Rotating mechanism for tubes and bars on horizontal straightening machine

A technology of rotating mechanism and straightening machine tube, applied in the field of rotating mechanism and steel pusher, can solve the problems of large and heavy body, complicated structure and high manufacturing cost, and achieve the effects of small volume, simple structure and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

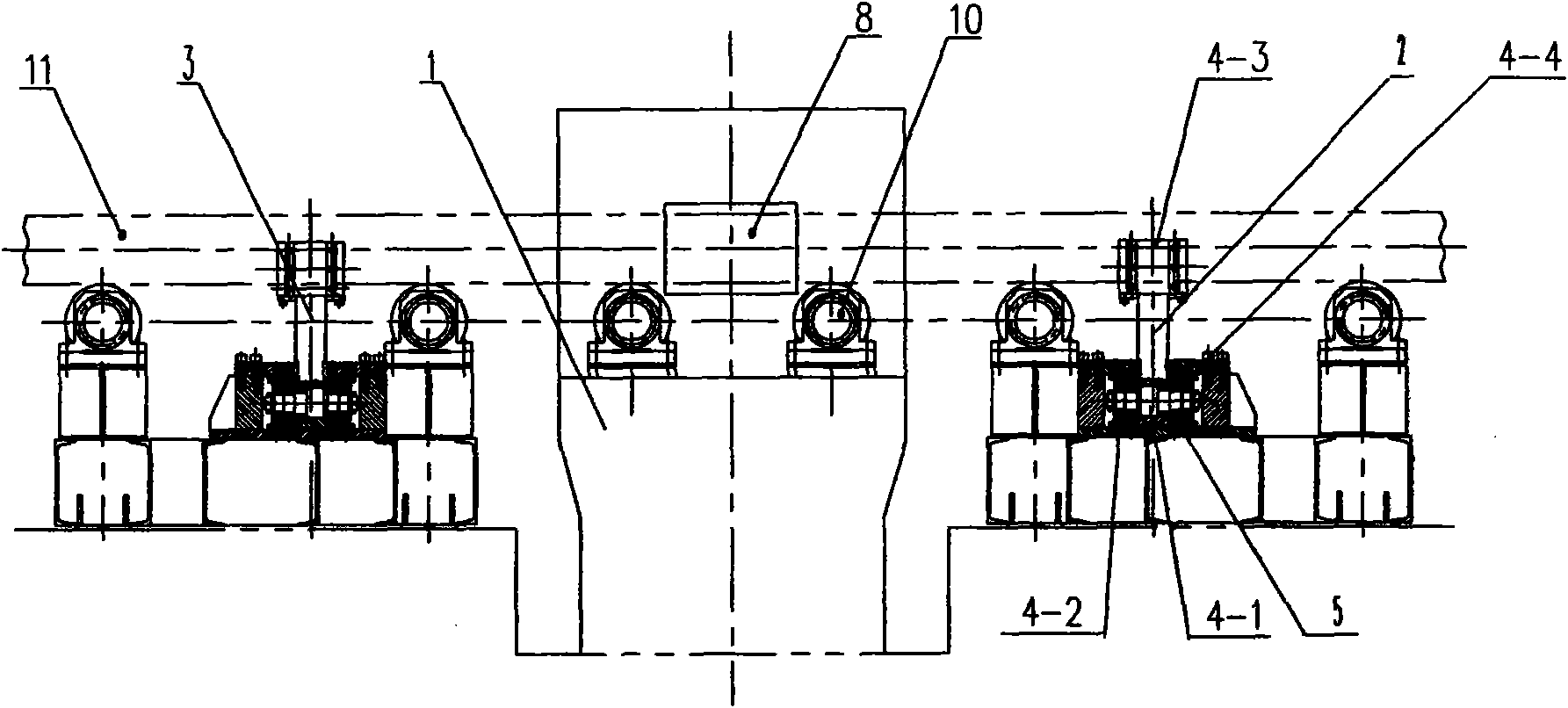

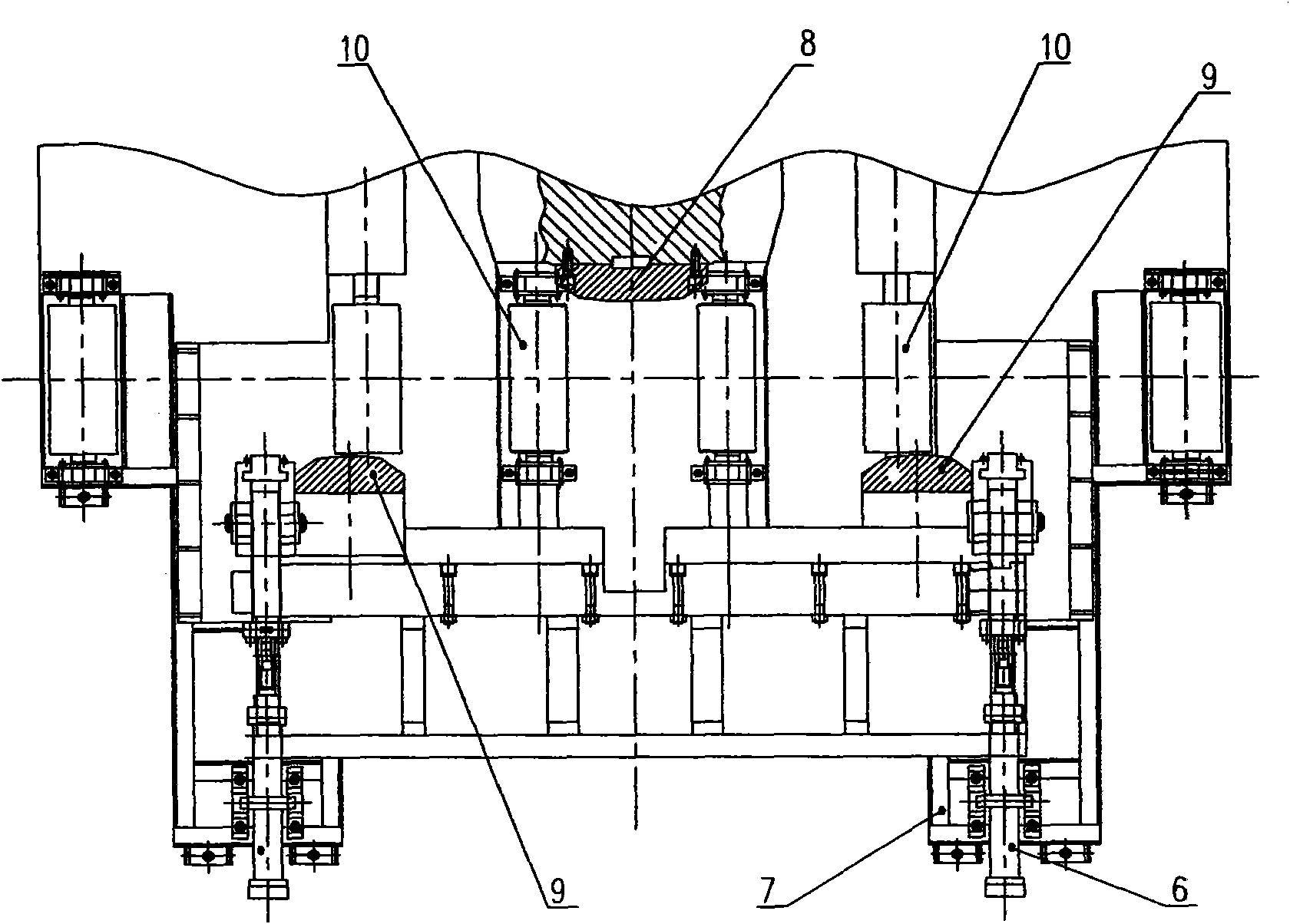

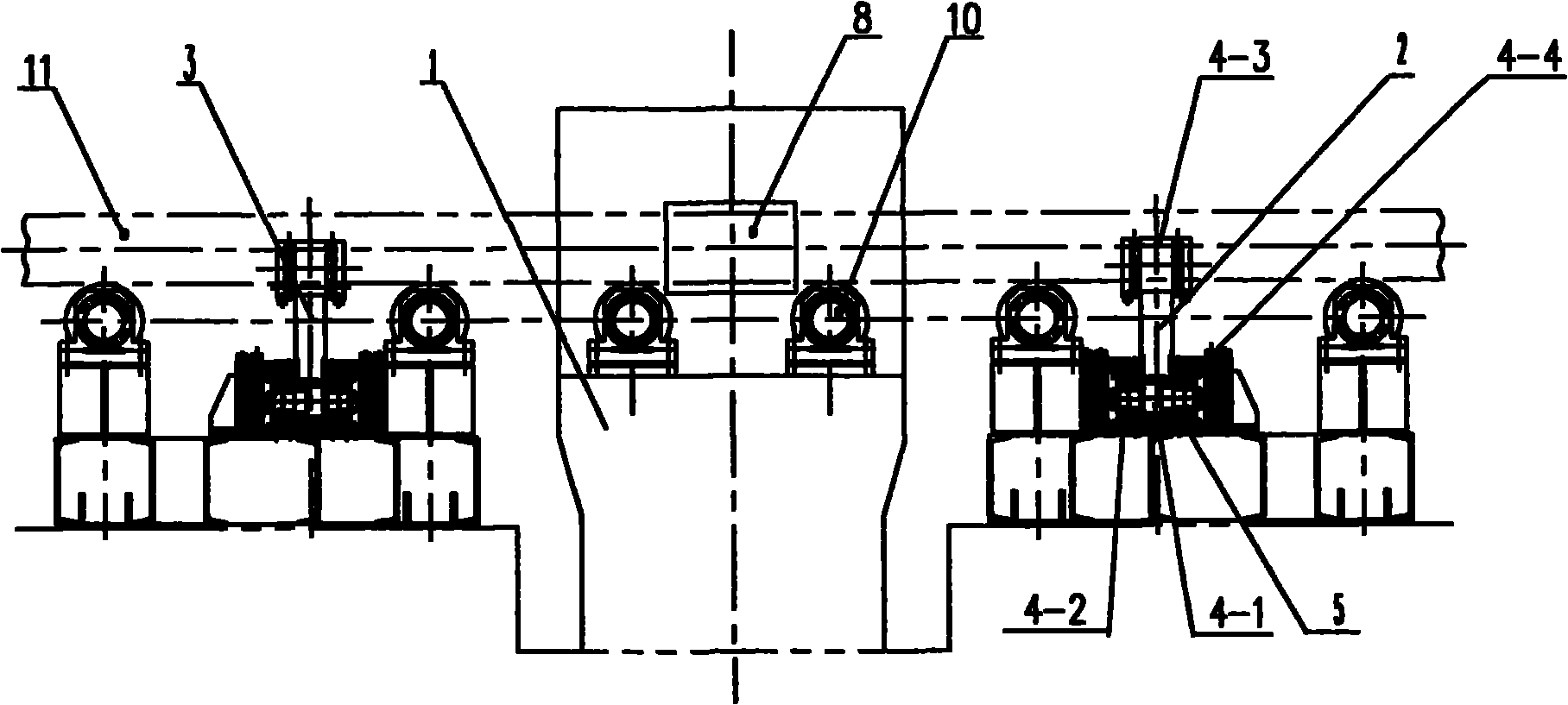

[0012] Such as figure 1 , 2 As shown, a horizontal straightening machine tube and bar rotating mechanism is installed symmetrically on both sides of the straightening machine body 1, the right push steel machine 2, the left push steel machine 3, the right push steel machine 2, the left push The steel machine 3 is composed of a pushing mechanism 4, a guide rail 5, and an oil cylinder 6. The pushing mechanism 4 is composed of a roller shaft 4-1, a roller bearing 4-2, a push plate 4-3, and a roller 4-4. The roller bearing 4-2 and the roller 4-4 are installed together and then mounted on the roller shaft 4-1, the roller 4-4 is arranged on the guide rail 5, and the push plate 4- 3 is connected to the roller shaft 4-1, the pushing mechanism 4 is driven by an oil cylinder 6, and the pushing mechanism 4, the guide rail 5, and the oil cylinder 6 are fixed on the base 7.

[0013] The working process of the present invention:

[0014] After the pipe bar 11 is transported to the straightening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com