Vibrating direction angle adjustable two-mass vibrating feeder

A vibrating feeder and vibrating direction technology, which is applied to vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of not being able to use the vibrating feeder, unevenness, and small feeding volume, and achieve novel structure, The effect of increasing the feeding amount and reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

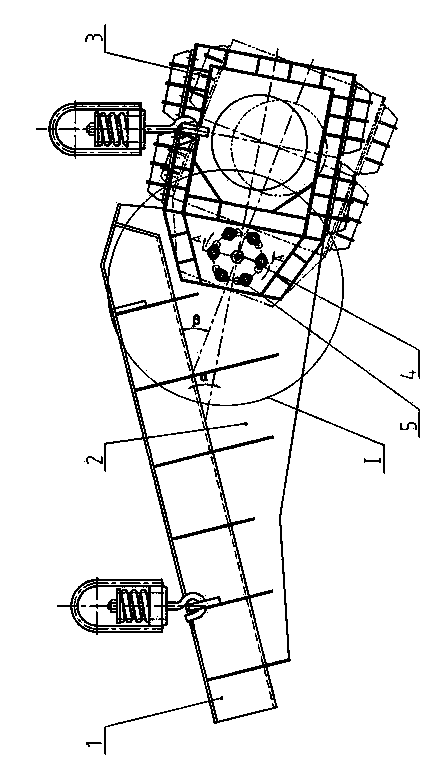

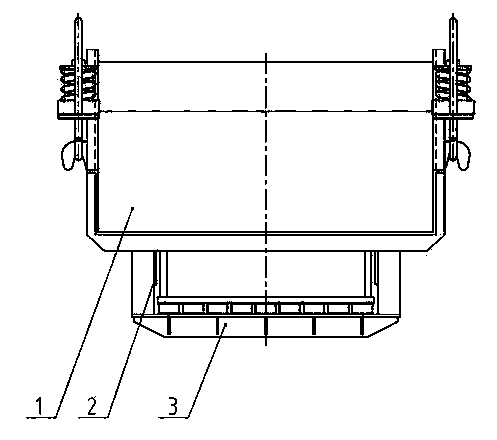

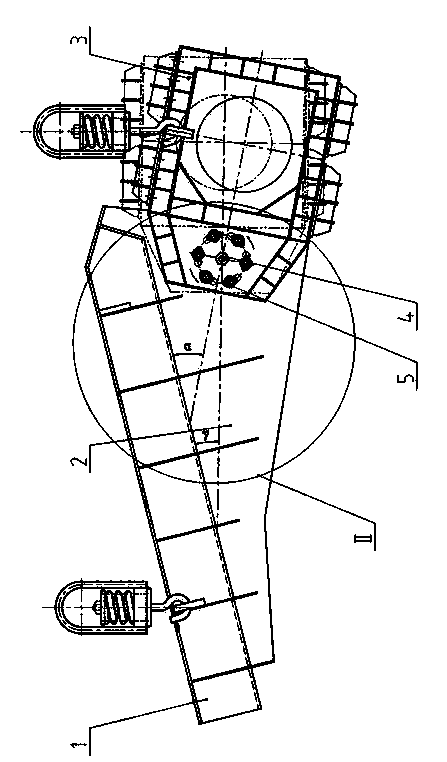

[0020] control Figure 1~6 , The double-mass vibrating feeder with adjustable vibration direction angle of the present invention is composed of a vibrating tank, a thrust plate, a vibrator, a central pin shaft and a fixing bolt. The vibration tank body 1 is welded with the thrust plate 2, and the thrust plate 2 is connected with the vibrator 3 through the fixing bolt 5 and the central pin shaft 4. At the joint between the thrust plate 2 and the vibrator 3, with the center pin 4 as the center of the circle, there are several circular bolt holes on the thrust plate 2, and on the vibrator 3, there are the same number of elongated bolt holes on the circumference. . The connection of the vibrator 3 and the thrust plate 2 is to fasten it together by each fixing bolt 5 and the central pin shaft 4 .

[0021] The working principle of the present invention is: in the figure, the angle α is the initial angle. When the vibration direction angle of the vibrating feeder needs to be increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com