Small-part sand rolling machine capable of automatically removing dust

A technology of automatic dust removal and small parts, which is applied in the field of sand blasting machines, can solve the problems of small workpieces that are not easy to fix, quality cannot be guaranteed, and high risk of operation, so as to avoid environmental pollution and personal health damage, eliminate difficult fixes, and improve paint quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

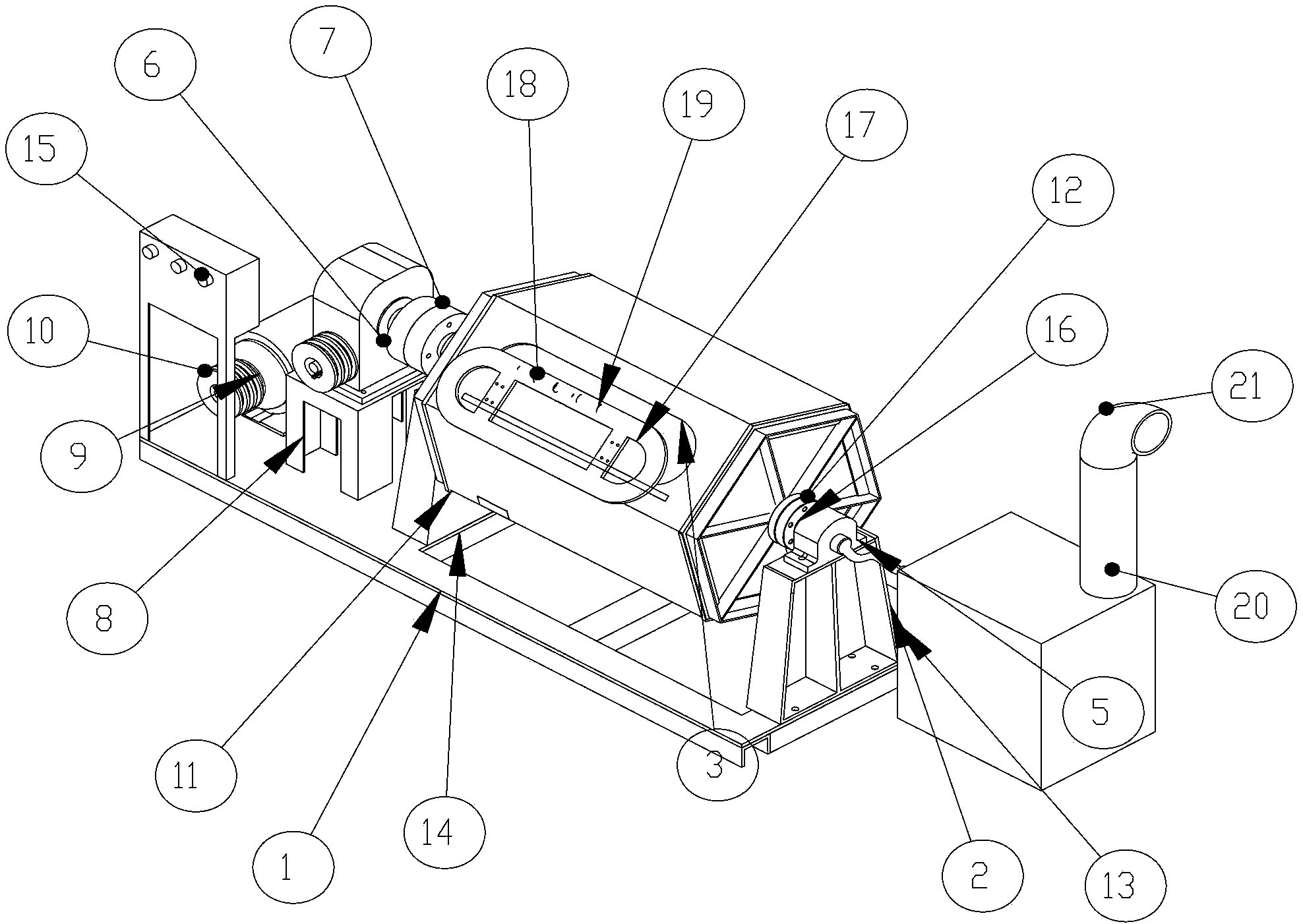

[0018] see figure 1 , the present invention provides a kind of automatic dedusting small parts sand blasting machine, this automatic dedusting small parts sand blasting machine comprises driving device, dedusting device and drum 3; Driving device drives drum 3 to rotate; The drum 3 cavity; the drum 3 is connected with the dust removal device.

[0019] The drum 3 is provided with a feed port 19; the feed port 19 is provided with a feed port cover 17 and a cover locking device 18 for locking the feed port cover 17.

[0020] The drum 3 is a prism; the feed opening 19 is arranged on the side wall of the prism. A drum reinforcing plate 11 is also provided on the drum 3 .

[0021] The dust removal device includes a rotary air inlet joint 7, a dust removal air outlet rotary joint 12, a dust removal exhaust pipe 20, a filter dust collector 13 and a dust removal exhaust pipe 20; the rotary air inlet joint 7 and the dust removal air outlet rotary joint 12 are respectively arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com