Straightening rotary drum device

A straightening and roller technology, which is used in metal extrusion cleaning equipment, metal extrusion, manufacturing tools, etc., to achieve good straightening effect, high production efficiency, and achieve the effect of tempering and strengthening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

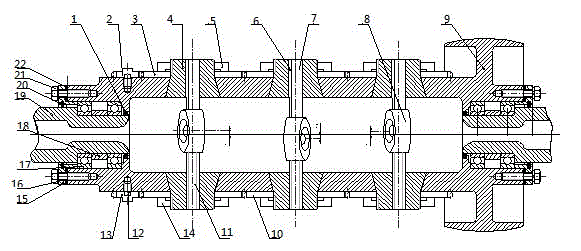

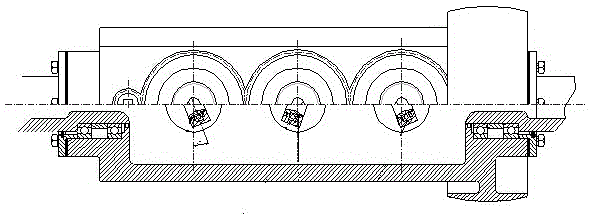

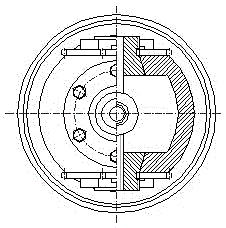

[0020] see Figure 1-4 ,

[0021] The present invention requires two inner sealing rings 1, one angle adjustment pinion 2, three angle adjustment large gears 3, six back caps 4, three lock nuts 5, three keys 6, and three hole mold upper brackets 7. Three straightening blocks 8, one wheel hub and pulley 9, three eccentricity adjustment gears 10, two hole die lower brackets 11, two pinion shafts 12, one eccentricity adjustment pinion 13, three Lock nut 14, two end caps 15, twelve flat washers 16, four bearings 17, two shaft sleeves 18, two hub supports 19, two sealing rings 20, twelve end cap bolts ( M8*40) 21, an outer gasket 22, three upper dust-proof covers 23, three die holes 24, three die bearings 25, three die shells 26, three retaining rings 27, three lower dust-proof cover 28

[0022] The straightening drum is supported on two bearings. There are three radial back cap installation through holes on the cylinder of the straightening drum, and a straightening block 8 mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com