Linear flow low noise liquid pump

A low-noise, liquid pump technology, applied in the direction of liquid fuel engines, pumps, pump components, etc., can solve the problems of large liquid output pressure fluctuations, fluctuating output liquid pressure, high plunger pump pressure, etc., to achieve uniform output pressure, tube The road is smooth and the sealing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

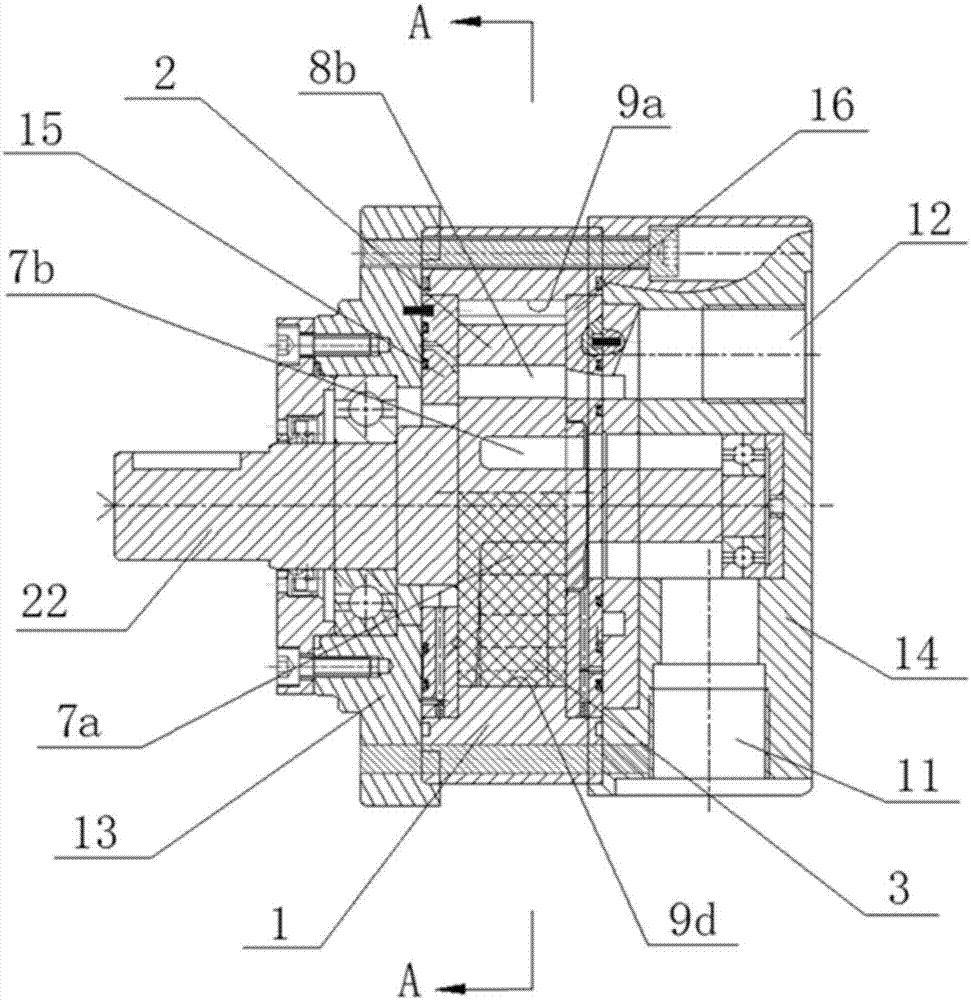

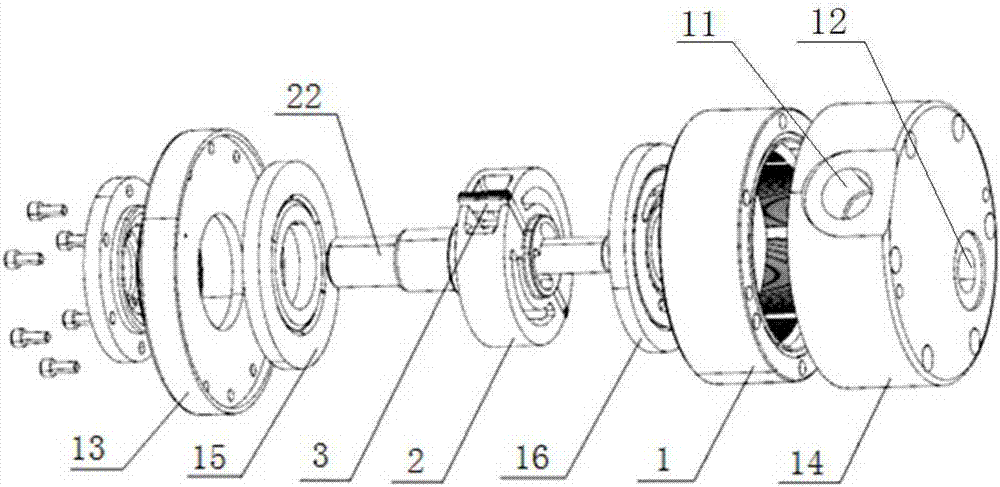

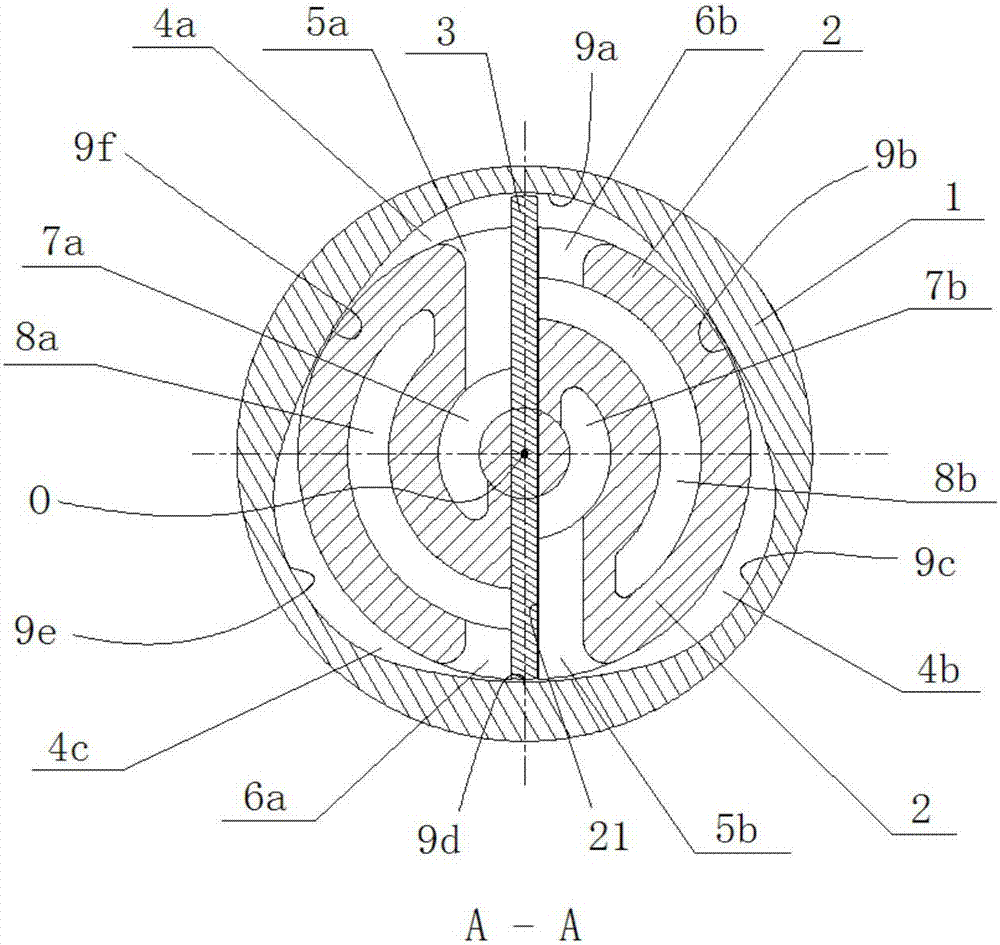

[0040] See Figure 1-Figure 5 , a linear flow low-noise liquid pump, including a casing, an input shaft 22 extending into the casing, a stator 1 fixed in the casing, a rotor 2 arranged on the inner ring of the stator 1, and blades of an integral rigid sheet structure 3. The input shaft 22 and the rotor 2 have a rigid structure or a rigid integrated structure; the wall surface of the inner ring of the stator 1 is a variable-diameter curved surface, the wall surface of the outer ring of the rotor 2 is an equal-diameter curved surface, and the inner ring of the stator 1 passes through all radial lines of the rotor center O The lengths are equal, the variable diameter surface of the inner ring of the stator 1 is divided into three equal parts, and the size and direction of each equal part are the same. Fitting, the three curved surfaces of 9a, 9c, 9e on the inner wall of the stator and the outer ring of the rotor form three isolated working cavities 4a, 4b, 4c; the rotor 2 is prov...

Embodiment 2

