High temperature testing machine for gears

A technology for high-temperature gears and testing machines, applied in the testing of machine gears/transmission mechanisms, etc., can solve problems such as large gaps and large errors in measured data, and achieve the effects of fast heating speed, stable performance, and long test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

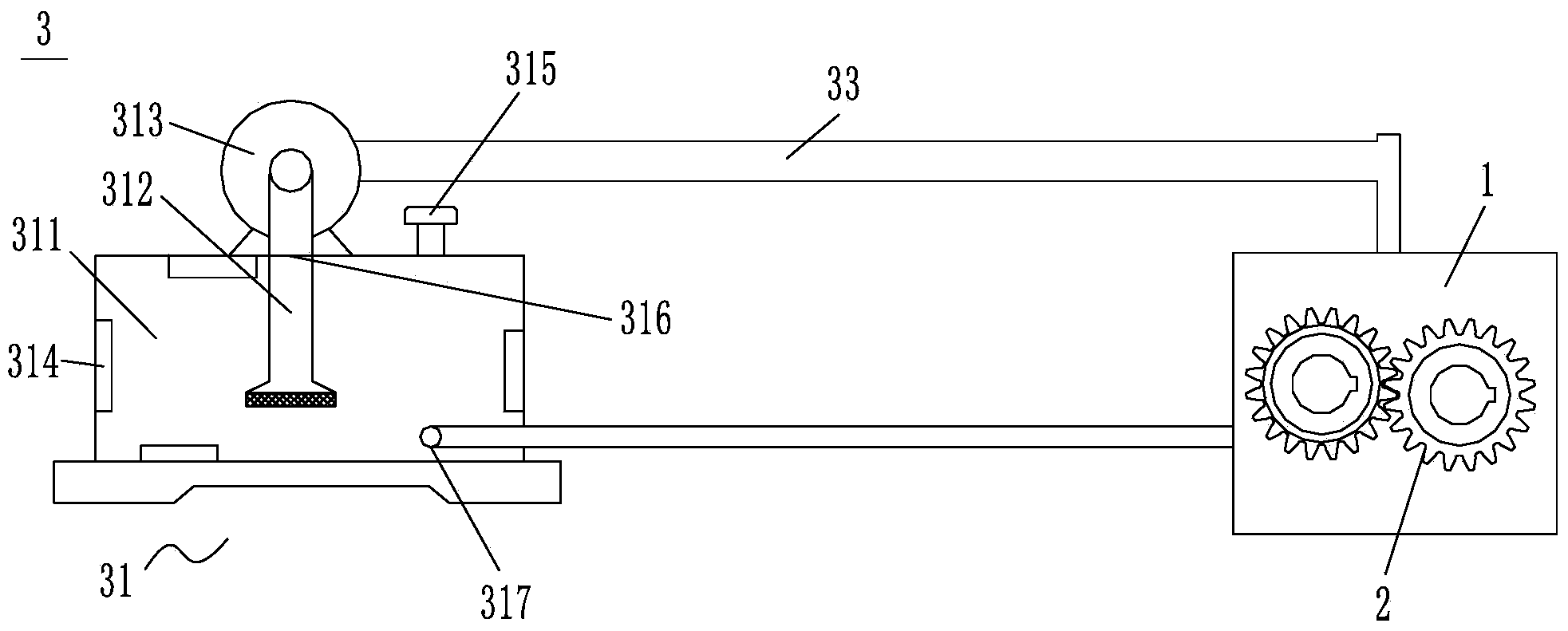

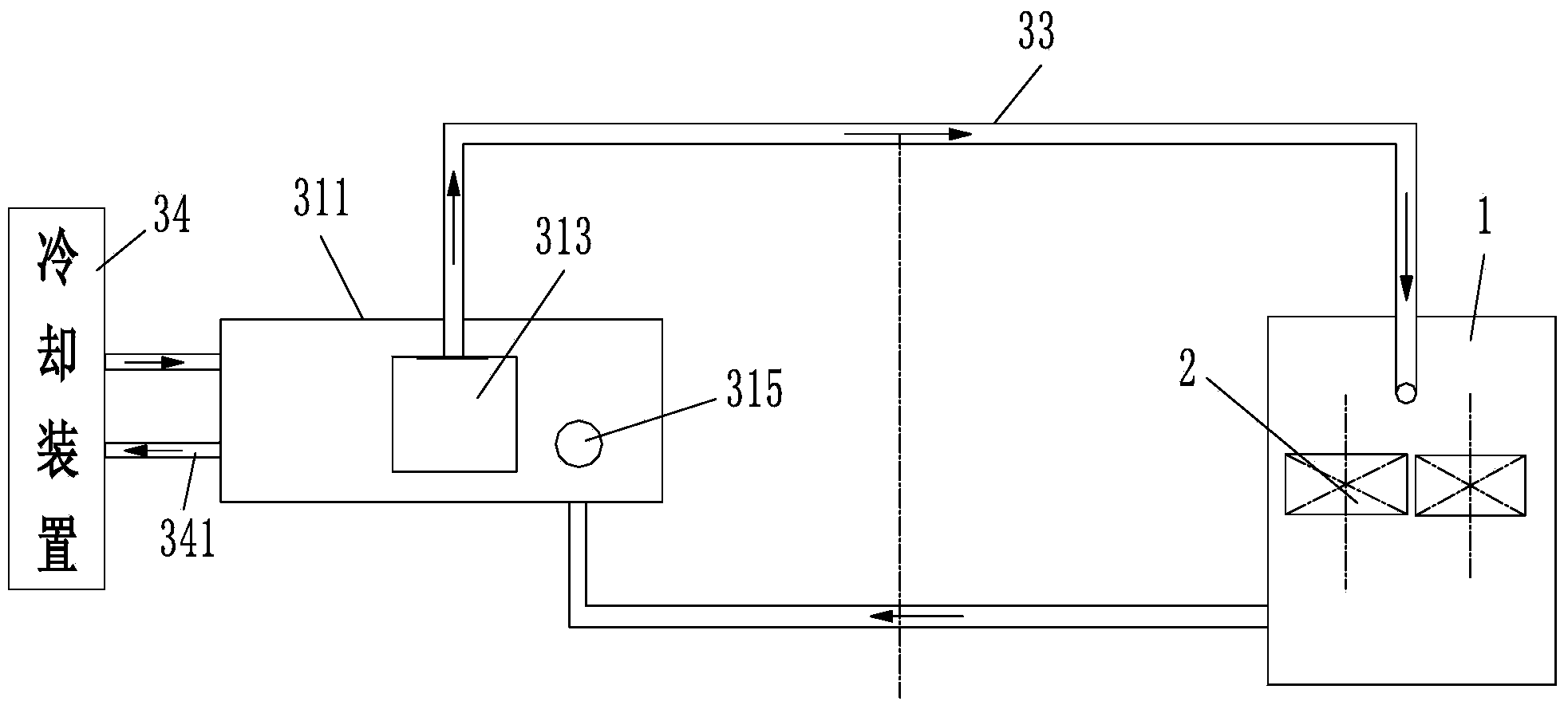

