Derusting construction method for cross section of constructional steel I-column

A construction method and cross-section technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, metal processing equipment, etc., can solve the problems of easy rusting of steel plates, influence of coating, and unsatisfactory rust removal effect, etc., to achieve easy to use, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

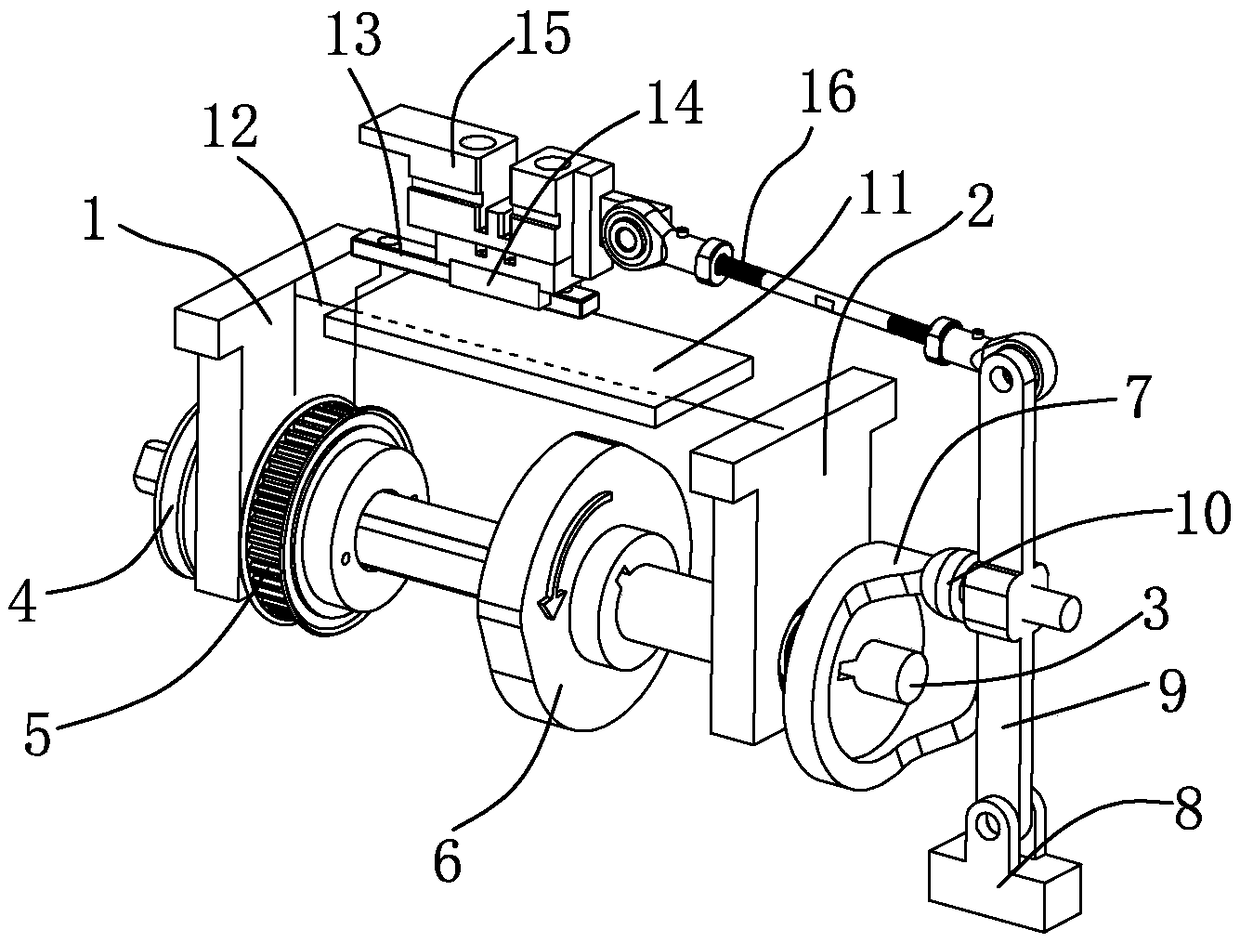

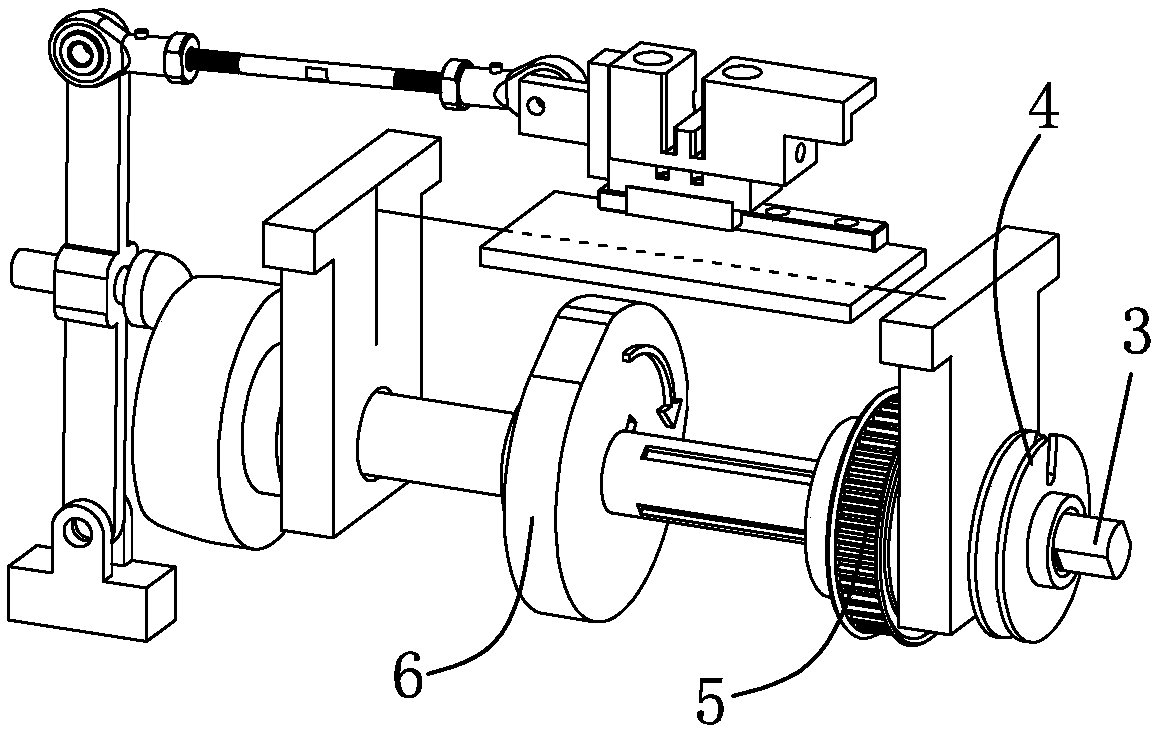

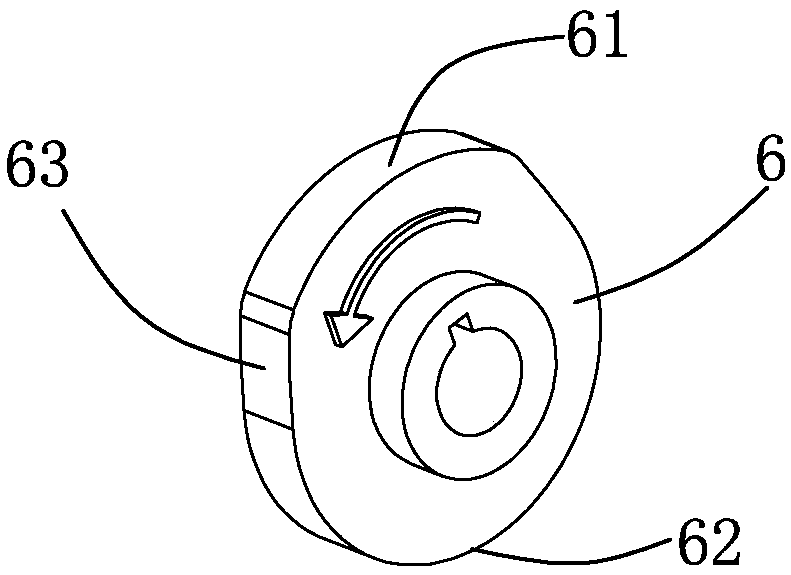

[0026] Embodiment: A construction method for derusting the cross-section of a building I-shaped steel column. Its main structures include: frame block a1, frame block b2, rotating shaft 3, calibration disc 4, crawler disc 5, top disc 6, lug disc 61, Disc disk 62, arc disk 63, displacement disk 7, low ring 71, high ring 72, steep slope ring 73, base block 8, pull rod 9, ball rod 10, top plate 11, through rod 12, slide rail 13, The slider 14, the clamping piece 15, the link 16, the iron brush plate 17, and the rotating shaft 3 successively passes through the calibration plate 4, the frame block a1, the crawler disc 5, the top plate 6, the frame block b2, and the displacement plate 7; The middle positions of the tops of the frame a1 and b2 are slotted, the through-rod 12 runs through the top plate 11, and the two ends of the through-rod 12 are respectively placed in the slots of the frame a1 and the frame b2 ;

[0027] The base block 8 is hinged with one end of the pull rod 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com