[0048] When the blade 3 rotates with the rotor 2, it is constrained by the variable diameter surface of the stator 1, and reciprocates in the radial direction. Taking into account the pressure of the blade 3 on the inner wall of the stator 1, the sealing effect of the blade 3 in the radial direction, and the needs of actual engineering, the following examples list several blade forms, but the protection scope of this patent is not limited to the following embodiments form.

[0049] Blade optimization 1: The blade is in the form of a master piece:

[0050] See Figure 9 , the blade includes a mother blade 31 and a daughter blade 32, the mother blade 31 is arranged in the blade groove 21, the two ends of the mother blade 31 are provided with a guide groove 33 opening toward the inner wall of the stator 1, and the daughter blade 32 is arranged in the corresponding guide groove 33 and move freely in the guide groove 33.

[0051] The thrust of the sub-blade 32 moving outwards co...

Embodiment 3

[0057] See Figure 12-Figure 16 A high-pressure chamber 8 is provided on one side of the rotor 2 facing the input shaft 22, and a low-pressure chamber 7 is provided on the other side of the rotor 2. The high-pressure chamber 8 and the low-pressure chamber 7 are separated by a separation plate 25, the liquid inlet 5 communicates with the low-pressure chamber 7, and the outlet The liquid holes 6a, 6b are connected to the cavities 8a, 8b respectively, and the liquid inlet holes 5a, 5b are respectively connected to the cavities 7a, 7b; the high-pressure balance ring 18 and the inner rotor 2 are an integrated structure or a rigid structure, and the high-pressure balance ring The function of 18 is to counteract the thrust of the high-pressure liquid through the front end cover 13 to the high-pressure chamber 8 . Among the figure, 23 is the spline shaft of the rotor 2, and 21 is the blade groove.

[0058] The working mechanism of embodiment 3 is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com