Control valve and hydraulic control system of loading machine

A control valve and hydraulic oil technology, applied in the hydraulic field, can solve problems such as poor stability, and achieve the effects of improving stability, improving comfort, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation will be described below in conjunction with the accompanying drawings.

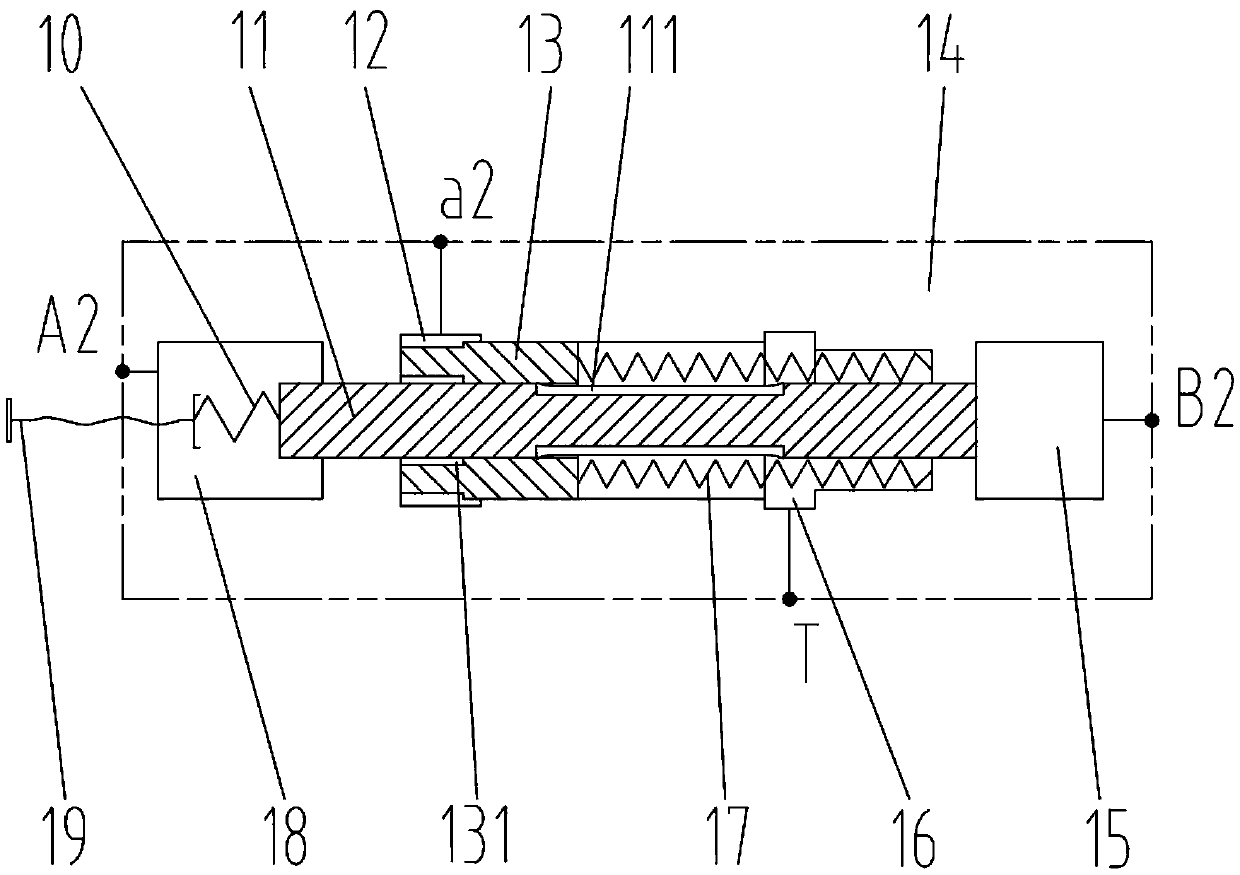

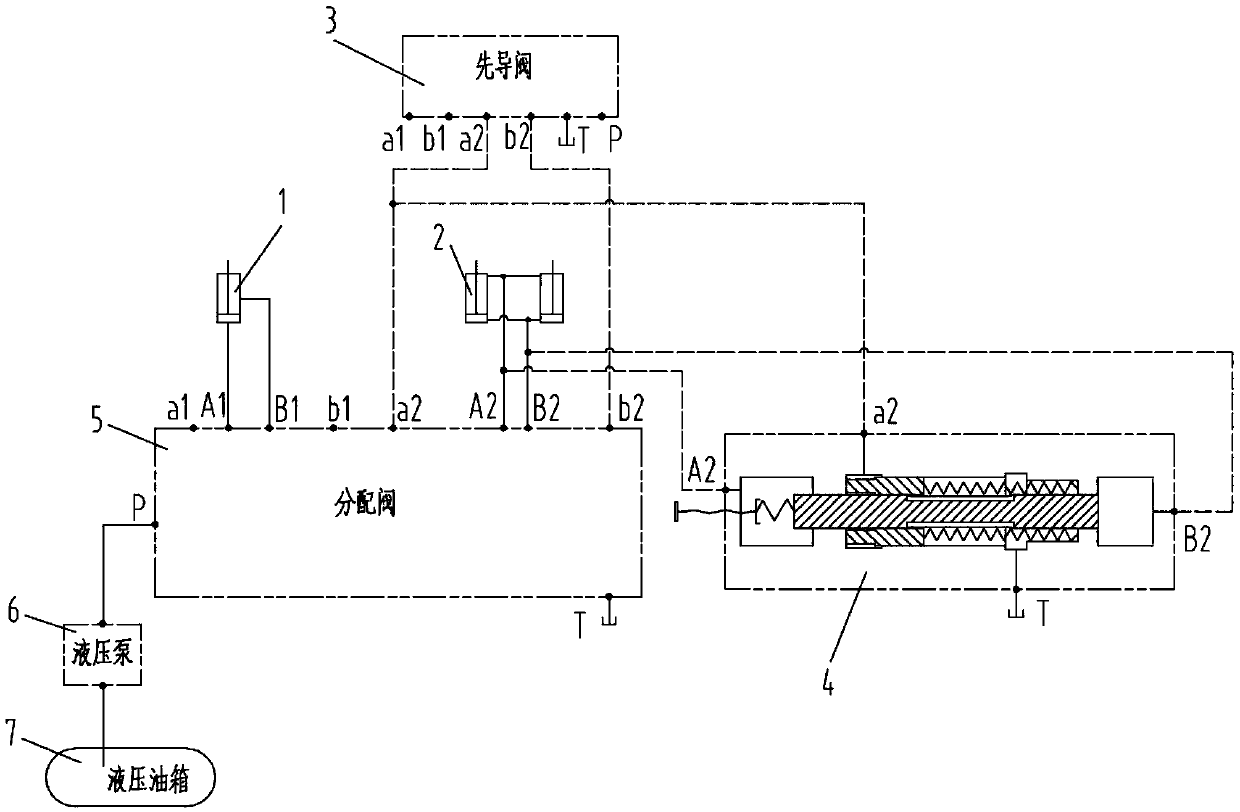

[0017] Such as figure 1 As shown, the control valve in this embodiment includes a valve body 14, a valve core 11, and a valve sleeve 13. The valve body 14 is provided with an oil return T port, a working A2 port, a working B2 port, a pilot a2 port, and a valve core 11 is located in the valve body 14, the left end and the right end of the valve core 11 are slidingly fitted with the valve body 14 respectively, an intermediate chamber is formed between the middle part of the valve core 11 and the valve body 14, and a first cavity 18 is arranged in the valve body 14 And the fourth cavity 15, the first cavity 18 is located at the left end of the spool 11, the first cavity 18 communicates with the working A2 port and the hydraulic oil in the first cavity 18 acts on the left end of the spool 11, the fourth cavity 15 is located at the spool 11, the fourth chamber 15 communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com