Hot-pressing heads and hot-pressing device consisting of same

A technology of hot pressing device and hot pressing head, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc. It can solve the problems of uneven hot pressing pressure of the hot pressing head, cumbersome pressure adjustment of the hot pressing head, etc., and achieve pressure regulation The process is simple and convenient, easy to detect and control, and the effect of maintaining a balanced output pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

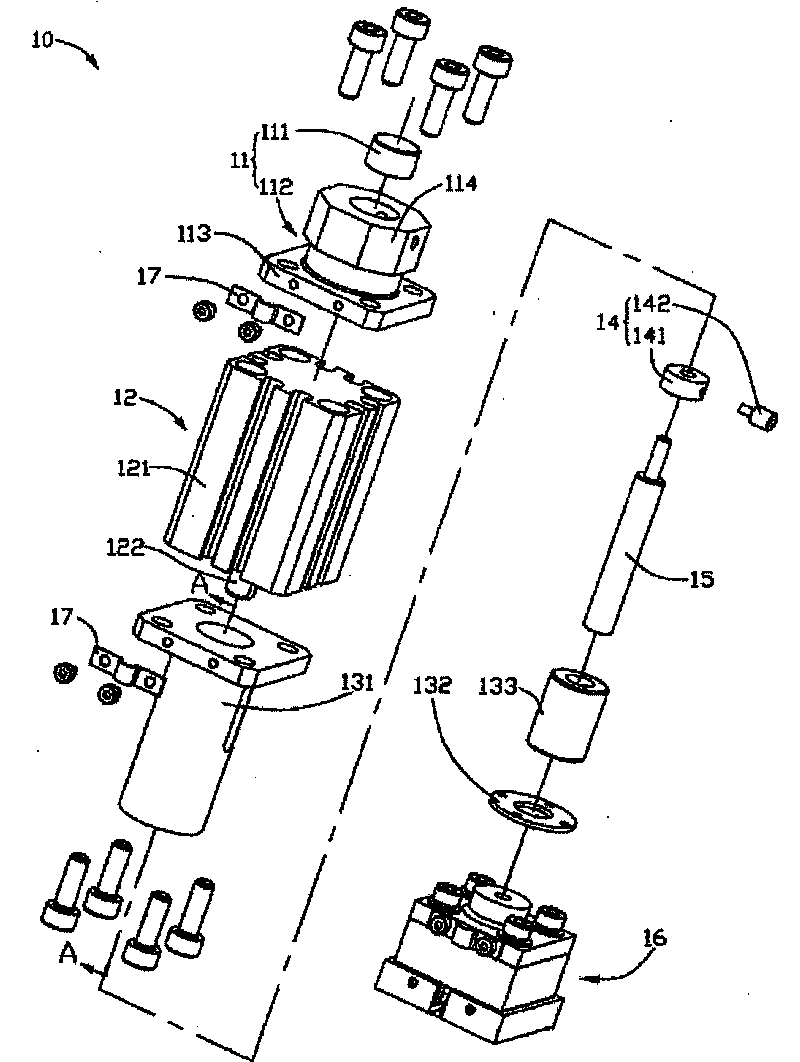

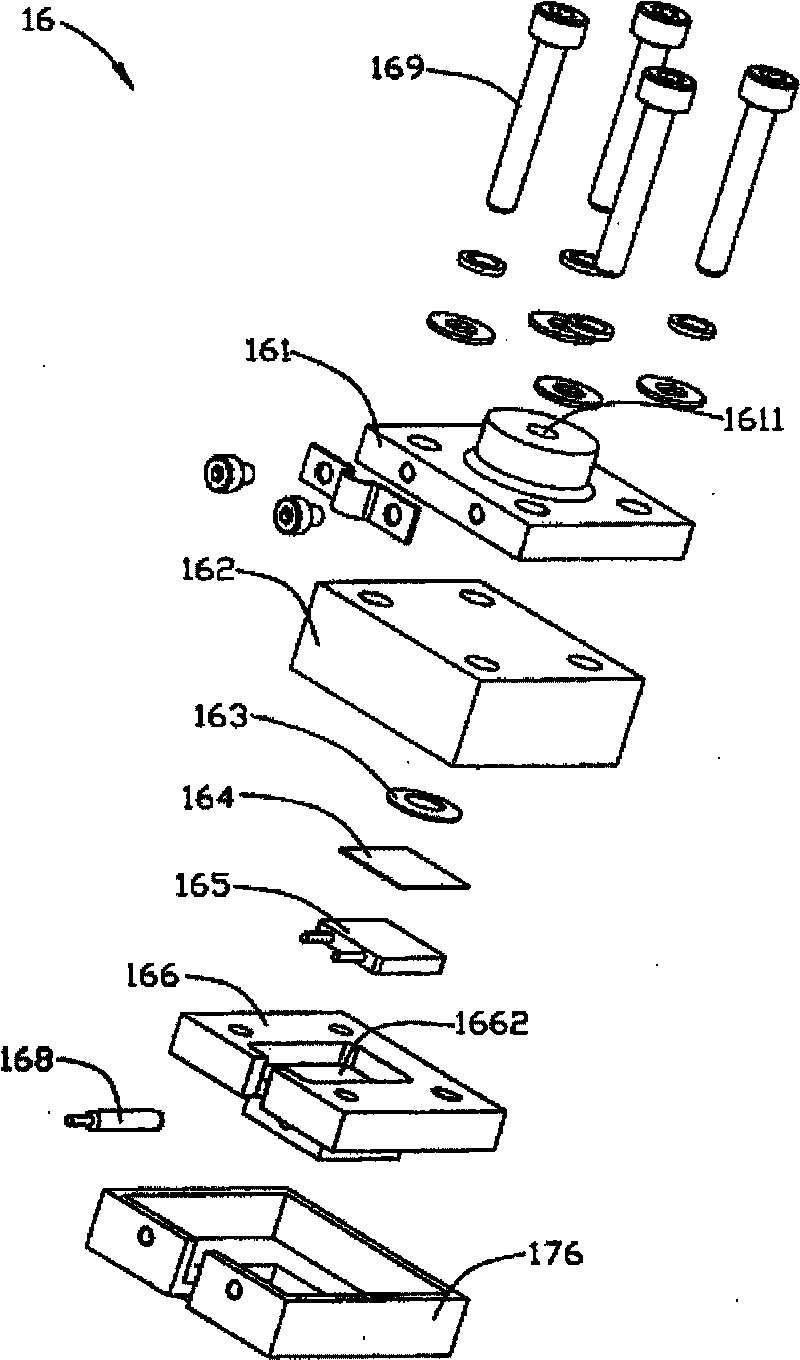

[0032] Such as figure 1 , figure 2 As shown, the embodiment of the thermal head 10 of the present invention includes a mounting assembly 11 , a cylinder 12 , a bearing assembly, a heating assembly 16 and several cable management clips 17 .

