Double Drum Winch Mill

A winch mill and double-drum technology, applied in motor vehicles, cable railways, transportation and packaging, etc., can solve problems such as inconvenient operation, accidents, and easily damaged equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

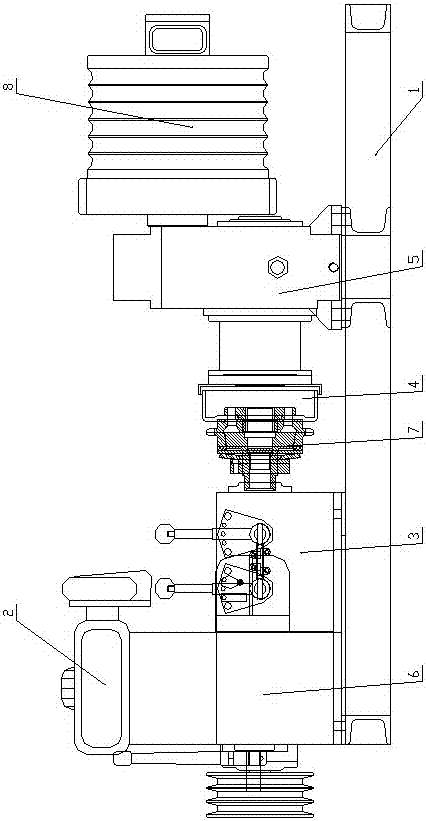

[0023] Such as Figure 1-9 As shown, the double-drum winch mill of the present invention includes a base 1. The base 1 is provided with an engine 2, a transmission device 3, an emergency external braking device 4, and a transmission system 5 which are connected in sequence. There is a forward and reverse gear mechanism 6 between the transmission device 3 and the transmission device 3. A torque limiter 7 is provided between the transmission device 3 and the emergency external braking device 4 on the base 1. The power output ends of the transmission system 5 are respectively connected to the first Reel 8 and second reel 9.

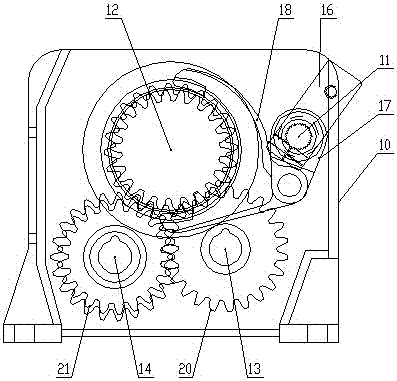

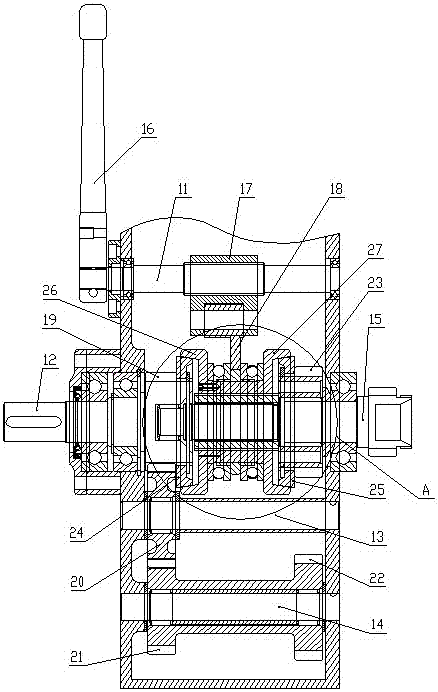

[0024] The forward and reverse gear mechanism 6 includes an outer casing 10, and the outer casing 10 is rotatably provided with a gear lever shaft 11, a first transmission shaft 12, a second transmission shaft 13, a third transmission shaft 14 and a fourth transmission shaft 15, and a gear lever shaft 11 The left end is provided with a reversing rod 16, the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com