Groove drum guide yarn electric folding-proof device employing self-adapting control and method thereof

A self-adaptive control and grooved drum technology, which is applied in transportation and packaging, textile and papermaking, and conveying filamentous materials, etc., can solve problems such as inappropriate curves, increased unwinding tension, and increased diameter and weight of yarn drums. , to achieve the effect of improving the degree of intelligence, simplifying the operation and improving the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

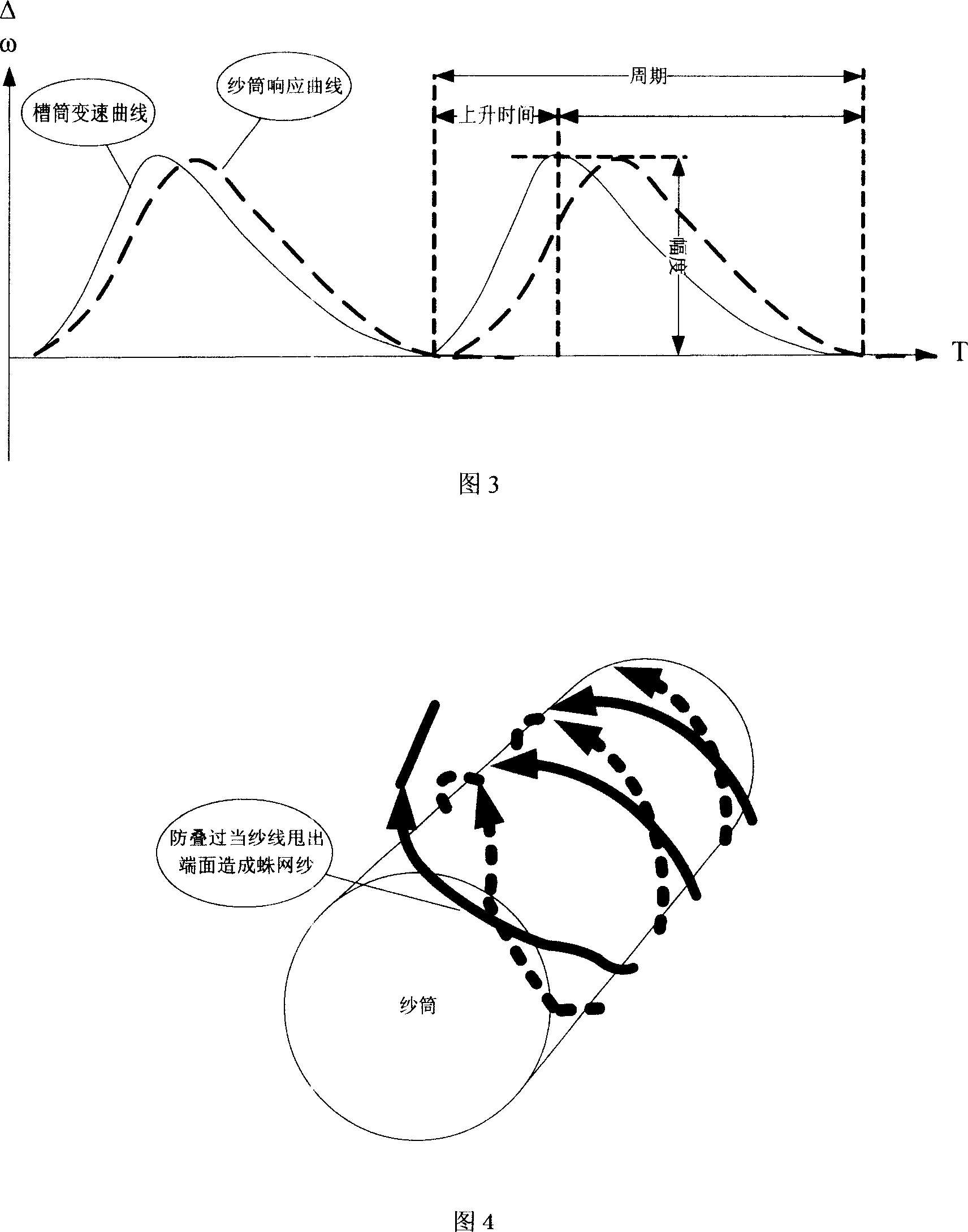

