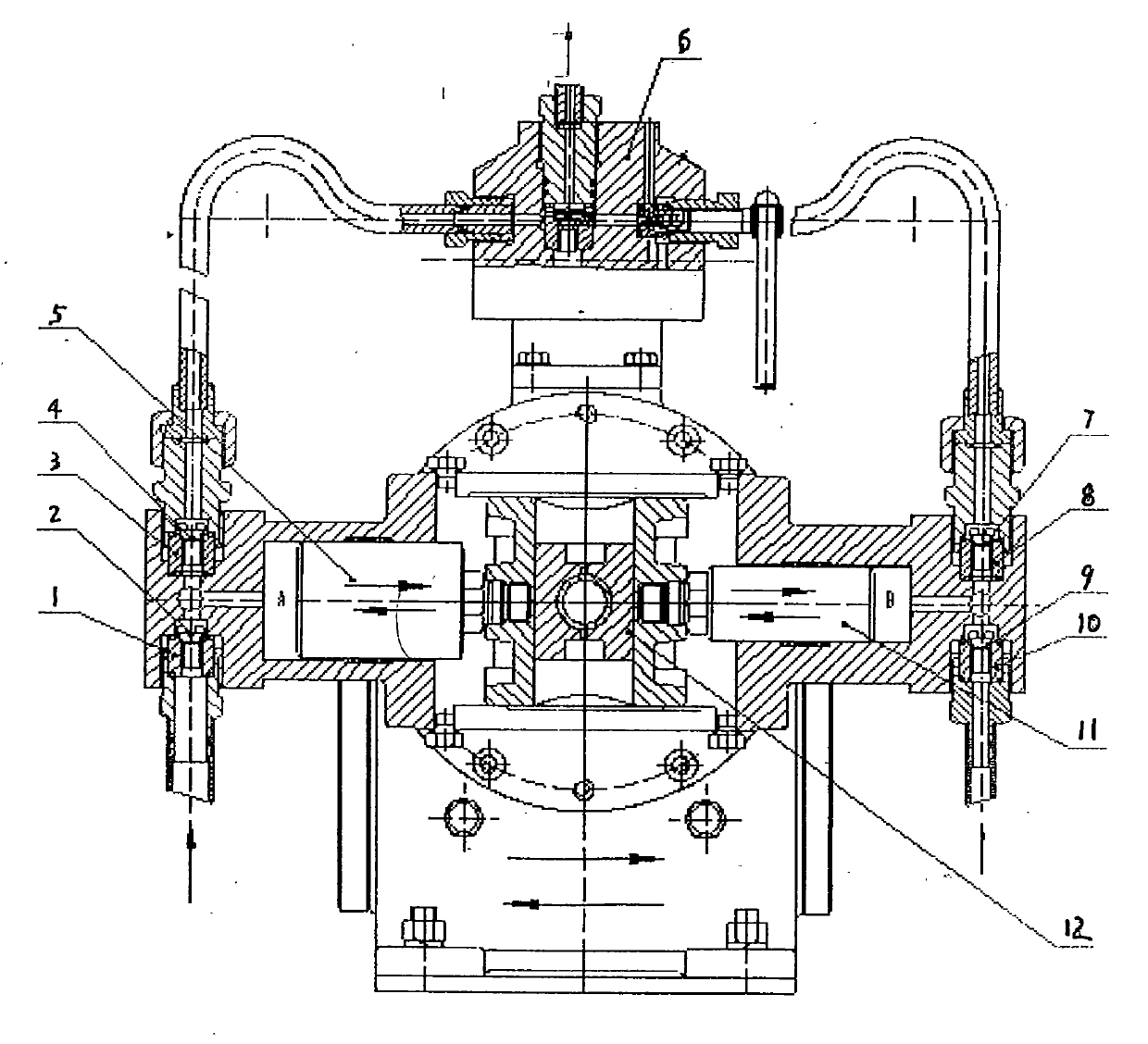

Combined type high and low pressure cylinder hydraulic end

A high-low pressure, compound technology, applied in liquid variable capacity machinery, piston pumps, machines/engines, etc., can solve the problems of complex structure, difficult installation, delaying assembly time, etc., to achieve simple installation structure and layout, pressure regulation Convenience, high design pressure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

