Horizontal rotation type movable counter weight mechanism

A technology of horizontal rotation and counterweight, which is applied to cranes and other directions, can solve the problems of poor lifting moment balance effect and poor adaptability, and achieve the effect of improving lifting capacity, good adaptability and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

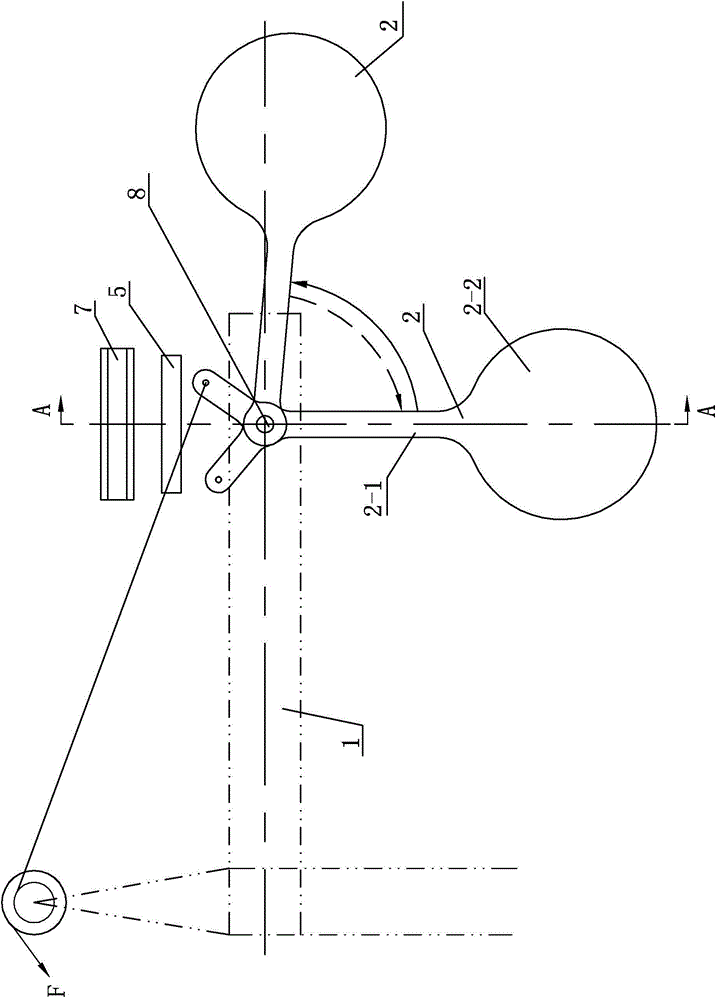

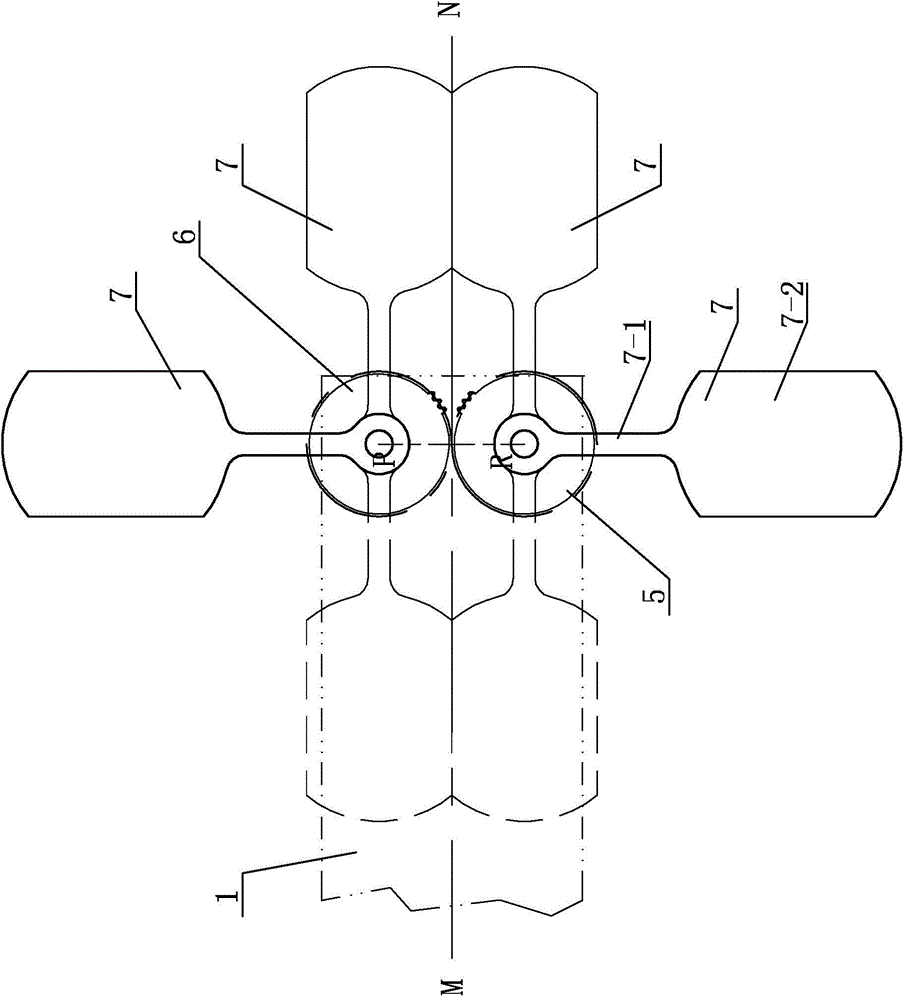

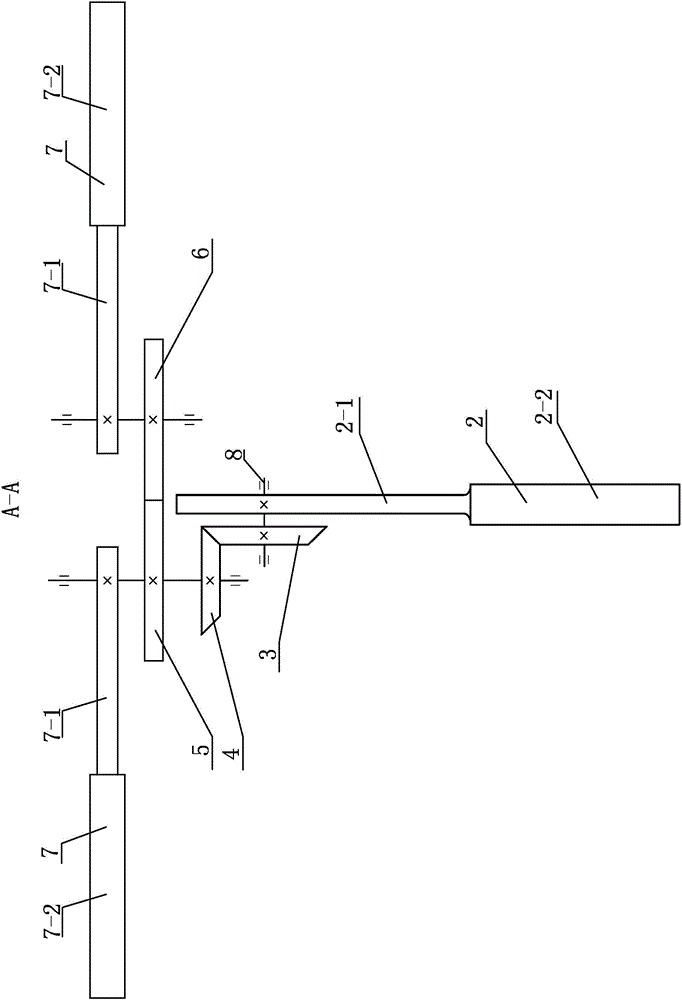

[0010] Specific implementation mode one: combine Figure 1-Figure 3 To illustrate this embodiment, a horizontally rotating movable counterweight mechanism in this embodiment includes a second counterweight 2, a first bevel gear 3, a second bevel gear 4, a first spur gear 5, a second spur gear 6 and Two first counterweights 7, the second counterweight 2 are installed on the balance arm 1 below the middle part of the connecting straight line PR of the two first counterweights 7 rotation centers, the second counterweight 2 can be positioned relative to the balance arm 1 Swing in the vertical plane, the second counterweight 2 swings in an angle range of 0° to 90°, the second counterweight 2 is connected with the force-bearing member of the tower crane that responds to the lifting moment, and the gear shaft of the first bevel gear 3 is installed with The second counterweight 2, the axial direction of the first bevel gear 3 is perpendicular to the vertical direction, the first bevel...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 and image 3 This embodiment is described. The second counterweight 2 in this embodiment is connected to the balance arm 1 through the horizontal shaft 8 provided on the balance arm 1. Swing in the vertical plane, the gear shaft of the first bevel gear 3 is connected with the horizontal rotating shaft 8 . With such arrangement, the connection is reliable and convenient, and the transmission is convenient. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination Figure 1-Figure 3 To describe this embodiment, the transmission ratio between the second bevel gear 4 and the first bevel gear 3 in this embodiment is 2:1. Such setting can well satisfy the actual transmission of the second counterweight and the two first counterweights. When the second counterweight rotates at an angle of 90 degrees, the two first counterweights rotate at an angle of 180 degrees to achieve reclining Optimum balance of moment and forward tilt moment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com