Methoxy group naphthyl fluorescence marked water treating agent and its preparing method

A methoxynaphthalene, fluorescent labeling technology, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc. The effect of reducing interference, simplifying field operation, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Add 4.65g (19.99mmol) 4-chloro-1.8-naphthalic anhydride in a 250mL four-necked flask equipped with a thermometer, condenser, dropping funnel and constant speed stirring device, and use glacial acetic acid under stirring and heating 50mL was dissolved, and 2.05g (20.10mmol) of 3-dimethylaminopropylamine was added dropwise, and reacted under reflux for 5h after the drop was completed. Cool to room temperature, add a certain amount of water to dilute, then neutralize with 50% sodium hydroxide solution, cool, filter with suction to obtain brown solid A, and dry it.

[0018] Add 6g of solid A into a 250mL four-neck flask equipped with a thermometer, condenser, nitrogen vent tube and constant speed stirring device, dissolve it with methanol, add about 2g of sodium methoxide, and pass N 2 , Reacted under reflux for 6h. Cool to room temperature, add a certain amount of hydrochloric acid to neutralize, and then distill off the solvent methanol under reduced pressure. ...

Embodiment 2

[0020] Example 2 Add 3.5g of phosphorous acid, 0.5g of fluorescent monomer in Example 1 and 3.5mL of telogen isopropanol into the reactor, stir and mix evenly, raise the temperature to 80°C, and drop over Ammonium sulfate 1.33g aqueous solution and the mixture of monomeric acrylic acid 8.99g and acrylamide 17.65g were added dropwise in about 2 hours. Keep stirring at this temperature for 2-3 hours and cool to room temperature to obtain the product.

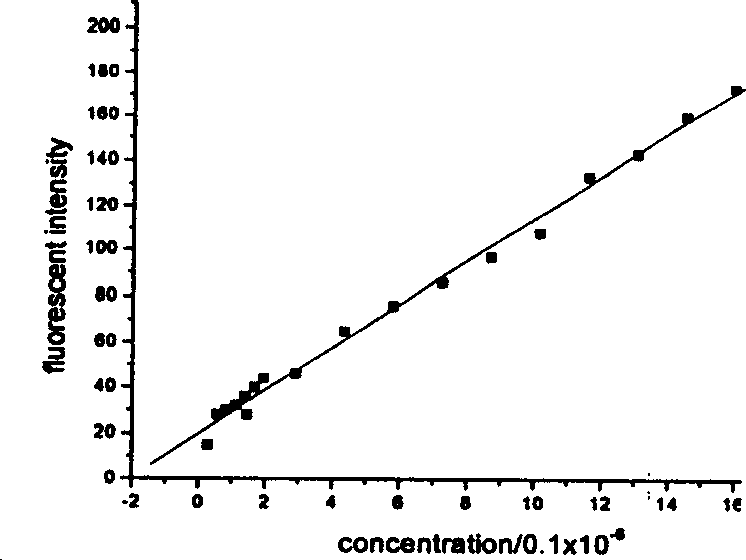

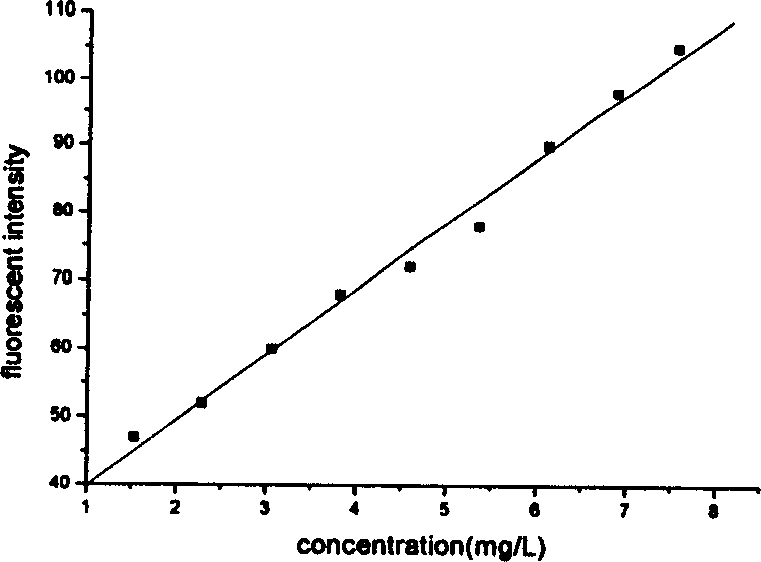

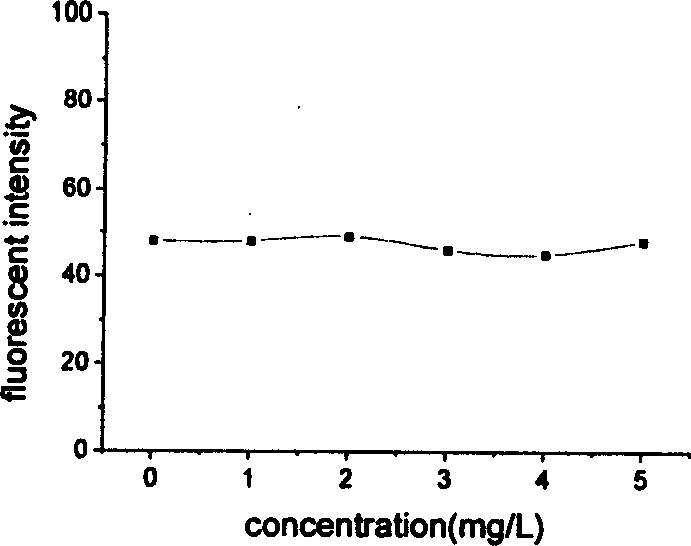

[0021] The UV absorption spectrum of the polymer is similar to that of the fluorescent monomer, respectively at 194nm -1 、240nm -1 、378nm -1 There is absorption. Its excitation and emission wavelengths are also 378nm and 450nm, respectively. The fluorescence intensity was enhanced after copolymerization. The reason for the enhanced fluorescence intensity may be due to the formation of hydrogen bonds after copolymerization, because some aromatic carbonyl compounds and nitrogen heterocyclic compounds, their (π, π * ) singlet en...

Embodiment 3

[0023] Example 3 Add 7.0 g of diethyl phosphite and 2.05 g of the fluorescent monomer in Example 1 into the reactor, stir and mix evenly, raise the temperature to 90°C, and add 3.52 g of ammonium persulfate aqueous solution and The mixture of monomeric acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid (17.25g) was added dropwise in 2.5h, then the reaction temperature was maintained and the reaction was stirred for 2h. After cooling, a yellow viscous substance was obtained, namely the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com