Method for determining duct piece splicing point position of universal ring for subway shield construction

A technology for shield segments and subway shields, which is applied in underground chambers, shaft equipment, earthwork drilling and mining, etc., and can solve problems such as the inability to easily, quickly and accurately determine the assembly points of general ring segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

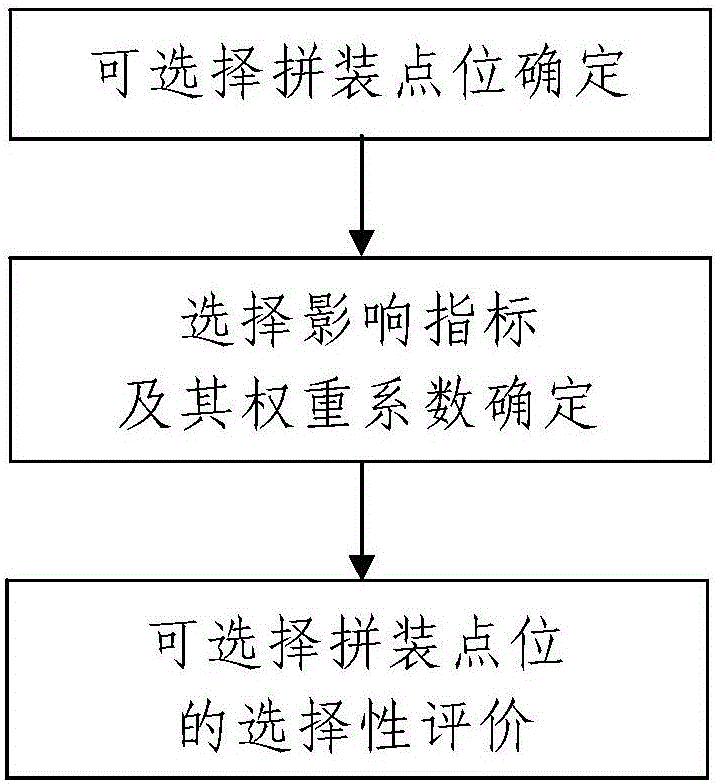

[0100] like figure 2 Shown is a method for determining the assembly point of the general ring segment in subway shield construction. The shield machine is used to excavate the tunnel to be constructed along the central axis of the tunnel from back to front. Shield segment assembly construction;

[0101] Before any ring shield segment is assembled and constructed, the segment assembly point of the current ring shield segment is determined first, and the process is as follows:

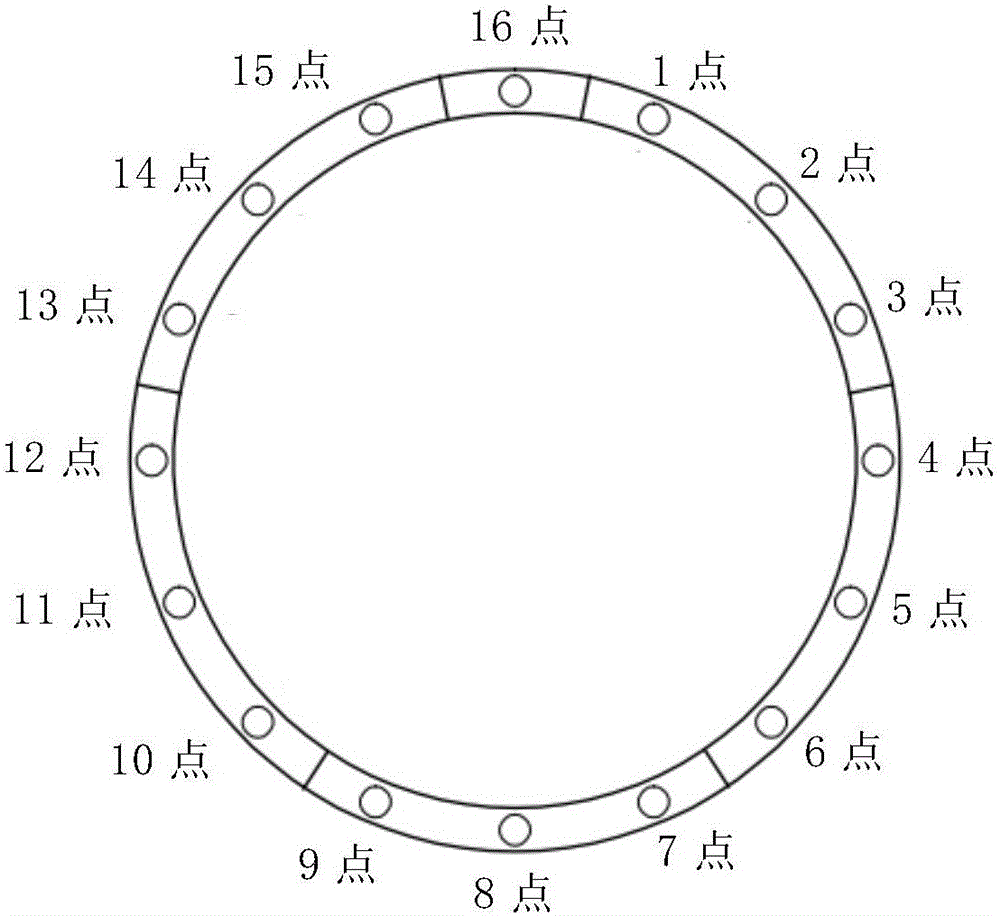

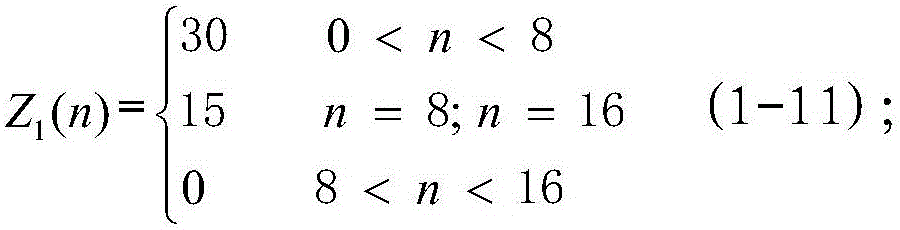

[0102] Step 1. Determining the optional assembly point: According to the staggered assembly method of the shield segment, and according to the segment assembly point of the previous shield segment, select the current ring shield from 16 assembly points to be selected 5 optional assembly points for structural segments;

[0103] The 16 assembly points to be selected are evenly arranged along the circumferential direction and they are 1 point, 2 points, ..., 16 points from front to back in the clockwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com