Full-automatic paint spraying machine

A technology of automatic paint spraying machine and paint sprayer, which is applied in the direction of pretreatment surface, coating, and surface coating liquid device, etc., which can solve the problem of unstable coating thickness, uneven coating quality, uneven thickness of spray paint, and inability to automate production and other problems, to achieve the effect of reducing labor intensity, high production efficiency, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

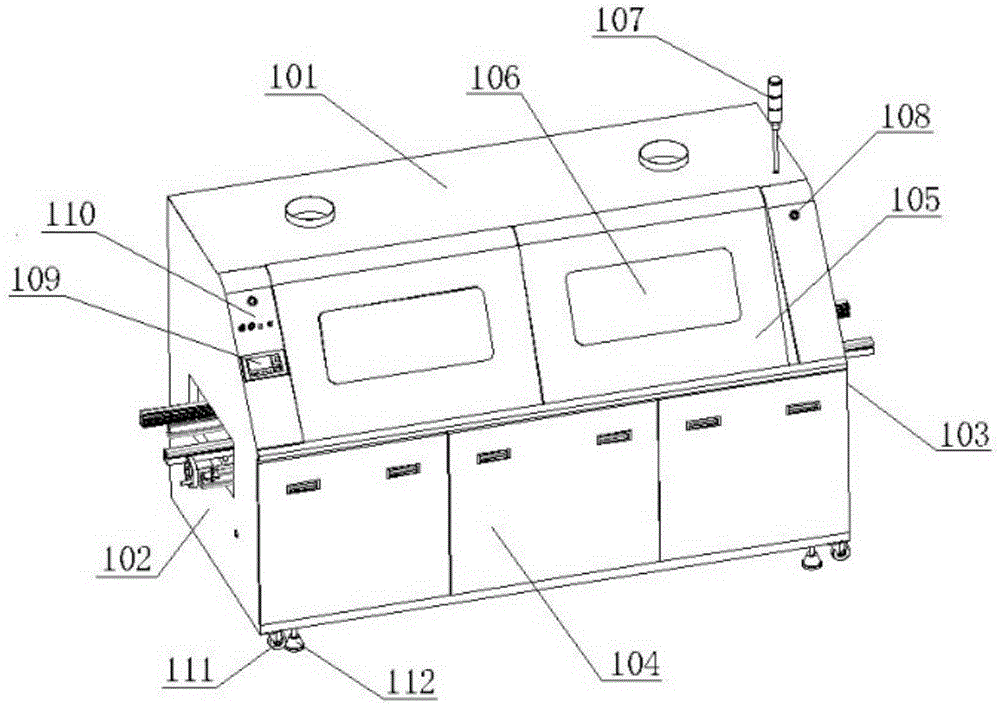

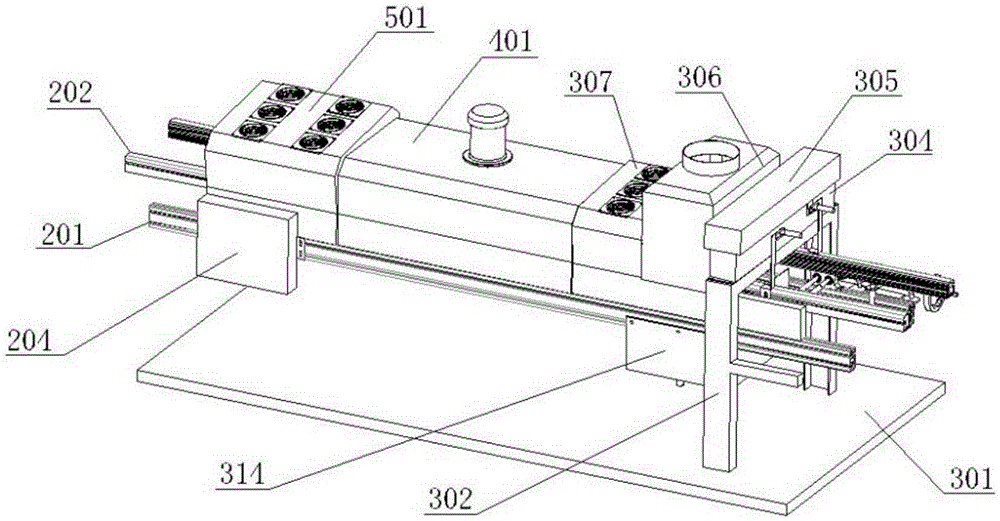

[0028] Such as Figure 1 to Figure 7 An automatic painting machine is shown, including a frame, a guide rail transportation system, a painting system, a drying system, a cooling system and a control system.

[0029] Such as figure 1 As shown, the frame includes a top plate 101, a left side plate 102, a right side plate 103, a front door plate 104, a front upper door plate 105 and a support 301, and the frame is welded by a square cold plate. Front upper door panel 105 middle part is provided with see-through window 106, and the four angles of frame bottom support 301 are all equipped with a castor 111 and a foot cup 112.

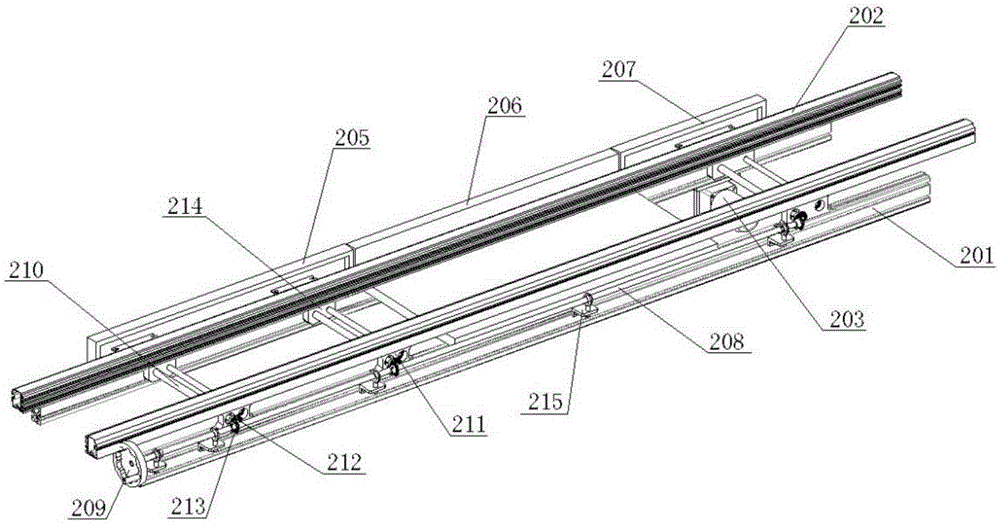

[0030] Such as image 3 As shown, the rail transportation system includes two fixed rails 201 and two movable rails 202 oppositely arranged, the fixed rails 201 are 40*80 rails, the movable rails 202 are 51*56 rails, and the movable rails 202 are located at Fix the top of the guide rail 201. A special stainless steel long-axis chain is installed on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com