Profile steel surface rust removal device

A technology of profiled steel and steel brush, which is applied to grinding drive devices, grinding workpiece supports, grinding machines, etc., can solve the problems of dust pollution of operators, increase the cost of rust removal, and reduce the efficiency of rust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

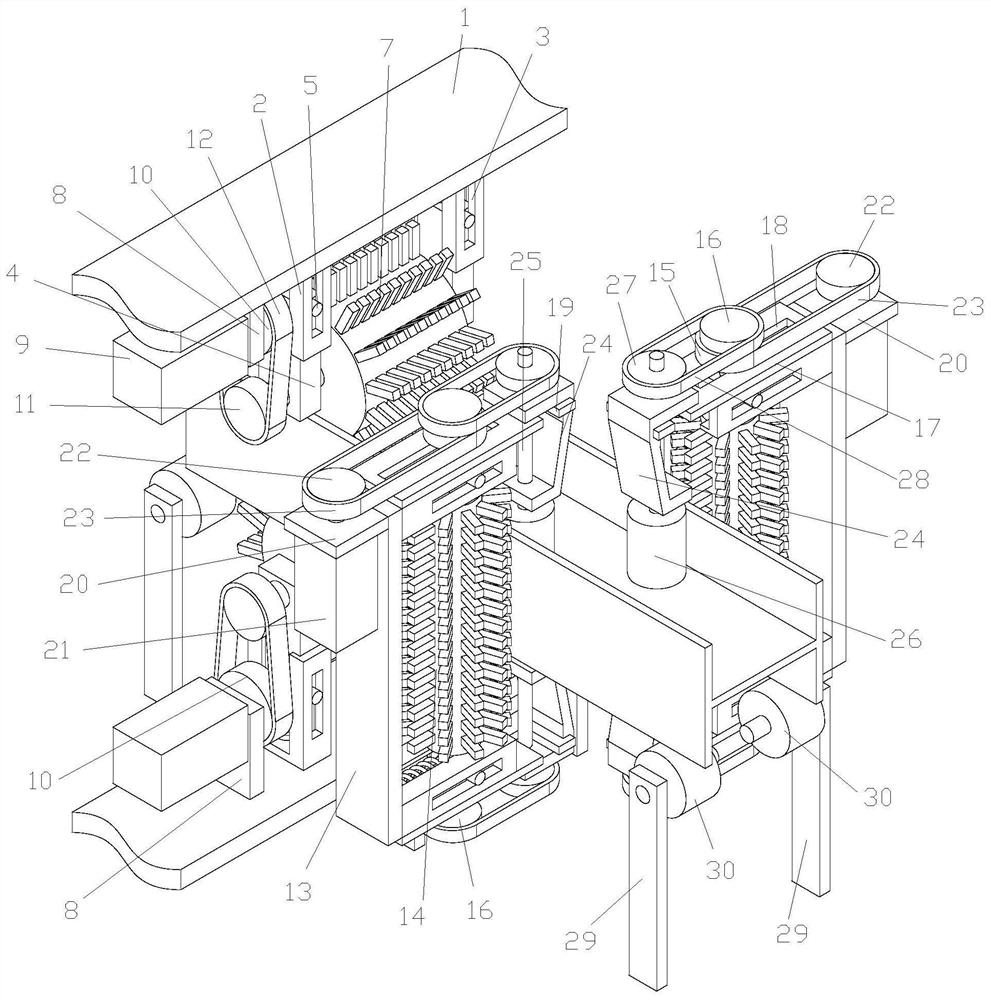

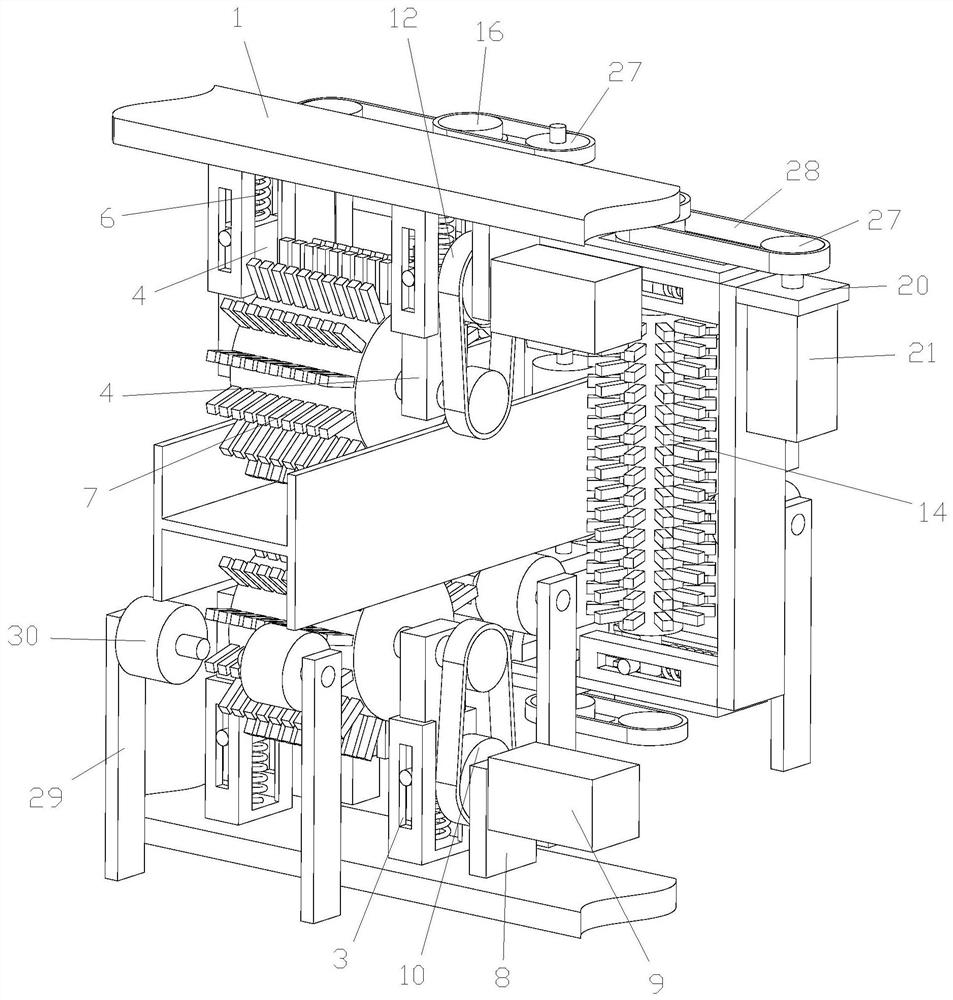

[0015] Embodiment: a kind of steel surface derusting device, as Figure 1-Figure 2 As shown, it includes two sets of oppositely arranged horizontal surface cleaning sections, two sets of oppositely arranged vertical surface cleaning sections and multiple sets of support roller groups, and the two sets of vertical surface cleaning sections are arranged on the two sets of horizontal surface cleaning sections. On the front side of the brush part, the horizontal cleaning part on the upper side includes a horizontal installation rod 1 arranged horizontally, and two sets of vertical support seats are provided on the lower surface of the horizontal installation rod 1, and the vertical support seats include a U-shaped base 2, the two sides of the U-shaped base 2 are respectively provided with a through-type first chute 3, sliding block 4 is provided in the middle of the U-shaped base 2, and the two sides of the sliding block 4 Each side is provided with a positioning pin 5, and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com