Automatic painting device of wooden door

A wooden door, automatic technology, applied in the direction of spraying device, liquid spraying device, device for coating liquid on the surface, etc. Paint quality and batch, improve paint quality, reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] As an embodiment of the present invention, the detection module 7 includes a smoothness detector, which is installed on the sliding seat 6 and connected to the controller. When working, the smoothness detector detects the smoothness of the surface of the dried wooden door.

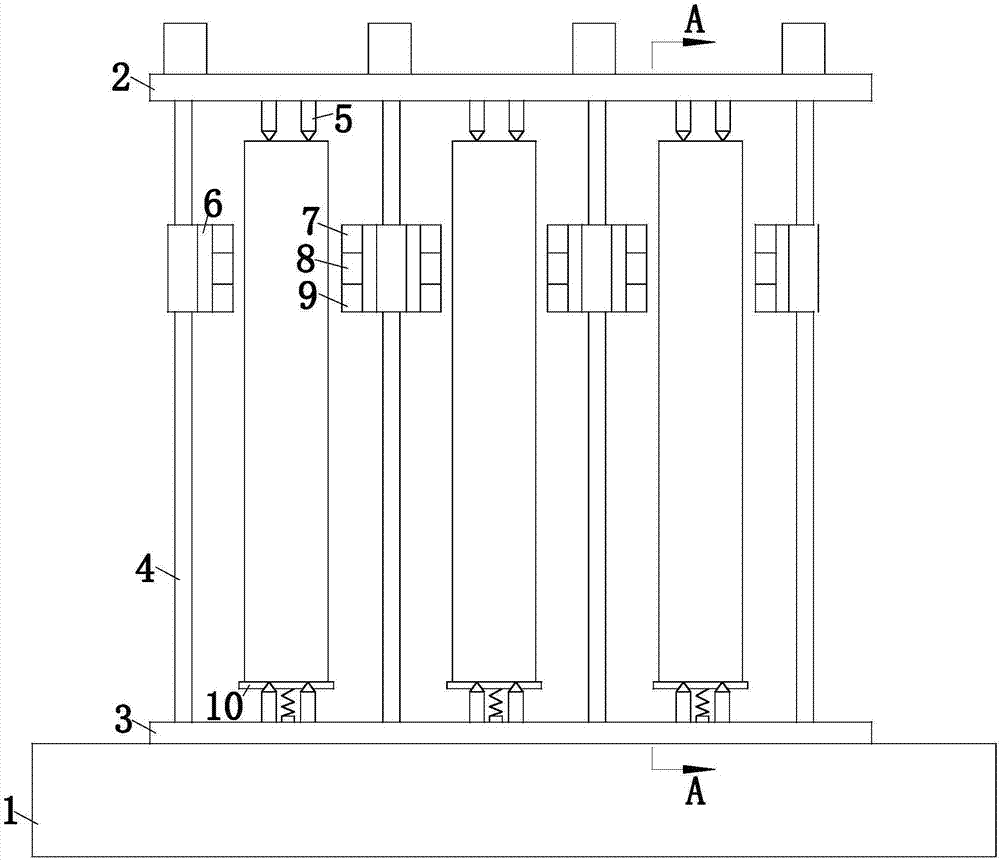

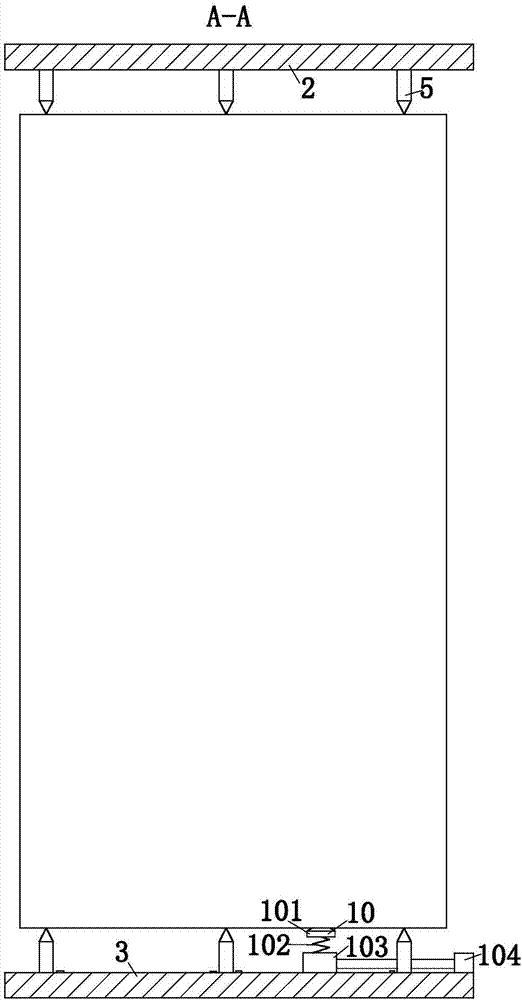

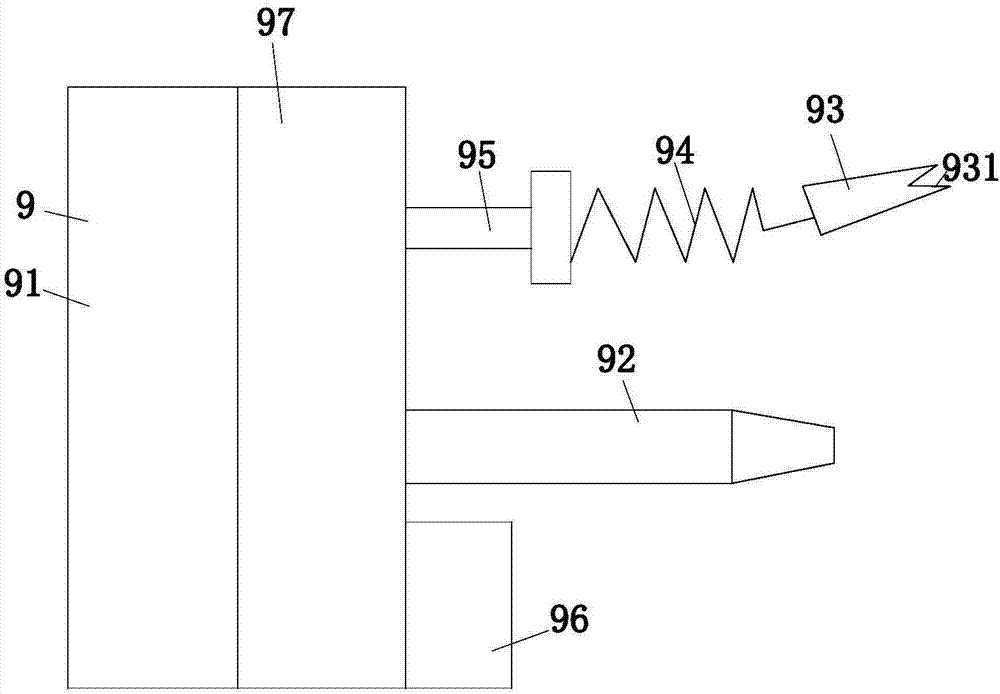

[0034] As an embodiment of the present invention, the vertical painting module 9 includes a mounting base 91, a nozzle 92, a silicone brush 93, a spring 94, a cylinder 95 of a silicone brush, a paint pump 96, and a paint box 97. 91 is fixed on the sliding seat 6; the spray head 92 is installed on the mounting seat 91, and the paint pump 96 transports the paint from the paint box 97 to the spray head 92 for ejection; 93 paints the paint surface, and the silica gel retaining brush 93 is installed on the telescopic rod of the silica gel retaining brush cylinder 95 by a spring 94; During work, the paint in the paint box 97 is sprayed from the nozzle 92 to the surface of the wooden door under the effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com