Straightening method of micro metal tube

A metal tube and fine technology, applied in the field of metal tube processing, can solve the problems of insufficient tube length, limited plasticity at room temperature, brittle tube and other problems, and achieve the effect of stable process, ingenious design and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

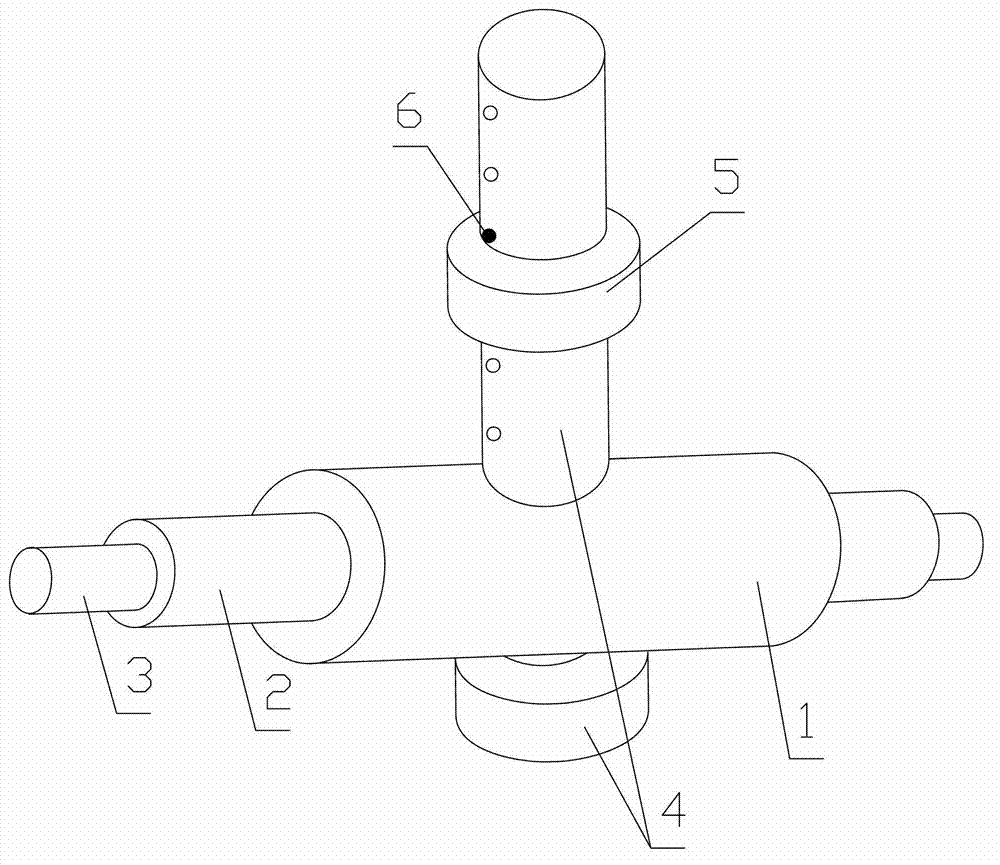

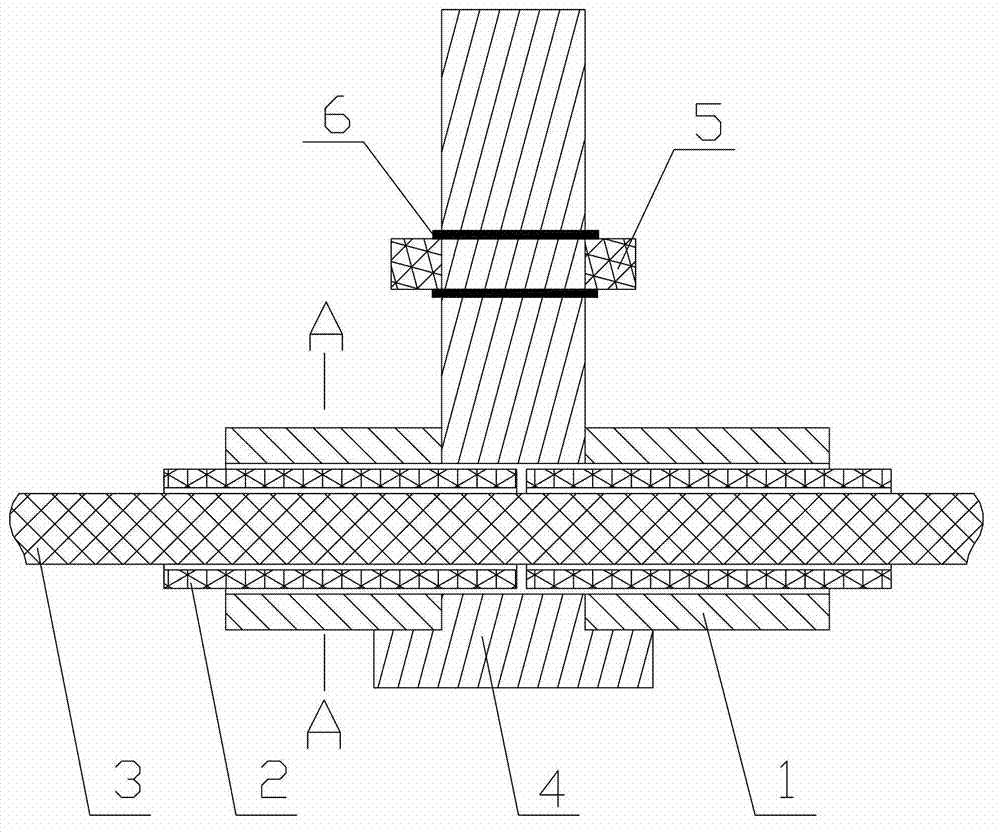

[0025] The straightening method of the present embodiment fine metal tube comprises the following steps:

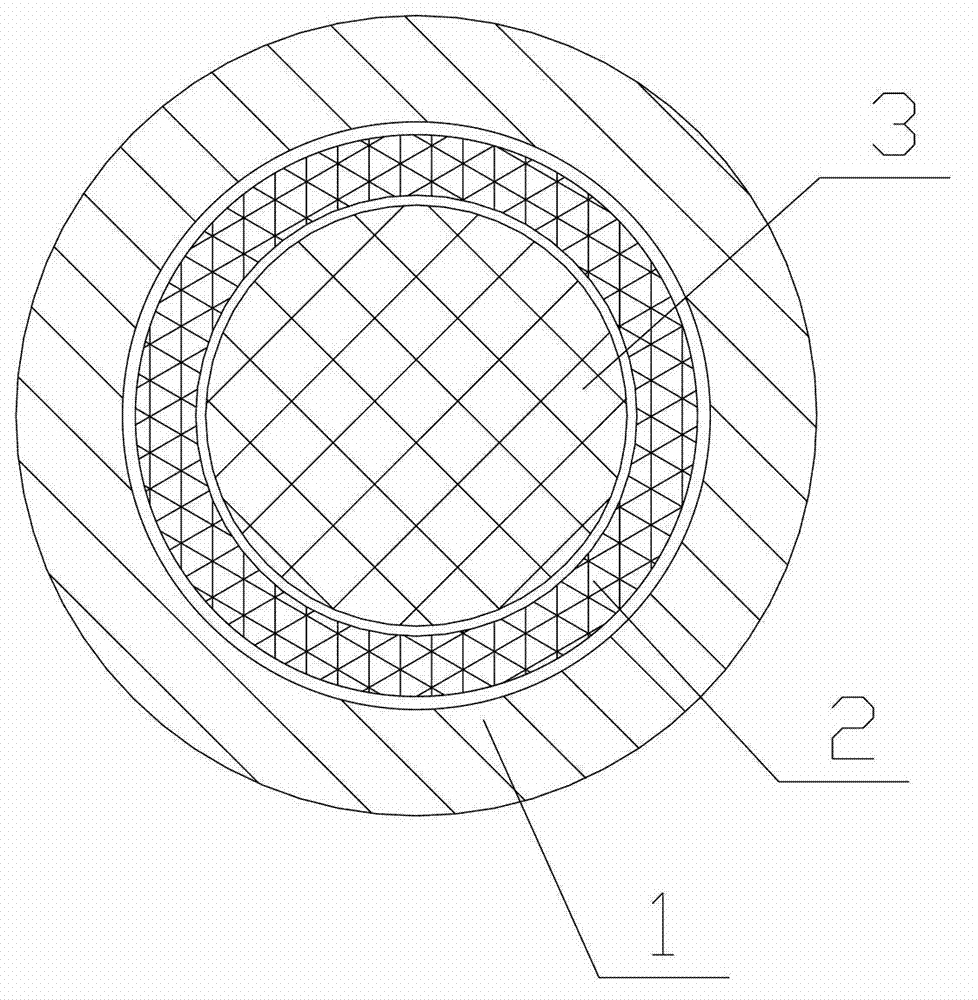

[0026] Step 1, a metal wire 3 coated with organic oil is inserted into an AZ31 magnesium alloy fine metal tube 2, the outer diameter of the fine metal tube 2 is 6mm, the wall thickness is 0.5mm, and the straightness is 100mm / m; the metal wire 3 is an iron wire; the diameter of the metal wire 3 is 4.5mm, and the length of the metal wire 3 is greater than the total length of the fine metal tube 2;

[0027] Step 2: Put the fine metal tube 2 with the metal wire 3 in the step 1 into the rubber drum 1, and then install the rubber drum 1 with the metal wire 3 and the fine metal tube 2 on the wire straightening machine (Shanghai Kindly On the JZ-1-6 type wire straightening machine produced by Medical Instrument Co., Ltd.), the wire straightening machine is turned on to make the rubber roller 1 together with the counterweight 4 arranged on the rubber roller 1 and the counterweight...

Embodiment 2

[0030] The straightening method of the present embodiment fine metal tube comprises the following steps:

[0031] Step 1. Thread a metal wire 3 coated with butter into three 3A21 aluminum alloy fine metal tubes 2 connected in series. The outer diameter of each fine metal tube 2 is 4mm, and the wall thickness is 0.3mm. , the straightness is 500mm / m; the metal wire 3 is a copper wire; the diameter of the metal wire 3 is 3mm, and the length of the metal wire 3 is greater than the total length of the fine metal tube 2;

