Horizontal adaptive mechanical precision straightening device for linear bars

A self-adaptive, mechanical technology, applied in the field of straightening, which can solve the problems of limited workpiece length, low rigidity of the straightening device, and unsuitable workpiece straightening processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

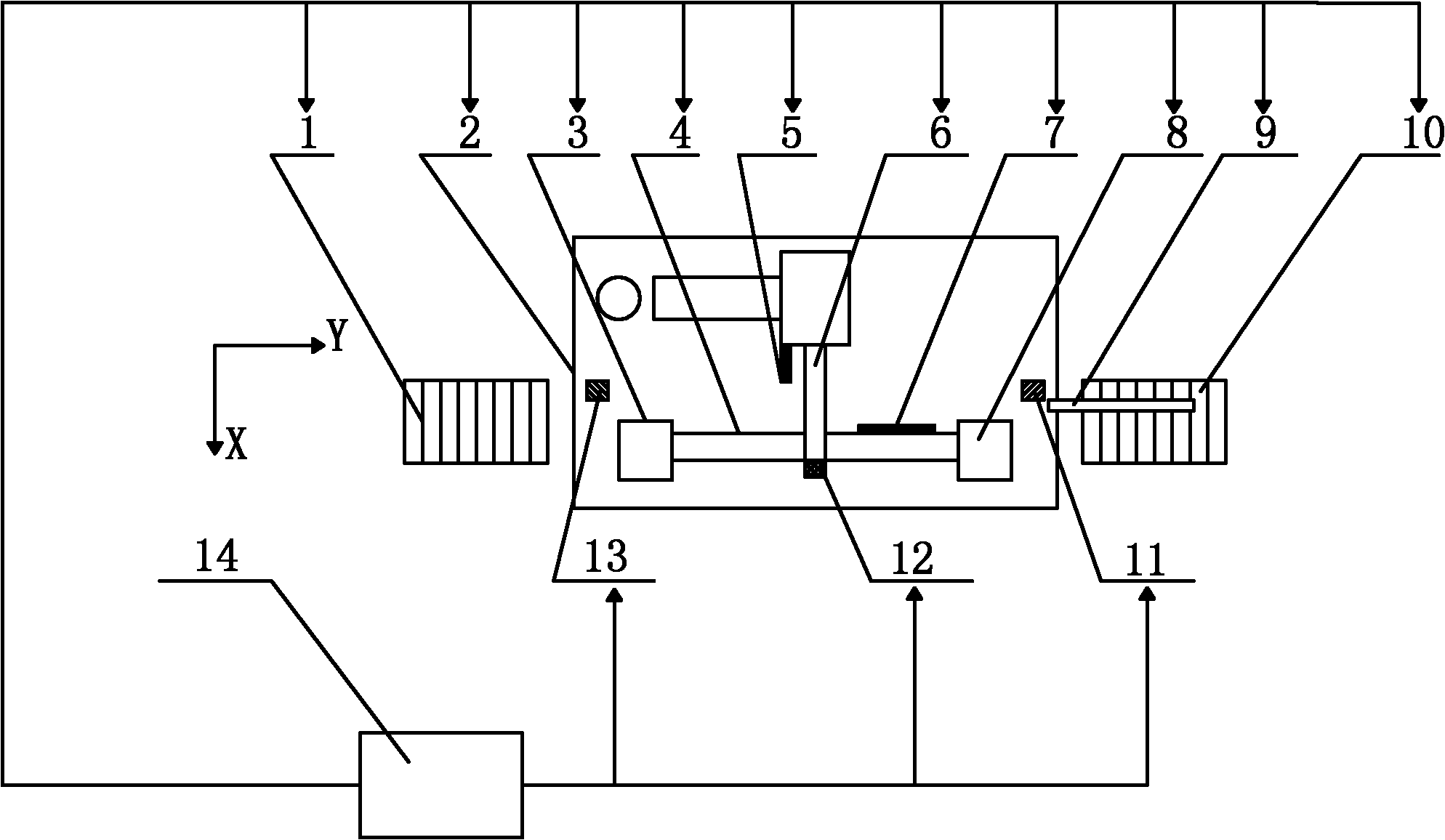

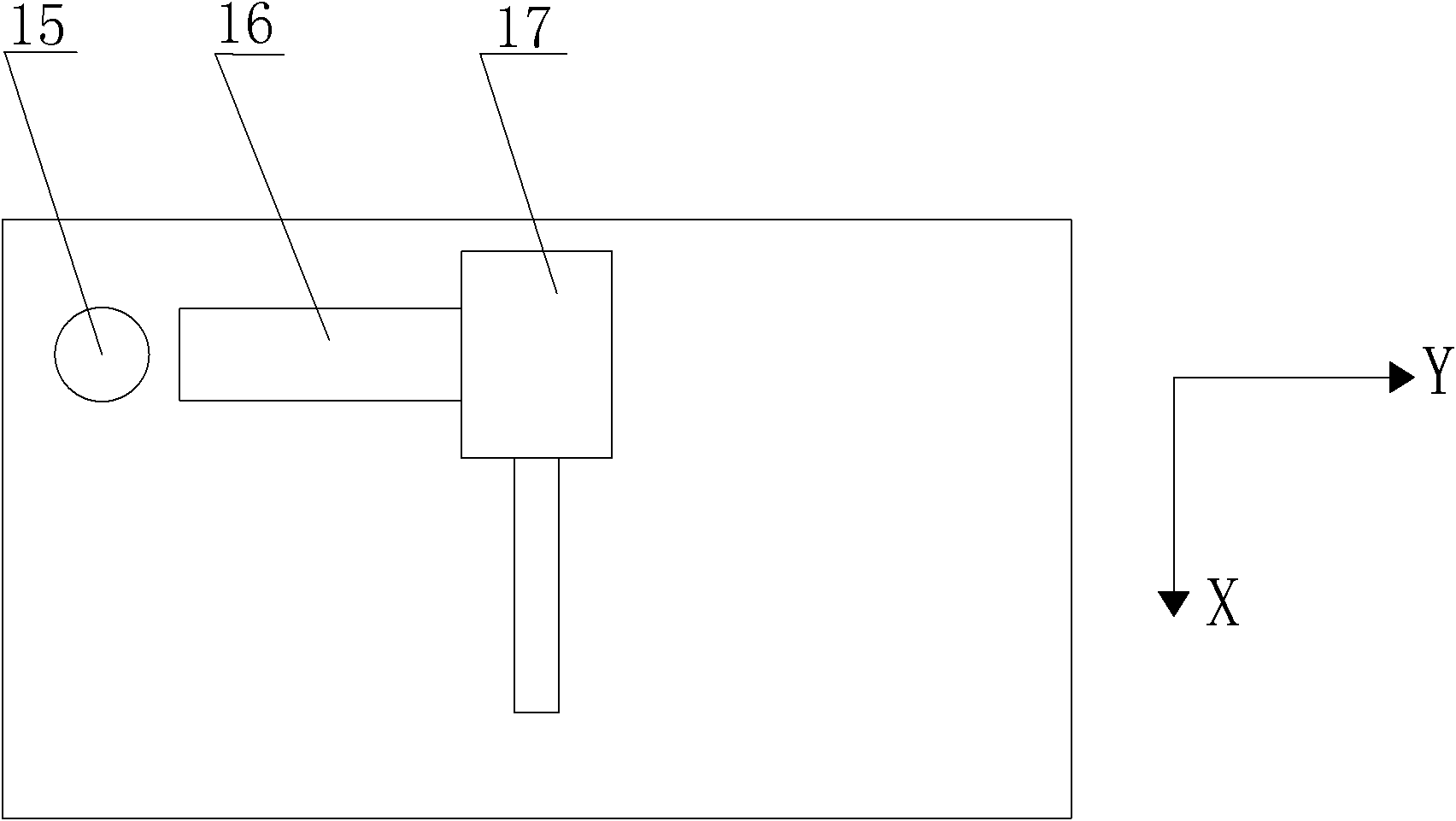

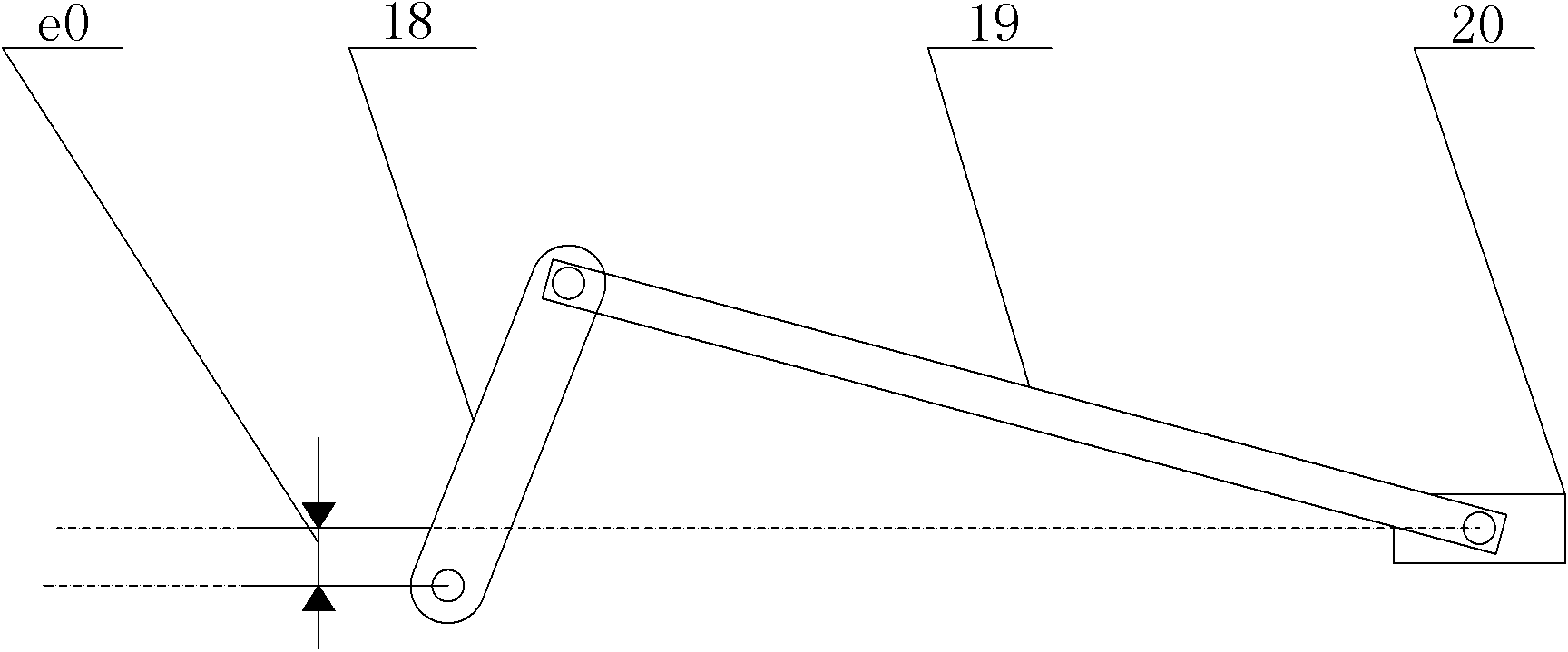

[0038] The horizontal self-adaptive mechanical precision straightening device for linear strips provided by the present invention has a structure comprising: a main machine base, a left workpiece presence detection sensor connected to the main machine base, a right workpiece presence detection sensor, a support The driving assembly and straightening mechanism, the left feeding mechanism and the right feeding mechanism located on both sides of the main machine base, the axial displacement meter and the workpiece bending measurement device connected to the supporting part supporting the driving assembly, the left The workpiece clamping assembly, the right workpiece clamping assembly, the straightening stroke displacement meter connected with the straightening mechanism, and the electrical and software processing control system for controlling the work of these components.

[0039] The present invention will be further described below in conjunction with the embodiments and the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com