Mesh placement machine and mesh placement method

A technology of mesh and frame, which is applied in the field of mesh placement machine and mesh placement, can solve the problems of inability to flip mesh and adjust mesh, and achieve the effects of ensuring accuracy, improving accuracy, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

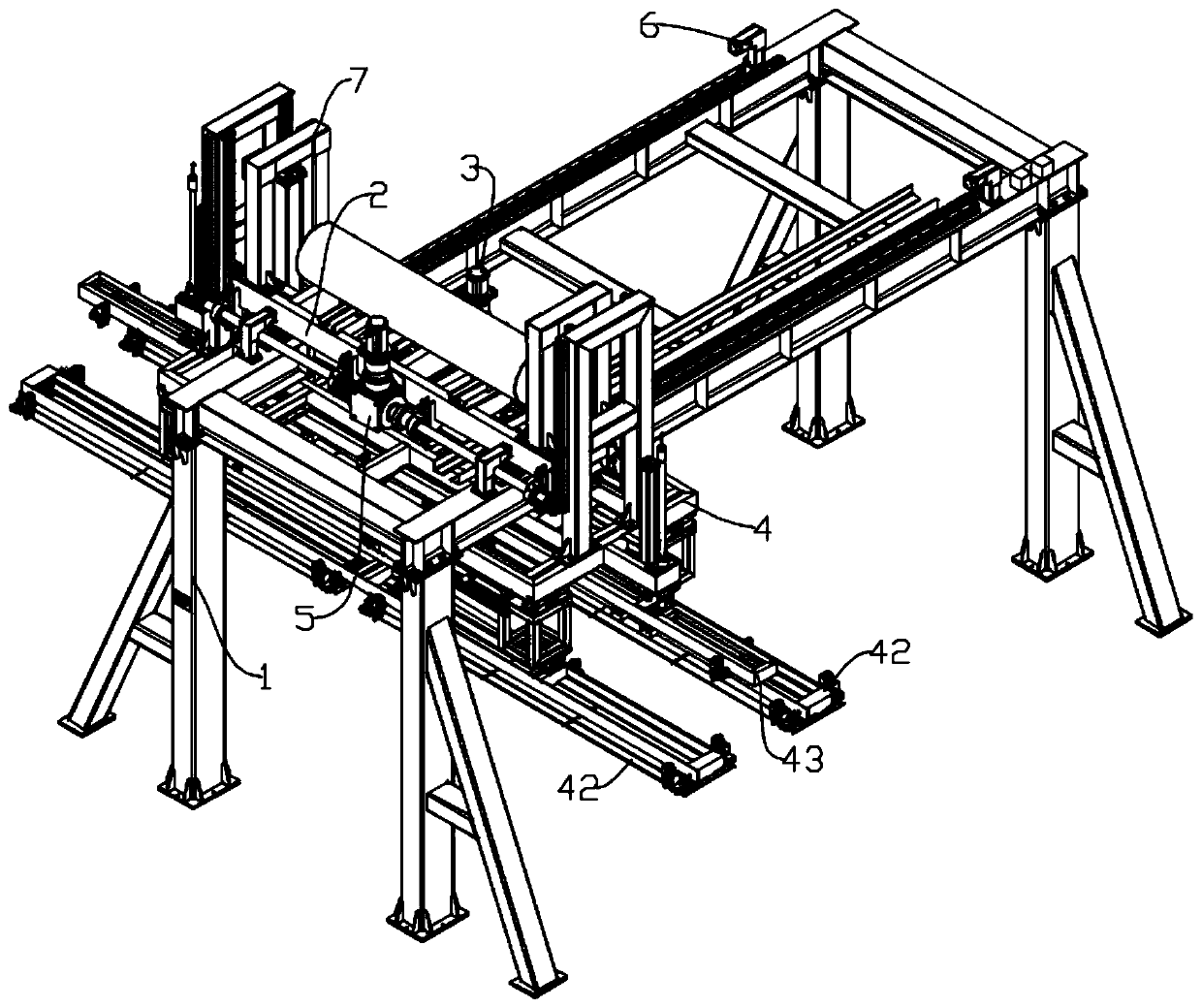

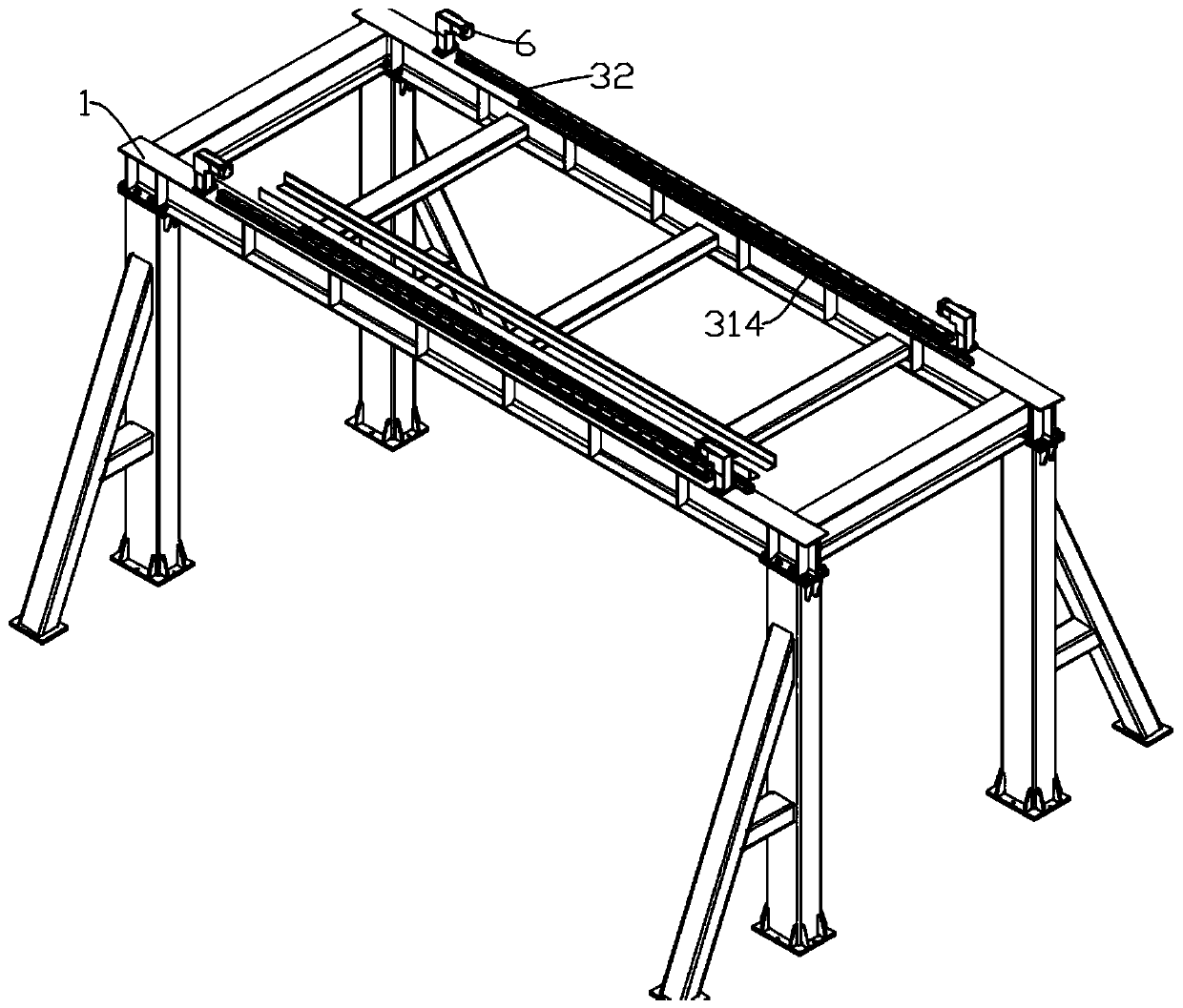

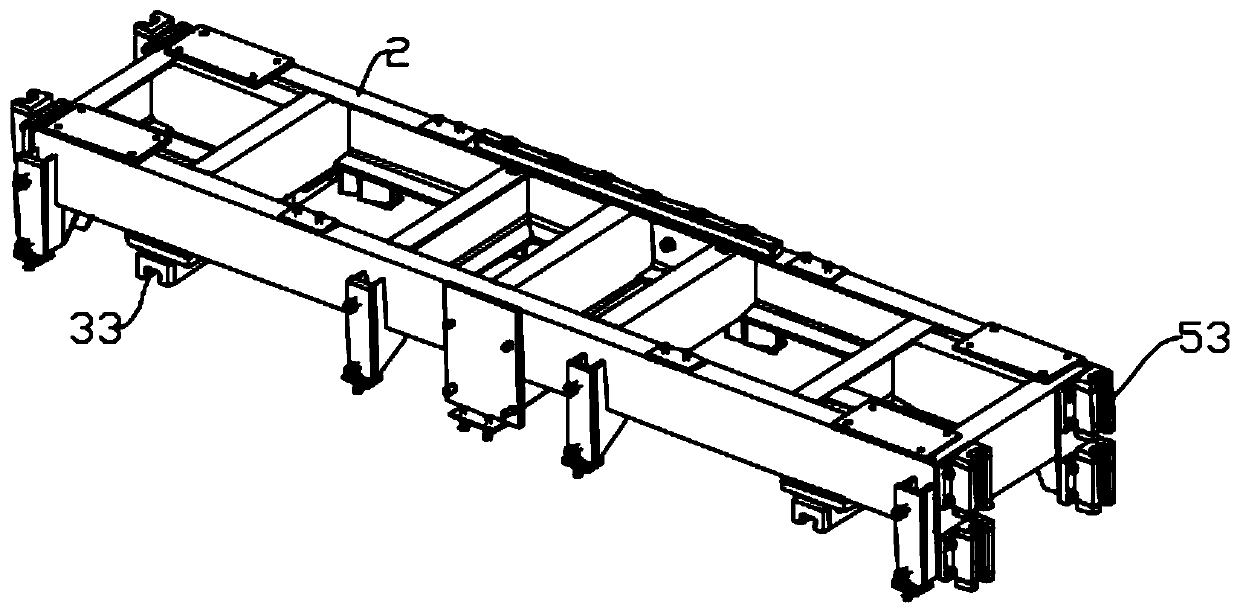

[0059] Such as figure 1 As shown, a mesh placing machine is used for clamping the steel mesh and sending the mesh into the fixing device, which mainly includes a frame 1, a car body 2, a horizontal driving device 3, a mesh picking device 4 and a vertical Direct Drive 5. Wherein, frame 1 is used as the installation main body of each device of the mesh placement