Cast iron product special-use gas nitrogen carbon oxygen QPQ (Quench-Polish-Quench) multicomponent composite co-infiltrating furnace

A multi-component composite, cast iron product technology, applied in metal material coating process, coating, solid-state diffusion coating, etc. Oxygen multi-composite co-infiltration and other problems, to achieve the effect of easy control of thickness, simple structure and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

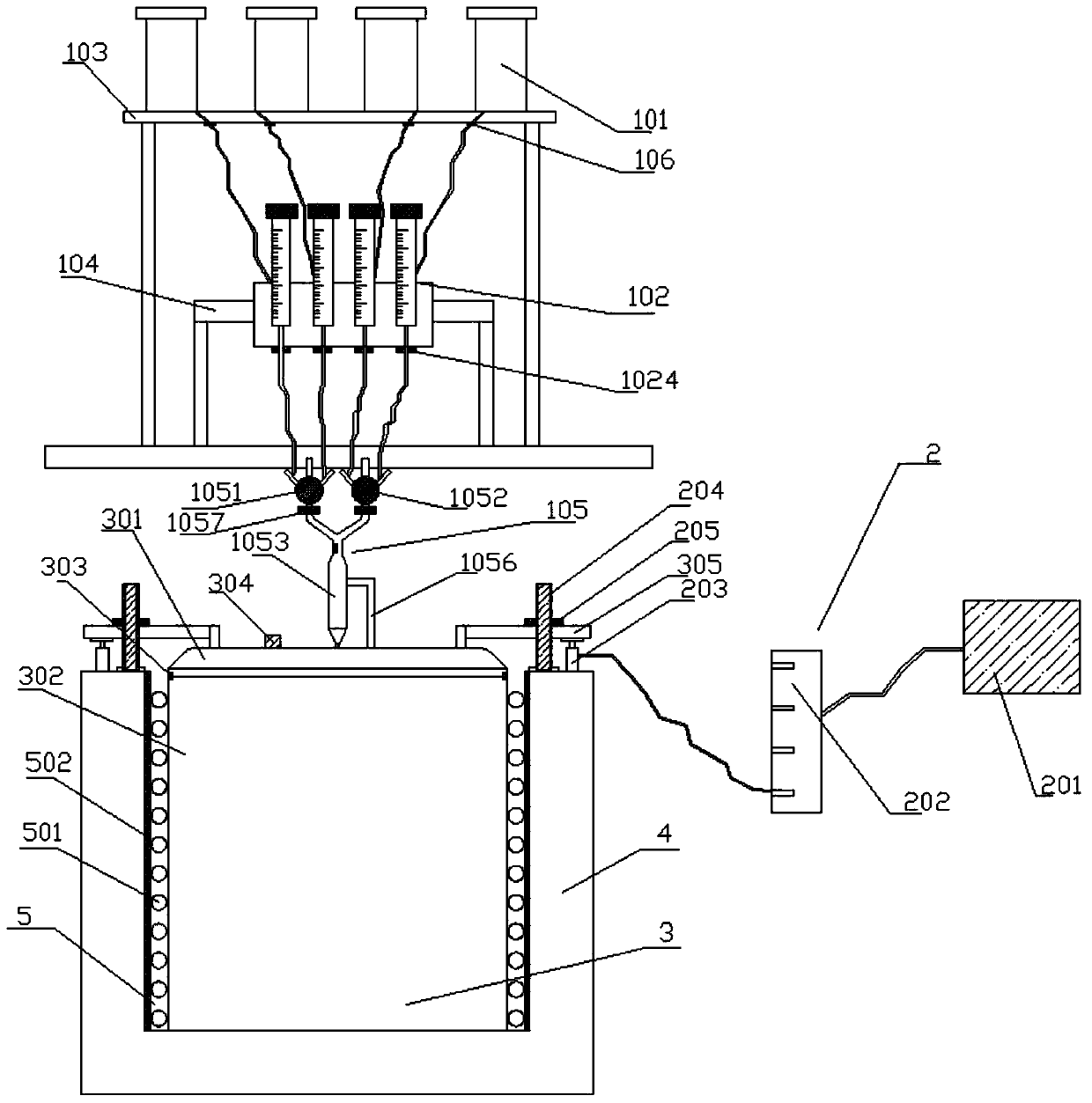

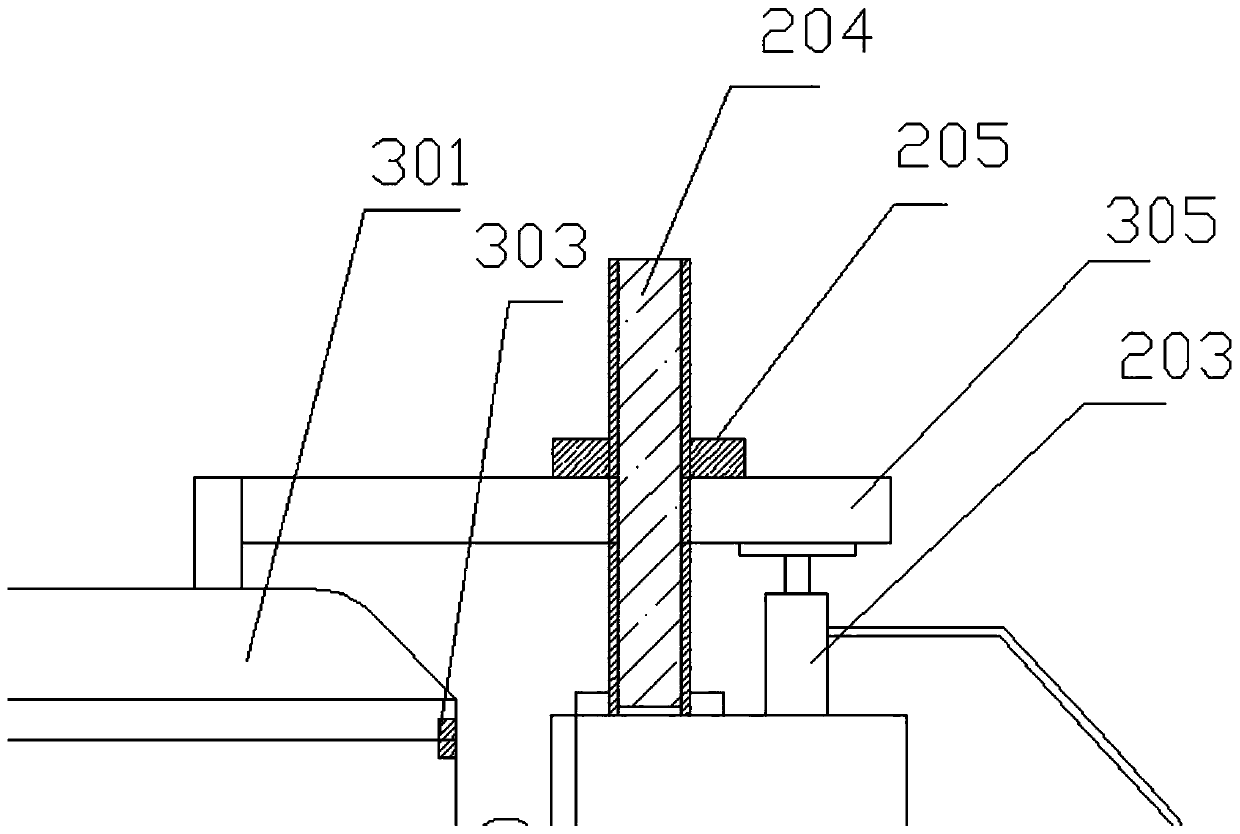

[0033] Such as Figure 1~4As shown, a gas nitrogen carbon oxygen QPQ multi-component compound co-infiltration furnace dedicated to cast iron products includes a drip irrigation assembly 1, a lifting assembly 2, a co-infiltration furnace 3 and an outer barrel 4; A heating chamber 5 matching the furnace 3, the co-infiltration furnace 3 is arranged in the heating chamber 5, the end of the drip irrigation assembly 1 is connected to the co-infiltration furnace 3, and the drip irrigation assembly 1 drips the medicament into the co-infiltration furnace 3 , so that the agent reacts with the surface of the workpiece to form a dense compound layer; the lifting assembly 2 is connected to the furnace cover 301 of the co-infiltration furnace 3, and the furnace cover 301 of the co-infiltration furnace 3 can be lifted or lowered smoothly and evenly through the lifting assembly 2 , so that the pressure in the co-infiltration furnace 3 is balanced and the pressure is stable. When operating the...

