Electrically driven automatic rope ranging device

An automatic row, electric drive technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material handling, etc., can solve problems such as hindering operation time, consuming operator's work energy, and overlapping cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

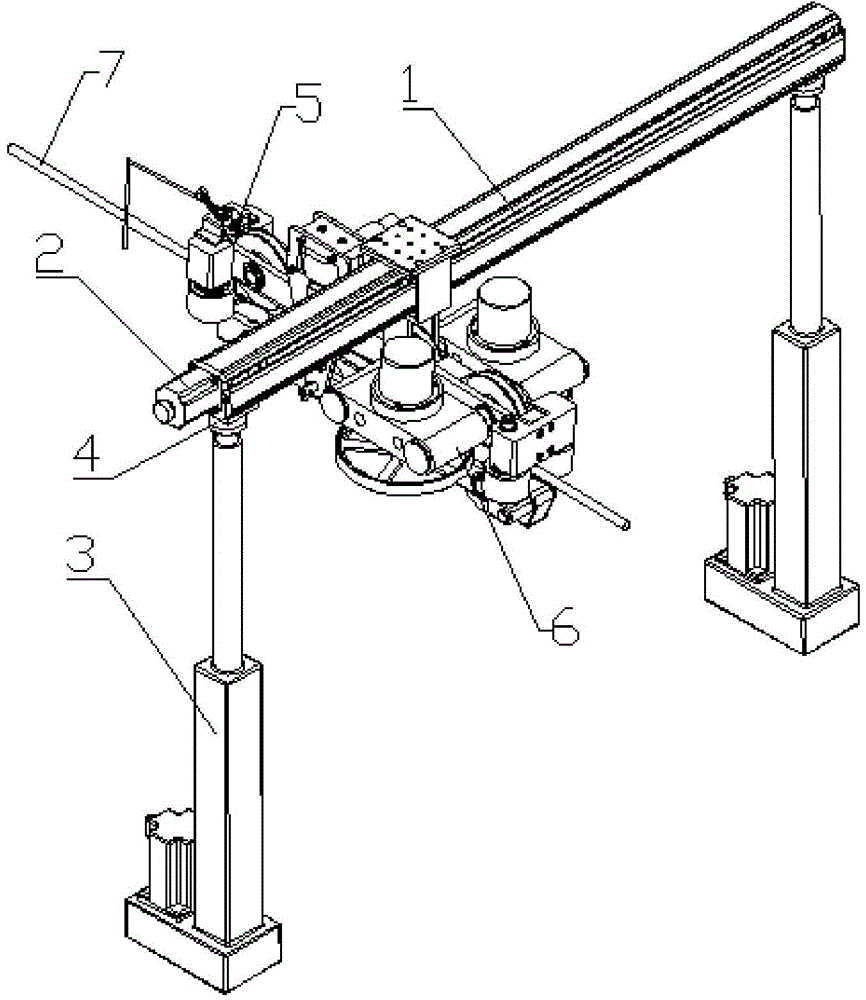

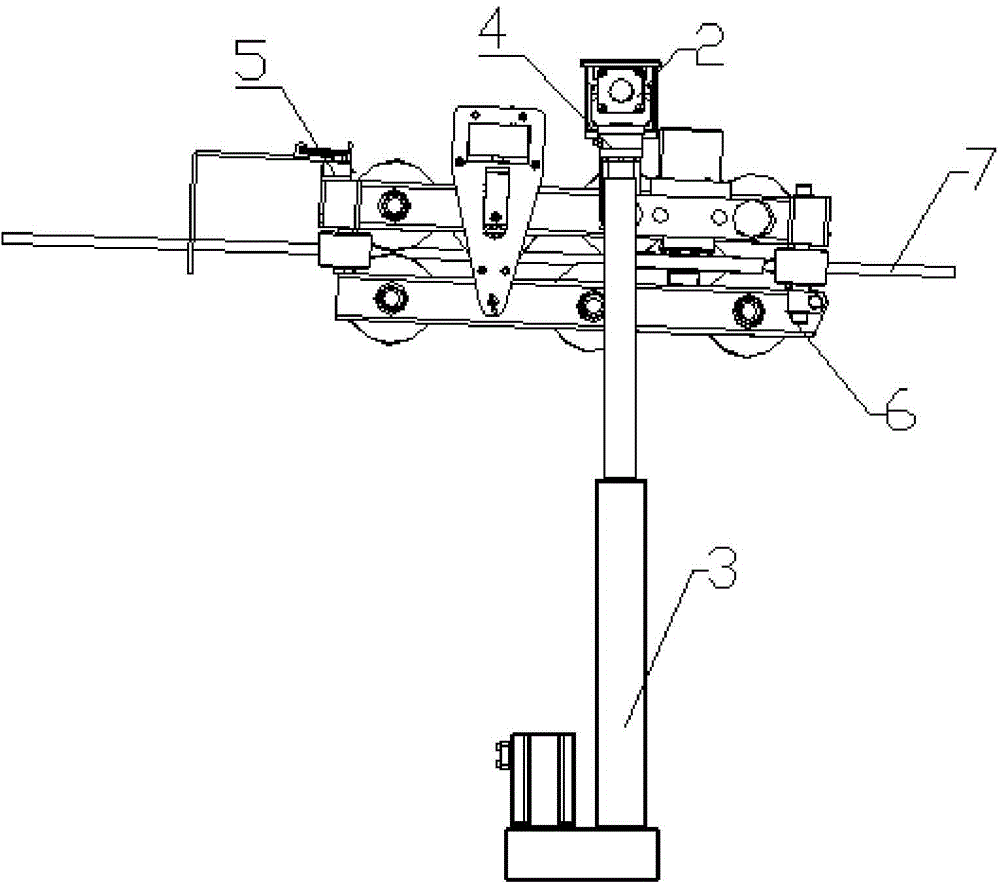

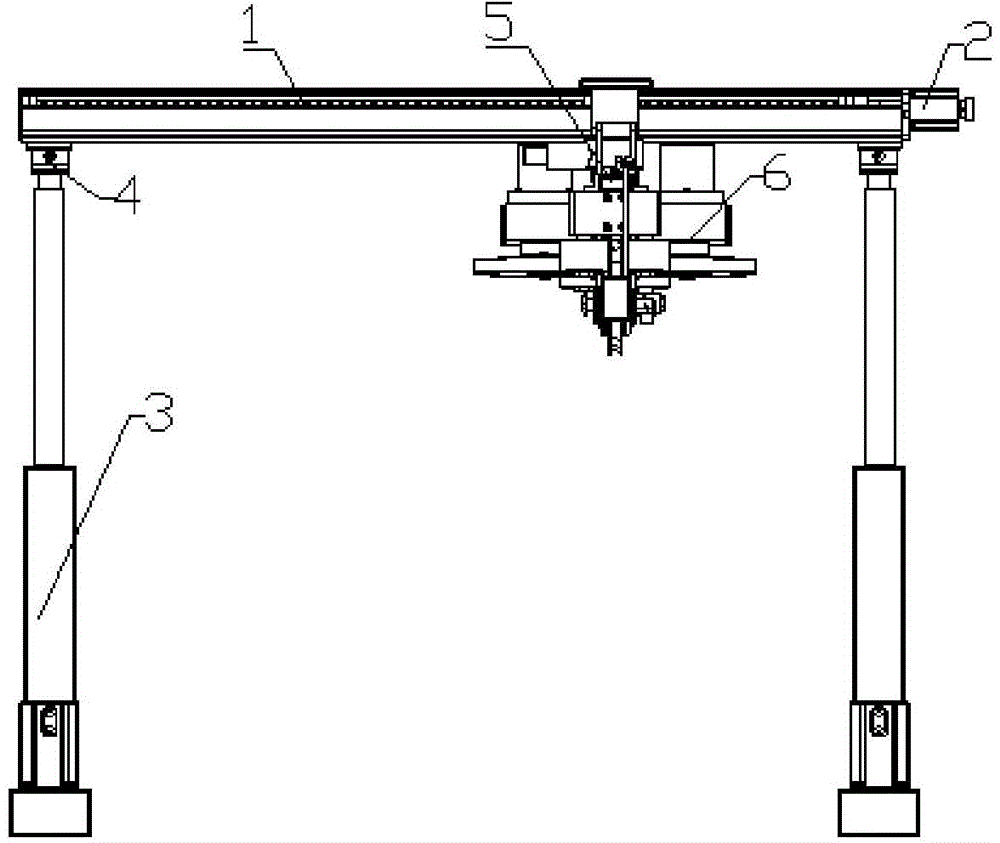

[0028] Such as Figure 1-4 As shown, an electric-driven automatic rope unwinding device includes a controller, an electric-driven lifting cylinder 3 , a moving mechanism, a Martindiker 6 and a pressure sensor 4 .

[0029] The martin dike 6 is powered by electricity, and the direction of the martin dike 6 passing through the line is perpendicular to the moving direction of the martin dike 6 on the moving mechanism.

[0030] The moving mechanism includes a supporting guide rail, a motor and a lead screw connected to it for transmission. The lead screw 1 is located inside the supporting guide rail. There are through grooves on both sides of the supporting guide rail. A guide frame is provided on the Martindiker 6 , the guide frame is threadedly connected with the lead screw 1 through the through groove of the support guide rail;

[0031] The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com