Laser rust-removing device

A laser rust removal and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as difficult operation and observation, difficult to clean the inner wall of small or miniature metal cylinders, etc., to improve efficiency and realize automatic The effect of simple detection and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

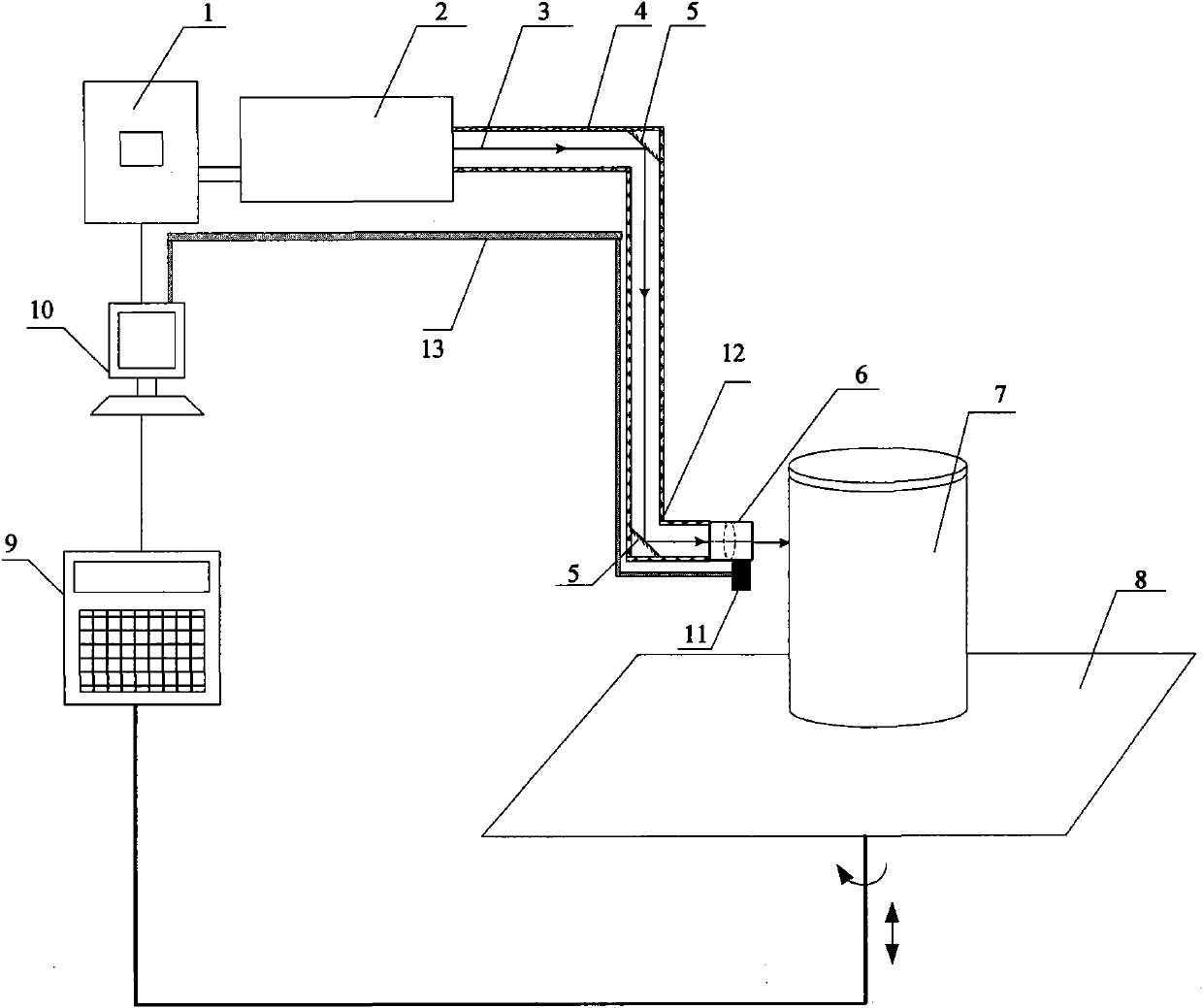

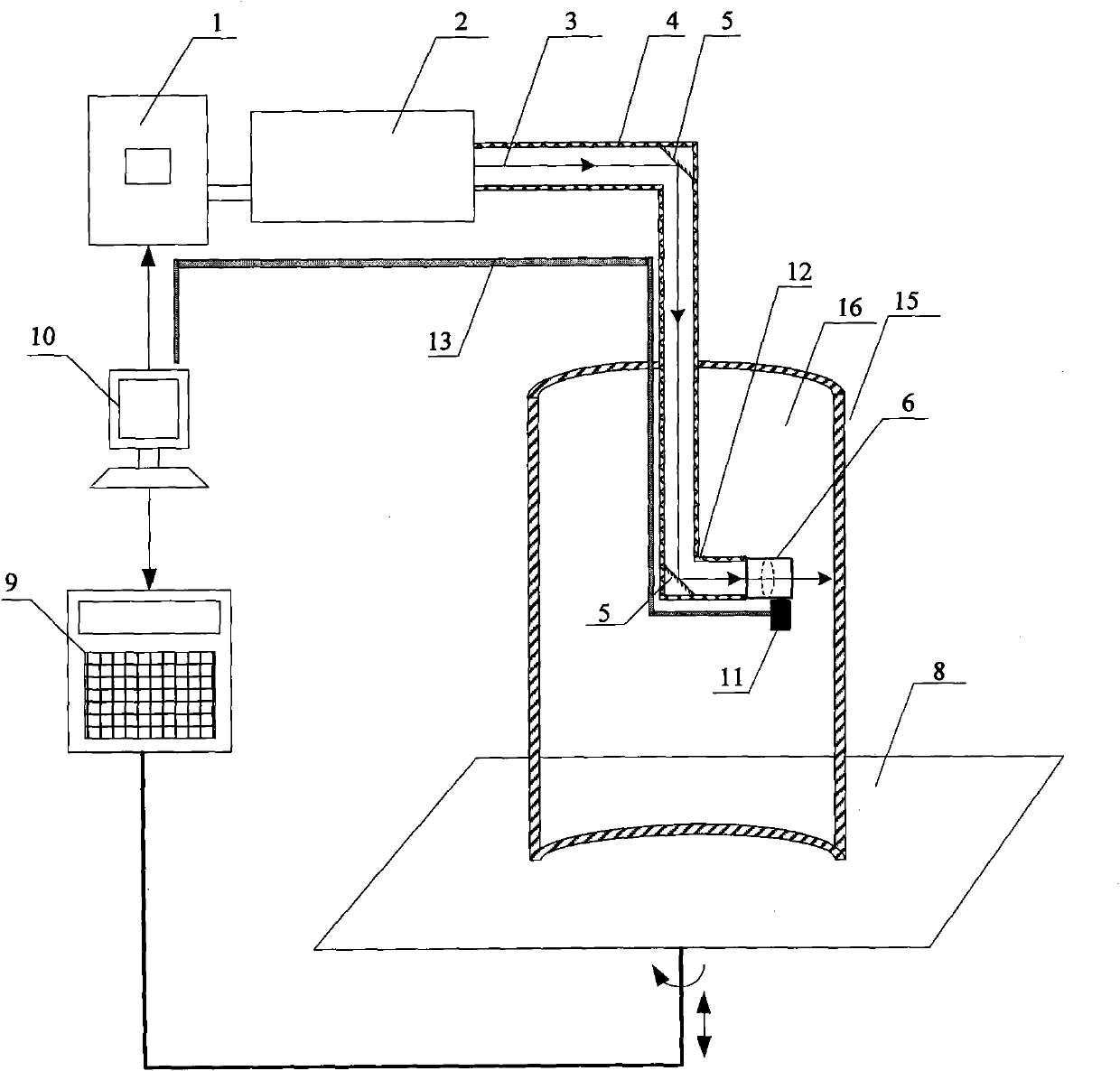

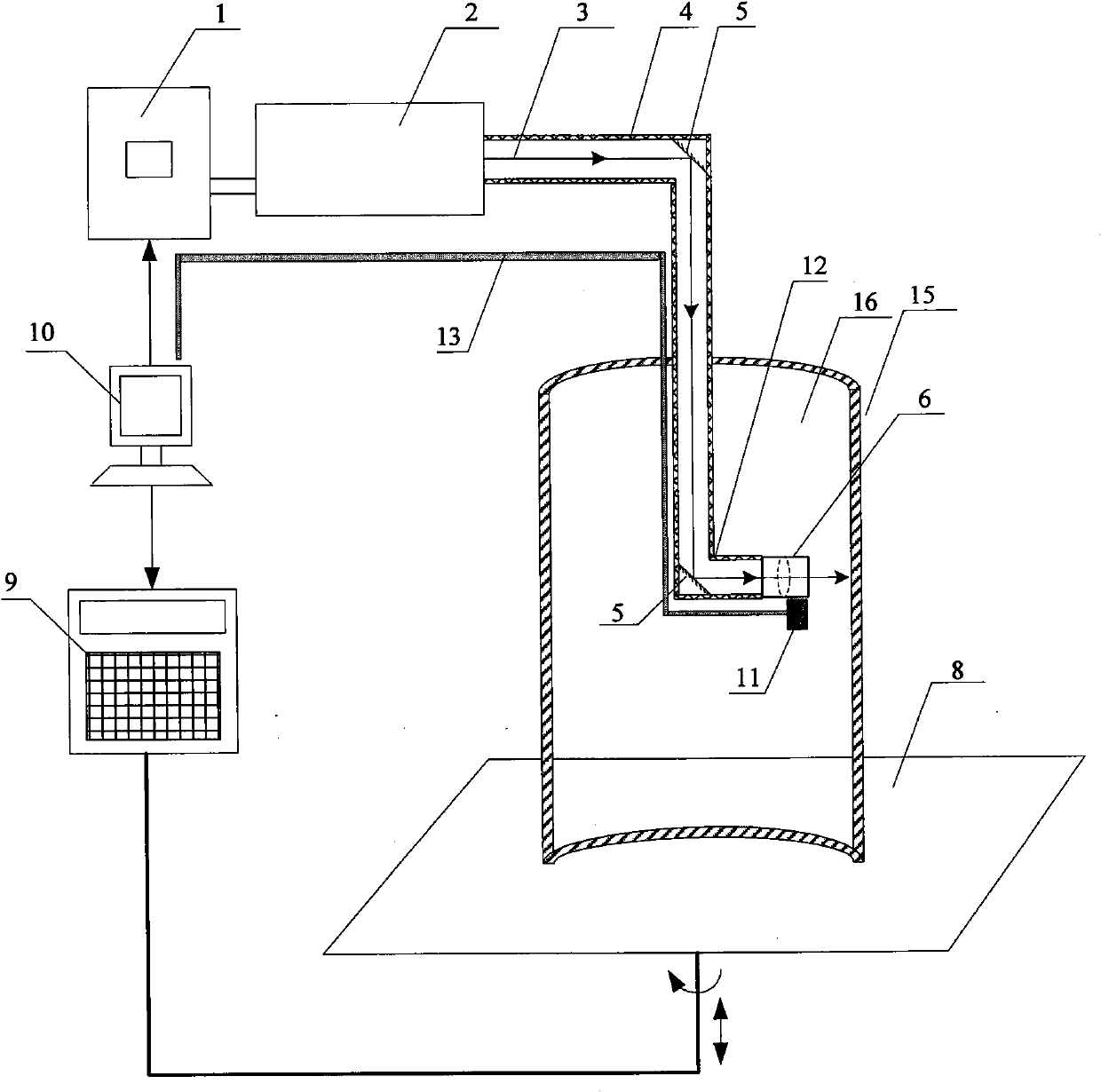

[0021] Such as figure 1 The shown laser derusting device comprises a laser controller 1, a laser 2, an acoustic sensor 11, a workbench controller 9, a workbench 8, a central controller 10 and a derusting head 12; the derusting head 12 is fixed on the light pipe 4, Its light outlet is perpendicular to the surface of the metal part 7 placed on the workbench 8, and a total reflection mirror 5 with a 45-degree angle is installed at the corner of the light guide 4; 13 Input the detection signal into the central controller 10; the central controller 10 is connected with the laser controller 1 and the workbench controller 9 through signal lines.

[0022] The working method of the laser descaling device is to put the metal piece 7 on the workbench 8, move the derusting head 12 to the position where the metal 7 to be derusted starts to be derusted, and adjust the distance between the derusting head 12 and the metal piece 7 , so that the output laser is focused on the surface of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com