Straightening, shearing and bending machine for steel bars

A bending machine and steel bar technology, applied in the field of steel bar straightening and shearing bending machine, can solve the problems of low work efficiency, high labor intensity, hidden safety hazards, etc., and achieve the effect of simple structure, high degree of automation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

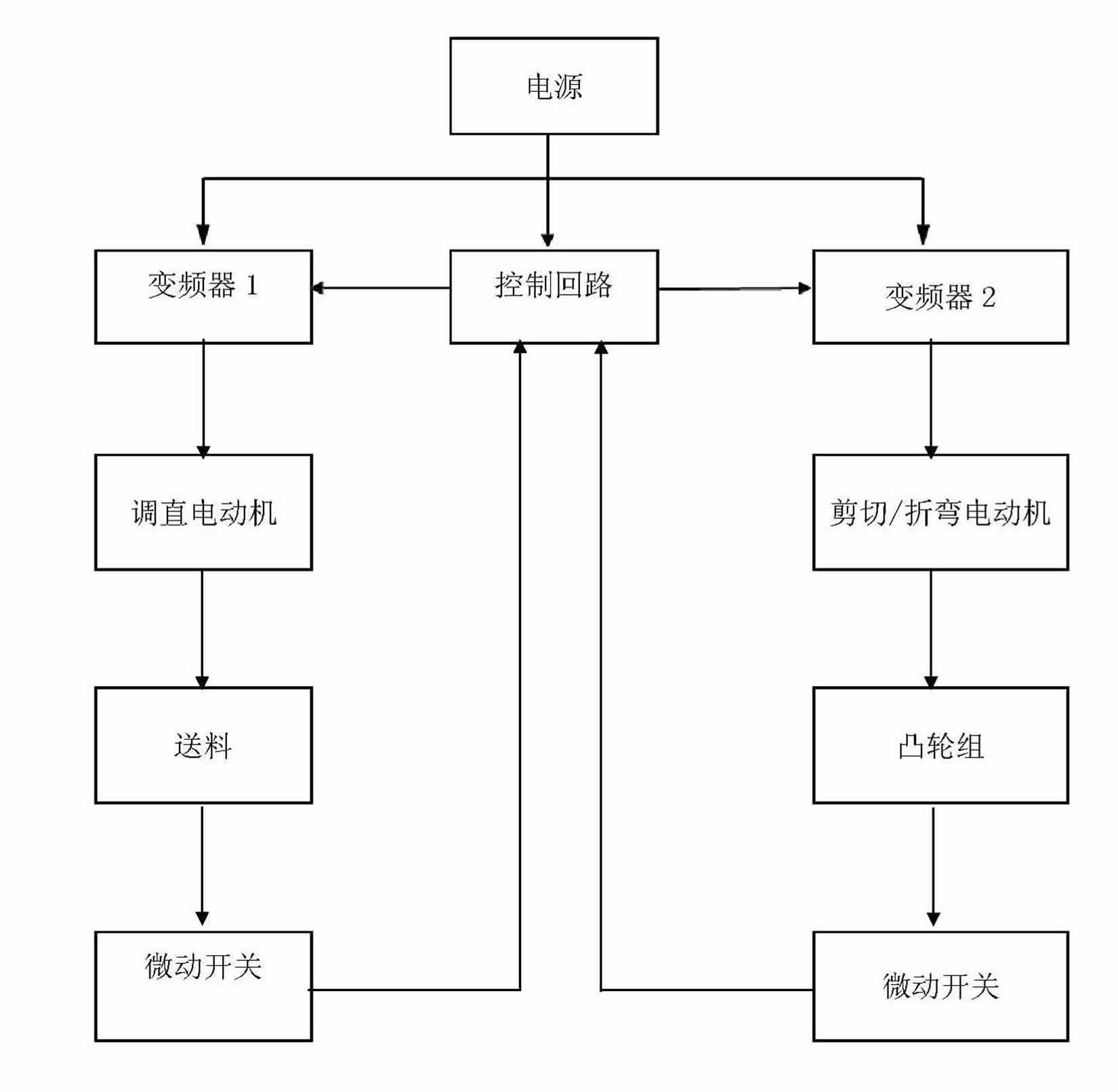

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

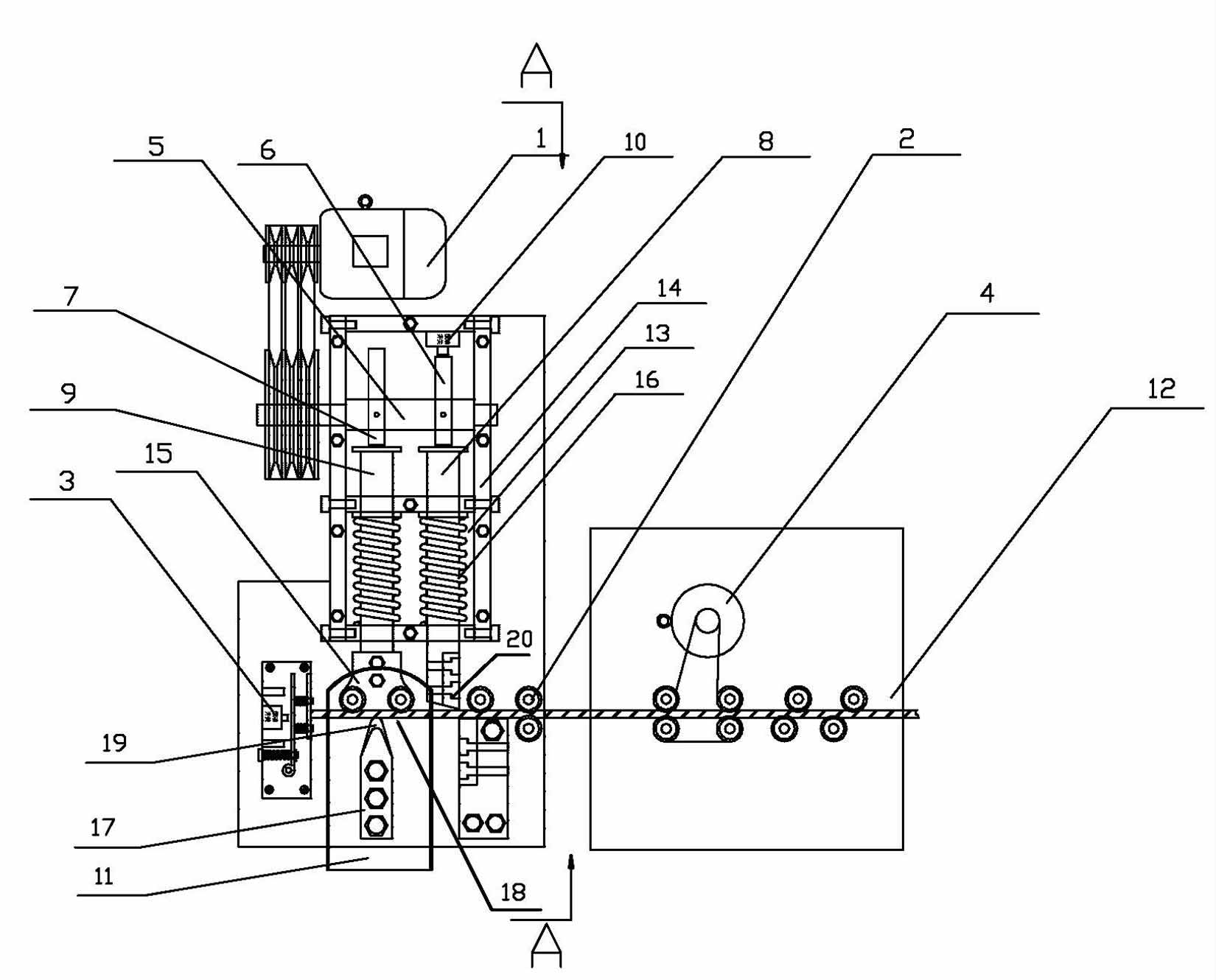

