Method for performing rotary feed straightening on metal pipes

A metal tube and rotary technology, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems that affect the reliability and accuracy of flaw detection, cannot meet the needs of metal pipe flaw detection, and signal amplitude changes, etc., to achieve The effect of compact structure, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

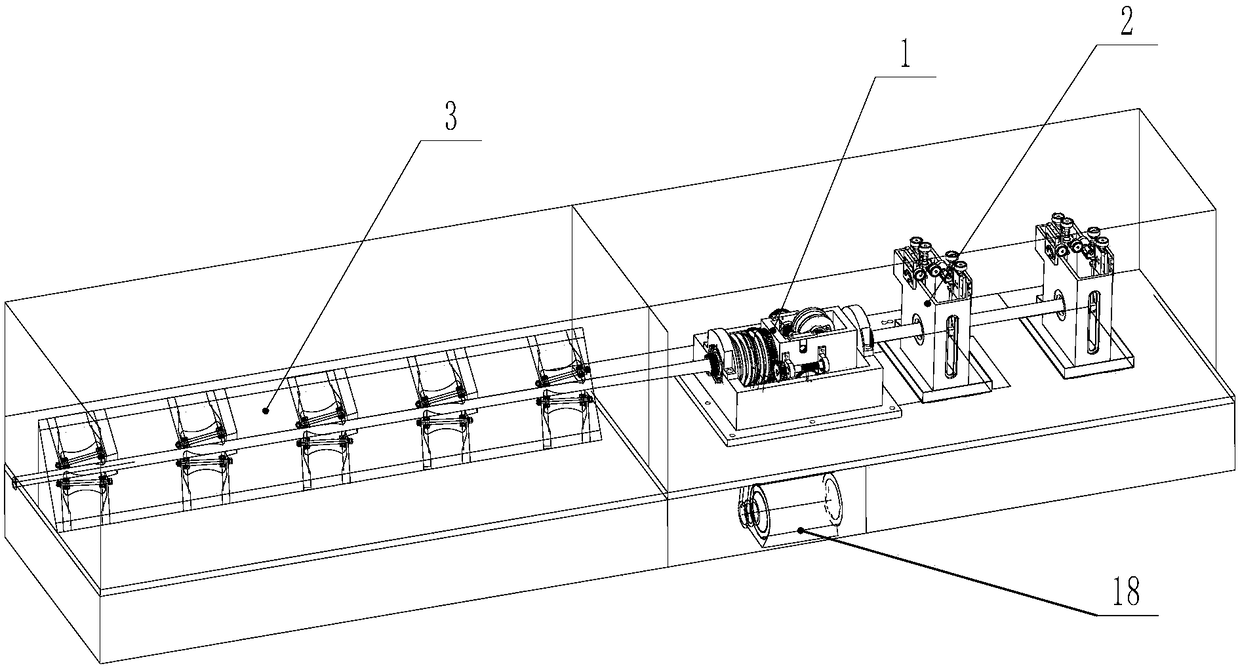

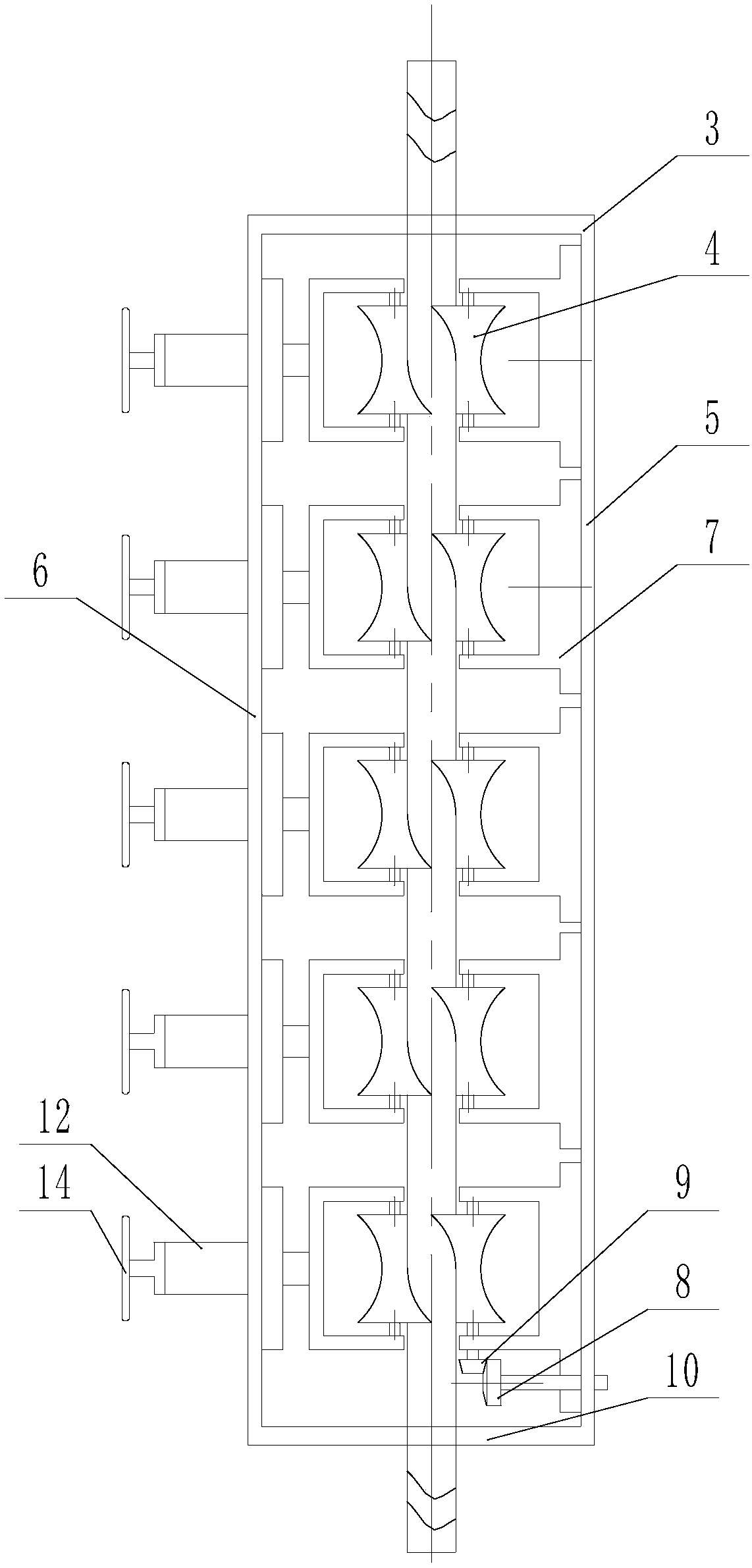

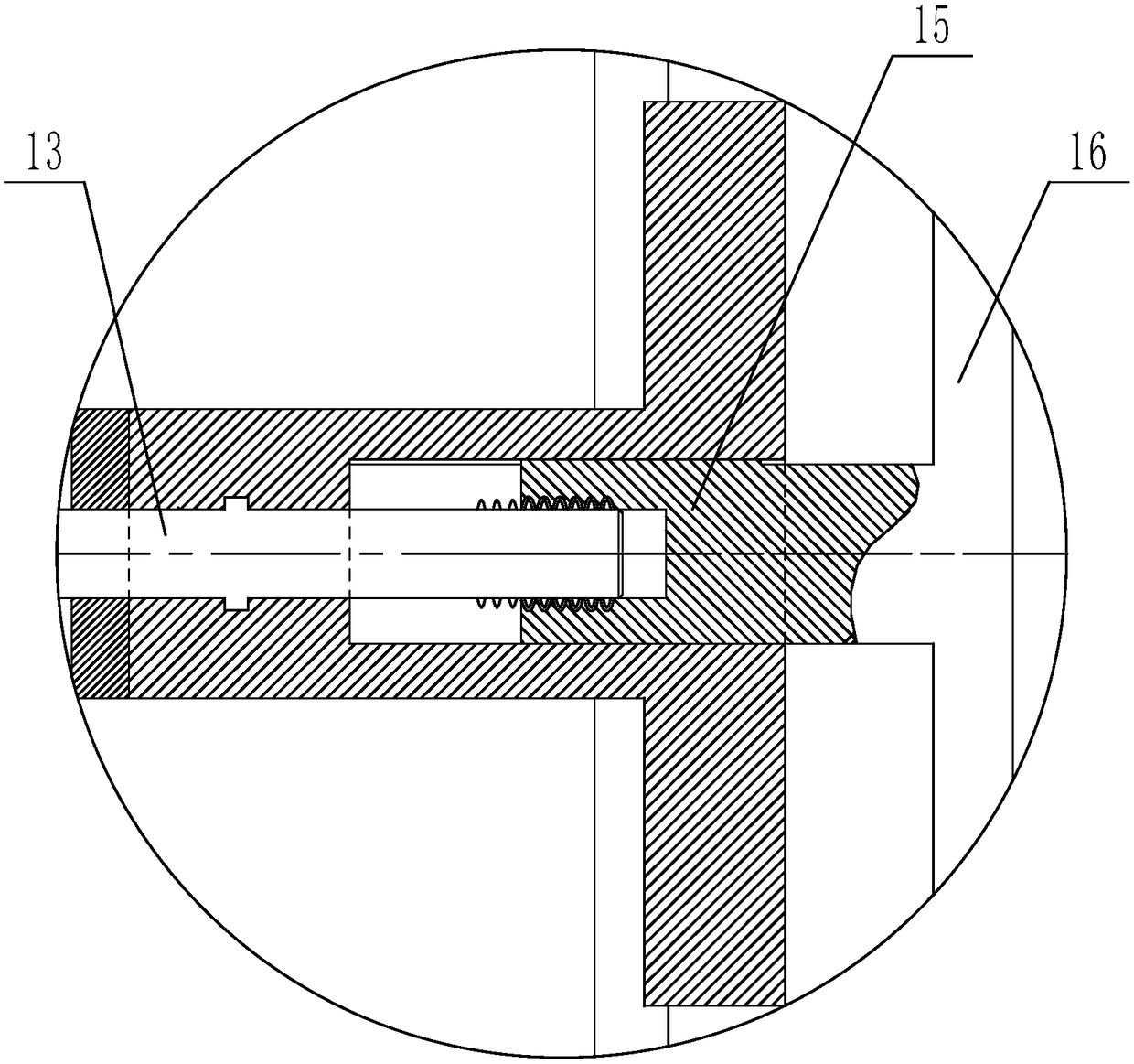

[0051] Specific implementation method: a method for straightening metal pipes with rotary feeding, including the step of relying on straightening rollers arranged in pairs to realize the straightening of metal pipes during the process of advancing the metal pipes in the axial direction. While the tube advances, it rotates itself to form a metal tube that advances in a spiral manner, and realizes straightening during the spiral advance of the metal tube.

[0052] In this way, the metal pipe rotates while moving forward, so that when the metal pipe is straightened, it is in the state of rotating and moving forward, so that the contact area between the straightening roller and the metal pipe per unit time increases, and the straightening effect is improved. Effectiveness and efficiency. At the same time, the metal pipe rotates forward, which can also make the detection range of the probe in the metal pipe flaw detection device larger. It can rely on the fixed probe to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com