Air pressure blasting device used for simulating excavation with tunnel drill blasting method

A technology of drilling and blasting and air pressure, which is applied in the field of rock mechanics model test equipment, can solve the problems of no basis for similar indicators and the difficulty of preparing small equivalent explosives, etc., and achieve the effect of simple structure, simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

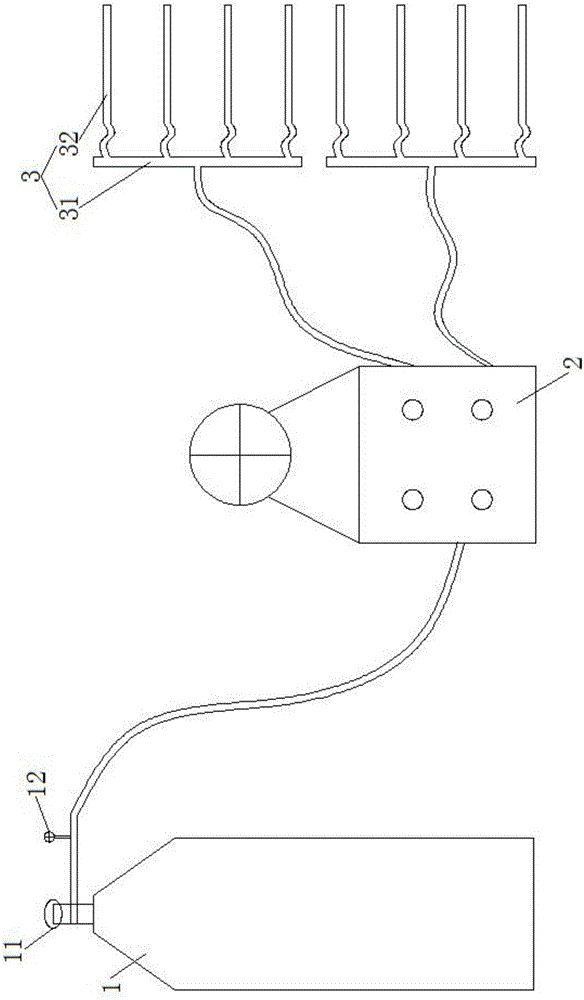

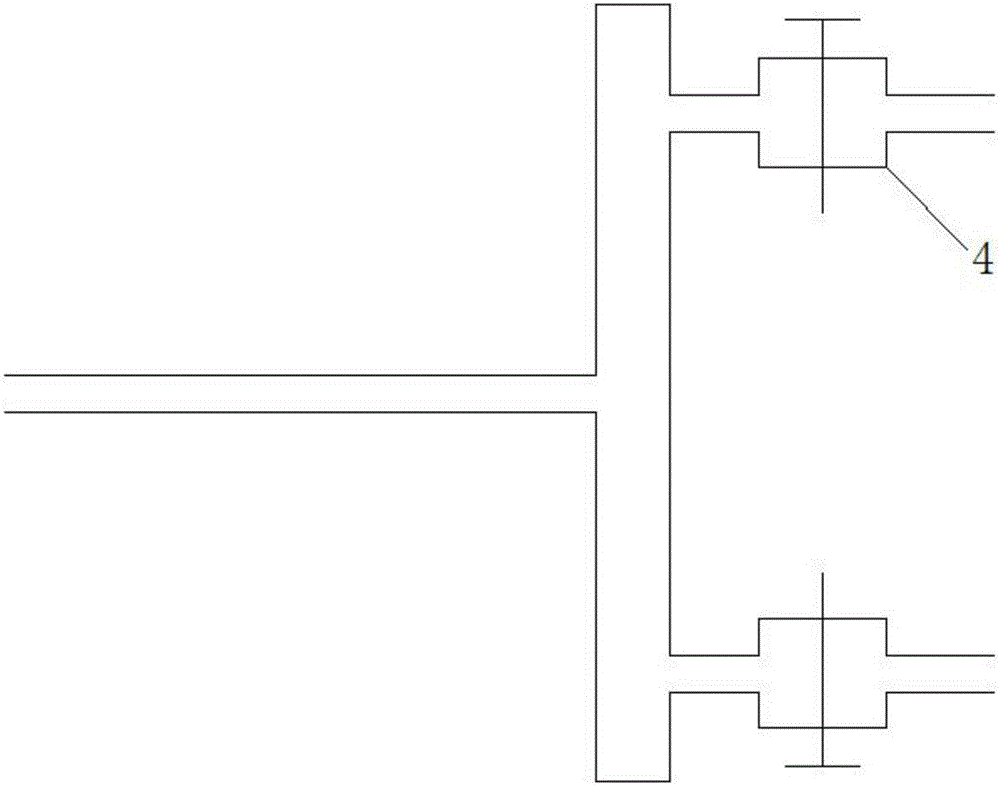

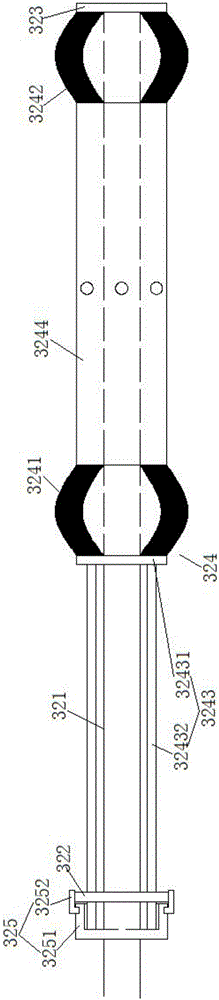

[0033] Example: such as Figures 1 to 3 As shown, the pneumatic blasting device excavated by the simulation tunnel drilling and blasting method of the present embodiment includes a self-pressurized liquid nitrogen tank 1, a console 2 and two groups of blasting pipe modules 3, and the above console 2 has two groups of SMC high pressure The switch 4 and the control module, the above-mentioned control module is respectively connected to two groups of the above-mentioned SMC high-pressure pressure switches 4 through lines, and is used to control the opening and closing of the SMC high-pressure switch 4 respectively, and the gas outlet of the above-mentioned self-pressurized liquid nitrogen tank 1 is respectively Two sets of SMC high-pressure pressure switches 4 are connected, and the above-mentioned two sets of SMC high-pressure pressure switches 4 are respectively connected to two sets of the above-mentioned blasting tube modules 3 through high-pressure hoses, and each set of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com