Adhesive dispersing mechanism and adhesive dispersing amount metering control method applying same

A dispensing mechanism and dispensing technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of difficult adjustment of dispensing volume, influence of dispensing volume, slow dispensing speed, etc., and achieve precise control The effect of dispensing volume and improving dispensing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

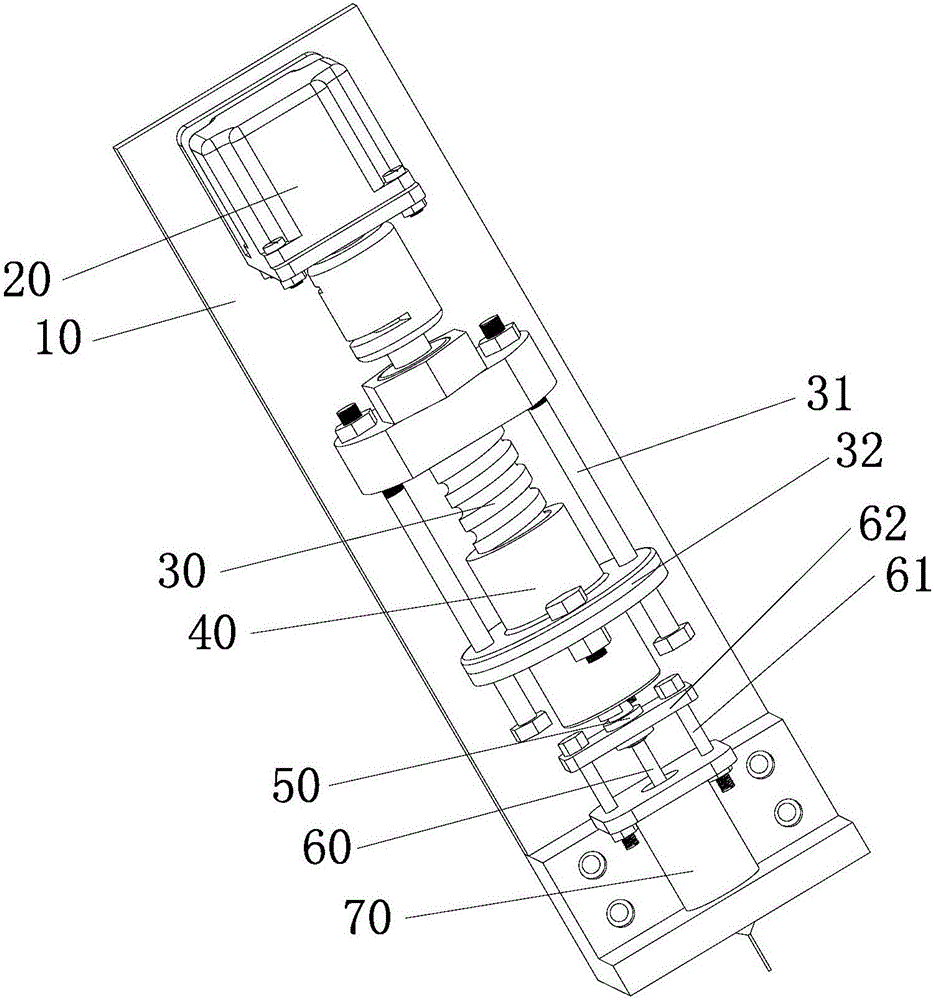

[0026] Such as figure 1 As shown, this embodiment provides a method for measuring and controlling the amount of glue dispensed. The glue dispenser used to realize this method needs to have a glue dispensing mechanism that can accurately control the amount of glue dispensed. Therefore, this embodiment also provides a method that can A dispensing mechanism that accurately controls the dispensing amount. The dispensing mechanism includes a base plate 10, a stepping motor 20 installed on the base plate 10, a ball screw 30 connected to the stepping motor 20, and a wire that cooperates with the ball screw 30. The rod nut 40, the flexible connection assembly 50 fixedly connected to the screw nut 40 at one end, the piston rod 60 fixedly connected to the other end of the flexible connection assembly 50, the piston (not shown) fixed on the piston rod 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com