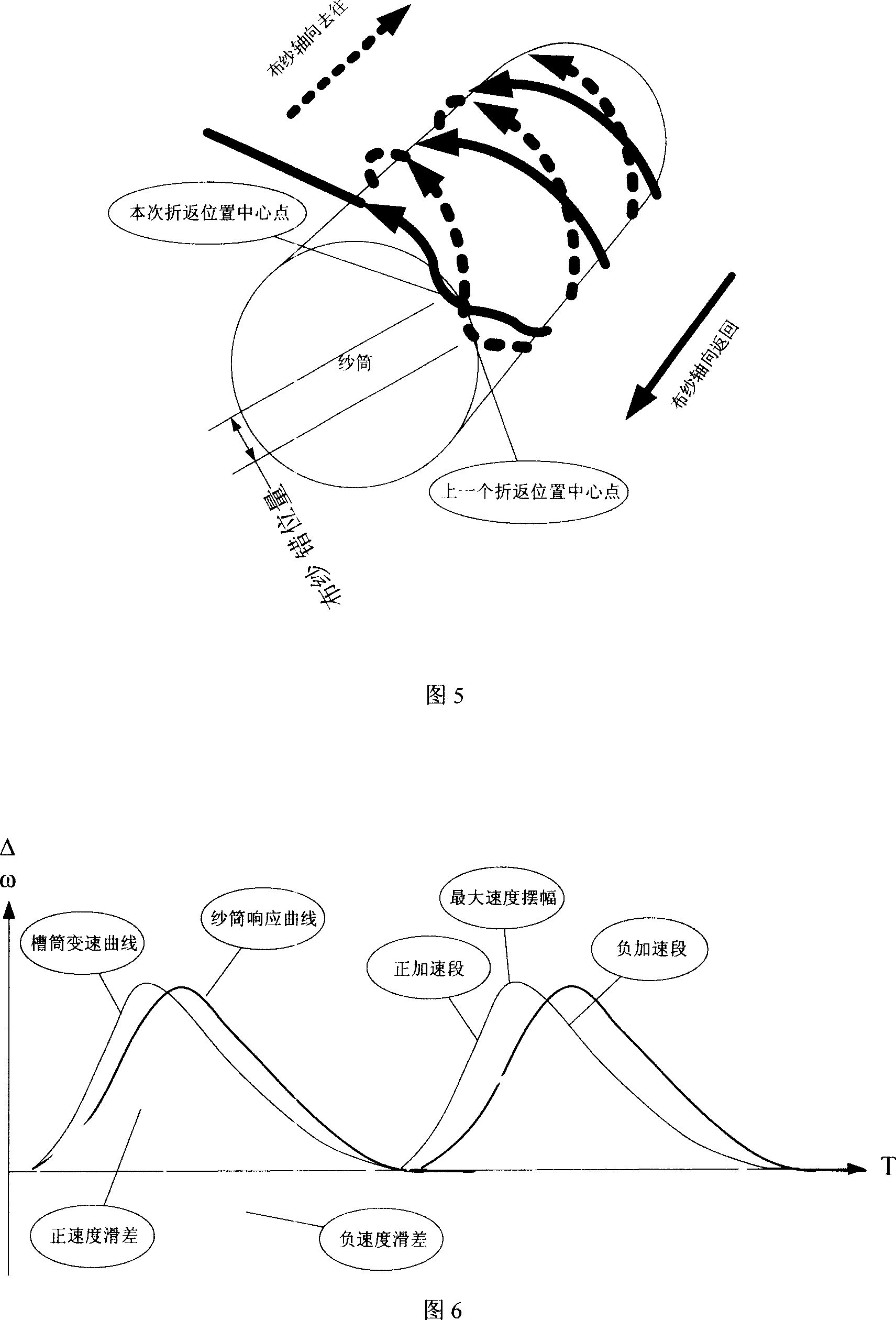

[0076] Referring to Fig. 5 to Fig. 10, in order to realize the object described in the present invention, the present invention has discovered the relation between the relevant parameter of anti-overlapping action, established mathematical model, derived mathematical relational expression:

[0077] Yarn misalignment amount = [instant speed of groove drum - instant speed of yarn drum × (winding speed of yarn drum / winding speed of groove drum)] × lead of each revolution of groove drum / winding speed of groove drum (Formula 1);

