Plate-and-frame dust remover filter core

A dust collector and filter element technology is applied in the fields of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

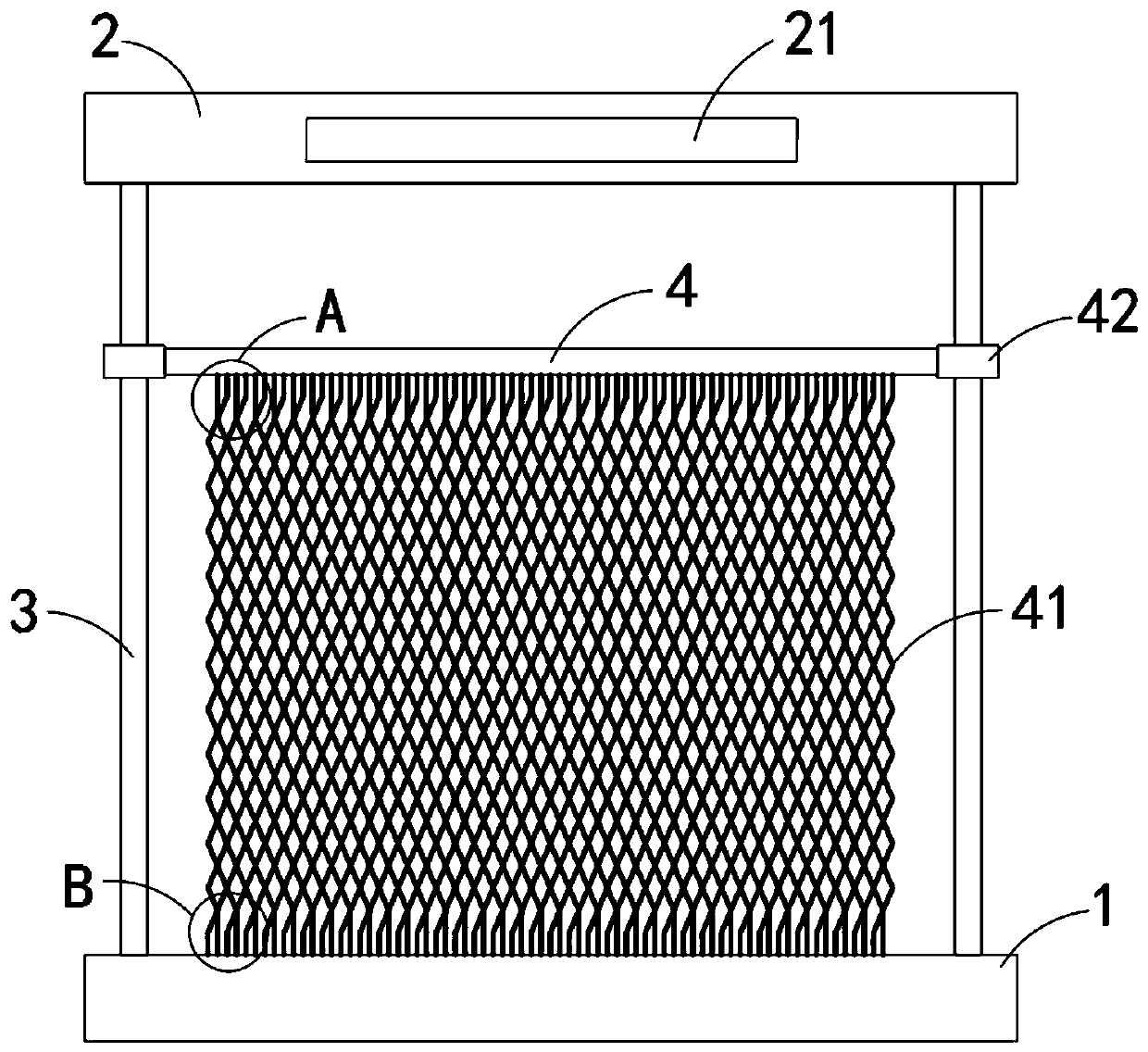

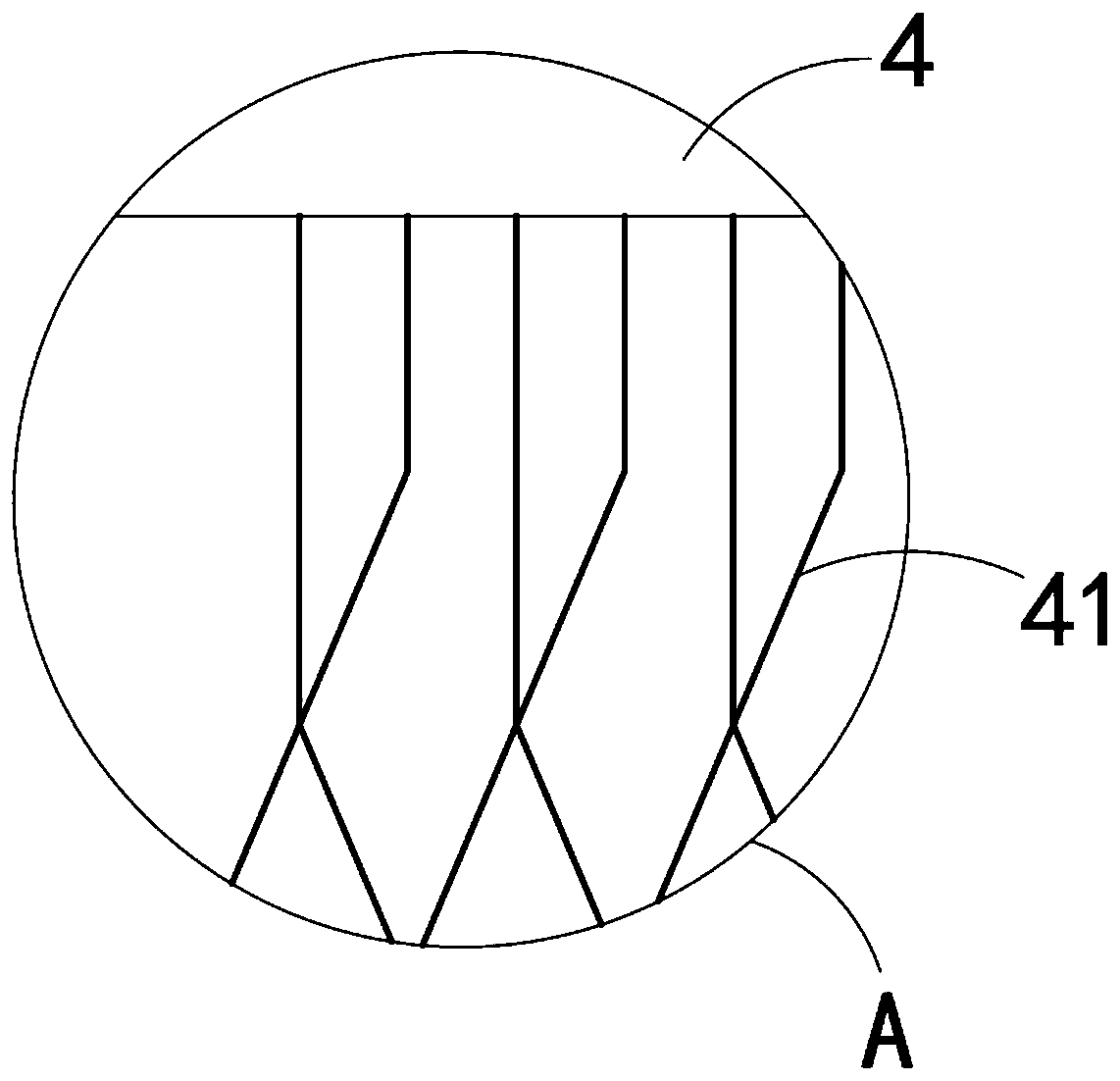

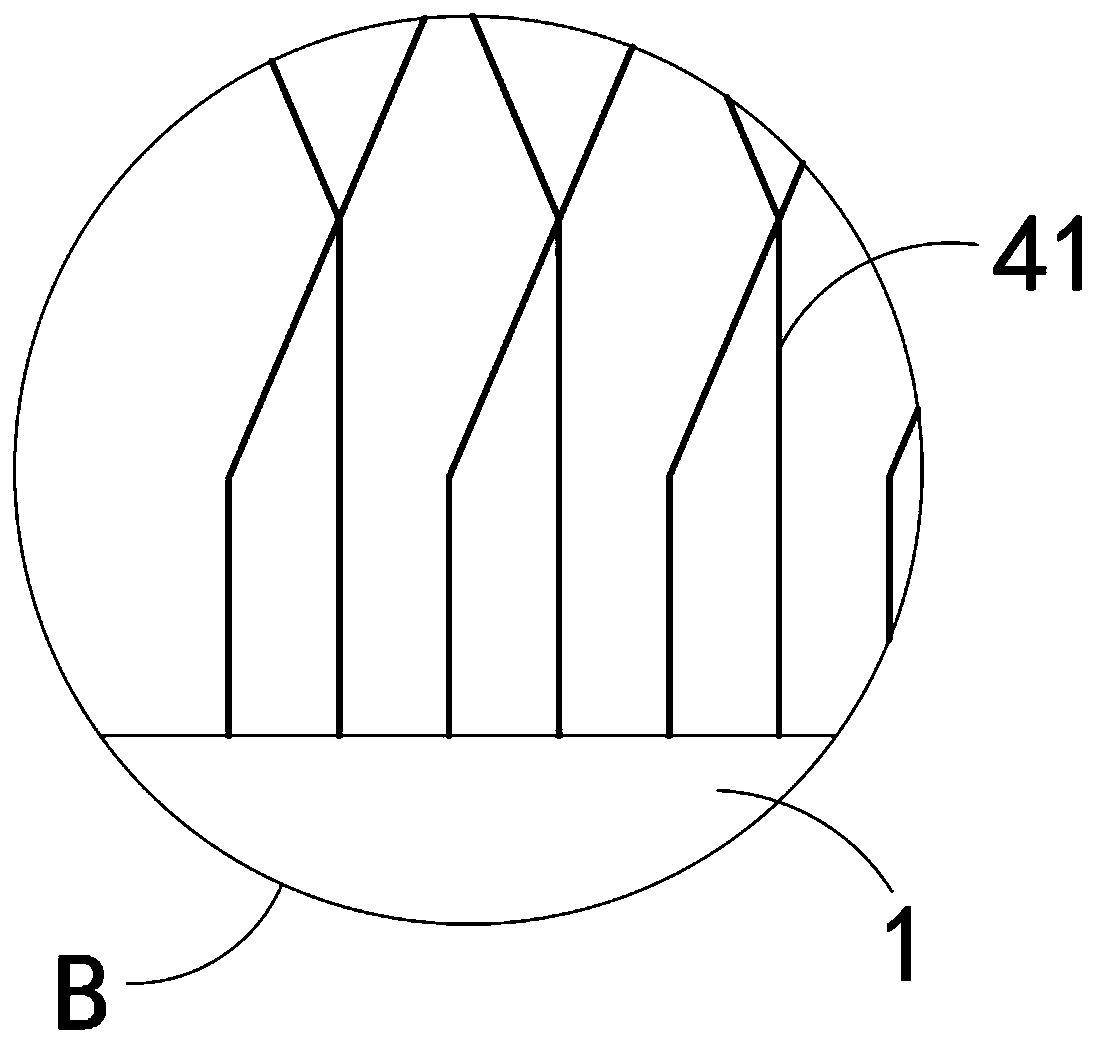

[0022] like Figure 1-4 As shown, a filter element of a plate and frame dust collector comprises a base 1 and a top seat 2, two sliding rods 3 arranged in parallel are fixedly connected between the base 1 and the top seat 2, and two sliding rods 3 are slidably connected by a The movable plate 4 made of ferromagnetic material, specifically, the sliding sleeve on the sliding rod 3 is provided with a sliding sleeve 42, and the two ends of the movable plate 4 are fixedly connected with the side walls of the two sliding cylinders 42 respectively, and the inside of the top seat 2 The electromagnetic element 21 that can generate suction force to the movable plate 4 is installed, and the electromagnetic element 21 is an electromagnet. It should be noted that when the electric current direction of the electromagnet changes, its magnetism also changes accordingly. The movable plate 4 and the base 1 are fixedly connected with a plurality of wavy and elastic filter paper boards 41, the cr...

Embodiment 2

[0027] like Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that the upper end of the sliding rod 3 is covered with a closed elastic bellows 31. Specifically, the elastic bellows 31 is composed of an elastic expansion part in the middle and fixed parts at both ends. , the elastic bellows 31 can be compressed under the action of the movable plate 4, and the elastic bellows 31 is provided with a one-way air intake valve, specifically, the one-way air intake valve is arranged on the fixed part located at the lower side, two elastic An exhaust cross pipe 32 is fixedly connected between the bellows 31. Specifically, the exhaust cross pipe 32 is arranged between two fixed parts on the upper side, and the elastic bellows 31 passes through the one-way exhaust valve and the exhaust cross pipe. 32 is connected, and the lower end of the exhaust horizontal pipe 32 is provided with a plurality of exhaust holes corresponding to the filter paper plate 41. It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com