machine, and is a rectangular frame structure, and a supporting column is respectively installed below the four corners of the rectangular frame. The car body 2 is a rectangular frame, which is installed on the frame 1 and is used to drive the mesh clamping device 4 to move. The mesh clamping device 4 is installed on the car body 2 for clamping the mesh. The horizontal driving device 3 is used to drive the car body 2 to move in the horizontal direction, and the vertical driving device 5 is used to drive the mesh clamping device 4 to lift. The specific structure and working principle of each device will be described in...

Embodiment 2

[0073] A method for placing mesh, adopting the mesh placing machine of embodiment 1 to place the mesh, the specific process is as follows.

[0074] 1. Before starting, the horizontal driving device 3 drives the car body 2 to move to the top of two adjacent piles of mesh, and the mesh is in a stacked state, and then, as Figure 10 As shown, the vertical driving device 5 works, drives the mesh clamping device 4 to descend to the mesh stacking position, and the flipping grippers 422 of the two flipping fixtures 42 are clamped to clamp a mesh respectively.

[0075] Two, such as Figure 11 As shown, after the vertical driving device 5 drives the mesh clamping device 4 to rise, the turning mechanism drives the turning fixture 42 to rotate until the mesh is in a vertical state. In this embodiment, the mesh is turned 90° inwardly. Then the drive cylinder 1 424 is retracted, and the overturning fixture 42 is sent to the designated position. In this embodiment, two mesh sheets are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com