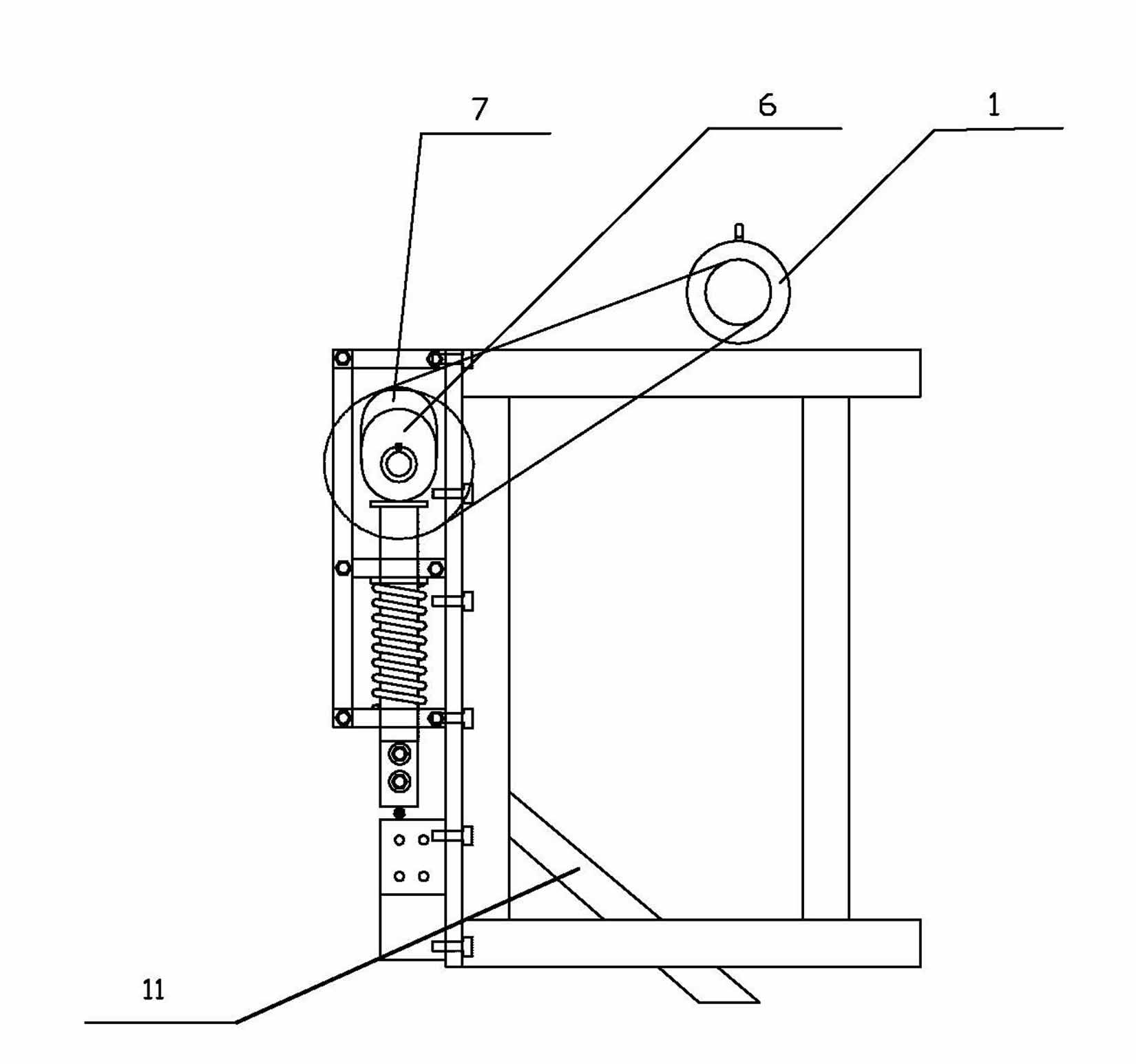

[0014] Such as figure 1 , 2 As shown, the steel bar straightening, shearing and bending machine includes a feeding mechanism 12, a shearing / bending assembly 13, a micro switch 3 and a shearing / bending motor 1; the shearing / bending assembly 13 includes a frame Body 14, the camshaft 5 that is horizontally arranged on the frame body 14 and the shearing cam 6 and the bending cam 7 that are sleeved on the camshaft 5 successively; the working radius of the bending cam 7 is greater than the working radius of the shearing cam 6 ( See figure 2 ), to ensure that after the shearing operation is completed, the large-stroke extrusion bending is continued. The output shaft of the shearing / bending motor 1 transmits power to the camshaft 5 through a belt; the movable shearing shaft 8 and the bending shaft 9 are parallelly arranged in the frame body 14; the shearing shaft 8 and the One end of the bending shaft 9 corresponds to the end faces of the shearing cam 6 and the bending cam 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com