Converter tilting frequency conversion timing control system

A control system, frequency conversion speed regulation technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of poor torque balance, slow dynamic response, etc., to achieve smooth start and stop, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

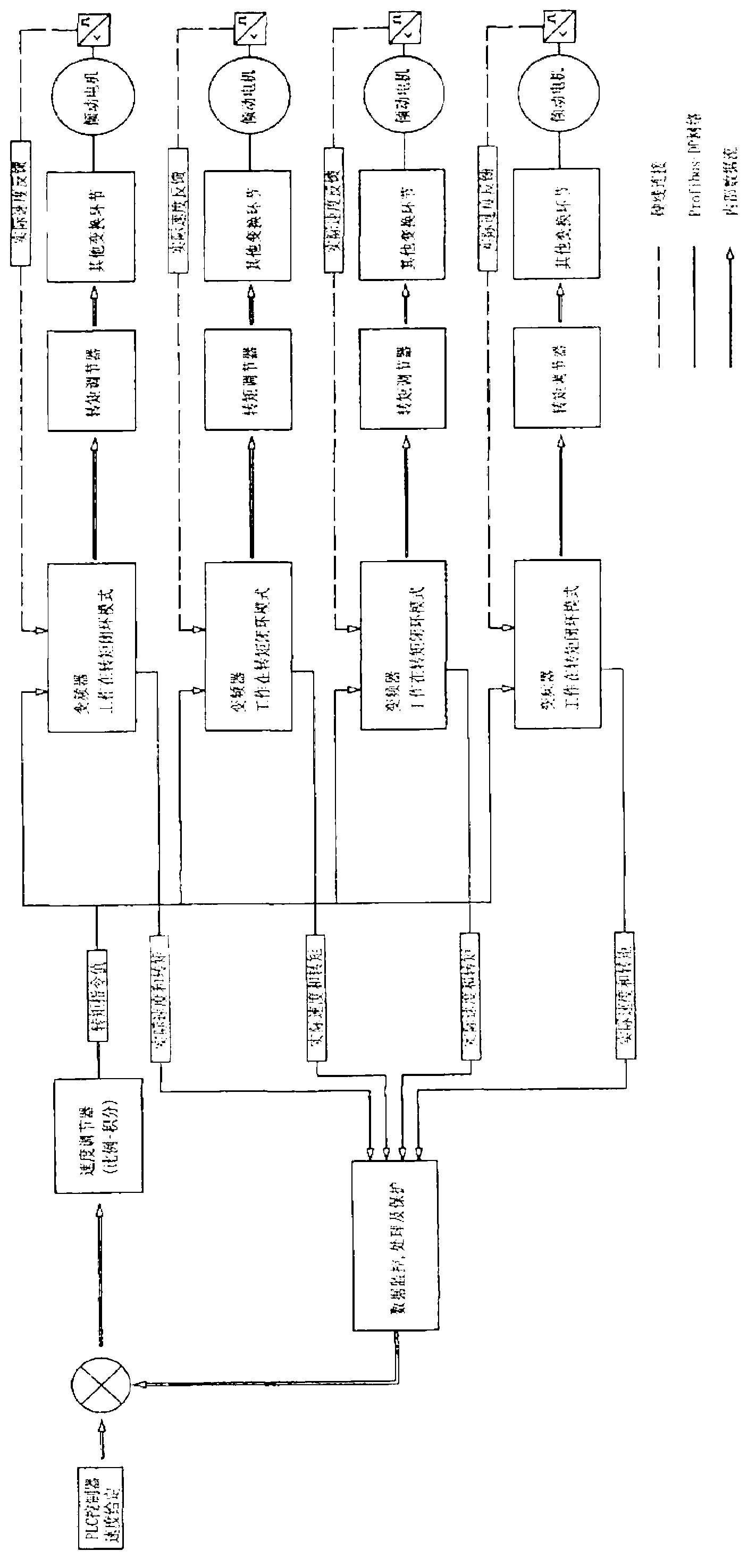

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

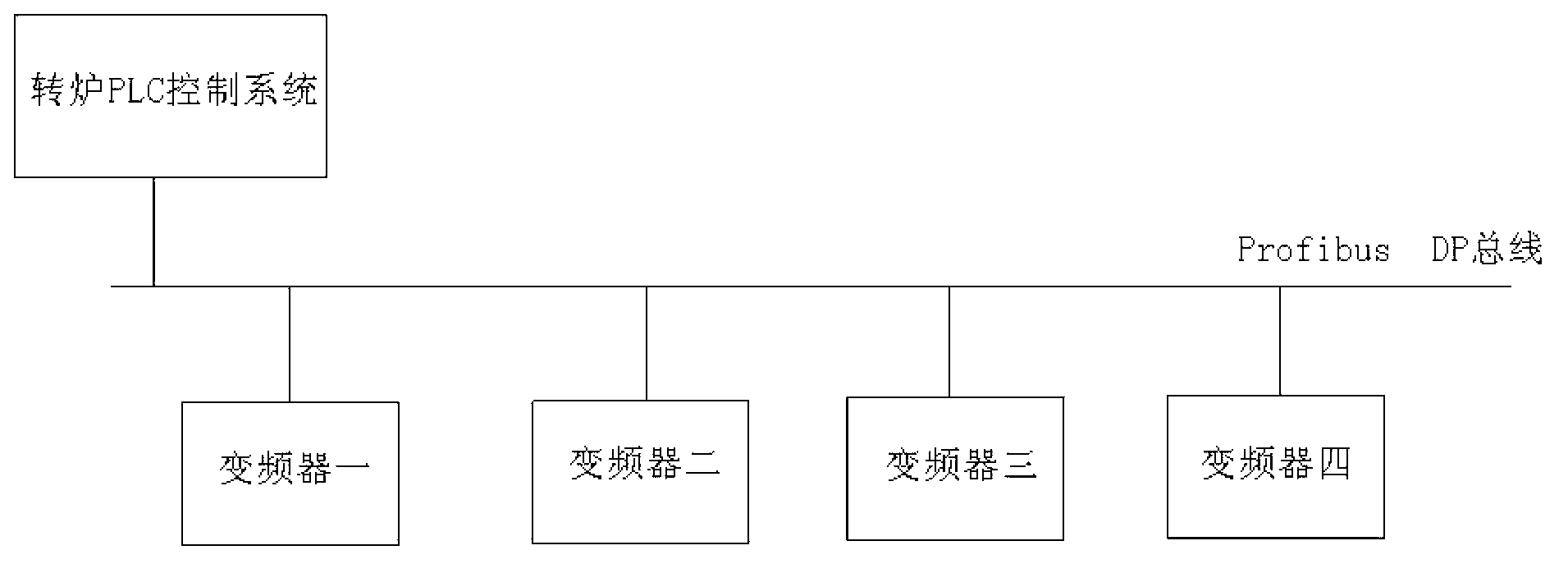

[0012] Converter tilting frequency conversion speed regulation control system, including four frequency converters, a tilting motor controlled by each frequency converter, and a converter PLC control system. Between the four frequency converters, a ring structure network is formed through an optical cable serial communication link , in the ring structure network, the converter PLC control system determines one master and three slave machines for the four frequency converters in the ring structure network, the converter tilting operation signal sent by the converter PLC control system is only connected to the master, and then the master passes through Optical cable serial communication link to control the three slave machines; each frequency converter and the converter PLC control system realize the communication of speed setting, torque setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com