[0051] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

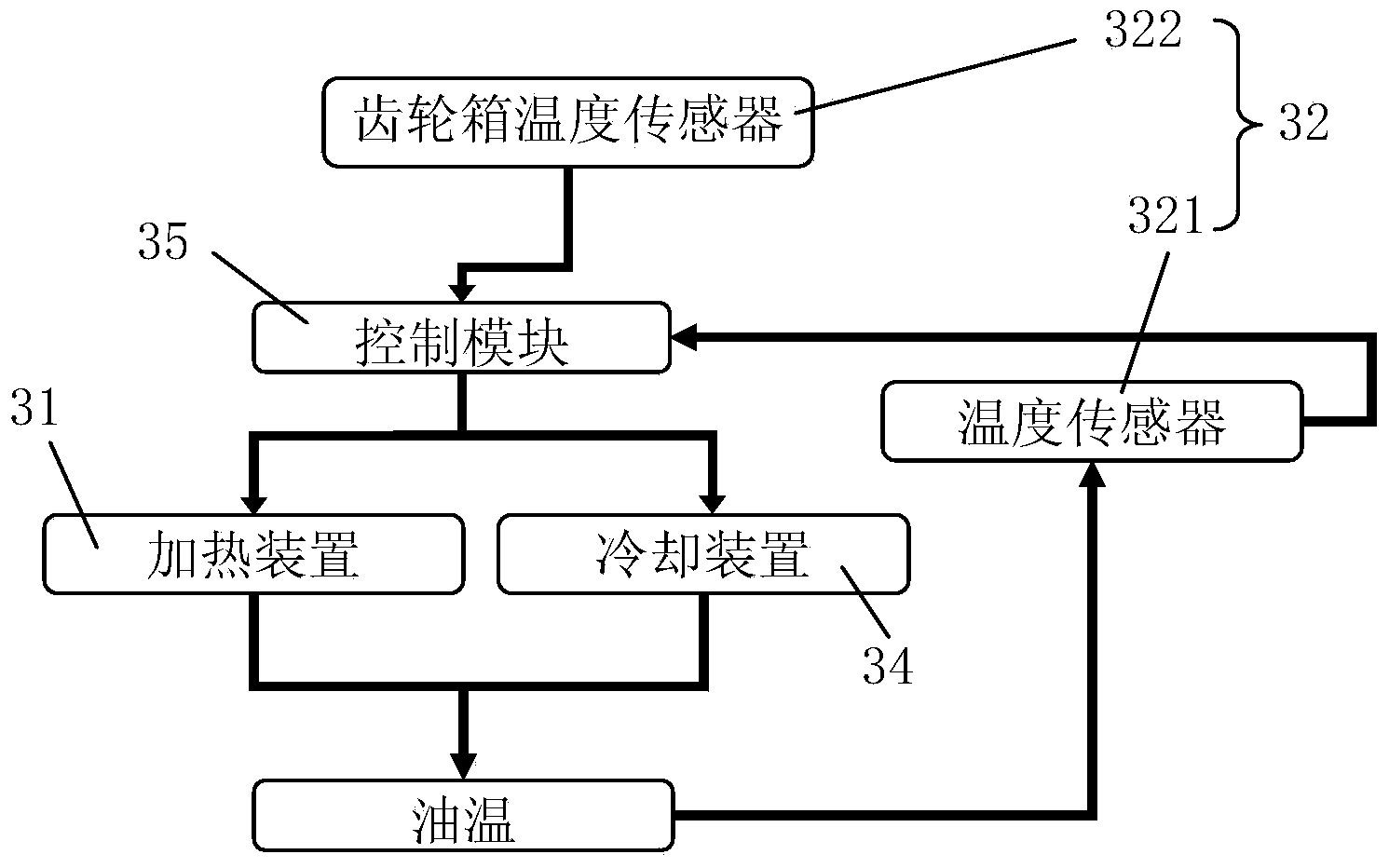

[0052] see figure 1 , figure 1 It is a structural schematic diagram of a gear testing machine according to an embodiment of the present invention. The gear testing machine of the present invention includes a gear transmission box 1 for gear test testing, the gear to be tested 2 is installed in the gear transmission box 1, and the gear transmission box 1 is connected with a temperature control system 3, and the temperature control The system 3 includes a heating device 31 and a temperature monitoring device 32, the heating device 31 is connected to the gear transmission box 1 through a pipeline 33, and the heating device 31 can transmit the heated lubricating oil to the In the gear transmission box 1, the gear 2 to be tested is heated and lubricated in an oil bath to simulate the working environment of the internal gear of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com