[0032] Step 2: Put the fine metal tube 2 with the metal wire 3 in the step 1 into the rubber drum 1, and then install the rubber drum 1 with the metal wire 3 and the fine metal tube 2 on the wire straightening machine (Shanghai Kindly On the JZ-1-6 type wire straightening machine produced by Medical Instrument Co., Ltd.), the wire straightening machine is turned on to make the rubber roller 1 together with the counterweight 4 arranged on the rubber roller 1 and th...

Embodiment 3

[0035] The straightening method of the present embodiment fine metal tube comprises the following steps:

[0036] Step 1. A metal wire 3 coated with organic oil is inserted into five TA16 titanium alloy fine metal tubes 2 connected in series. The outer diameter of each fine metal tube 2 is 2 mm, and the wall thickness is 0.1 mm. , the straightness is 300mm / m; the metal wire 3 is a copper wire; the diameter of the metal wire 3 is 1.3mm, and the length of the metal wire 3 is greater than the total length of the fine metal tube 2;

[0037]Step 2: Put the fine metal tube 2 with the metal wire 3 in the step 1 into the rubber drum 1, and then install the rubber drum 1 with the metal wire 3 and the fine metal tube 2 on the wire straightening machine (Shanghai Kindly On the JZ-1-6 type wire straightening machine produced by Medical Instrument Co., Ltd.), the wire straightening machine is turned on to make the rubber roller 1 together with the counterweight 4 arranged on the rubber rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com