Embodiment 2

[0049] This embodiment provides a control method for the gas nitrogen carbon oxygen QPQ multi-element compound co-infiltration furnace 3 dedicated to cast iron products:

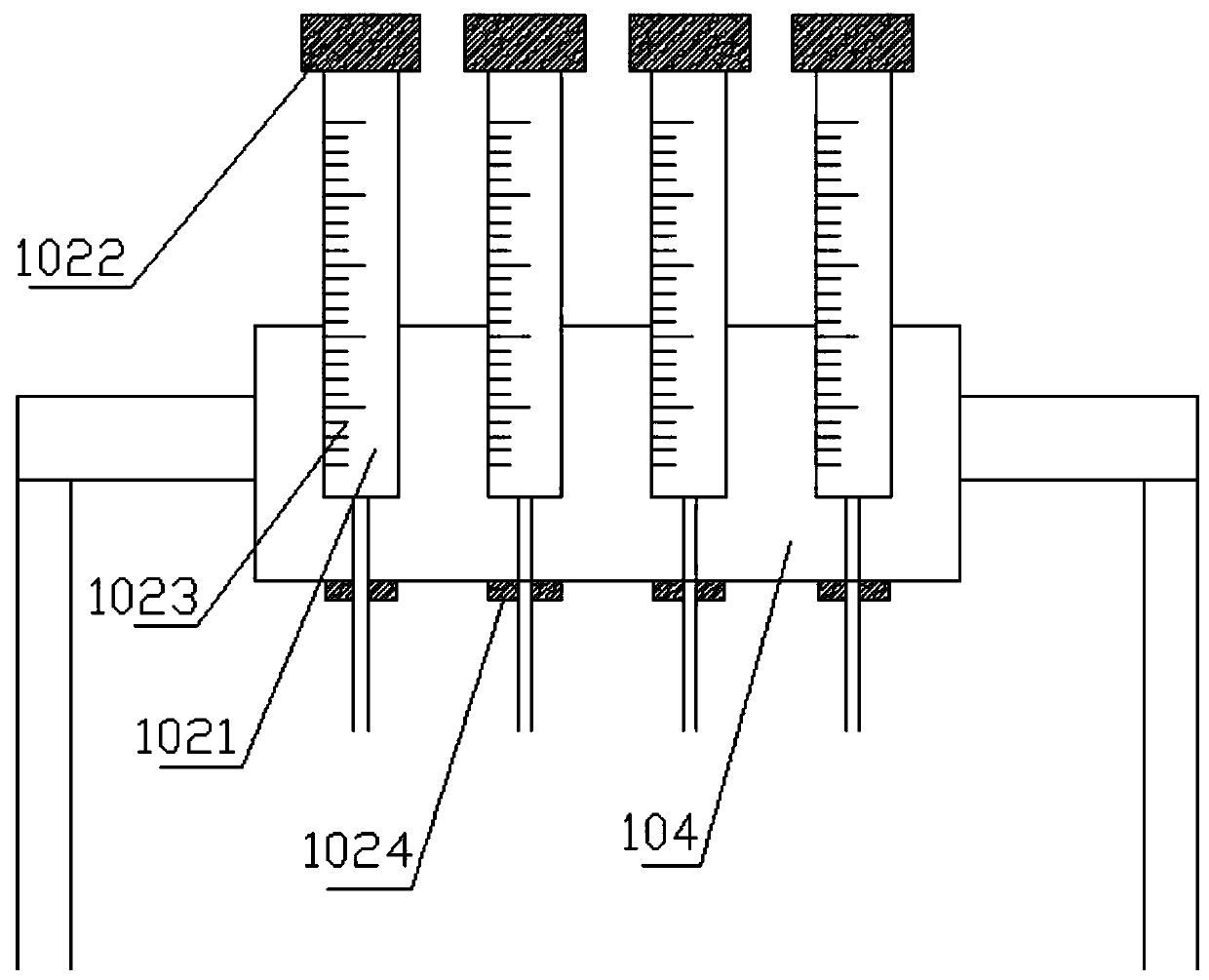

[0050] Step 1: Add nitrogen source A base liquid, nitrogen source B base liquid, carbon source, and oxygen source to each solvent barrel 101; turn on the first switch 106 of each solvent barrel 101, and transport each agent to its corresponding flow tube In 1021, precisely control the dose of input medicine;

[0051] Step 2, turn on the second switch 1024 according to the need, accurately deliver the required mixed reaction medicine to the mixing chamber 1059 through the scale on the flow tube 1021, turn on the agitator 1061, observe the reaction degree of the medicine after stirring in the transparent cover, Wait for the reaction to be completed; at this time, the furnace cover 301 is lifted by the jack 203, the workpiece is placed in advance, and the cover box furnace cover 301 is locked by the nut on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com