Full-automatic multifunctional wall plastering machine

A multi-functional, powder wall machine technology, applied in the direction of construction, building structure, etc., can solve the problems of inaccurate positioning and long moving positioning time, and achieve the effect of easy and convenient work, saving process time, and reducing walking positioning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

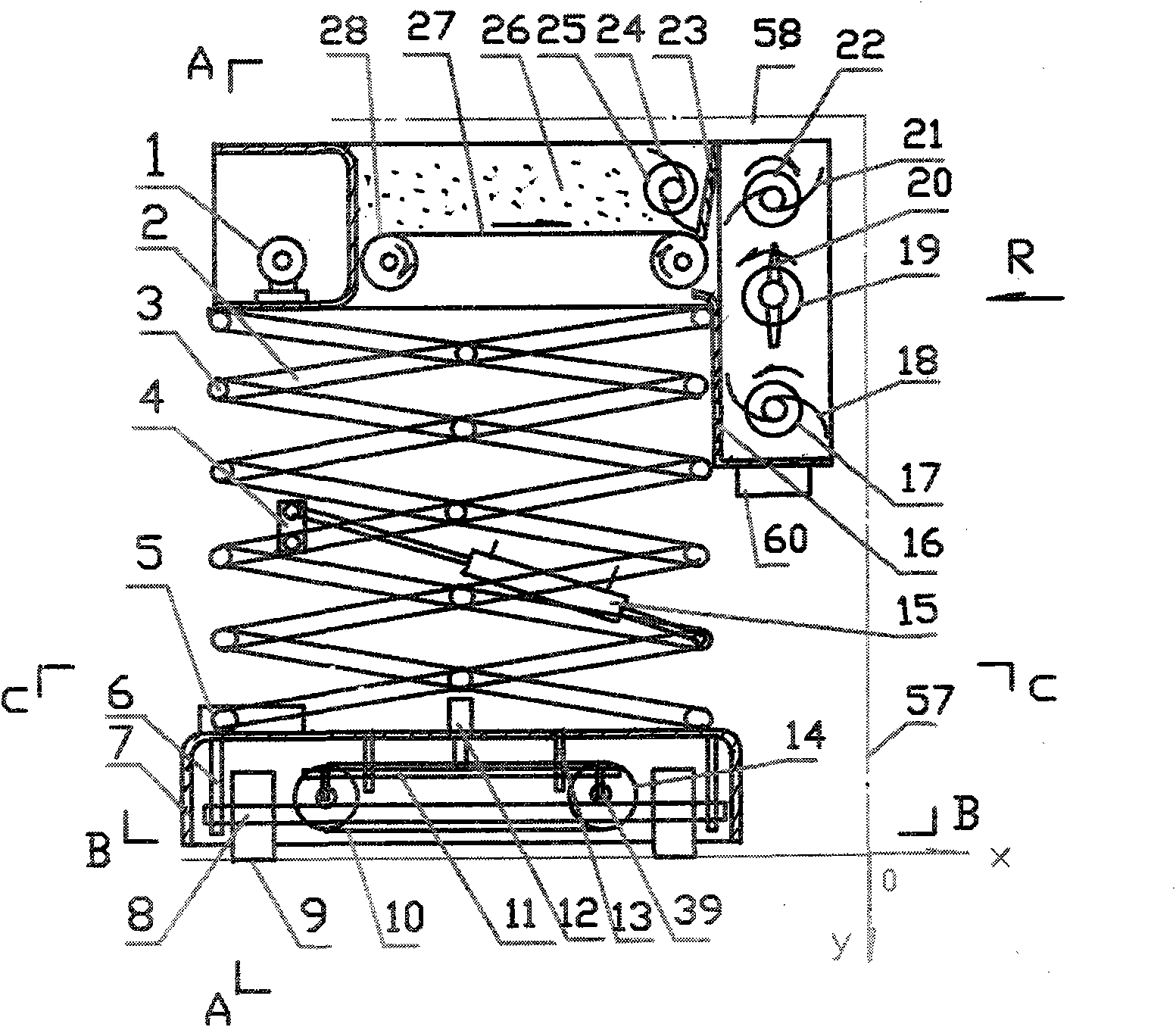

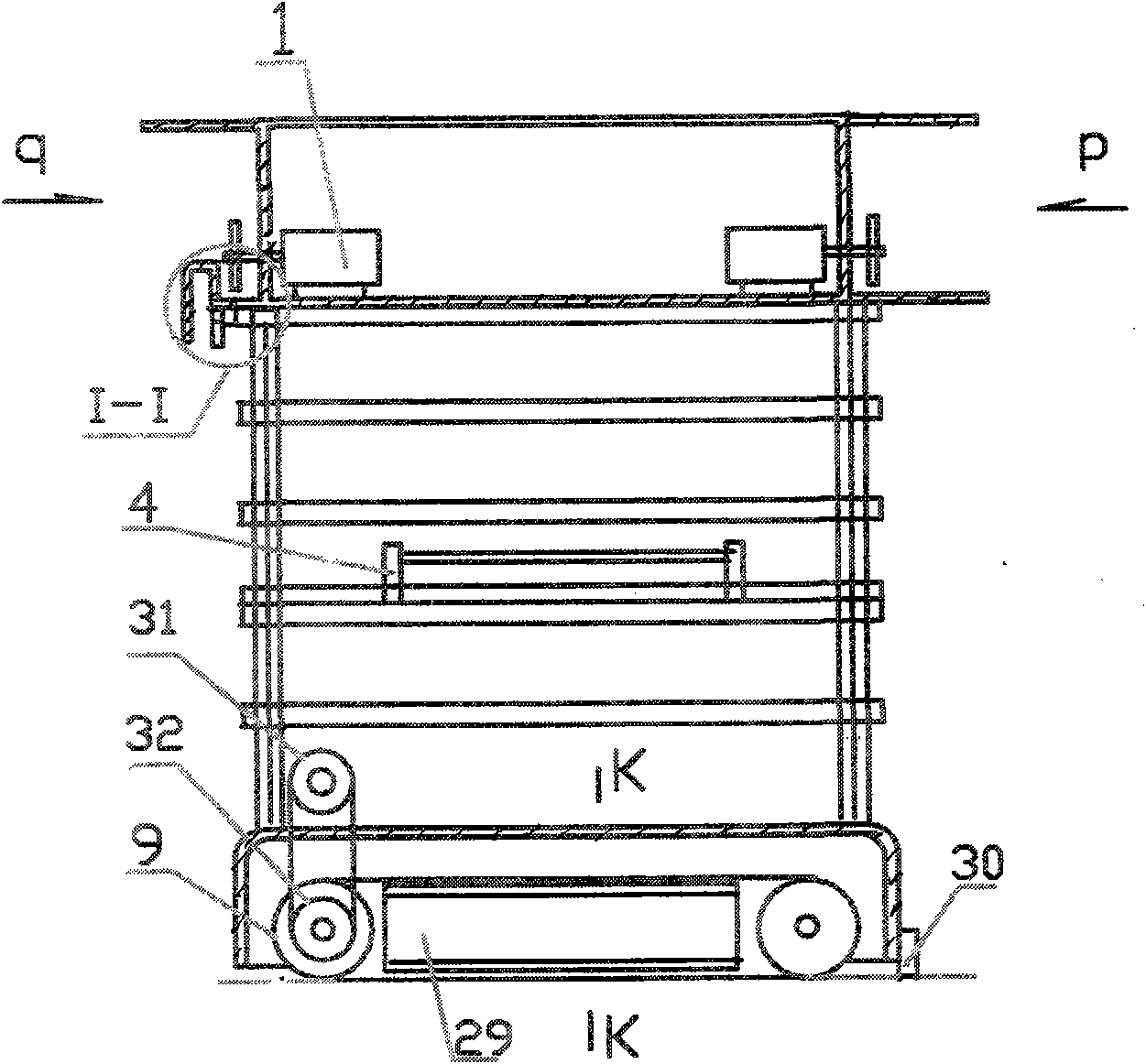

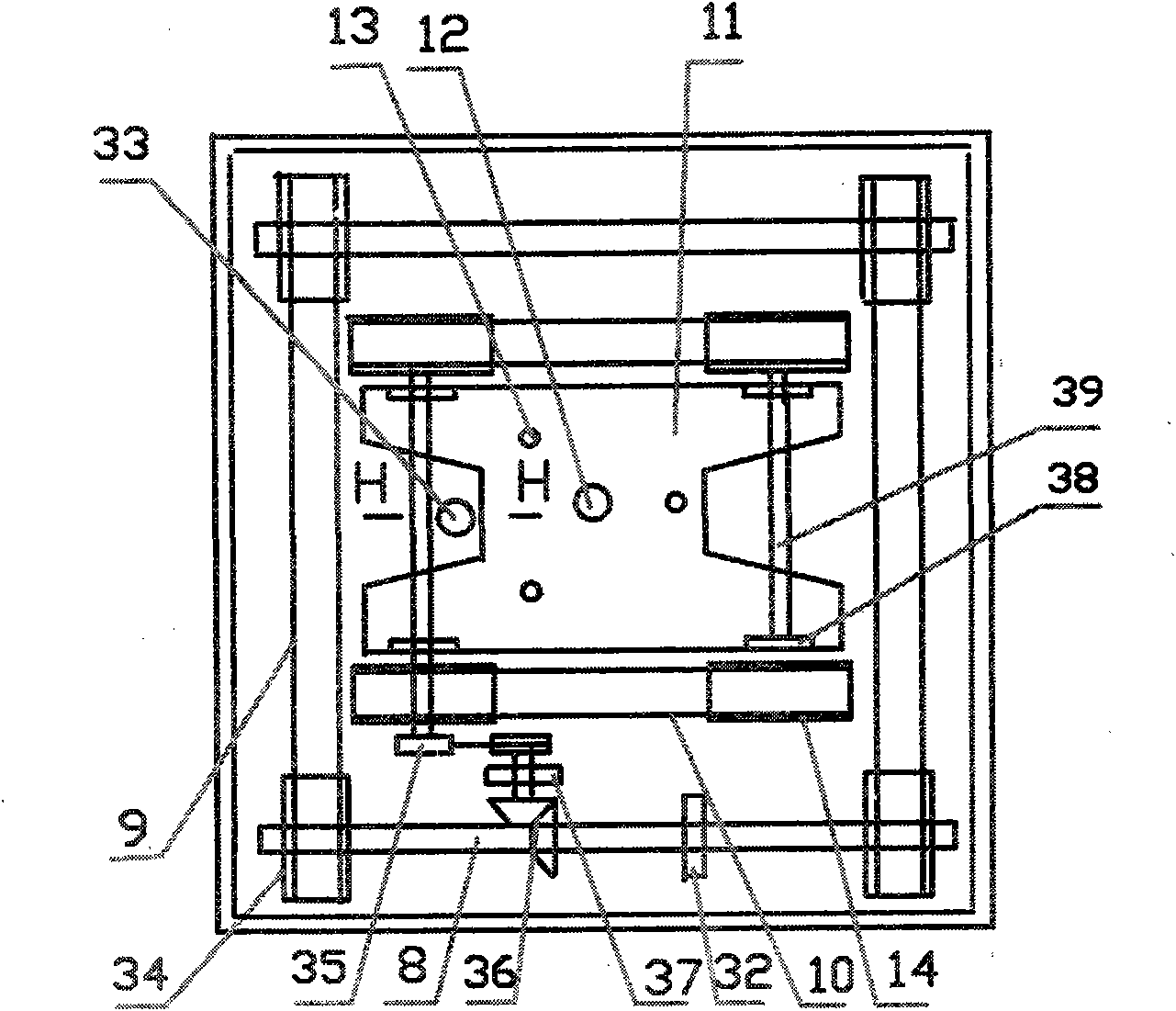

[0031] Attached below figure 1 to attach Figure 10 A detailed description of each technical solution:

[0032] The fully automatic multifunctional powder wall machine includes a control mechanism, a power mechanism, a transmission mechanism, a lifting mechanism fixed on the base 7 and a working mechanism supported on the lifting mechanism, and the working mechanism is arranged in the base so that the working mechanism can move horizontally and vertically synchronously. The crawler type walking positioning mechanism for positioning and steering. Described control mechanism comprises electromagnetic control valve 43 and remote control device; Figure 4 As shown, the power mechanism includes a fuel tank 45, an oil pump 44, an oil pump motor 63, and an oil pipe 47; figure 1 , Figure 6 and Figure 7 As shown, the transmission mechanism includes a motor I1 that drives three painting rollers to rotate, a transmission chain 61 and a conveyor roller 28 that drives the conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com