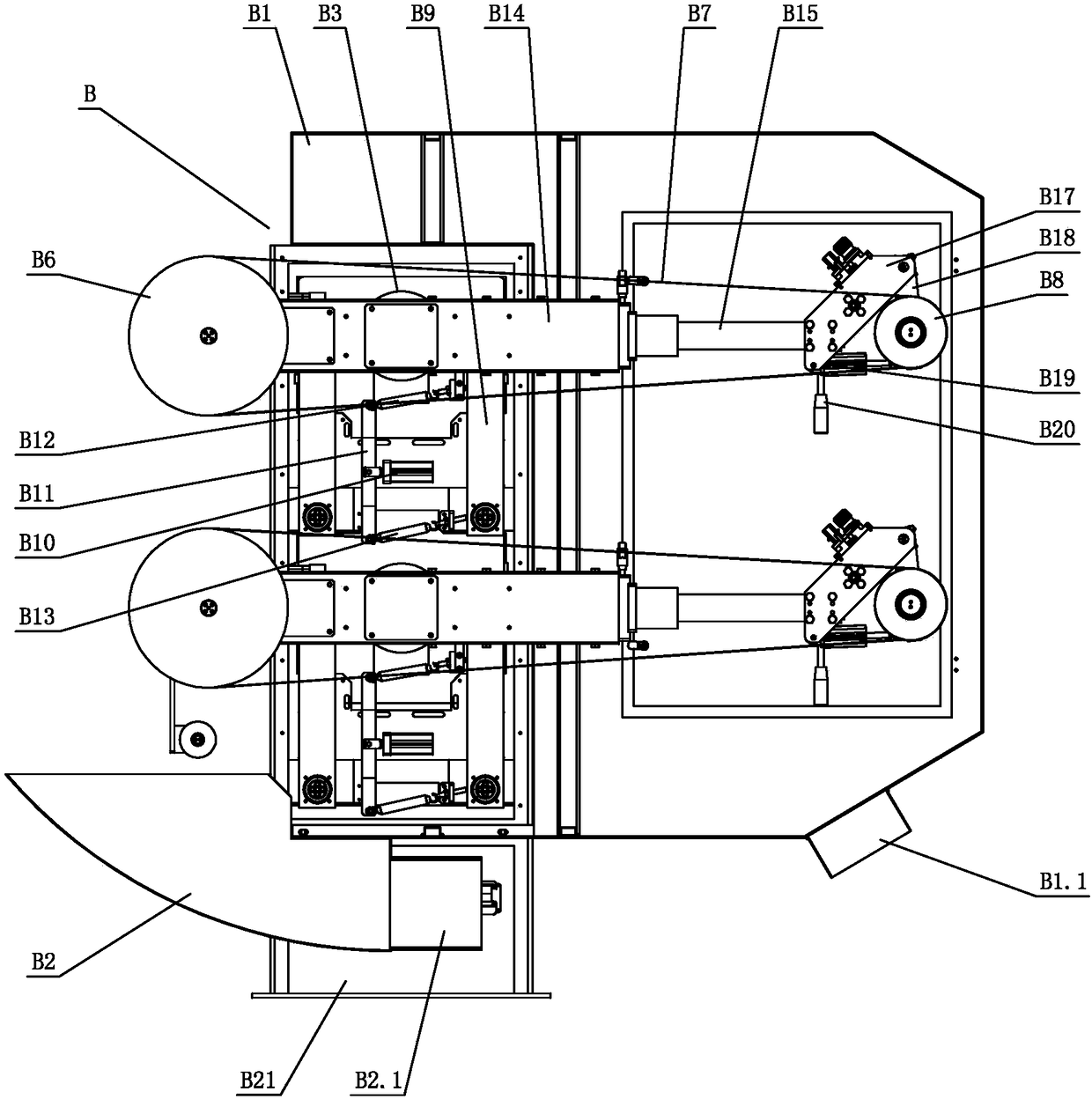

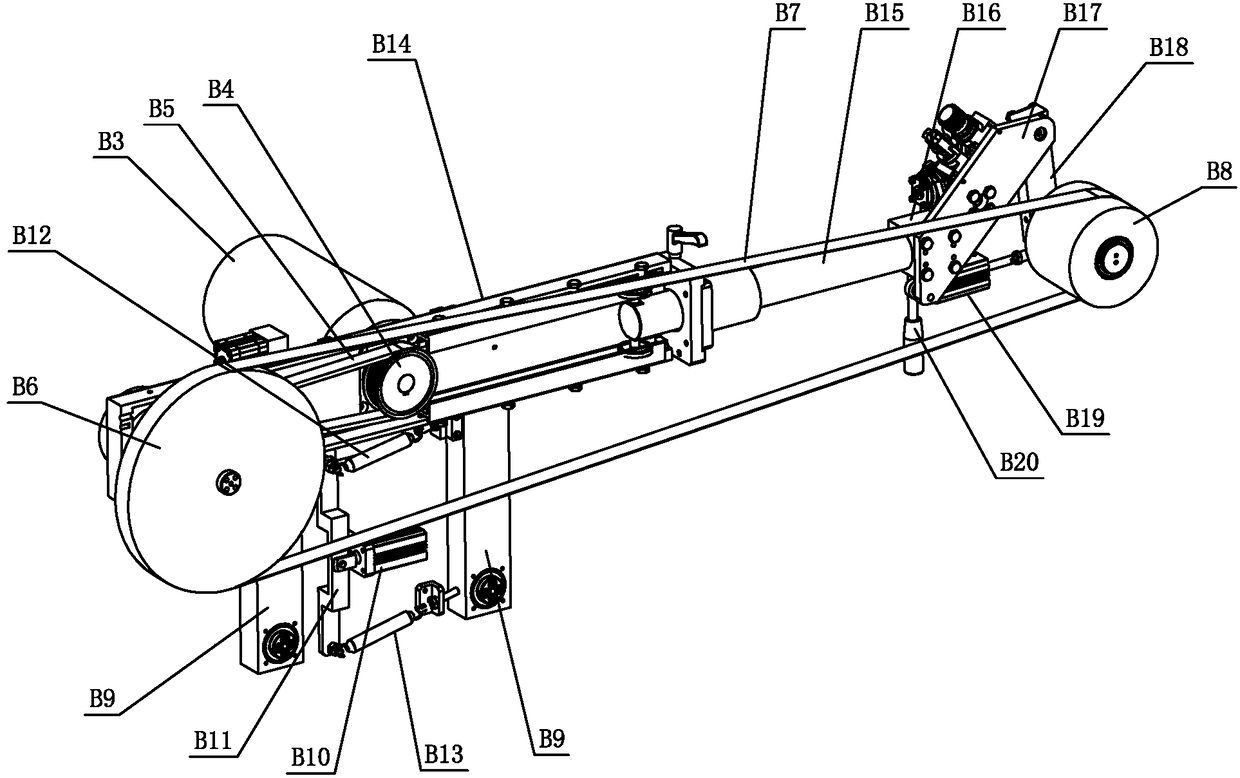

[0031] see Figure 1-Figure 10 , the double-station abrasive belt grinding system used for grinding the hammer head includes the abrasive belt grinding mechanism B, the loading and unloading mechanism D, the handling robot H and the control mechanism, and the abrasive belt grinding mechanism B, the loading and unloading mechanism D and the handling robot H are respectively electrically powered. The transfer robot H is equipped with a hammer clamp A, which clamps the hammer workpiece G from the loading and unloading mechanism D through the hammer clamp A to the abrasive belt grinding mechanism B to complete grinding; the abrasive belt grinding mechanism B Including two sets of abrasive belt grinding components, the two sets of abrasive belt grinding components are arranged up and down on the grinding bracket B21; the overall abrasive belt grinding compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com