Precise automatic straightening and material returning control system of high-speed cold heading machine used for manufacturing steel balls

A control system and technology of cold heading machine, which is applied in the field of automatic straightening and material return control system of high-speed cold heading machine for precision steel ball manufacturing, can solve the problem of high operator cost, limited material tail length, and a lot of time. problems, to achieve the effect of reducing equipment maintenance costs, improving utilization, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

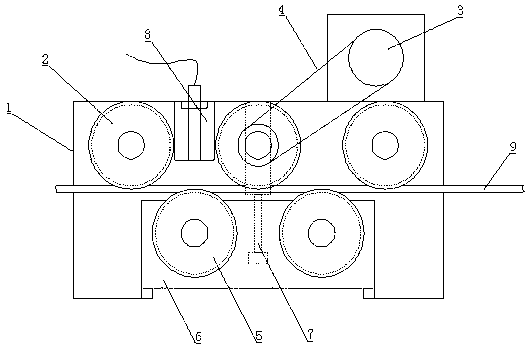

[0010] Such as figure 1 As shown, it includes machine base 1, fixed pressing wheel 2, motor 3, belt drive 4, movable pressing wheel 5, slider 6, pneumatic cylinder 7 and material tail detection system.

[0011] The fixed binder wheel group, slide block 6 and motor 3 are installed on the above-mentioned machine base 1, and the fixed binder wheel group includes an odd number of fixed binder wheels 2, and the fixed binder wheels 2 are horizontally and equidistantly distributed on the top of the machine base 1, wherein A fixed pressing wheel in the middle is a material return wheel 21, and the material return wheel 21 is driven by a motor 3 through a belt drive 4.

[0012] The movable binder wheel group includes an even number of movable binder wheels 5, and the movable binder wheels 5 are horizontally and equidistantly distributed on the slider 6, and the spacing between adjacent movable binder wheels 5 is the same as that of adjacent fixed binder wheels 2; The movable pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com