Wall-climbing robot for removing rust on wall surfaces of ships and working method thereof

A wall-climbing robot and wall surface technology, which is applied in the field of wall-climbing robots, can solve the problems of small quality of ultra-high pressure water jet rust removal cleaners, difficulty in achieving application results in the field of ship rust removal, and low load capacity of the load-carrying pipeline. Achieve the effects of high rust removal efficiency, enhanced load capacity, and large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

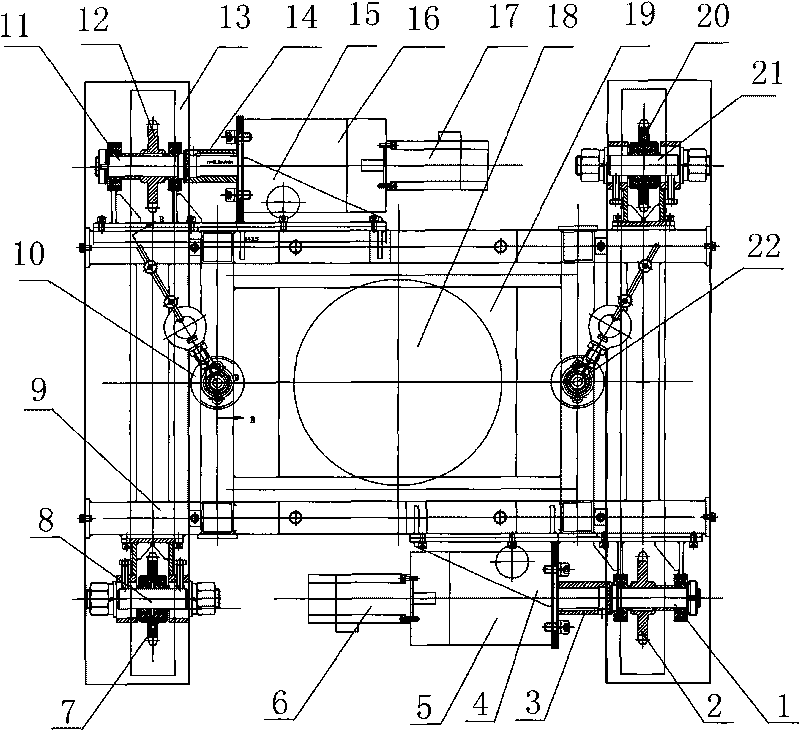

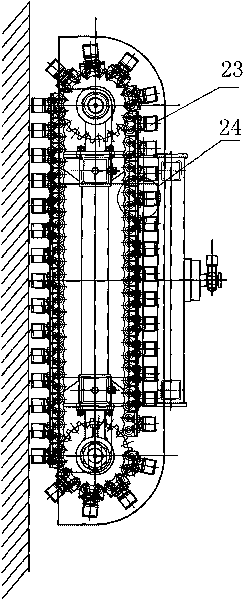

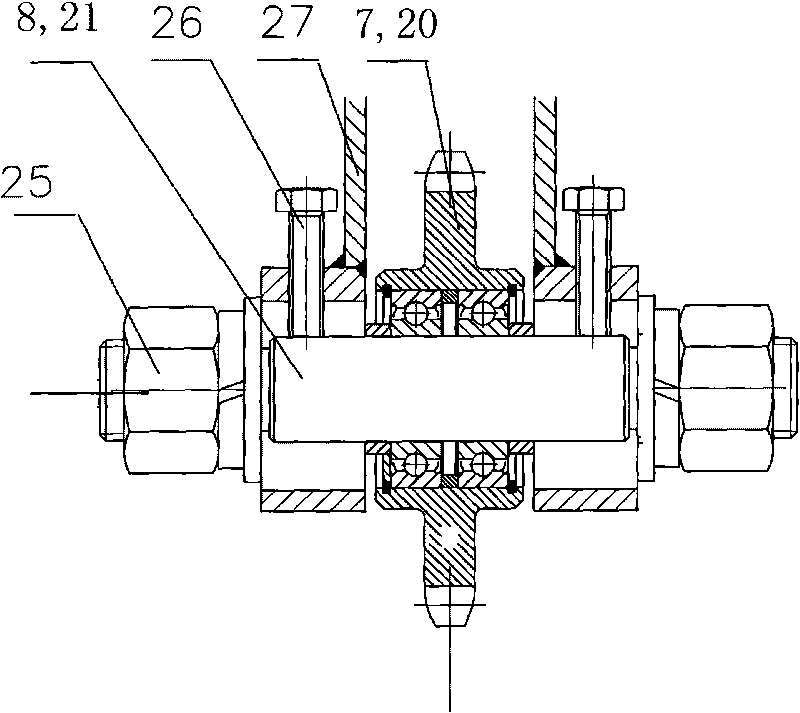

[0026] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, a ship wall surface derusting wall-climbing robot includes a frame 9, a chain crawler walking mechanism 24, a permanent magnet adsorption unit 23, an upper left drive motor 17, an upper left reducer 16, a lower right drive motor 6, and a lower right reducer 5, Its left upper side mechanism and right lower side mechanism are symmetrical structures relative to the left and right diagonal centers on both sides of the robot, and the described upper left drive motor 17 is connected with the upper left reducer 16, and is installed on the mounting plate on the upper left side of the frame 9; Reducer 16 is connected with left upper driving sprocket 12 through left upper coupling 14, and left upper driving sprocket 12 is installed on the left upper driving sprocket shaft 11 through rolling bearing, and left upper driving sprocket shaft 11 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com