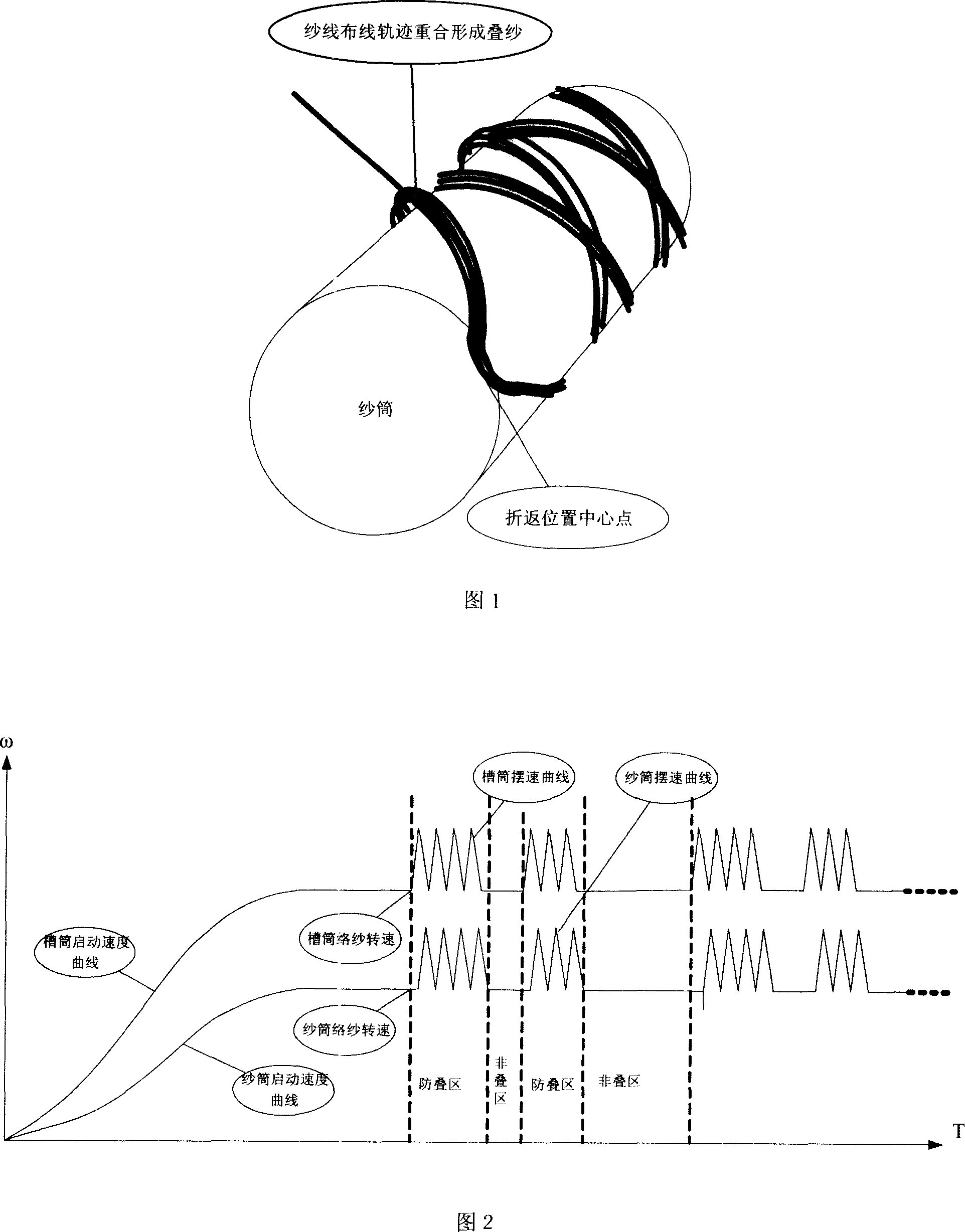

[0078] Yarn misalignment: when winding, the yarn travels back and forth along the axial direction of the bobbin for one round, and the stagger interval mm between the center points of the adjacent return positions near the end face;

[0079] Instantaneous rotational speed of the tank: when the sawtooth swing speed of the tank is detected, the rotational speed can be detected at any time;

[0080] Instantaneous speed of the bobbin: when the bobbin responds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com