[0033] The mounting assembly 11 is installed on the cylinder block 121 at one end of the cylinder 12, and the heating assembly 16 is connected to the piston rod 122 at the other end of the cylinder 12 through a bearing assembly;

[0034] The cylinder 12 includes a cylinder body 121 and a piston rod 122, the piston rod 122 can slide back and forth relative to the cylinder body 121, the upper and lower ends of the cylinder body 121 are provided with mounting threaded holes, and the end of the piston rod 122 is provided with a threaded hole;

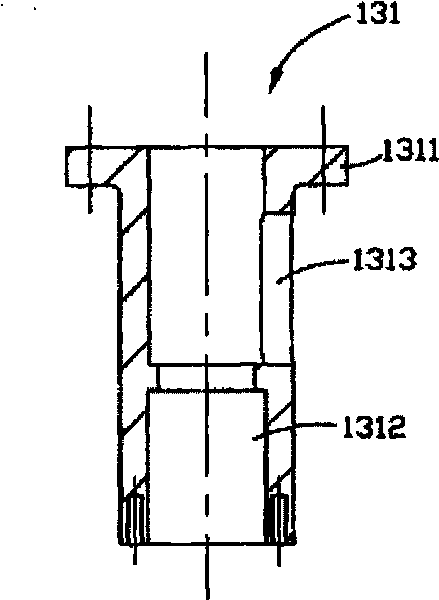

[0035] The bearing assembly includes a bearing seat 131, a blocking piece 132, a linear bearing 133, a slide rod 15 and a stopper 14. The bearing seat 131 is mounted on the cylinder body 121 of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com