Large cross-section coiling steel uncoiling equipment

A large-section and equipment technology, applied in the field of uncoiler equipment, can solve the problem that large-section coiled steel cannot be roughly straightened, and achieve the effect of reasonable and reliable transmission structure, convenient operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

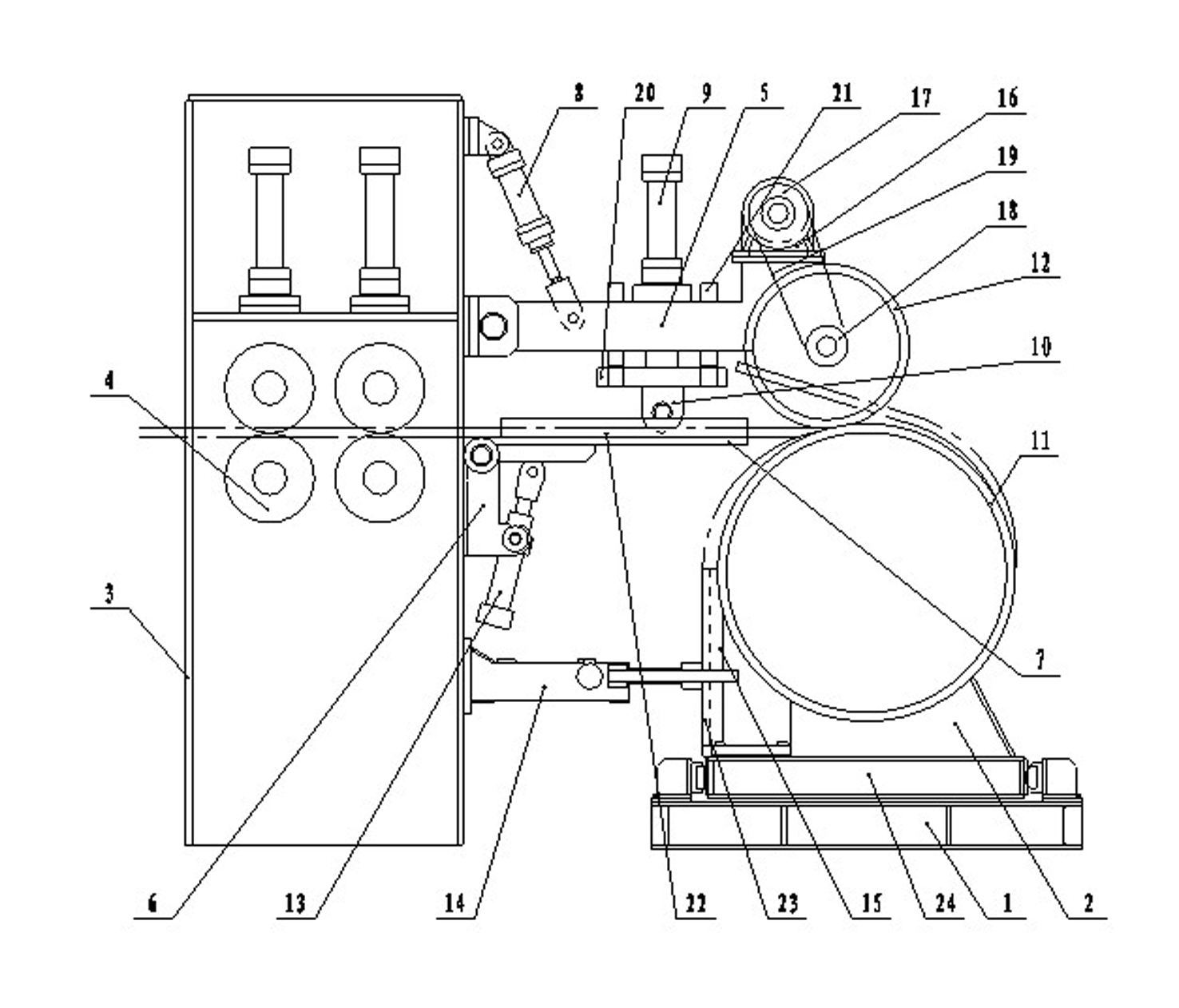

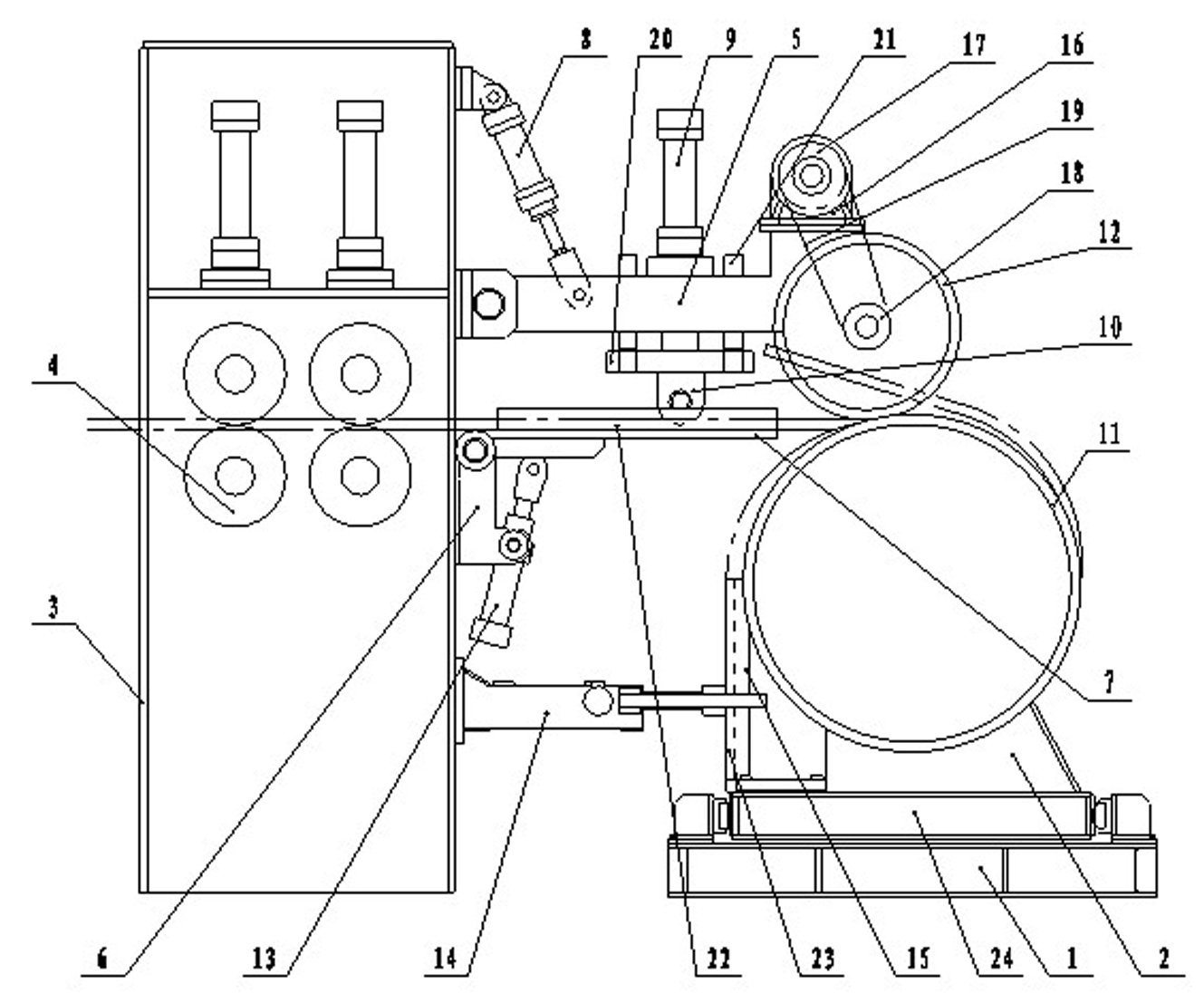

[0012] Coiled steel uncoiling equipment with large section, including pinch roller device and uncoiler 2 sliding on machine base 1, uncoiler 2 includes base 24 and sleeve 11 located above it, pinch roller device includes machine frame 3 and equipment Inside the pinch roller 4, the rear wall of the frame 3 on the upper side of the pinch roller 4 is hinged with a pressure plate 5, and the rear wall of the frame 3 on the lower side of the pinch roller 4 is fixed with a support seat 6, and the support seat 6 The upper part is hinged with a supporting plate 7, and a first oil cylinder 8 hinged with both is provided between the pressing plate 5 and the rear wall of the frame 3 above it, and a second vertical cylinder 8 is fixed on the pressing plate 5. Oil cylinder 9, the end of the second oil cylinder 9 below the binder plate 5 is provided with a pressure wheel 10, the rear of the binder plate 5 is provided with a pressure roller 12 above the sleeve 11, and the pressure roller 12 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com