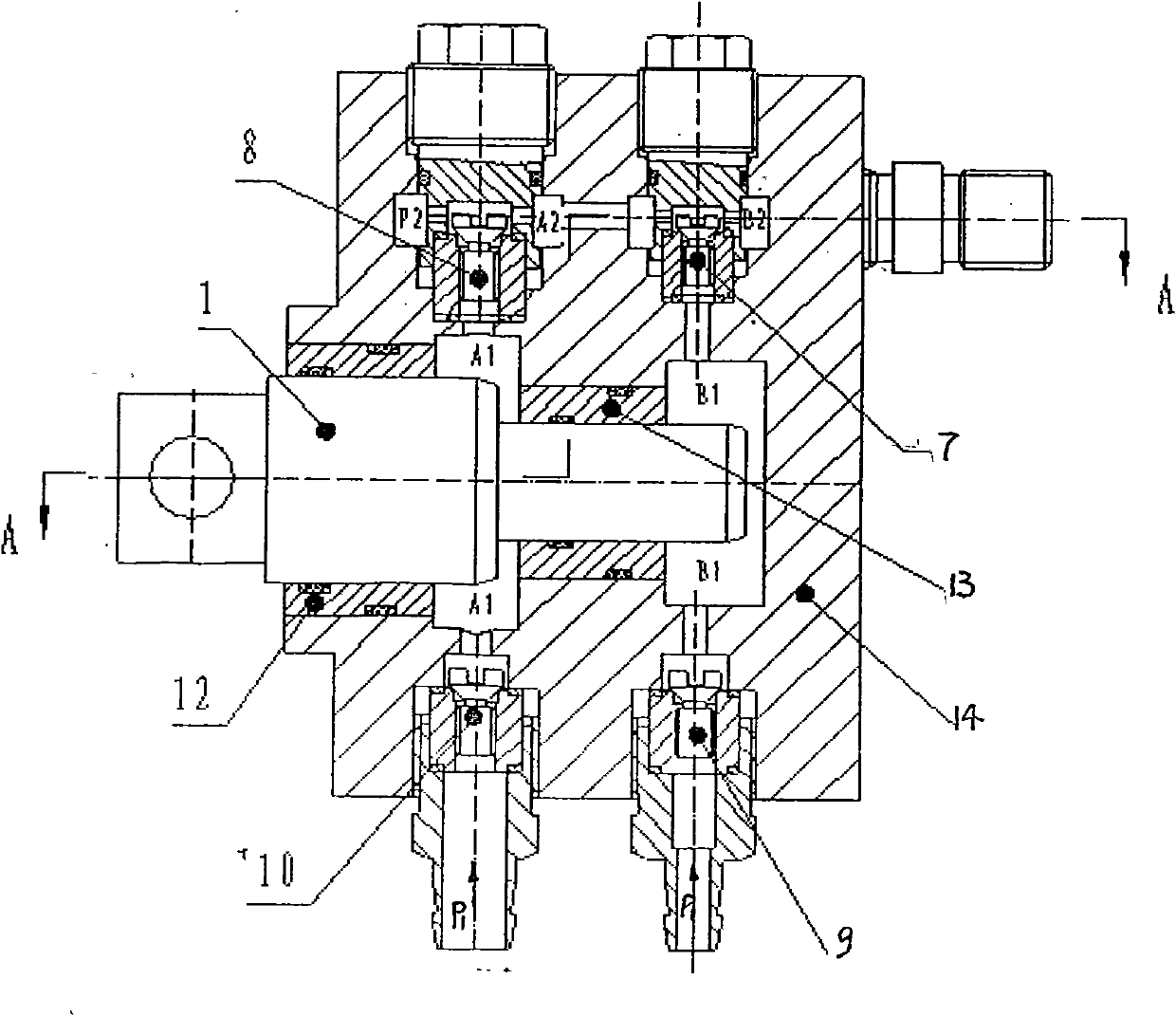

Embodiment Construction

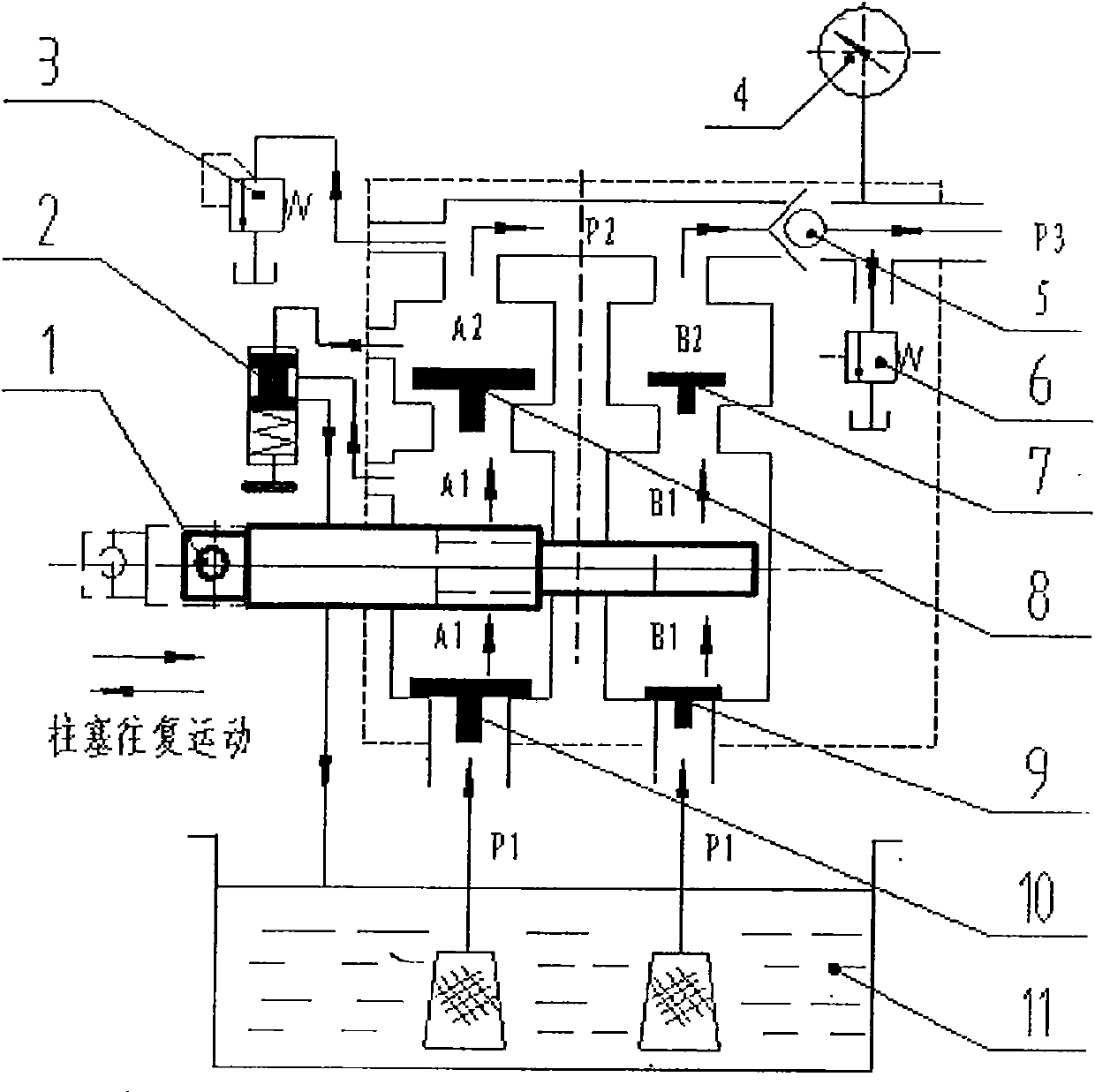

[0027] The working principle of the fluid end of the composite high and low pressure cylinder: see the principle of the fluid end of the composite high and low pressure cylinder figure 2 .

[0028] The rotary motion of the motor drives the stepped plunger 1 to reciprocate in the water tank through the transmission mechanism, so that the working volume of each working chamber changes continuously, and then the alternate suction and discharge process of the pump is realized.

[0029] When the stepped plunger is in the suction stroke (the dotted line position in the figure), the working volume in the water tank (A1 cavity and B1 cavity) increases, resulting in a partial vacuum, and the working medium in the water tank passes through a large flow rate under the action of atmospheric pressure. The water inlet valve 10 and the small flow water inlet valve 9 enter the working chamber (A1, B1). When the plunger is in the discharge stroke (the position of the solid line in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com