Production paint shop design

a paint shop and production technology, applied in the direction of spray booths, pretreated surfaces, coatings, etc., can solve the problems of increasing the cost of paint, requiring a significant amount of advanced technology, and requiring hundreds of millions of dollars in advanced technology, so as to reduce the flow rate of particulate paint, improve the quality of paint finish, and improve the effect of paint finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

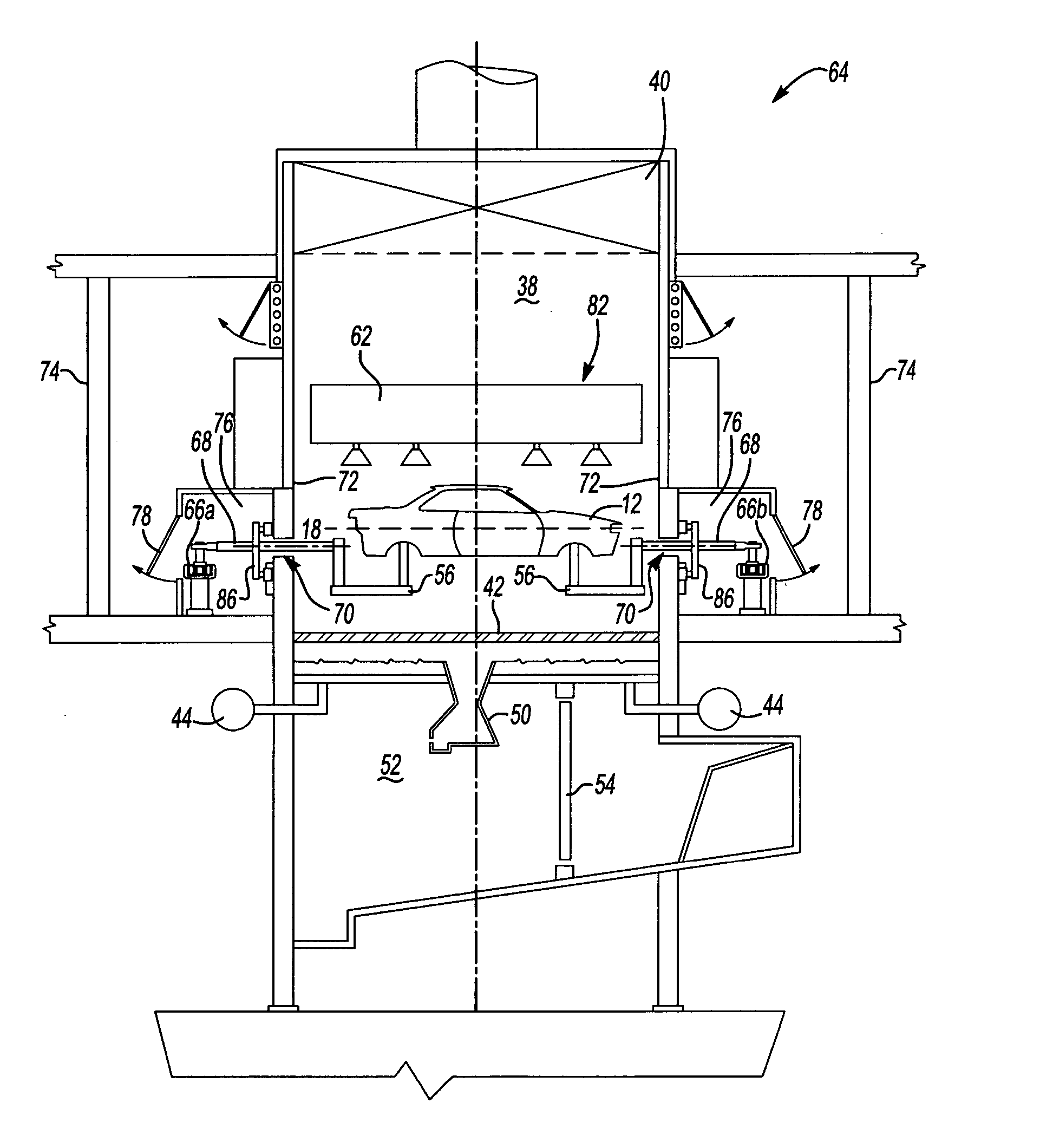

Embodiment Construction

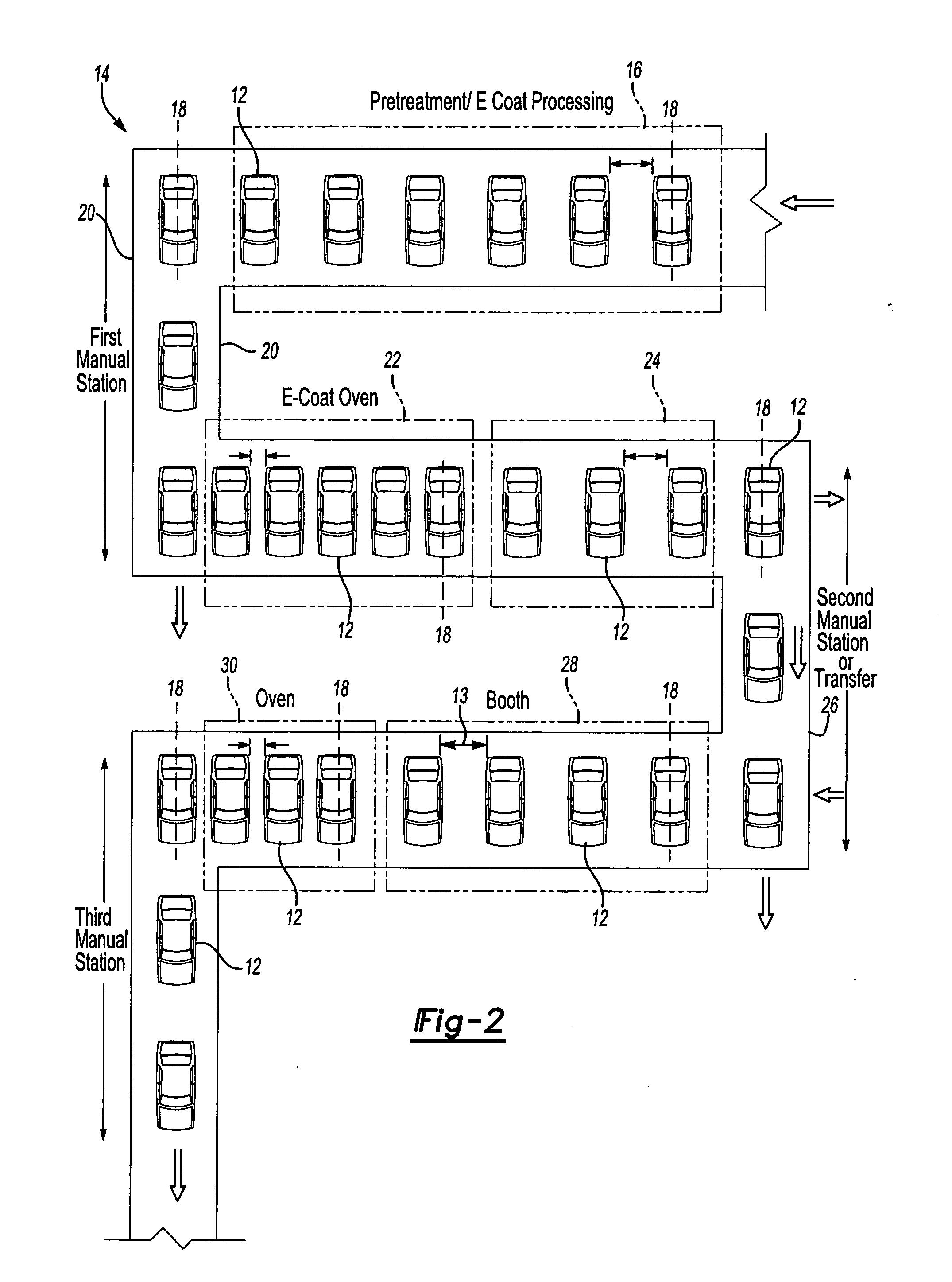

[0022] Referring to FIG. 2, one preferred arrangement of the inventive paint application facility is generally shown at 14. In this embodiment, like conventional paint application facilities, vehicle bodies 12 are initially introduced to the paint application facility from a body fabrication shop (not shown). The first processing step of the vehicle bodies 12 are processed in pretreatment and electrodeposition coating tanks. As is known to those of skill in the art, a pretreatment station cleans and treats the vehicle body, known as body-in-white, with a phosphate coating to improve paint adhesion and reduce corrosion of the vehicle body. The pretreatment station uses several immersion and spray clean, rinse, and conversion tanks to apply a high quality phosphate coating to the body-in-white. Subsequent to the pretreatment station, the vehicle body 12 is cleansed with deionized water and submerged in an electrodeposition tank where electrocoat paint is applied.

[0023] The vehicle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com