Multi-functional automatic wall plastering machine

A plastering machine and multi-functional technology, which can be used in construction, building construction, etc., can solve the problems of time-consuming, labor-intensive, low work efficiency, etc., and achieve the effect of improving efficiency and quality and reducing labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

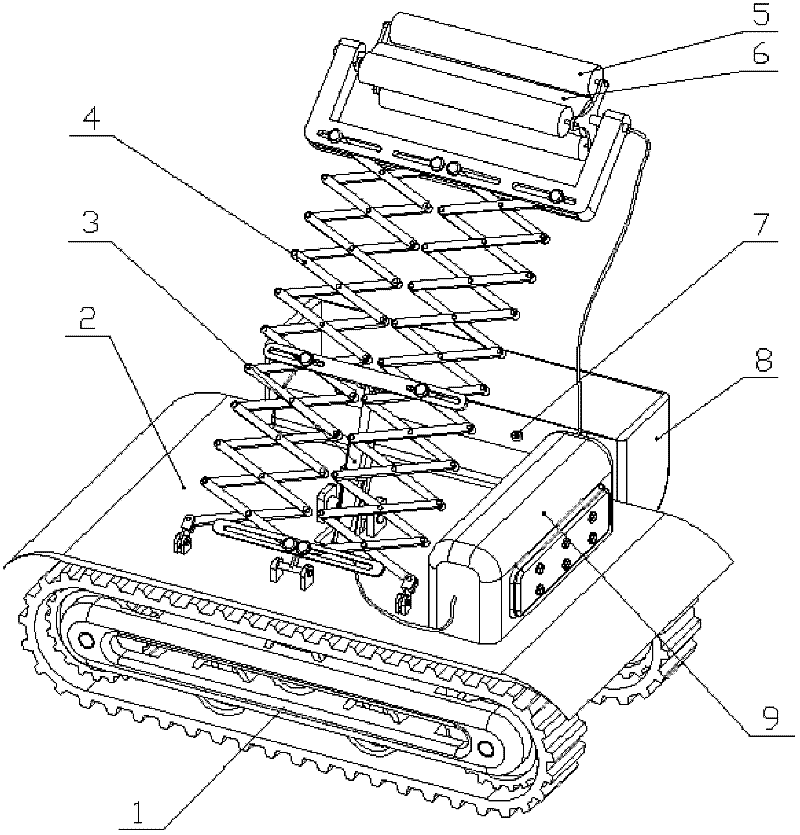

[0034] Such as figure 1 As shown, a multifunctional automatic wall plastering machine includes a walking support mechanism, a lifting mechanism, an operating mechanism and a working mechanism.

[0035] The walking support mechanism includes a rubber crawler trolley 1 and a platform 2 arranged on the rubber crawler trolley 1 . The crawler chassis trolley 1 supports the weight of the main engine, has the function of forward and backward turning, has good driving performance and dynamic performance, and can make the trolley crawl over low obstacles and stairs, thus solving the disadvantage of inconvenient movement due to the heavy weight of the whole machine; chassis The platform 2 above is welded by four square steels and the chassis beam.

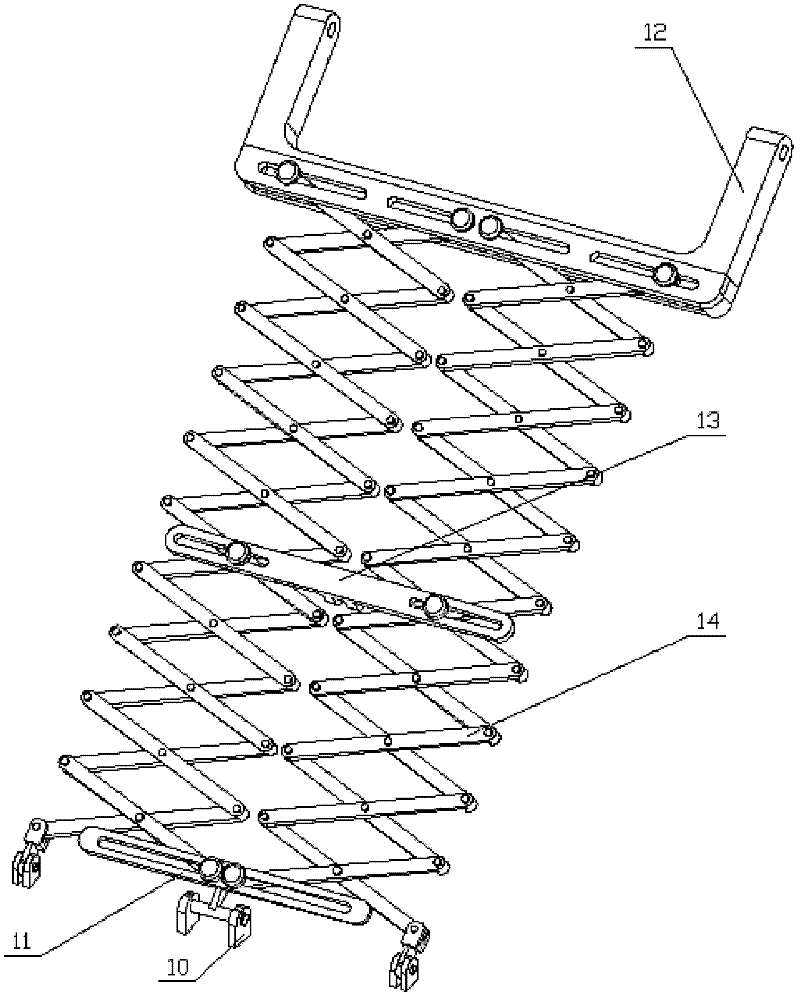

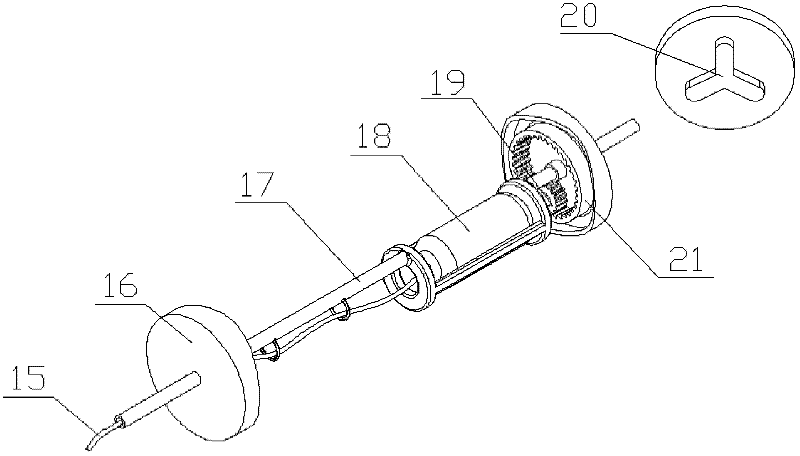

[0036] Such as figure 2 As shown, the lifting mechanism includes an arm frame 4 and a power unit arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com