Automatic forming machine and method for transformer enameled wire U-shaped coils

An automatic forming machine, enameled wire technology, applied in the direction of inductor/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of low work efficiency, high labor intensity of operators, and inability to guarantee the accuracy of pin spacing, etc. Improve work efficiency and ensure the effect of forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

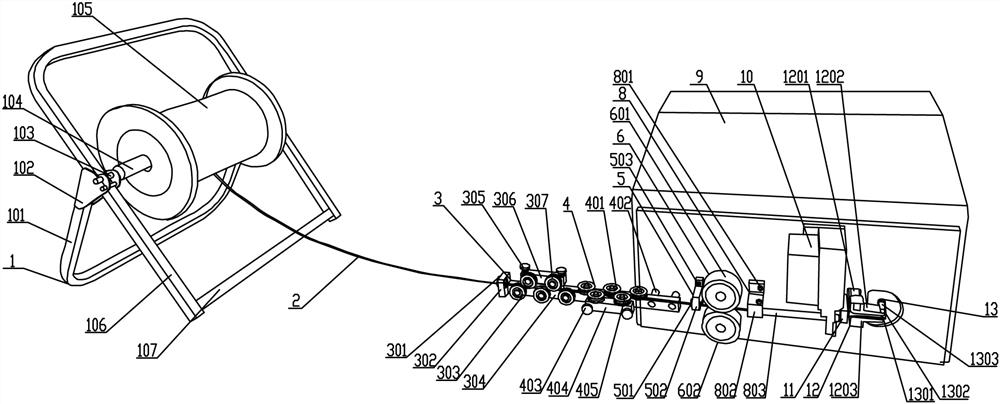

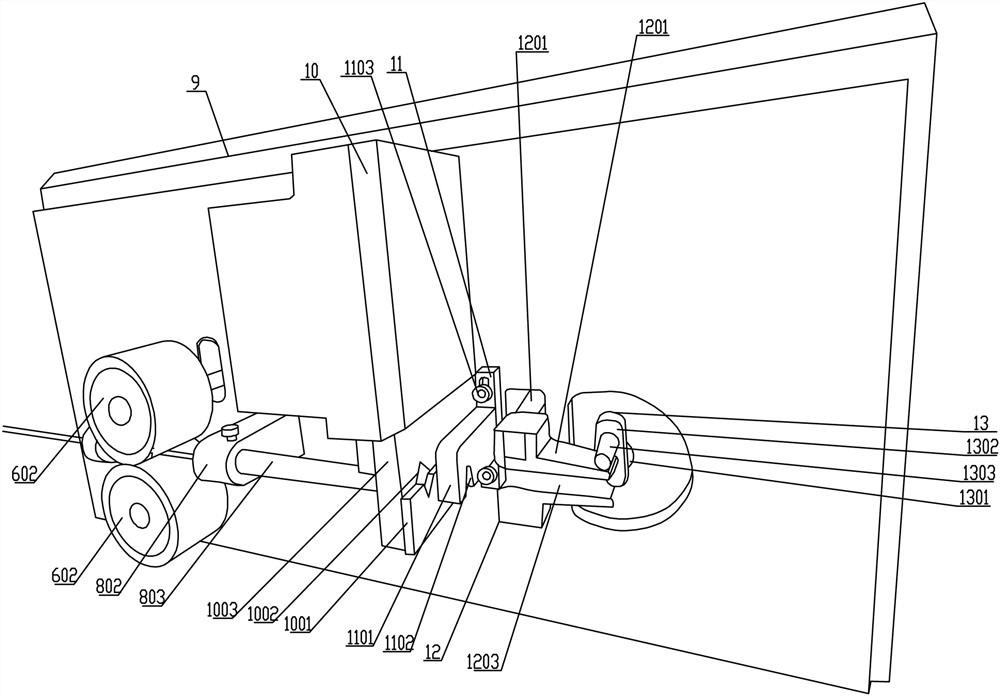

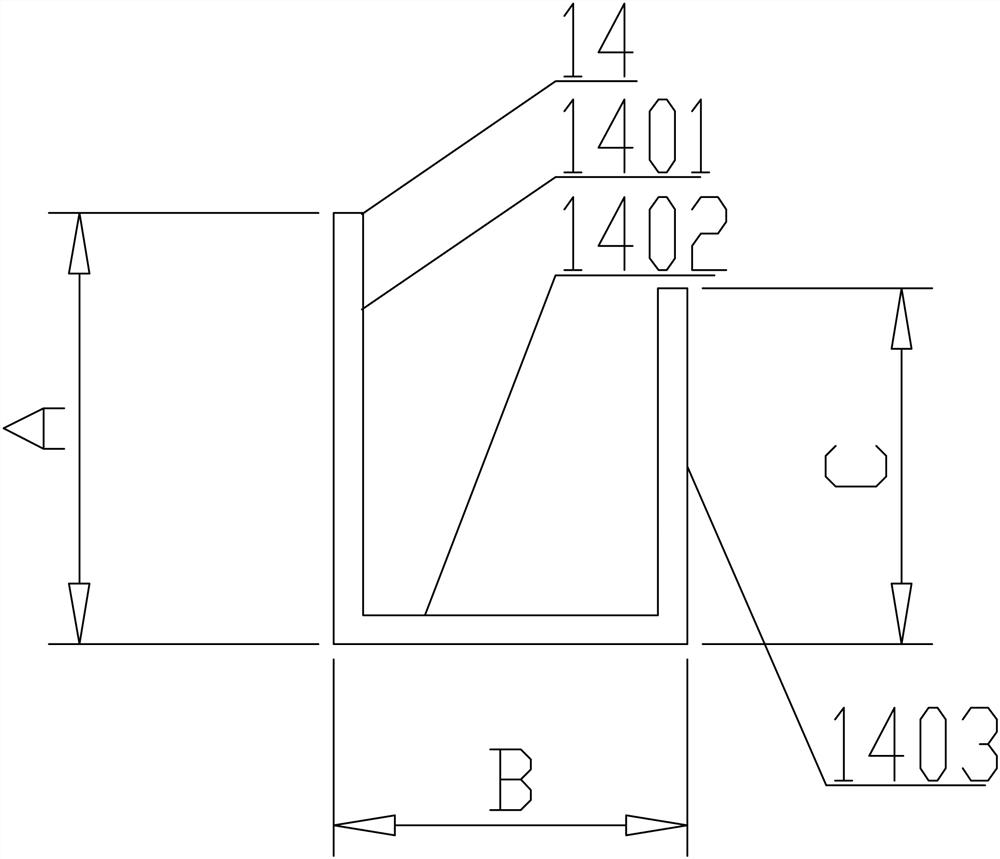

[0054] See Figure 1-4 , An automatic forming machine for transformer enameled wire U-shaped coils, which includes a copper wire coil support frame 1 for storing copper wire coils; and also includes a main box 9 whose front side wall is fixed for alignment A feeding guide structure 5 for feeding and guiding copper wire raw materials. The station before the feeding guide structure 5 is provided with a vertical straightening structure 3 and a transverse straightening structure 4 for compound straightening of the copper wire. The station after the feeding guide structure 5 is provided with a traction power device 6 for traction of the copper wire, and the output end of the traction power device 6 is provided with a discharge guide structure for guiding the copper wire after straightening 8. The output end of the discharging guide structure 8 is provided with a cutting mechanism 10 for cutting the copper wire. The station after the cutting mechanism 10 is provided with a rear guide...

Embodiment 2

[0068] The automatic forming machine performs the bending forming method of the U-shaped winding skeleton of the transformer enameled wire, which includes the following steps:

[0069] Step 1: Place the copper wire storage tray 105 on the copper wire coil support frame 1;

[0070] Step two, lead the copper wire 2 out, pass through the vertical straightening structure 3, the lateral straightening structure 4 and the feeding guide structure 5 in turn, and then introduce the traction power device 6, start the traction power device 6, and pass through the active roller 601 The rotation of the moving roller 602 drives the copper wire 2 to be transported forward;

[0071] Step 3: The copper wire is drawn and straightened and transported to the discharging guide structure 8, and from the discharging guide structure 8 through the cutting mechanism 10, the rear guide plate structure 11 and the telescopic pressing mechanism 12 to the bending mechanism 13;

[0072] Step 4: When the length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com