Stretching-bending straightening machine

A technology of stretching, bending, straightening, and rolling mills, which is applied in metal rolling, manufacturing tools, metal processing equipment, etc., and can solve problems such as poor strip quality and warping of metal strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

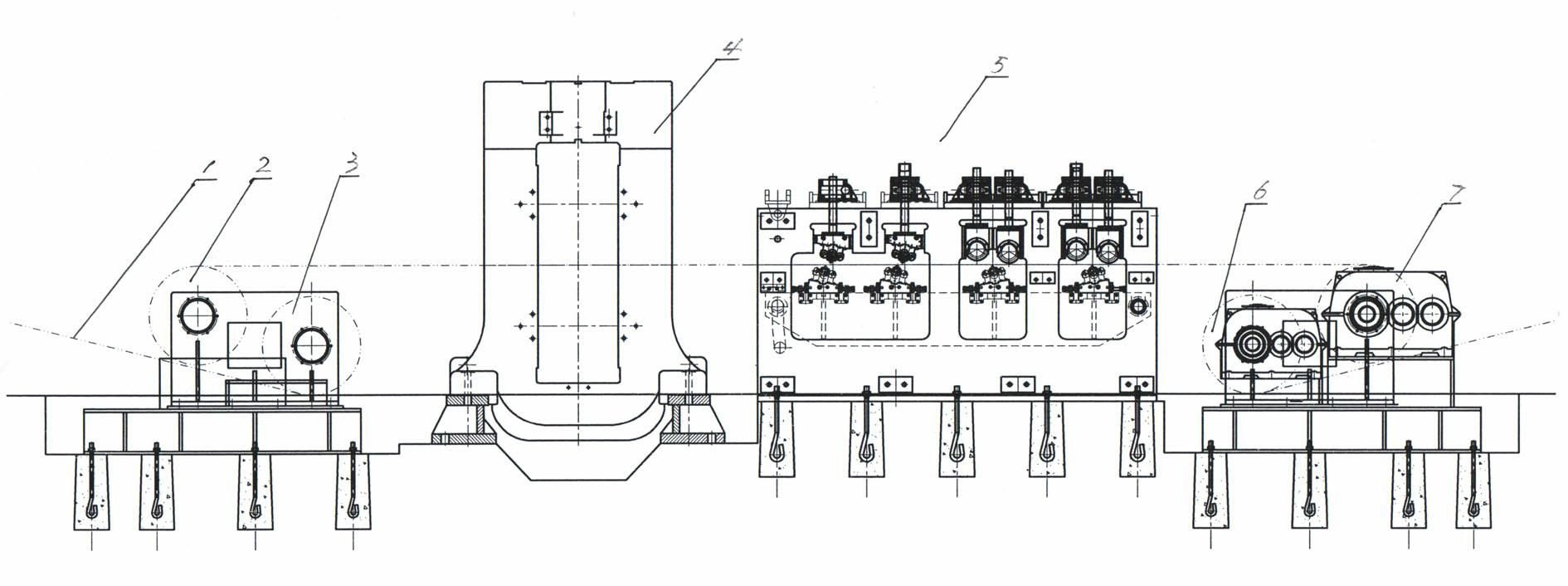

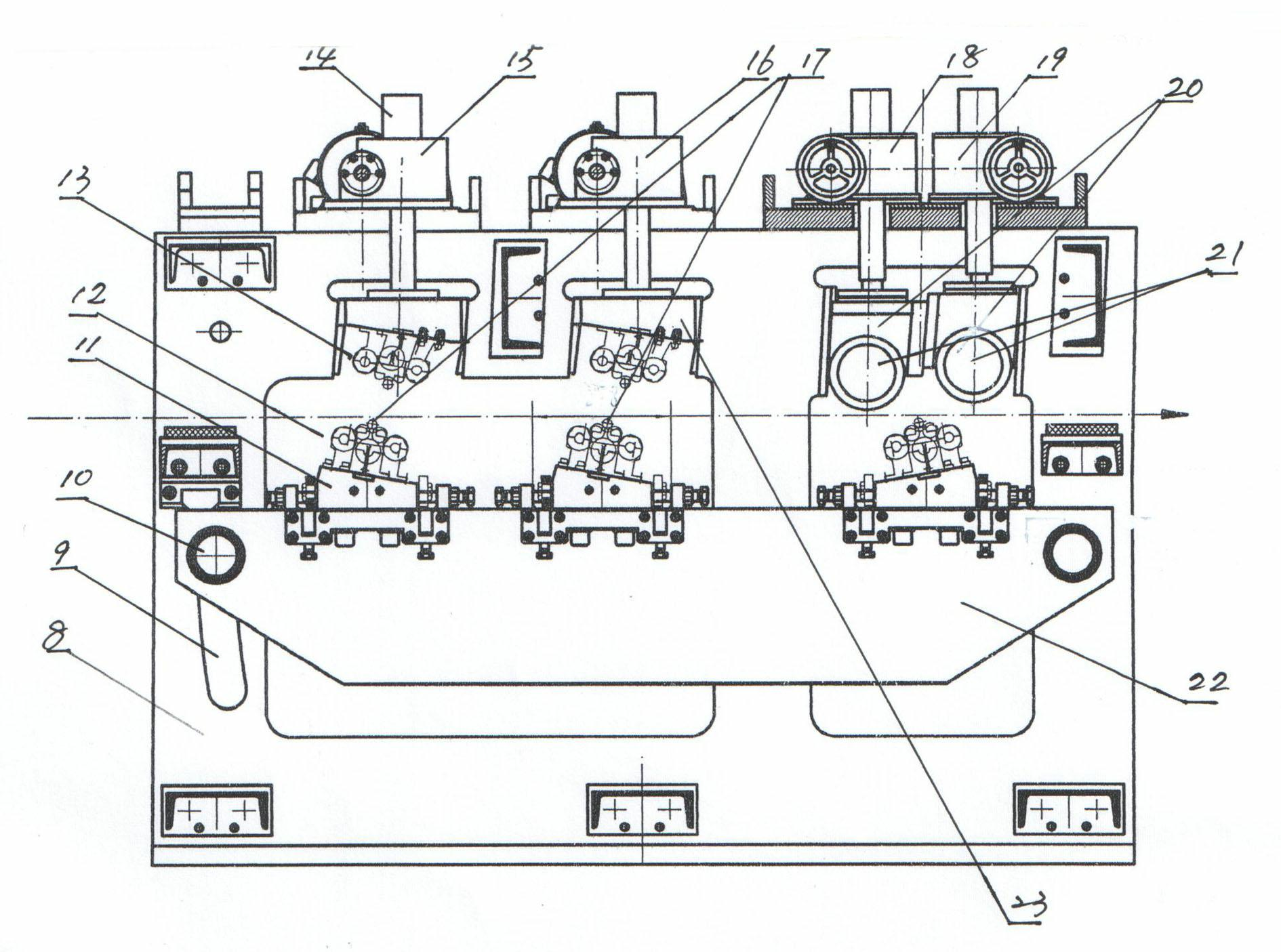

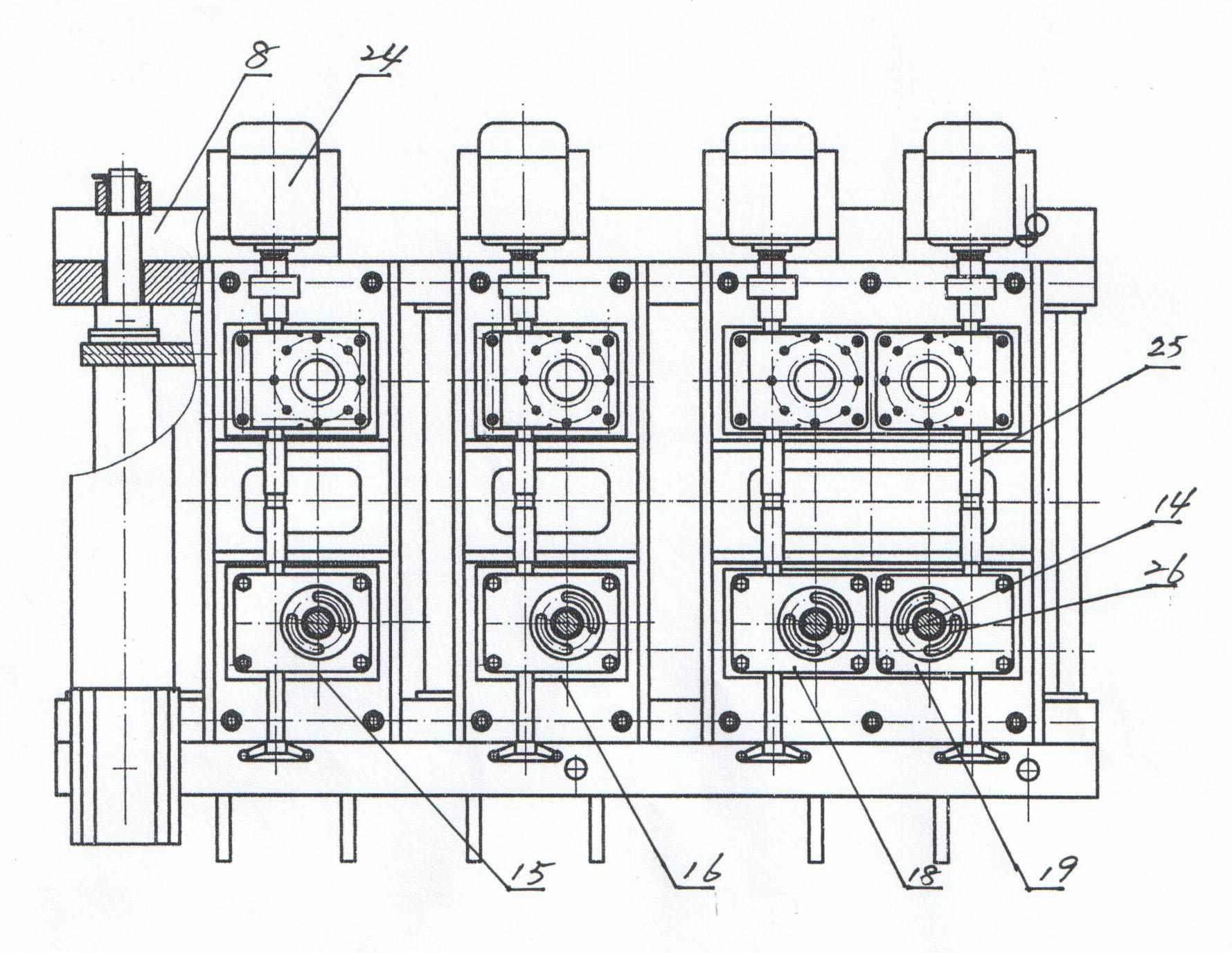

[0015] like figure 1 As shown, the stretch bending straightening machine of the present invention includes a rolling mill 4, and the front and rear sides of the rolling mill 4 are respectively provided with a front tension mechanism and a rear tension mechanism. The front tension mechanism includes a first roller 2 and a second roller 3, the axial directions of the first roller and the second roller are parallel and arranged in a high and a low shape from left to right, and their vertical There are gaps between projections. One end of the roller shaft of the first roller 2 and one end of the roller shaft of the second roller 3 are connected with a first power mechanism, which is composed of a motor and a speed reducer. Described back tension mechanism comprises the 3rd roller 6 and the 4th roller 7, and the axial direction of this 3rd roller and the 4th roller is parallel and from left to right is one low one high shape arrangement, their vertical There are gaps between proj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com